SECTION 1 – Intentionally excluded

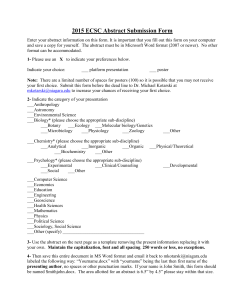

advertisement