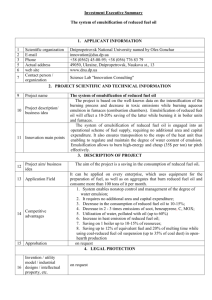

Новые технологии в энергосохранении и

advertisement

New technologies in energy-saving equipment and ecologies. Agency on energy-saving technologies www.energy-saving-technology.com www.afuelsystems.com (Cherkassy, Ukraine) - technologies and equipment for economy of fuel. +380+472+540454, +380+50+5183898 Equipment for processing (without use of complementary or additional reagent) of boiler or black oil, incineration flooded (water cut), sub-standard, water cut black oil. (and for recycling of liquid hydrocarbons, reception of water - black oil emulsions) Economy of black oil from 3.5 up to 12 %. Payback time of equipment is 1-3 months Our homogenizing device eliminates remove incomplete burning, slashes temperature of leaving gases, slashes emission CO, Nox, SOx up to 85 %. 1. Black oil-water sludge. Boiler oil shipped a factory, already contains up to 1,5 % of water. After haul (transportation) , draining and a warming up the water content in black oil reaches 10-15 %. Water is laied out in black oil is nonuniform and level-by-level. It is very bad for incineration of black oil as water there is in greater bubbles - gets in an atomizer and quality of incineration very bad, black oil does not burn completely. It needs more quantities of black oil and expensive atomizers for incineration of black oil well and completely. Incineration is handicapped, work of atomizers is destabilized, frustratings a plume are observed, in line room there are significant peephole temperature variations. It result to incomplete burning, to increase of issue of harmful matters in flue gass- nitrogen, carbon and elementary carbon (soot). Use of our systems (homogenizing device) eliminates the pointed lacks, provides high quality of homogenization, provides full and steady incineration of boiler oil, including thin dispergation resinous associates in black oil and make irreversible effect. Time of stability, conservation of new qualities of black oil, after treating on our unit is from 6 up to 10 months Use of our unit allows to burn completely black oil with water, black oil of poor quality, not conditioned fuel-oil, pyrolized black oil, to make and burn mixtures of black oil and waste of industrial and automobile oils, oven fuel of poor quality.... Equipment homogenizer-mixer Technical parameters Size - 0.8*0.25*0.25 m. Weight - 28 kg. Dispersiveness of a mix of black oil with water - 4-5 microns. Time of stability of a mix - 8 months Power consumption - depends on the pump Productivity - 2 - 40 tons \hours. Principle of work - jet, passive. The additional equipment - is not necessity Adjustment mechanical Working temperature - 40 - 150 C Working pressure - 2-16 atmospheres Term of manufacturing - 30 days. Guarantee - 2 years (Improvement of quality of black oil, diesel fuel, gasoline) *) the additional Information on this model below Technical features Most simple in installation and service passive homogenizer Works by a principle "has puthas forgotten". It is installed on fuel (black oil) highways and works from the regular or additional pinion pump in a wide range of pressure and temperatures. The max. water contents in black oil is - 9 %.. The economy of fuel (black oil ) reaches from 3 up to 12 %, combustion of fuel - full. Caloric content in water-black oil emulsion on 10-15 % above caloric content of pure black oil. Why it occurs? Pure black oil (Water in black oil, distance Between risks of 100 micron) burning standard black oil Water -black oil emulsion ( black oil after homogenezation Containing up to 12 % of water) atomized drops of waters - it is not visible. burning black oil after homogenization on our device The comparative table of data received at burning standard black oil and black oil after homogenization on our device standard black oil black oil after homogenization on our device black oil after homogenization on our device with water Heat value in kcals at an o'clock 9700 9900 10500 Dispersiveness of mechanical additions in microns 5-100 0.1 - 1 0.1 - 1 Essential reduced is absent - NOx 360-450 reduced lowered 30-50% - CO 38-45 reduced lowered 50-80% - SOx 1800 - 2100 reduced reduced Parameter Formation of soot on surfaces of heating Toxicity in combustion gases After put the working process with water-fuel emulsion - black oil with water contents 12-15 % - the fuel consumption is reduced up to 5 %, - Issue of oxides of nitrogen NOx decreases up to 40 %, sulfur anhydride SO up to 50 %, hydrogen sulphide H2S on 50 %, - Not burned down hydrocarbons are absent. - With increase of efficiency of use of fuel the temperature of leaving gases decreases on 80-100 С Failures of the hydrodynamical equipment it is not observed. Service of this device demands small time and low qualification of the personnel The list of the effects connected with use for burning water-black oil emulsions Possible economy of burnt fuel Transformation of water which contains in black oil in finely divided condition by emulsification up to 2% Decrease excess-air coefficient in boiler furnace on 0,1 up to 0,7% Decrease in temperature of leaving gases on 10°С up to 0,6% Heating of a feedwater in water waste-gas heater on 10°С up to 1,6% Decrease in temperature of a feedwater on an input in water waste-gas heater on 10°С up 0,24% Decrease in ejection of sootflake up to 0,2% Keeping of cleanliness boiler heat-exchange apparatus (surfaces) up to 2% Reduction of temperature of heating of black oil on 30°С up to 1% Opportunity of replacement of steam dispersion atomizers on simply mechanical atomizers up to 1% Keeping up of nominal EFFICIENCY of a thermal boiler in a mode 75 % from nominal up to 0,7% Decrease in losses of fuel on evaporation of water containing in structure of black oil up to 0,8% Possible total economy of fuel up to 10 % In this the table does not include estimation of yield ( economic benefit ) connected with decrease of toxic ejections (for example, CO, NOx and SO3 in leaving gases ) Rough calculation Economy of black oil In money terms At an annual expenditure of black oil incineration = nearly 10.000 tons per year, cost of black oil = 200 usd/ton in case of the savings of = 5 % black oil Annual economy of black oil, In money terms, will make 10.000*200*0,05 = $ 100. 000 standard black oil modified black oil The main differences from existing analogues black oil activator for oil-fired boiler There is no necessity - to make additional alterations in working equipment, - to recustomize its modes, - to pass additional certification. We can develop the similar equipment on lower productivity 1. Small weight (28 kg) at high efficiency (up to 40 tons per hour). The minimal transportation costs. 2. An opportunity of simple mechanical adjustment and alteration of a mode of treatment of fuel. Not clogged device with a greater resource of work. 3. Small power consumption which allows to work from the regular pinion pump without its essential load. A pressure drop on the device - 0.2-0.3 atmospheres. Can be installed on - any place black oil pressure line (before an atomizer) or on special mobile the chassis – mobile homogeniser for treatment of black oil and fuel capacities 4. The universal device, provides adjustment of productivity from 2 000 up to 40 000) litres p\h (it that does not provide any similar device). 5. It is installed by the mechanic of average qualification in current of hour. Economy on starting-up and adjustment works. 6. High working temperature - 40 - 150 C. and pressure (4-16atm.) 7. Does not contain dear packings and wearing out parts and can work in a passive mode, without the electric power. 8. Changes physical and chemical properties of black oil - reduce density - increases fluidity - reduce temperature of freezing - changes the fractional structure which reduces flash point . - twice reduce smoky exhaust - In some times reduce toxicity of an exhaust - external walls of collectors, inside of a boiler, become clean - practical economy of fuel - up to 9 %. 9. Treatment of fuel is made without any addition compounds or additives. Our activator has no connect with magnetic systems, filters and catalysts. 10. The activator of fuel has ф long term of work, does not get chocking , does not demand a clearing, recyclings and works by a principle " has put and has forgotten ". 11. Ecology. The activator really and essentially reduces issue of toxic substances - NOx, CO, H2S and other TRGA homogeniser tank with black oil black oil filter oil pump At the left - the scheme of full treatment of black oil for restoration of its properties and preparations for burning black oil with water and substandard black oil Below the scheme of treatment of black oil directly ahead of burning (before submission in atomizers) oil-fired boiler (black-oil) tank with black oil TRGA homogeniser black oil filter oil pump One more direction of application of our activators - gas-turbine power station. They are manufactured by Siemens, Kawasaki, General Electric, Hitachi, Turbomax and Solar. These power stations work on natural gas, but SHOULD have reserve fuel - as a rule it is solar oil. This fuel is stored long - 6 - 16 months, fuel soaks up water, starts to be dense, and start polymerizing The fastest, simple and cheap path of reduction of properties this aged solar oil - its processing on our homogeniser for preparation of this fuel before burning. In this situation - key factor - the maximal productivity of the device as I also wrote - only our devices process about 40 tons of fuel per hour We can instal additional simplified homogenisers directly ahead of a nozzle and then solar oil will burn as benzine Detailed Application of emulsified black oil allows to raise efficiency of burning of fuel and to achieve a gain of EFFICIENCY of a thermal boiler due to following effects: 1. Presence in burnt black oil of water at usual its non-uniform distribution in the form of large drops, lenses, etc. necessarily entails falling EFFICIENCY of a boiler because of granularity of burning, and the additional discharge rate of fuel for evaporation of this water. Even at burning black oil with standart water content (up to 5 %) the average factor of surplus of air is appears above optimum on 5,5 % and the average EFFICIENCY of a boiler falls on 0,5-1,1 %. At a water cut of black oil at a level of 10 %-15 % of EFFICIENCY of a boiler decreases at for 2,0-3,5 %. Thus, an effective utilization of flooded black oils probably only under condition of uniform distribution of water in finely divided emulsion on all volume. 2. As a rule, burning of black oils is conducted at appreciable surpluses of air (a = 1,2 and more), that conducts to growth of losses of heat with leaving gases. Usually the reason of the raised surpluses of air is insufficient quality fuel dispersion and mixture of fuel with blast air. Application water-black oil emulsions allows to raise quality of burning due to crushing fuel-air mix and to conduct burning on the lowered air blasting without accretion incomplete burning , down to values "a" close to unit. 3. Keeping up the boiler EFFICIENCY close to nominal values heat boiler at work on modes, smaller nominal, is reached due to effect of secondary crushing drops fuel boiler in furnace. 4. Passing boiler into modes of burning with small surpluses of air allows to lower temperature of a dew-point of leaving gases roughly up to 100 оС. It essentially reduces a degree of sulfuric acid corrosion of the equipment and allows to increase EFFICIENCY of a boiler due to recuperation heat of leaving gases on water- and air heater 5. Decrease of penal sanctions due to drop reduction of harmful noxious gas in an environment. Application of water-black oil emulsions allows to diminish the content of harmful matters in flue gass, thus CO, NOx, SOх on the average twice, soot fragments in 3-4 times. 6. Use as propellant of combustible waste of various productions (for example, waste of cake and by-product process, oil refining, etc.), which one cost essentially below cost of boiler oil. In the emulsified kind these waste oil products can be burnt without damage to ecology. Recycling in structure of water-black oil emulsions - waters with the black oil, the fulfilled oils, etc. 7. An opportunity use of cheaper high-sulphur (sour) black oil, so as the technology of emulsification allows to enter simultaneously into boiler oil water soluble desulfurize additives, for example MgCl2. 8. Return from steam mechanical atomizers to simple mechanical, it reduces the discharge rate of a steam on own needs. 9. Dispersion (liquid atomization) not removed fraction of water in boiler oil, the subsequent homogenization emulsification of this boiler oil, economizes the energy indispensable on vaporization of water in boiler oil. 10. Magnification of quantity of heat given to heat carrier due to smaller impurity of heating surfaces that allows to push up boiler efficiency. Another important factor characterizing efficiency of the WFE usage in the boiler processes, is effectiveness increase and long-lasting operating of the firebox equipment. A part of WFE drops reaches heating surfaces, explodes on them, what results not only in the measures preventing, but also cleans previous carbon blacks (soot and unburnt residues of combustion ) According to some foreign scientific sources overfire of fuel (because of contaminated heating surfaces with soot, unburnt residues of combustion and coke fragments - in boilers, on heat interchanger surface ) can approximate to 30 – 35 %. A serious problem arising during burning fuel oil is high sulfur content. Sulphides fly away together with smoke fumes and pollute the air. When using fuel oil in the metallurgy, the sulfur containing in the fuel oil usually transfers into the liquid metal melt and lowers the metal's quality. Even partial sulfur neutralization in fuel in the metallurgical industry, is obligatory if high-sulfur fuel oil is used. The method of the highest efficiency, in this problem, resolving by input additives introduction, that will bind sulfur on the stage of the fuel preparation for burning, namely on WFE preparation stage. It is the most effective method on the point of view of economizing, as the most of the additives applied is water-soluble. But even without use of such additives, incineration WFE considerably moderates the sulfur content in metal melt Citations from scientific articles about burning black oil with water after treatment on special homogeniser … Made by Centre Energy-Saving of Technologies the hydrodynamical equipment, basically, is applied in fuel systems of power installations to preparation high-grade, homogenous water-fuel emulsions /WFE/. The equipment can be applied for compound fuel, oils; preparations of suspensions; in oil refining, petrochemical manufacture. The developed technologies for processing high viscosity fuels in hydro dynamical devices the modulated high-frequency fluctuations, allow operating intensity cavitations processes to carry out conversion of molecular structure of hydrocarbons at a power level of the phase transformations. After processing in installation My viscosity of residual fuel of IFO-180, IFO-380, IFO - 700 decreases in 4, 5 times, density on 3 %, the temperature of flash is reduced on 30 %, and the volume of residual fuel is increased by 3 %. Conglomerates of residual fractions of fuel were crushed up to1-5 microns. The mix fuels, prepared on the basis of 70 % of marine diesel fuel and 30 % of residual fuel, had viscosity 5 cSt, that corresponded to viscosity of marine diesel fuel. Use high viscosity residual fuel, with the improved properties raises profitability of working process of diesel engines on 6 %. With conversion of work of ship main engines on water-fuel emulsion/WFE/ the consumption of fuel is reduced on 9-11 %, in boiler units on 6-8 %. Complete sets of the hydro dynamical equipment can be fragmentary established in fuel system of diesel engines, boiler units; gas turbines operate from energy streams of fuel. In the power installations working on water-fuel emulsion, except for decrease consumption of fuel, is reached significant improvement of ecological characteristics of exhaust gases. In the diesel engines working on WFE - with the water-contents of 5-12 %, emission the NOx decreases on 30-37 %, SO on 50 %, H2S and the not burned hydrocarbons down in some times. It allows execute reduction of harmful emissions with gases. With conversion of work on WFE the temperature exhaust gases of engines on an output from cylinders is reduced on 8-10 °C, the oil film on walls of cylinders, works in more comfortable conditions, thermal stress of details of cylinder-piston group accordingly decreases. With use in working process of diesel engines WFE: - It is sharply reduced carbon deposits on surfaces of the basic details of cylinder-piston group, in all exhaust manifold a path; - Speed of pollution of cylinder and motor oils is considerably reduced; - Raise reliability of work of the fuel equipment, an operating time of fuel filters between next clearness it is increased in some times; - Period of an operating time of diesel engines between the next maintenance service grows, expenses for repair are reduced; - Ultrasonic cavitations processing of fuel, before submission to a separator, allows to reduce losses of combustible fractions of hydrocarbons by 85 %; - Inclusion in structure of fuel systems of hydro dynamical devices provides an opportunity of input in structure of fuel of the additives, allowing to improve ecological characteristics of exhaust gases, velocity of burning; to delete the polluted sewage, harmful waste products of industrial production; Changes in dynamic at burning of water fuel emulsion, in burner space of boiler units, can be observed visually. A torch burning WFE in comparison with dehydrated heavy fuel, it is reduced in volume, is shortened, and becomes transparent. Owing to increase a contact surface of fuel with oxygen of air, oxidizing processes are intensified. Participation in reaction of burning molecules OH accelerates process of burning of fuel, transfer of heat to surfaces of boiler units. Submission of air in burner space decreases, that allows reducing losses of heat with leaving gases. The temperature of gases decreases on 20-30°C. Change of parameters of burning in boiler units and structure of leaving gases convincingly testify to increase of efficiency of use of fuel. Water-fuel emulsion is a special kind of fuel; it is qualitative and quantitatively varying process of burning. The jet injected WFE, owing to a smaller superficial tension, collapses on border division phases between fuel and particles of water. Contained in drops highdispersive particles of water, turning at heating in steam bubbles, instantly are crushed fuel on the smallest particles, increasing the area of contact of fuel with oxygen of an air charge. With rise in temperature the water phase dissociates on oxygen and hydrogen, their reaction in areas a lot of oxygen compensates expenses of energy on dissociating waters. Participation in reaction of additional quantity of hydrogen increases amount of products of combustion, changes of concentration harmful substances in gases. Manufacturing, delivery of the equipment, development of the engineering specifications on its application in structure of power installations, my enterprise is made on the basis of the contract. The equipment is protected by patents for inventions.