Rendicontazione 2004 - Università degli Studi di Trento

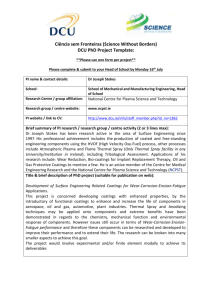

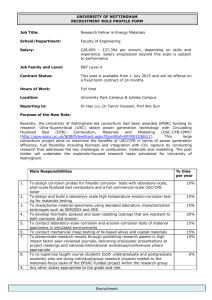

advertisement