41_SWP_Pouring Acrylamide Gels_SW

advertisement

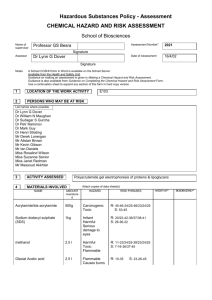

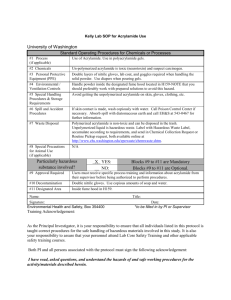

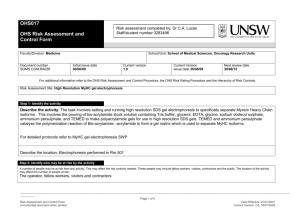

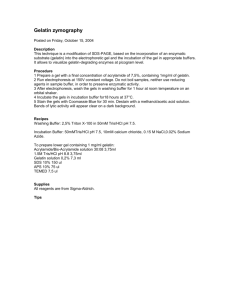

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP041 School/ Divisional Unit School of Medical Sciences Initial Issue date 23rd June 2009 Current version 1.0 Current Version Issue date 23rd June 2009 Next review date 23rd June 2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Sodium Dodecyl Sulphate - Polyacrylamide gel for electrophoresis (SDS-PAGE) Description: Separating cell extracts in a denaturing polyacrylamide gel by electropheresis. Associated risk assessment title and location: 41_RA_Pouring Acrylamide Gels_SW Describe the activity or process NOTE: Read all MSDS’s before starting experiment Polyacrylamide – carcinogenic and neurotoxic, wear protective clothing and gloves, once set, can be disposed of in the purple cytotoxic bin Solution Required 30% Acrylamide/Low-Bis solution (Refer to SWP “Making 30% Low-Bis Acrylamide Solution) Polyacrylamide – carcinogenic and neurotoxic, wear protective clothing and gloves, once set, can be disposed of in the purple cytotoxic bin 10% Ammonium persulphate (AMPS) N,N,N',N'-Tetramethylethylenediamine (TEMED) Harmful if inhaled or swallowed. Corrosive - causes burns. Irritant. Wear protective clothing, face mask and gloves. Addition of TEMED to acrylamide gel solution should be carried out in a well ventilated area or a fume hood. Resolving buffer (1.5M Tris.Cl pH 8.8) Stacking buffer (0.5M Tris.Cl pH 6.8) 10% (w/v) Sodium dodecyl sulfate (SDS) ___________________________________________________________________________________________________________ ___________ Page 1 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Description: 12.5 % Low-Bis Acrylamide Resolving Gel: 1 gel 2 gels 4 gels 5ml 10ml 30% Acrylamide- 2.5 ml Low Bis 1M Tris pH8.8 2.25ml 4.5ml 9ml Water 1.14ml 2.3ml 4.6ml 10% SDS TEMED 10% APS Prepare PAGE apparatus following manufacturer’s instructions. Combine H2O, resolving buffer, acrylamide monomer. Allow to warm to room temperature (degassing optional). Add SDS, TEMED, and AMPS and mix well. Pour gel to within 2cm (4.5cm for large Bio-Rad apparatus or 2.5cm for smaller gels) of the top of plates, overlay with water or ethanol and allow to polymerise for approximately 30 mins. Can now leave gel overnight if covered with Parafilm. Remove overlay, rinse gel with distilled water, dry with filter paper, and pour stacking gel. 12.5 % Low-Bis Acrylamide Stacking Gel: 1 gel 30% 2 gels Acrylamide 4 gels 1.33ml Bis 1M Tris pH6.8 Water 1.25ml 1.45ml 2.9ml 7.25ml 10% SDS TEMED 10% APS Combine H20, stacking buffer, and acrylamide monomer Allow to warm to RT (degassing optional). Add SDS, TEMED, AMPS and mix well. pour stacking gel, insert comb and allow to polymerise for approximately 30 minutes. Gels can be stored at 4oC by wrapping in paper towel soaked in transfer buffer and covered in plastic wrap. ___________________________________________________________________________________________________________ ___________ Page 2 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List all resources required including plant, chemicals, personal protective clothing and equipment, etc Equipment: Gel Pouring Apparatus Short and Spacer Plates Plastic Lane Combs Plastic Falcon Tubes Fume Hood Chemicals: 30% Acrylamide/Low-Bis solution 10% Ammonium persulphate (AMPS) N,N,N',N'-Tetramethylethylenediamine (TEMED) Resolving buffer (1.5M Tris.Cl pH 8.8) Stacking buffer (0.5M Tris.Cl pH 6.8) 10% (w/v) Sodium dodecyl sulfate (SDS) Personal Protective Equipment: Safety Goggles Lab Coat/Gown Face Mask (for addition of TEMED to acrylamide solution) List potential hazards and risk controls including specific precautions required Potential Hazards: Contact and absorption of acrylamide via contact of solution with skin or splashing into eyes. Inhalation of TEMED via vapors Risk Controls and Precautions: Gloves, Safety goggles and lab coat should be worn when handling acrylamide solutions and TEMED Making of polyacrylamide gels should be carried out in a well ventilated area, preferably in a fume hood. List emergency shutdown instructions ___________________________________________________________________________________________________________ ___________ Page 3 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List clean up and waste disposal requirements Spillage of any solution used for the making of polyacrylamide gels should be cleaned up using the spill kit located in Rm 502. Paper towel used to mop up excess acrylamide solution should be disposed in the cytotoxic waste container Excess acrylamide solution should be polymerized with addition of AMPS and TEMED and disposed in the cytotoxic waste container. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection Sodium Dodecyl Sulphate - Polyacrylamide gel electrophoresis (SDS-PAGE) Children’s Cancer Institute Australia Standard Operating Procedure (No. CCIA-LB-57) Supervisory approval, training, and review Supervisor: Peter Gunning Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction into the Lab, Training on this SWP. ___________________________________________________________________________________________________________ ___________ Page 4 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007