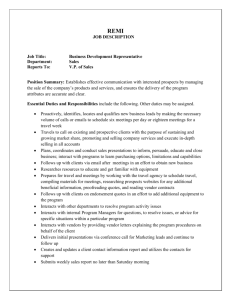

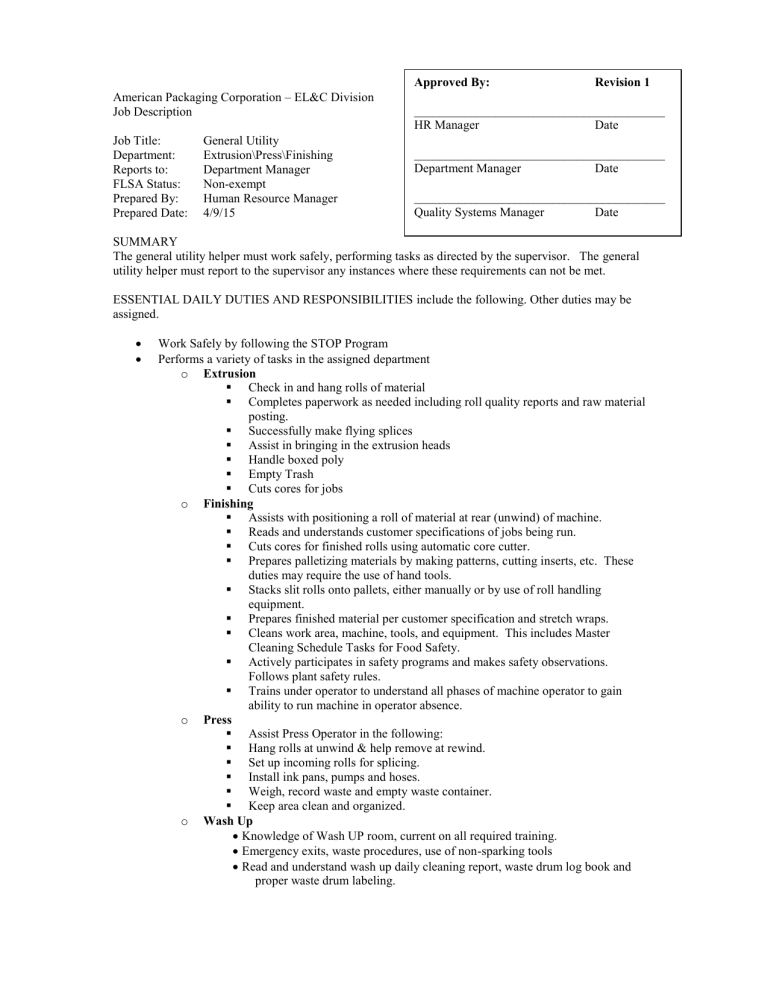

General Utility - American Packaging Corporation

American Packaging Corporation – EL&C Division

Job Description

Job Title:

Department:

General Utility

Extrusion\Press\Finishing

Reports to: Department Manager

FLSA Status: Non-exempt

Prepared By: Human Resource Manager

Prepared Date: 4/9/15

Approved By:

HR Manager

Revision 1

________________________________________

Date

________________________________________

Department Manager Date

________________________________________

Quality Systems Manager Date

SUMMARY

The general utility helper must work safely, performing tasks as directed by the supervisor. The general utility helper must report to the supervisor any instances where these requirements can not be met.

ESSENTIAL DAILY DUTIES AND RESPONSIBILITIES include the following. Other duties may be assigned.

Work Safely by following the STOP Program

Performs a variety of tasks in the assigned department o

Extrusion

Check in and hang rolls of material

Completes paperwork as needed including roll quality reports and raw material posting.

Successfully make flying splices

Assist in bringing in the extrusion heads

Handle boxed poly

Empty Trash

Cuts cores for jobs o Finishing

Assists with positioning a roll of material at rear (unwind) of machine.

Reads and understands customer specifications of jobs being run.

Cuts cores for finished rolls using automatic core cutter.

Prepares palletizing materials by making patterns, cutting inserts, etc. These duties may require the use of hand tools.

Stacks slit rolls onto pallets, either manually or by use of roll handling equipment.

Prepares finished material per customer specification and stretch wraps.

Cleans work area, machine, tools, and equipment. This includes Master

Cleaning Schedule Tasks for Food Safety.

Actively participates in safety programs and makes safety observations.

Follows plant safety rules.

Trains under operator to understand all phases of machine operator to gain ability to run machine in operator absence. o

Press

Assist Press Operator in the following:

Hang rolls at unwind & help remove at rewind.

Set up incoming rolls for splicing.

Install ink pans, pumps and hoses.

Weigh, record waste and empty waste container.

Keep area clean and organized. o Wash Up

Knowledge of Wash UP room, current on all required training.

Emergency exits, waste procedures, use of non-sparking tools

Read and understand wash up daily cleaning report, waste drum log book and proper waste drum labeling.

Understanding of all Press & Extrusion parts and cleaning procedures.

Keep the wash up room clean and organized

Support the needs of all departments

Follow direction and have good communication skills with all levels

WORK ENVIRONMENT: The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is occasionally exposed to moving mechanical parts, vibration and fumes or airborne particles (a specific list is available upon request). The noise level in the work environment is usually moderate.

Maintain quality standards by following specifications.

Performs tasks as directed from machine setup to job tear down to insure setup and production targets are met and minimize downtime.

Completes tasks to insure work area is clean to GMP & Food Safety standards

Must possess a healthy work ethic.

Good communication skills, both verbal and written.

Must take responsibility for work assigned.

Follow all Plant Safety Rules, GMPs, and other procedural training requirements.

Other duties as assigned by supervision.

QUALIFICATIONS: To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

EDUCATION and/or EXPERIENCE: High school diploma or general education degree (GED); and one to three years related experience and/or training; or equivalent combination of education and experience.

LANGUAGE SKILLS: Ability to read and interpret documents such as safety rules, operating and maintenance instructions, and procedure manuals. Ability to write routine reports and correspondence.

Ability to speak effectively before groups of customers or employees of organization.

MATHEMATICAL SKILLS: Ability to add, subtract, multiply, and divide in all units of measure, using whole numbers, common fractions, and decimals. Ability to compute rate, ratio, and percent and to draw and interpret bar graphs.

REASONING ABILITY: Ability to apply common sense understanding to carry out detailed but uninvolved written or oral instructions. Ability to deal with problems involving a few concrete variables in standardized situations.

PHYSICAL DEMANDS: The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations will be made to enable individuals with disabilities to perform the essential functions.

These demands include:

Moving throughout the facility, in between and on top of machinery

Remaining in a stationary position for extended periods of time.

Accessing materials and equipment from various areas of the facility including those located in high places.

Occasionally moves materials and equipment weighing up to 25 lbs.

Frequently communicates with co-workers; must be able to exchange accurate information in these situations.

Specific vision abilities required by this job include close vision, distance vision, color vision, peripheral vision, depth perception, and ability to adjust focus.

WORK ENVIRONMENT: The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

While performing the duties of this job, the employee is occasionally exposed to moving mechanical parts, vibration and fumes or airborne particles (a specific list is available upon request). The noise level in the work environment is usually moderate.