Department Strategic Plan - College of Engineering

advertisement

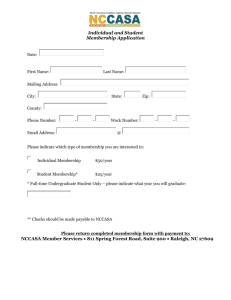

FIVE YEAR STRATEGIC PLAN FOR THE DEPARTMENT OF CHEMICAL ENGINEERING UNIVERSITY OF SASKATCHEWAN 2008-2013 June 2007 BACKGROUND Chemical engineers are primarily involved in producing new technologies for value-added processing of Canada’s natural resources, producing wealth for Canadians while minimizing environmental impacts. Saskatchewan is blessed with many of Canada’s natural resources (2003 GDP data): 1) Agriculture ($2.2 billion); 2) Oil, Gas and Minerals ($4.2 billion); as well as 3) Water (11 % of Canada’s wetlands). Teaching and research in the Department of Chemical Engineering is focused on added-value processing of these and other Western Canadian resources in an environmentally sustainable manner. Mission of The Department of Chemical Engineering: The Department of Chemical Engineering at the University of Saskatchewan provides a fundamental and innovative education for chemical engineering students, providing them with the skills to become strong participants and leaders in the industrial development and utilization of Saskatchewan’s and Canada’s natural resources and to enter exciting careers in research and academia throughout the World. Equally as important, through their research activities, the faculty and staff of the Department develop new, innovative technologies to add value to natural resources and protect the natural environment in Saskatchewan and throughout the World. Undergraduate Program: Historical As this report is written, the Department of Chemical Engineering is a fully accredited engineering department (CEAB) until the year 2009, with our next accreditation visit scheduled for the Fall of 2008. The undergraduate program has become very popular over the past few years, such that it is currently saturated (even exceeding our maximum second year intake of 60 students). The graph below shows the increasing trend of BE chemical engineering graduates from Saskatchewan over the past 6 decades: 1 In spite of the difficulty of the academic material, the popularity of the program is growing due to two factors, 1) industrial development, driven by both the petroleum and mineral production and processing sectors, has greatly increased the demand for chemical engineering graduates and 2) chemical engineering training at Saskatchewan has a reputation of being superior relative to other Canadian chemical engineering programs. The strong demand for chemical engineers is reflected in the most recent National Association of College’s and Employers salary survey: Table 1. NACE Survey of Engineering Starting Salaries ($Can), 2007 Degree Chemical Electrical Mechanical Comp Sci Civil Bachelor $70864 $64427 $64413 $60263 $55631 Currently, there are 170 undergraduate students enrolled in the upper three years of the Chemical Engineering program (an increase of 29% since the last strategic plan). Table 2 lists the 2003-2008 undergraduate program goals and whether those goals were obtained. Table 2. 2003-2008 Chemical Engineering Plan Undergrad Goals 1 2 3 4 5. 6 7. Renew Laboratories Increase Tech Elec Courses Add Mineral Processing Option Add Petroleum Option Remove a ChE Course, add GE 210 Contribute to Chemistry and GE Teaching Increase intake to 55 2nd year students Yes, 6 new operational experiments No. No. Yes. In place as of 2006. No. Partial, took over Chemistry 347. Yes, surpassed to over 60 students. 2 Although all seven objectives were not met, considering that the resources requested by the Department in the 2003-2008 Plan were not provided by the University from its priority fund, it is commendable that progress was achieved. Research Program: Historical Research in the Department of Chemical Engineering has remained strong over several decades. The Department research funding averaged $650K per year, with 2.25 journal publications and 3.5 conference presentations per faculty member for the 10 year period up to 2001 (with only 8 faculty on staff). In the most recent planning cycle with 10 or 11 faculty on staff, the results are listed in Table 3 (numbers in brackets represent faculty numbers that year). Table 3. Some Recent Research Data for Chemical Engineering 2003-04 (10) 2004-05 (10) 2005-06 (11) $1.447 million $1.525 million $2.515 million 1.40 journals/faculty 2.50 journals/faculty 3.73 journals/faculty 4.00 conferences/faculty 5.80 conferences/faculty 5.55 conferences/faculty The research performance of our Tier II Canada Research Chair (Ajay Dalai) was very strong and resulted in the position being renewed in 2006. Chemical Engineering was the first Engineering Department at Saskatchewan to receive a Canada Research Chair and has subsequently received two large CFI awards. Professor Dalai regularly uses synchrotron radiation in his research projects. Chemical Engineering staffing has remained stable except for an additional tenure-track faculty member added in 2005 (temporary based on the retirement of another position in 2011) and two recent resignations (one faculty and one clerical staff in 2007). The following table indicates the success of the Department in trying to meet its previous plan’s research goals: Table 4. 2003-2008 Chemical Engineering Plan Research Goals 1 2 3 4 5. 6 7. Planned Outcome 40 graduate students per year 15 of 40 are PhD students Average annual funding of 1 million Reduce graduate course load Revise qualifying examination Provide systematic safety training 3 journals, 3 conferences/faculty/year Actual Outcome Achieved? Yes, average = 40 plus 8 PDFs/year Yes, average = 15/yr. Surpassed, see Table 3. Yes. MSc = 4: PhD =6; down one each. Yes, see website of Dept. Yes, DHSE courses documented in Dept. Journals = 2.54 avg.; Conf = 5.11 avg. Given the fact that no investments from the first University priority fund were made available to the Department, it is amazing that this increased research activity has taken place and almost all research goals were achieved. The Department is working at maximum capacity and cannot possibly increase its research activities without added investments from the University. Another measure of research productivity is hosting national and international conferences. Over the 2003-2008 cycle, faculty in the Chemical 3 Engineering Department hosted three conferences in Saskatoon: National Association of Corrosion Engineers Canadian Division (2005, Evitts); Symposium on Green Biotechnology and Biochemical Engineering (2005, Lin); and Canadian Symposium on Catalysis (2006, Dalai and Wang). In 2010, the Chemical Engineering Department will be hosting the Canadian Chemical Engineering Conference here in Saskatoon. This conference normally attracts about 1500 delegates. 4 FIVE YEAR PLAN (2008 – 2013) UNDERGRADUATE PROGRAM: The Department undergraduate program is strictly monitored and regulated by the Canadian Engineering Accreditation Board. The Department is committed to maintaining the strong undergraduate program that has made its graduates successful for the past 70 years and will likely continue to do so in the next five years. This includes training in: Mathematics (calculus, statistics, linear algebra, differential equations), Basic Sciences (physics, chemistry, life science), Complementary Studies (economics, ethics, professionalism, business, humanities, social sciences), Engineering Sciences (mechanics, electrical, materials, transport, control, thermodynamics) and Engineering Design (process design, health and safety, process simulation). Much of this training includes experiential study in the basic sciences laboratories and in the chemical engineering undergraduate laboratory; in the biannual field trips to chemical processing companies; and in the summer and internship work experiences in chemical industries. Using funding from the Dow Chemical Company, the Department has successfully upgraded its experiential learning, practicum laboratories in the first round of strategic planning by commissioning six new experiments. Given the growth in the Chemical Engineering student numbers, the program is now at capacity (intake of 60 students per year in second year) and the ability of the Department to expand in undergraduate student numbers is limited, in part, by the lack of hours that we can operate the laboratories. If another professor, laboratory technician, and teaching assistant were available, it is estimated the laboratories could be run at 30% more capacity, increasing our student intake to 75. This could translate to 35 more students in Engineering and more tuition revenue for the University. Although no progress was made on adding Technical Elective courses to our program in the first strategic planning cycle, the importance of doing this (concern of both the previous SPR and CEAB reviewers) means that this has now become an urgent issue for the second planning cycle. The goal here has not changed, to add at least two more technical elective courses. Possible topics include: mineral processing, environment, fuel cells, and/or a research project course. Faculty teaching is already high in Chemical Engineering, so it will be a struggle to add these courses to the curriculum with the current faculty allotment. Given our current student numbers (175 in 2nd, 3rd and 4th year plus shared teaching of over 400 first years) and the potential to increase our overall total student numbers by 35 with an increase in second year intake (potential of 210 students in 2nd, 3rd and 4th year), it seems reasonable to request more faculty and introduce extra technical elective courses. The Department will be a key player in the new Environmental Engineering program in the College of Engineering. Some of our third years will likely choose that path for their studies and we will open up many of our environmentally related courses to permit Engineering students who do not have 5 the first two years of chemical engineering training to achieve an Environmental Engineering degree. The Department is planning to establish an enhanced computer training facility for the purpose of training undergraduates “high-end” chemical engineering software. These types of dedicated computer facilities exist in almost every chemical engineering department in Canada. The students learn how to use advanced computer software such as Hysys Dynamics, Aspen Electrolytes, Comsol Multiphysics, Matlab and Fluent. The software training would be embedded into one or more of our existing Technical Elective courses. Although a DOW donation is expected to capitalize this facility, an ASPA position is requested from the University, in part to maintain and instruct students on the use of this high end software. The Department will explore the possibility of opening our courses to industrial engineers not currently trained in basic chemical engineering principles, or our graduate courses to industrial chemical engineers. If this can be done on a one-off course basis at a reasonable registration cost, the Department would advertise the availability of these positions to local industry. Courses which could be of interest include process engineering, process fluid mechanics, basic thermodynamics, advanced reactor engineering, advanced waste treatment, advanced biochemical engineering, advanced petroleum production/processing or our new petrochemical engineering. This could generate extra revenue for the University. Safety is a major concern of the Chemical Process Industries and over the 2003-2008 cycle many new lecture hours have been incorporated into existing course material to address safety concerns at chemical processing facilities. In the next planning cycle, the Department will continue to expand these lecture hours by incorporating increasing amounts of educational materials provided by the SAChE organization in the United States, particularly in terms of Process Safety Management and Risk Assessment. Finally, should the Department achieve its goal of having 12 tenured faculty members (two additional faculty members), four new technical elective courses would be introduced in the next planning cycle. These courses would be i) mineral processing; ii) mineral production; iii) fuel cell technology and iv) research project. GRADUATE (RESEARCH) PROGRAM: As noted earlier, the Department met its initial strategic plan research goals without University priority fund investments. But the Department is heavily constrained by both the low tenured faculty allotment and the low operating budget. The Department is performing at a research level that cannot be increased given these constraints, but it is certain that one or two new term Chair positions or one or two new tenure-track positions could contribute to increased intensiveness of our research program. Since it is not known if new positions will be achieved, the proposed research productivity goals for the forthcoming 6 planning cycle are identical to the previous planning cycle as shown below. The research theme areas for the next planning cycle (2008-2013) will be: Biofuels; Petroleum and Gas Processing; Environment; and Mineral Processing. Table 5. Research Output Plan for Chemical Engineering 2008-09 2009-10 2010-11 2011-12 2012-13 $1.1 million $1.1 million $1.1 million $1.1 million $1.1 million 3 journals & 4 conf./faculty 3 journals & 4 conf./faculty 3 journals & 4 conf./faculty 3 journals & 4 conf./faculty 3 journals & 4 conf./faculty 40 grad students 40 grad students 40 grad students 40 grad students 40 grad students Improvements in the research program that will be investigated and perhaps implemented in the next five years are noted below: 1. Funding Investment for Top Graduate Students: In order to compete in the national and international arena, it is clear that the Department must attract the brightest graduate students. Currently, NSERC scholars are being provided automatic top up funds without any questions asked in most Colleges of Engineering across Canada. This is not the case at Saskatchewan. It is felt that a modest $5000/annum top-up grant per NSERC scholar should be automatic here at Saskatchewan. The Department wants to work with the College, the University and local industries to see if a package of $25000 per year (providing automatic top-ups to five NSERC scholars) can be put together for the Chemical Engineering Department. 2. Internationalization: The Department wants to develop formal linkages with four Universities over the next five years. Direct relationship with the National Chung Cheng University in Taiwan, Okayama University in Japan, IIT, Delhi and through the College of Engineering, a relationship with Tamilnadu Agricultural University in India. The initial MOUs will discuss sharing students and research projects in a general way, but it is our intent to carefully document the joint activities that take place and to judge if significant research or teaching benefits accrue by the end of the next strategic plan. 3. Research Chairs in Biofuels, Gasification Technology, Environmental Design, and Mineral Processing will also be pursued by the Department. The Department already has a lot of biofuel research including biodiesel, bioethanol and biomass gasification. The area of gasification is important in heavy oil production as well as biofuel energy. The Department has 3 faculty who perform environmental related research as their main research thrust with a number of other faculty involved in environmental research projects. In conjunction with the Mineral Research initiative of the University of Saskatchewan and the many mineral processing industries in Saskatchewan, the Department is the natural place to incorporate a Mineral Processing Chair. PERSONNEL: Other than the current allotment of ten tenured and one term faculty members, the Department has one ASPA employee in charge of the undergraduate laboratories, three permanent CUPE employees performing technical tasks to support the undergraduate and research programs (equipment 7 maintenance, stores, analytical services), and two CUPE employees providing clerical work to manage all the paperwork (including placing purchasing orders) for the Department. The Department feels this is a good mixture of staff and does not plan to change any of these functions over the next planning cycle. However, the Department would like to add to its faculty complement (two new tenure-track positions) to expand its teaching and research activities and to add one ASPA employee whose duties would include managing Department initiatives such as strategic planning, managing Department common areas and managing our electronic media, both website and course material including our new high end undergraduate software. SPACE: The Department needs to modify its infrastructure to turn its workshop area into a laboratory. With the Dean of Engineering now occupying laboratory space in the Chemical Engineering wing, another laboratory is required for a new faculty member being hired to replace Dr. R. Sumner’s position, or with the expansion of instrumentation in the analytical laboratory, more space is also needed to install analytical equipment that is either in the application process or currently being purchased. SUMMARY of UNIVERSITY INVESTMENT REQUESTS in the NEXT PLANNING CYCLE The pages that follow list the details of activities that are planned to take place in seven strategic theme areas over the next planning cycle. To meet the expectations presented in those pages, the Department is requesting the following additional resources from the University over the next planning cycle for which we also list expected revenue and productivity improvements: 1. Two new tenure-track positions ($160K/yr): contribute to increased student numbers: 35 students per year by the end of the planning cycle (tuition revenue of approximately $350K per year); increased CU in three lab courses (tuition revenue of $120K/yr); 8 new graduate students per year (tuition revenue = $40K/yr); increased journal and conference output; increased research funding expected to be $200K per yr). 2. One new ASPA employee ($50 K/yr) : Enhanced management of Department administration tasks, common space and electronic media. 3. Operating Budget: $25K/yr for increased laboratory and software expenses for the undergraduate program; for top-up funding and graduate student travel support for the graduate program; for support for faculty teaching initiatives. 4. Capital = $150K for new undergraduate laboratories in order to increase CU to 3 for each laboratory course (revenue in Item 1 above) and $350K? for infrastructure change to add a research laboratory for a new faculty hire. 8 APPENDIX List of the Seven Strategic Themes of the Department (2008 – 2013) General Department Themes: 1. Enhancing the Undergraduate Experience 2. Enhancing the Graduate Experience 3. Improving Faculty Recruitment and Retention Research Themes: 4. Bioenergy Research 5. Petroleum and Gas Research 6. Environmental Research 7. Mineral Processing Research 9 1. Theme: Enhancing the Undergraduate Experience Initiative Title: Chemical Engineering Undergraduate Program Description of Initiative: Objective: To revise the current Chemical Engineering undergraduate program within the constraints of the Canadian Accreditation Board by: (i) improving industrial input to our program, (ii) continuing to improve our undergraduate laboratory courses, (iii) replacing untenable option streams with new options suitable to local industry, (iv) streamlining our undergraduate mathematics course path and (v) improving the quality and variety of courses. Details: (i) To ensure our undergraduate program meets the needs of employers, an Industrial Advisory Board (IAB) will be set up with annual meetings. Representatives would be chosen from both local and out-of-province industry and consulting firms who often hire our graduates. Representatives from each of our 2nd, 3rd and 4th year classes would also be invited. (ii) The undergraduate laboratories require more working lab modules to ensure more variety within each lab course, thereby increasing student enthusiasm. Specific modules to be developed within the 2008-2013 period include: Biodiesel Reactor, Photocatalysis Reactor, Floatation Cell, and a Thermodynamics PVT Cell. Due to the recent expansion of our undergraduate lab offerings and to better reflect the time and effort students spend in our unit operations labs, the CU for each lab will increase from 2 CU for each lab course to 3 CU. Because these courses act as our bottleneck to student enrolment, further growth of our undergraduate program requires an additional laboratory section be added to each lab course. (iii) Current undergraduate options in our program are: (a) Biochemical, (b) Biotechnology, and (c) Petroleum. The Biochemical Option continues to be popular with our students while the Biotechnology Option offers a multitude of scheduling hurdles and thus is much less popular. Scheduling the Biotechnology Option classes within a four-year program has become nearly impossible. Thus the Biotechnology Option will be removed from our program. However, with the addition of a chair in Mineral Processing and in collaboration with the Department of Civil and Geological Engineering and the proposed Mineral Resource Center, a new Mineral Processing Option will be introduced. (iv) The lecture courses and their content will be streamlined with input from the IAB. The four courses in our chemical engineering mathematics stream (Mathematical Modeling I & II, Process Dynamics and Process Control) are being assessed to determine if they can be reduced to three chemical engineering classes plus the general engineering statistics class (GE 210). This has the potential to decrease our faculty’s teaching loads while increasing our commitment to general engineering courses. 10 (v) Enhancement of the student experience will, in part, be achieved through an increased use of computational tools and high performance computing. This incorporation of e-learning strategies will be achieved with the help of Dow to purchase a High Performance Computing Cluster and software to aid in training of our undergraduate students in state-of-the-art simulation and project management software while providing better facilities for visualization and discussion of complex chemical engineering problems. The Department of Chemical Engineering is a key player in the development of a new Environmental Engineering Program in the College of Engineering and in collaboration with the proposed School of Environment. The faculty in our department will contribute to teaching of several relevant courses including the final year design project. Participation by Engineering students without a Chemical Engineering background will enhance the experience of all the undergraduates. Four technical electives will be added to the program to enhance the student experience. With the addition of a Mineral Processing Chair, a Mineral Processing technical elective will be created and will alternate each year with a second Mineral Production technical elective, both promoting the local mining industry. In collaboration with the Department of Mechanical Engineering and the new School of Environment, a Fuel Cell Technology technical elective will also be created. For students interested in applied research, a fourth technical elective allowing students to complete a supervised research project will be implemented after careful consideration with respect to accreditation. Revenues and Costs: Revenue: The increased CU per each of our three laboratory courses will result in increased revenue for the University. Following the generous investment by the Province and University for new undergraduate laboratory equipment in 2002, the endowment from DOW (2006-2008) has allowed several new laboratory experiments to be brought on stream. In 2008 – 2012, these experiments will be amalgamated into the Chemical Engineering curricula. This wider experiential learning for our undergraduate student will bring these laboratory courses to a full 3CU learning value. A DOW endowment for 2007-2010 of $250,000 ($50000 per year) will allow a high performance computing center to be set up with software to aid in flow visualization, simulation and numerical analysis in the first three years followed by the purchase and installation of two of four new laboratory modules in the final two years of the next planning cycle. Costs: The operating costs of both the new laboratories and the High Performance Computing Center will need to be embedded into our existing Department budget (on-going supplies, maintenance and TA support). This is expected to require $10000/yr in on-going budget expenses for the Department. The cost associated with the 4 new laboratory modules is $250,000 spread over the 5 year planning period. To allow our program to grow with increased student numbers, increased laboratory sections and increased 11 numbers of technical elective courses, both one extra ASPA position ($55K per year) and another tenure-track position ($80K per year) needs to be allocated to our department. Performance Measures/Metrics: Unless more laboratory sections can be added to our program, enrolment targets for will remain fixed at 60 students per year. With the additional resources required for the lab, it is expected that enrolment would increase to 75 by the end of the planning period. Responsibility: Associate Professor Aaron Phoenix, Ph.D., P.Eng. Timeline: Implementation of the High Performance Computer Lab, deletion of the Biotechnology option and formation of the IAB would occur at the start of the planning period. Restructuring of the program’s math content, introduction of new technical electives and new laboratory modules would occur as the resources became available. Comments: The two proposed technical electives in Mineral Resource Production and in Mineral Procession provide an excellent opportunity to collaborate with the proposed Mineral Research Center and with the Department of Civil and Geological Engineering. Both of these units are also fundamental in our plans to develop a Mineral Processing Option within our Department. The Fuel Cell technical elective will also play an important role as an elective for students taking the proposed Environmental Engineering program within the College and for science students in the proposed School of Environment. Because of the multi-disciplinary nature of fuel cells, their development and their operation, this course suits itself to a collaborative effort between Chemical and Mechanical Engineering. 12 2. Theme: Accelerate Research Initiative Title: Chemical Engineering Graduate Program Description of Initiative: Objective: To improve and enhance the Chemical Engineering graduate program by revising course scope and developing new learning opportunities. Details: 1. Deletion of dormant course: The course CHE 873.3 “Process Dynamics and Control” will be deleted from the calendar. This course has not been taught since 1999 and there is no faculty member whose specialty is in this area. 2. New graduate courses: Dr. Janusz Kozinski has proposed to offer a graduate course “Waste Remediation in Environment & Society" once he becomes settled in his new position as the Dean of Engineering. Some faculty members working in the areas of Bioenergy and Petroleum are developing courses, for example, such as Fuel Cell Technology, Natural Gas Processing, Chemicals and Energy from Renewable Resources and Principles and Applications of Heterogeneous Catalysts, that are relevant to green technology and biofuels. 3. Linkages with other universities: The Department of Chemical Engineering is vigorously developing formal linkages with the National Chung Cheng University in Taiwan, Okayama University in Japan, and Tamilnadu Agricultural University and IIT-Dehli in India. It is expected that the joint activities through sharing of students and research ideas will benefit all who are involved. 4. Working with the University Learning Centre to foster online learning opportunities for our students. 5. Working with the Gwenna Moss Centre for Teaching Effectiveness to build complementary learning opportunities for graduate students in the areas of teaching and cross-disciplinary skills. Revenues and Costs: No additional revenue will be generated from the tuition fees in connection with the deletion/addition of courses. With one extra faculty position, the Department would generate 4 extra graduate students per year, resulting in additional tuition revenue expected to be about $15K per year. The Department will require funds to top up the NSERC scholarships (at least $5000 per NSERC scholarship student per year) to start to compete with other Chemical Engineering departments in Western Canada for highly qualified students. Some funds will be needed for graduate students to travel to linked universities, expected to be about $5000 per year. In addition to these financial requirements, one Graduate Teacher-Scholar Fellowship is required to support a student who will be trained under the GTSF program. 13 Performance Measures/Metrics: The total number of graduate students in the department and the student population in the new courses will serve as indicators and as a measure of the success of this initiative. Responsibility: D.-Y. Peng will be responsible for monitoring the development in this theme area Timeline: The enhancement of the graduate program is a continuing process. While the deletion of dormant courses can take effect immediately, the proposed new courses will take approximately two years to be completely on stream. Comments: The new courses may be open to students from other colleges such as Arts and Science, Agriculture and Bioresources, Commerce, and Law. Working with the UTC and GMCTE is required. In addition to the devolved scholarship funds from the CGSR and a GTF allocated by the College of Engineering, the financial support in the form of a Graduate Teacher-Scholar Fellowship from the CGSR will be indispensable to the success of this initiative. 14 3. Theme: Enhance Faculty Retention and Recruitment Initiative Title: Chemical Engineering Faculty Development Description of Initiative: Although the Department is very proud of the current productivity of its faculty, further incremental investments will be made to enhance faculty productivity in both research and teaching, the two main responsibilities of University faculty. Objective: To provide new and existing faculty the opportunity to develop or maintain an active research program and develop contemporary teaching skills. Details: 1. Research: The Department will continue to use its Discretionary research fund to help support faculty attendance at one research conference per year. The Department’s Thorvaldson fund will be used to support one equipment or infrastructure upgrade per year, preferentially for new faculty. 2. Teaching: To divert funds from the Department’s operating budget to help one faculty member per year attend a teaching course or develop improved teaching facilities. Costs and Revenues: Costs: Research: Arguably, the major task of faculty members is to develop and maintain active research progress, measured by publications, supervisory tasks, funding and conference presentations. The Department aspires to be recognized both nationally and internationally in its thematic areas. To help faculty obtain this recognition, the Department will provide $500/faculty/yr to support travel and attendance at one research conference per year, for a total cost of $5500/yr. The new research facility of Chemical Engineering was developed on a very limited budget resulting in many infrastructure and equipment shortcomings. The Department will fund up to $15K per year to help new faculty obtain capital equipment to develop an active research program, or to established faculty to upgrade their existing research space. Teaching: Faculty in chemical engineering have a wide range of core and new academic materials to present each year. With limited faculty numbers, it is important that faculty have opportunities to attend courses that will quickly bring them to a high knowledge level in all core and technical elective areas. As well, teaching is becoming more and more computerized each year. Faculty need to have both training and assistance in learning and converting lecture material into electronic material. Although the University provides a professional allowance to help fund these activities, over the next strategic planning cycle, the Department aspires to provide one $1000/yr investment to assist faculty members meet these objectives. 15 Revenues: Research expenses (travel and infrastructure) will be funded by the Department’s Discretionary ($5500/yr) and Thorvaldson funds ($15K per year). Teaching support will come from the Department’s operating budget but requires an increase in the annual operating budget of $3000 per year. Performance Measures/Metrics: Faculty development in research will be measured by the productivity change from the previous planning cycle in terms of journals, funds and supervisory duties. These changes will be related to the investments made to support conference and infrastructure upgrades per faculty member. Teaching improvements will be measured by the increased assessment ratings of existing faculty and new electronic teaching materials developed over the next planning cycle. Responsibility: The Department Head will be responsible for monitoring these activities. Timeline: Faculty investment is on-going in the Department and will continue to be conducted annually with no change in investments over the next planning cycle. Comments: The Department hopes that both the College of Engineering and the University of Saskatchewan will match the Department investments in improving the ChE faculty research and teaching. If this were so, the amount of support would triple for each of the initiatives mentioned above. Given the large amount of research activity in the Department which helps to bring NSERC infrastructure and discretionary overhead monies to the University; and the growing undergraduate population of Chemical Engineering, it seems reasonable to expect that the College and University would commit to these investments over the next planning cycle. 16 4. Theme: Accelerate Research and Engaged University Initiative Title: Bioenergy Description of Initiative: Objective: To develop a bioenergy research center focussed on the conversion of Saskatchewan and other Western Canadian biomass to useful forms of energy. Details: 1. Bioethanol: Research in this area includes: i) fundamental scientific investigations to determine the protein and metabolic profiles inside ethanol fermenting microorganisms that lead to higher ethanol productivities; ii) genetic manipulation of Saccharomyces cerevisiae to directly convert grain starches to ethanol without the addition of enzymes; iii) purification of bioethanol using Saskatchewan agriculture residues acting as adsorbents; iv) membrane purification of ethanol vapors from a flash process; v) production of ethanol from cellulosics by the syngas process. 2. Biodiesel: Research projects include i) production of biodiesel from lards, waste oils and green canola seed; ii) conversion of bio-oils to syngas; iii) glycerol conversion to added value products; iv) syngas to liquid technologies. Through the work of Professor Ajay Dalai (Canada Research Chair), the Department has gained worldwide recognition for its expertise in these areas. 3. Fluidized combustion: The Department has the World’s best fluidization research facility (FLASK) in an academic institution. Projects for energy generation include: i) fluidized combustion of waste cellulosics to capture thermal energy; ii) fluidized combustion of animal wastes to destroy prions and capture thermal energy. 4. Microbial fuel cells (MFCs): A brand new technology to generate electricity is under investigation. Current projects include: i) Using photosynthetic cultures as cathodes in MFCs; ii) Coupling bioethanol fermentation and algae cultures for a complete MFC battery; iii) Anaerobic treatment of sulphide wastes in a MFC. Costs and Revenues: Costs: This area involves the work of at least five of the eleven chemical engineering professors, but each faculty member who is involved is also involved in other research areas. It is estimated that this area consumes 2.5 of our current faculty research time, valued at about $200K per year. This research area also consumes about 0.5 of our 6 non-faculty positions, estimated at about $25K per year. Each project listed above (12 projects), on average, involves the work of one graduate student, one summer student and $10K in materials and supplies each year valued at $38K per year, for a total yearly expense of $456K. Capital equipment purchases for each of the four areas is estimated at $75K per 17 year, for a total yearly expense of $300K. Not including faculty or technical staff salaries, the research expenses to be covered by faculty grants amounts to $756K each year. Industrial Support: The following industries have invested in these research projects: March Consulting; Ag West Innovations; Sask. Canola Growers Association; SaskPower; Advanced Biorefinery Inc.; Auto21; Bioco. Government Support: The following government agencies provide funding: NSERC, Saskatchewan Agriculture and Food; NRC; SRC; SCDC; CFI; Agriculture Canada; CRC. University Support: Besides salary and lab support, the UofS has provided TSE and Research Services Grants. Net Cash Flow: It is anticipated that over the next strategic period, the annual revenue flow for this area will amount to about $350K leaving an annual shortfall of $406K.This will limit the ability to carry out about 50% of the projects in the list shown above. Performance Measures/Metrics: It is expected that this area will result in the graduation of 3 graduate students per year over the next strategic planning phase and the publication of 7 journal papers and 10 conferences per year. Responsibility: Gordon Hill will take responsibility for monitoring the productivity of this research area. Timeline: This is an on-going research area for the Department of Chemical Engineering which began in the seventies and will continue into the future due to the increasing need for bioenergies due to the falling production of traditional energy sources. Comments: More than any other area, this area has the greatest opportunities for collaboration. The College of Agriculture is increasing its activities in this area. The Department of Agriculture and Bioresource Engineering has at least two faculty members working in this area. Industry is opening both bioethanol (Husky) and biodiesel (Milliken Biotech) facilities in Saskatchewan. The Governments of Saskatchewan and Canada have placed importance on research in this area and are developing research funds to increase research activity, such as the new ABIP initiative. 18 5. Theme: Accelerate Research and Engaged University Initiative Title: Petroleum and Gas Processing and Recovery Description of Initiative: Objective: To undertake oil and gas research in order to optimize the economic productivity and environmental stewardship of Saskatchewan’s and Western Canada’s non-renewable resources. Details: 1. Hydroprocessing of bitumen derived feed stocks: New catalysts are being developed for the hydroprocessing of heavy and light gas oils derived from bitumen. Studies include understanding the interactions of catalysts with sulphur and nitrogen compounds present in these materials. A new, sonochemical treatment method is being developed to improve the hydroprocessing efficiencies for the removal of these heteroatoms. New process configurations for hydroprocessing have lead to the Syncrude Owl Award for Dr. Dalai in our Department. The Department has one of the best academic hydroprocessing facilities, which has prompted many industries, government organizations and world class researchers to use this facility. The EXAFS beamlines at the Canadian Light Source and at the Advanced Photon Source have been used to probe into the catalysts designed for these processes. 2. Bitumen slurry pipe-line flow: The Department has a long tradition studying the flow behaviour of solid-liquid mixtures transported in pipe lines. The research results have been exploited by industry and by Saskatchewan Research Council in Saskatoon. Personnel in the Department have access to the World’s largest and best slurry pipe-line facility located at SRC’s Saskatoon facility. 3. Thermodynamic properties of petroleum fluids: The Department has a worldrenowned expert who specializes in the study of the properties of petroleum fluids. During the past 30 years, the Peng-Robinson equation of state has been featured in almost all chemical engineering thermodynamic text books. According to the information available from the various scientific journals, the original paper on this equation is one of the most-cited papers in the field of chemical engineering. The Department has the necessary infrastructure to study the thermodynamic properties of petroleum fluids under a wide range of process conditions and continues to develop new information on thermodynamic properties of industrial relevance. 4. Performances and hydrodynamics of gas-solid fluidized beds: New hydrodynamic data are being developed for the modelling of gas-solid fluid beds, which are relevant to fluid bed operations in petroleum refining industries. Mathematical models are also being developed for circulating fluid bed combustor and lignite boilers. 5. Removal of hydrogen sulphide from natural gas: The Department has developed expertise on the removal of hydrogen sulphide from natural gas using 19 activated carbon catalysts. The process is being extended to other gas pollutants. The study includes creating the kinetic data for reactor modelling of a fixed-bed reactor for this novel process. A process in eliminating flaring of acid gases generated from small-scale gas plants through adsorption, regeneration and underground disposal is also being developed in the Department. Cost and Revenues: Costs: This theme area involves the work of five of the eleven chemical engineering professors, with at least three professors dedicated full time in this research, valued at $250K per year. Another faculty member is being recruited at this moment in this theme area. This theme also consumes the time of at least one of six non-faculty members in the Department, estimated at $30K per year. There are four adjunct Professors and four Professional Associates also working on this theme area, indirectly supporting the theme area valued at $300K/year. There are over 10 graduate students working on these projects with a salary of $200K per year, with additional operating costs of $100K per year. Four PDFs with a salary of over $150K/year are employed to work in hydroprocesing research. The total infrastructure for the petroleum and gas processing, evaluation of thermodynamic properties of petroleum fluids, and gas-fluid systems is valued at over $2.5 million dollars. Not including the faculty and technical staff salary, the research expenses related to this theme is over $670K per year Industrial Support: Support has been received from industries such as Syncrude Canada Ltd. Nexon, Imperial Oil Ltd., and Petro Canada Ltd. for research in this area. Government Support: Saskatchewan Research Council, Saskatoon; National Centre for Upgrading Technology (NCUT), Devon, AB; and Natural Sciences and Engineering Research Council of Canada (NSERC) have provided funds for research in this theme area. University Support: Besides the salary for the faculty and staff members, the University has provided support for HQP to attend conferences related to this theme area. The Department and the College of Engineering have also provided financial support for the faculty members and students to attend conferences. The Department provides support from overhead funds for related research. Performance Measures/Metrics: It is expected that this area will generate over 10 journal papers and 15 conference presentations per year involving 10 graduate students and four PDFs and four summer students per year. Responsibility: 20 Ajay Dalai will take responsibility for monitoring the productivity of this research theme. Timeline: This is on-going research area in the Department of Chemical Engineering which began with the creation of the Department and will continue into the future. The expansion of oil sands industry estimated at six billion dollars over the past six years is now producing over one million barrels of synthetic crude oil per day. The target is to expand the production to 2.5 million barrels per day within the next five years. There have been very similar demands on the natural gas and coal industries. This puts large pressures on the research community for developing new technologies and/or modifying existing technologies for the betterment of Society. Research in this area will definitely expand in the future and is expected to lead to more activities in the Department Comments: This research theme is vital for the industrial growth of Western Canadian provinces. Large numbers of our undergraduate and graduate students are employed in the oil and gas industries. The Department has taken several measures including the creation of additional courses for our students in this area. The Department is able to generate large research interests in petroleum and gas processing and production area and is able to attract top students for the graduate program. There are opportunities to develop collaboration with new industries such as the Co-op upgrader in Regina and with the Petroleum Technology Research Centre in Regina. Also, there are opportunities to develop new research initiatives with our existing collaborators. 21 6. Theme: Accelerate Research and Engaged University Initiative Title: Environmental Remediation Description of Initiative: Objectives: To continue environmental research in order to contribute to reductions in global warming and the removal of toxic pollutants from the ecosphere. To collaborate and participate fully in the new School of the Environment. Details: 1. Remediation: Remediation research in the Department of Chemical Engineering has two sub-themes of Air Pollution Control, and Water and Soil Bioremediation. Air Pollution Control research encompasses studies on the chemical and biological strategies to capture and minimize the atmospheric emission of greenhouse gases, using the catalytic conversion of CO2 to value added products, and capture of CO2 by algae in bioreactors with concomitant production of valuable metabolites such as β-carotene. Both biological and chemical options to control the production of H2S in oil reservoirs, and emission of sulphur containing gases, especially H2S and SO2 from industrial settings and livestock operation are being investigated. Biotreatment of air and gaseous effluents contaminated with volatile organics is another strong research thrust in the Department which contributes significantly to the provision of clean air. The Bioremediation of Contaminated Water and Soil theme is fairly broad and includes the treatment of Acid Mine Drainage and other metal and sulphate containing waste streams such as nickel plating rinse water, utilizing anaerobic bacterial processes for the reduction of sulphate and oxidation of sulphide, as well as removal of metallic contaminants by natural biosorbents. Development of novel bioreactors and bioremediation of petroleum contaminated water, soil and sludge from the contaminated sites in these bioreactors is another area in which the Department is actively involved. Fundamental studies on the genetics and metabolic pathways of microorganisms frequently used in bioremediation processes with the aim of developing a thorough understanding of the processes involved at the cellular level and improving the efficiency of the bioremediation process are also pursued. The Department has expertise in the catalytic conversion of H2S present in natural gas, sewage gas and other sour gases using activated carbon. The mercury emitted from coal fired power plants are released to atmosphere on a continuous basis. The Department has developed a pilot plant to produce activated carbon from various sources and applied this for mercury capture from the flue gas of coal fired power plants. The Canadian Light Source is used to elucidate the reaction mechanisms involved in these processes. 2. Environmental Sciences: The Department of Chemical Engineering is a key player in the development of a new Environmental Engineering Program (undergraduate level) in the College of Engineering. In addition to involvement in the initial planning and ongoing administration of this program, the faculty in our Department will contribute to teaching of several relevant courses including the 22 final year design project. Our Department will open up many of our environmentally related courses to permit Engineering students without Chemical Engineering backgrounds to achieve the Environmental Engineering degree. Several Chemical Engineering faculty members currently teach graduate level environmentally oriented courses and are involved in the supervision of graduate students in the Division of Environmental Engineering in the College of Engineering. Costs and Revenues: Costs: Six faculty members are involved in Environmental remediation research but some of these faculty members are also involved in other research areas. This area is estimated to consume 3 of our current faculty research time, and 0.5 of our 6 non-faculty position, translating to about $240K and $25K per year, respectively. Each project described in the remediation section (10 projects), on average, involves the work of a graduate student (in some cases a postdoctoral fellow), one undergraduate student and requires materials and supplies, for a total yearly expense of $380K. Capital equipment purchases for this research theme are estimated at $250K. Thus the research expenses to be covered by faculty grants amounts to $630K. Industrial Support: The research in the Environmental Remediation has been supported by Moose Jaw Asphalt (Gibson Energy), Sask Power, Advanced Biorefining Inc. Government Support: NSERC, CFI, Environment Canada (NWRI), NRC, SRC, Saskatchewan Agriculture Development Fund, Alberta Funding Consortium, SEIMA. University Support: Besides salary and lab supports, the UofS has provided TSE, Research Services Grant, and various start-up funds to three faculty members. Performance Measures/Metrics: Five Chemical Engineering professors are members of the Division of Environmental Engineering and actively supervising several graduate students in this division. Furthermore, the Department has had an active participation in the administration of this division and is involved as one of the key players in the development of a new undergraduate Environmental Engineering Program. As far as research output is concerned, it is expected that the activity in this research theme will result in annual training of 3-4 graduate students, 3-4 undergraduate student and the publication of 6 journal papers and 10 conference papers, as well as the possibility of the development of patentable technologies. Responsibility: Mehdi Nemati will take the responsibility for monitoring the productivity of this research area. Timeline: Environmental Remediation is an ongoing research theme in the Department of Chemical Engineering and recent recruitment of faculty members with strong 23 backgrounds in this field has turned this to one of the major research thrusts in the Department. Environmental issues which are the legacy of our previous and current activities, have long lasting impacts and research to tackle these problems will continue into the future. Comments: There are many opportunities for collaboration in this area, considering that many faculties in the Departments of Civil Engineering and Ag and Bioresources are conducting research in this field. In addition, initiation of the program in the School of the Environment will open-up the possibility of multi-disciplinary collaborations across the campus. Environmental issues appear to be one of the major global concerns. Bearing in mind the key role which Canada plays as a leading industrial country and our commitments in maintaining a safe and healthy environment, provision of support for the research both at the provincial and national levels is expected to increase. 24 7. Theme: Accelerate Research and Engaged University Initiative Title: Mineral Processing Description of Initiative: Objective: To develop a mineral processing research centre focussed on the production of potash, uranium and other minerals found in Saskatchewan and Canada into value-added end products in an environmentally responsible manner. Details: 1. Potash Fertilizer Degradation Due to Environmental Factors: This research will include: i) fundamental studies of heat and moisture transfer into packed beds of potash fertilizer; ii) Compositional analysis of thin films formed on wetted potash fertilizer particles; iii) investigations on thin film movement and ion transport in the films to predict crystal formation points on particle surfaces; iv) development of new equipment and protocols to detect a) moisture ingress into fixed beds of potash, b) the extent of caking and c) the fracture strength of caked potash; v) the influence of chemical composition, drying rate and pressure on the strength of caked potash. 2. Corrosion Control in Mineral Processing Circuits: Research projects to be undertaken include: i) Measurement and modelling of localized corrosion in potash processing slurries and brines; ii) spectroscopic and CLS analysis of corrosion films. Costs and Revenues: Costs: This area will involves the work of at least two of the eleven chemical engineering professors, but each faculty member who is involved will also be involved in other research areas. It is estimated that this area will consume one of our current faculty research time, valued at about $80K per year. This research area will also consume about 0.25 of our 6 non-faculty positions, estimated at about $12K per year. Each project listed above (7 projects), on average, will involve the work of 0.75 graduate students, one summer student and $10K in materials and supplies each year valued at $34K per year, for a total yearly expense of $238K. Capital equipment purchases for each of the three areas are estimated at $50K per year, for a total yearly expense of $100K. Not including faculty or technical staff salaries, the research expenses to be covered by faculty grants will amount to $338K each year. Industrial Support: The following industries will be approached to invest in these research projects: PotashCorp; Cameco; Agrium, Mosaic, AREVA, AECL. Government Support: The following government agencies provide funding: NSERC. 25 University Support: Besides salary and lab support, the UofS will be asked to provide TSE and Research Services Grants. Net Cash Flow: It is anticipated that over the next strategic period, the annual revenue flow for this area will amount to about $100K leaving an annual shortfall of $238K.This will limit the ability to carry out about 35% of the projects in the list shown above. Performance Measures/Metrics: It is expected that this area will result in the graduation of 2 graduate students per year over the next strategic planning phase and the publication of 4 journal papers and 4 conferences per year. Responsibility: Richard Evitts will take responsibility for monitoring the productivity of this research area. Timeline: This is a new research area for the Department of Chemical Engineering. However, Richard Evitts has been pursuing research in this area since 2001. Comments: Saskatchewan is the world’s largest exporter of refined potash and partially processed uranium (yellowcake). In addition to having the largest global reserves of these minerals, many other valuable minerals (gold, diamonds, sodium sulphate, etc) are located in the province. Saskatoon is the home to the headquarters of the largest producers of potash and uranium, PotashCorp and Cameco. The University is developing a new mineral resource centre and this theme is aligned with this. There will be opportunities to collaborate with members from other academic units, including Mechanical, Geological Engineering and Chemistry (SSC and CLS). 26