WBLS2005Guillotine - University of Cambridge

advertisement

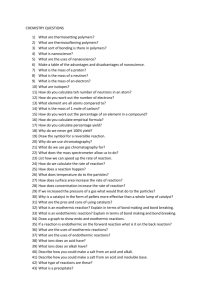

Fresh aluminium surfaces in oil THE ELECTRODE POTENTIAL OF FRESHLY GENERATED ALUMINIUM SURFACES IN LUBRICATING OIL P. Wanga, G.T. Bursteina*, H.R. Leb and M.P.F. Sutcliffeb a: Department of Materials Science and Metallurgy, University of Cambridge, Pembroke Street, Cambridge CB2 3QZ, United Kingdom b: Department of Engineering, University of Cambridge, Trumpington Street, Cambridge CB2 1PZ, United Kingdom. Abstract The electrode potential of freshly generated aluminium surfaces submerged under lubricating oil is presented. An initially low value of the bared metal surface is followed by a slow rise towards the steady state as repassivation proceeds. The presence of lauric acid, a surfactant, in the oil raises the potential of the initially bared surface, demonstrating its direct cathodic activity, an effect which decreases as repassivation progresses. KEY WORDS: aluminium surface; electrode potential; guillotined electrode; lubricant; surfactant. Introduction In strip rolling of aluminium, the friction between the roll and the strip influences the surface quality of the finished product, and the production efficiency. Mechanical modelling and analysis of the transfer film on the roll surface indicates that cold metal rolling is in the boundary lubrication regime. In this condition, hydrodynamic entraining of the oil, and asperity contact between the roll and the strip exist at the same time [1]. When the aluminium strip is elongated through the bite a virgin aluminium surface is created by rupture of the surface oxide film. The reaction between the denuded aluminium surfaces and the additives in the lubricant or other * To whom correspondence should be addressed. E-mail: gtb1000@cam.ac.uk 1 Fresh aluminium surfaces in oil species in the local environment is an important issue in the understanding of the mechanism of boundary lubrication between the roll and the strip. Various methods have been used to investigate the tribochemical interaction between the lubricant additives and the materials of the sliding surfaces in several tribology systems. To analyse the transfer film generated, and the changes of the chemical compositions of the surfaces, X-ray absorption [2,3], X-ray photoelectron spectroscopy [4], Auger electron spectroscopy [5,6] and Raman spectroscopy [7] have been used. With the exception of Raman spectroscopy, these ex-situ techniques give potential information about the state of the surface, but only after removal, washing and inserting into a vacuum chamber. The electrical contact resistance between the roll and the strip have also been measured [8,9], and this was done in situ. However, it is difficult to use this type of information to elucidate mechanisms of the boundary lubrication involved. One possible method for this, as shown below, is the use of the guillotined electrode [10-13], a technique developed for analysis of freshly generated surface in aqueous solutions. The guillotined electrode technique requires a sharp unreactive blade to be driven rapidly through a specimen of the metal under submersion, and the electrode potential of the metal to be measured simultaneously against an appropriate reference electrode. In previous experiments [10-13] the cutting edge was made of boron nitride and employed a spring-loaded guillotine assembly to cut the metal at speeds of around 1-2 m s-1. Apart from a saturated calomel reference electrode (SCE) the equipment was also fitted with a platinum counter electrode so that the test metal could be held under electrochemical control, either potentiostatically or galvanostatically [11,14]. In this way the electrode potential could be monitored in situ as a function of time through the guillotining process and afterwards. The effects of the environment could be interpreted unambiguously, as for example, the role of chromate on the potential of the repassivating metal [12]. Experiments were also carried out in water of low conductivity, such as tap-water and even distilled water [13]. 2 Fresh aluminium surfaces in oil In this paper, we present the preliminary data obtained by guillotining aluminium whilst it is submerged in a lubricant system, and demonstrate the role of a surfactant additive, in this case, lauric acid (dodecanoic acid). Experimental method Figure 1 shows the guillotined electrode cell and assembly. A rectangular cell constructed of polytetrafluoroethene (PTFE) was fixed to a solid steel base which was bolted to the bench. The test material was pure aluminium (Johnson-Matthey, 99.999%) in the form of wire of diameter 1 mm. This was threaded through an axial hole drilled into a 6 mm diameter rod made of PTFE, with a thin film of epoxy resin covering the metal surface. A steel blade with the edge sharpened as a cutting surface was attached to the aluminium carriage, which was mounted so as to be able to travel on four parallel steel rods positioned between the two holding frames. At first the carriage and springs were pushed to the lower, left-hand end of the travel, and held there with a catch. Release of the catch allowed the blade to be spring-driven upwards, through the end of the sample which had been positioned so that the end protruded through the block. Full details of the method have been given by Burstein and Cinderey [10]. The difference in present design is the fact that the blade here is driven upwards, so that when the guillotining action is complete, the blade has cleared the newly cut surface completely. This allowed easy access of a Luggin capillary probe for logging the potential. The Luggin capillary probe was connected to a tube filled with the lubricating oil from the cell for about 10 cm. The remaining length of tube, remote from the cell was filled with an aqueous solution containing an agar gel (made from 3 g agar and 30 g KCl in 100 cm3 water) and it was into this that the reference electrode was placed. The reference was an aqueous saturated calomel electrode (SCE). The liquid junction between the oil and the aqueous gel solution was not estimated, and the potentials given below are therefore relative to the aqueous SCE scale. The potential between the guillotined electrode and the SCE reference electrode were monitored using a high-impedance electrometer (Keithley model 6571) which fed directly into a data-acquisition card (PCI-9114A, from ADLINK Technology Inc., 32 bit) mounted into a personal computer. Data were logged at a higher rate between 20-100 kHz during early stages of repassivation and at lower rate of 1-1000 Hz during later stages. 3 Fresh aluminium surfaces in oil The metal was guillotined in Somentor grade 32 lubricating oil supplied by ExxonMobil Ltd., a mixture of saturated hydrocarbons. Because of the extremely low conductivity () of the oil ( = 13.3 fS cm-1), a conductivity improver, Octastat 3000 (Octel Corp., Manchester, UK) was added to reduce the high impedance of the cell. Experiments were also carried out using a lubricant additive: the present work shows the effects of lauric acid (Sigma-Aldrich, purity 99.5%) which was added as 0.5 wt-% or 1.0 wt-% into the Somentor 32 oil (containing the conductivity improver). Experimental results The results are shown in the form of potential transients of the aluminium as a function of time after guillotining (on a logarithmic scale) in Figure 2. The time axis is given as a logarithmic scale to show the full detail of the transients and also because it is immediately apparent that the repassivation of the guillotined surface occurs approximately as log time. The guillotine event starts around the left side of the graph, and this together with the associated cavitation occurs up to ~ 70 ms. The cavitation event lasts a little longer than it does in aqueous solutions [10-14], presumably an effect of the higher viscosity of the oil relative to water, and perhaps also a function of the wettability of the new metal surface by the two fluids. The potential then plunges to the minimum value of ~ -1.47 V(SCE) (in the absence of the surfactant), and then slowly recovers over a period of more than 1000 s (after which the recording was terminated) towards the initial potential. The initial rate of rise of potential is high, and the recovery slows continuously with time. After 1000 s, the surface is still ~ 50 mV below that of the recovered surface. The incorporation of lauric acid into the oil has a striking effect. The lowest potential achieved immediately after guillotining is higher in the presence of the additive, and increasing its concentration from 0.5 to 1 wt-% raises the minimum potential slightly further. The effect was very reproducible; this was checked by running identical experiments three times each. As the potential rises through repassivation, so the potentials of the three systems shown in Figure 2 merge; after ~ 200 s no further difference is detectable. 4 Fresh aluminium surfaces in oil To illustrate these effects clearly, Table 1 shows some data taken at specific points from recorded transients and it is plain that the oils containing the surfactant show a higher potential, particularly at the earliest times, or a shorted time to reach a defined potential. Lauric acid accelerates repassivation of the freshly bared surface in the lubricating oil. Discussion The action of the guillotine is a denuding one, and the resulting oxide-free surface is very reactive. The recorded potential transient represents the reaction of the oxidefree surface as it repassivates by oxide film growth. The cathodic reactant to the oxidation of the denuded aluminium surface must be the reduction of water or oxygen entrained in the oil phase. Components in the liquid phase which retard the repassivation process would show a lower potential over a longer time; components which accelerate that process would show a higher potential. Thus we conclude that the lauric acid is reactive on the native metal surface, particularly in the early stages of repassivation, and accelerates repassivation. We deduce from this that the lauric acid must be electrochemically reduced on the denuded metal surface; effectively lauric acid is a cathodic reactant additional to the traces of entrained water and oxygen. One possibility is that the lauric acid reacts with the virgin metal surface to form the aluminium soap directly, as: Al + RCOOH → Al(RCOO)3 + 3/2H2 (1) where R = [CH3(CH2)10-]. Alternatively, some of the oxygen required for repassivation could come from the lauric acid, involving reduction of the –COOH group, for example to the aldehyde group as: 2Al + 3RCOOH → 3RCHO + Al2O3 (2) wherein the carbon of the COOH group acts as the cathodic reactant, rather than the H group as in reaction (1). This reaction could also act to form the Al soap after accelerated oxidation of the metal, in addition to, or instead of the oxide. Which one 5 Fresh aluminium surfaces in oil predominates is not yet known, since both reactions would accelerate the anodic reaction by providing an added cathodic reactant. In this connection, it is of note that secondary ion mass spectroscopic analysis of the rolled surface shows fragments that can be associated with aluminium soap [15], consistent with the observations described above and the interpretation via reactions (1) or (2) or variations thereof. We believe that this is the first time that the electrode potential of these denuded surfaces has been measured under immersion in a lubricant system, and the role of lubricant additives observed. The technique appears to be quite sensitive in detecting these. Conclusions The open-circuit potential transient of aluminium denuded of the oxide film in situ under submersion in lubricating oil shows an initial sharp plunge followed by a slow return towards the steady state. The potential transients are interpreted by the reaction of the denuded surface which involves repassivation of the metal by oxide film growth and reduction of the entrained water and/or oxygen dissolved in the oil. Incorporation of lauric acid, a surfactant, into the oil phase results in a more positive transient potential, a feature most pronounced immediately after guillotining. The effect of the additive slowly disappears with time as the metal surface repassivates. The role of the lauric acid is to accelerate the cathodic reaction by its own reduction, either through the carbon or the hydrogen of the functional group. The reaction results in the early formation of an aluminium soap and/or the oxide on the denuded metal surface. The result demonstrates that the surfactant is reactive on the bared metal surface, an effect which is believed to participate in boundary lubrication. Acknowledgements We are grateful to the EPSRC and to Alcan International Ltd for financial support of this programme. Provision of lubricating oils by ExxonMobil Ltd is acknowledged with thanks. We also thank Dr K Waterson (Alcan International) and Mr D Fenwick (ExxonMobil Ltd) for valuable discussions. References 6 Fresh aluminium surfaces in oil [1] H. R. Le, M. P. F. Sutcliffe, P. Wang and G. T. Burstein, Acta Mater., 52 (2004) 911 [2] E S Yamaguchi, Z Zhang, M Kasrai and G M Bancroft, Tribol. Lett., 15 (2003) 385 [3] Z F Yin, M Kasrai, M Fuller, G M Bancroft, K Fyfe and K H Tan, Wear 202 (1997), 172 [4] R Unnikrishnan, M C Jain, A K Harinarayan and A K Mehta, Wear, 252 (2002) 240 [5] M Abdelmaksoud, J W Bender and J Krim, Tribol. Lett., 13 (2002) 179 [6] Y Y Su, Tribol. Int., 30 (1997) 423 [7] A Kovalchenko, Y Gogotsi, V Domnich and A Erdemir, Tribol. Trans., 45 (2002) 372 [8] K Komvopoulos, V Chiaro, B Pakter, E S Yamaguchi and P R Ryason, Tribol. Trans., 45 (2002) 568 [9] E S Yamaguchi, P R Ryason, S W Yeh and T P Hansen, Tribol. Trans., 41 (1998) 262 [10] G T Burstein and R J Cinderey, Corros. Sci., 32 (1991) 1995 [11] G T Burstein and R J Cinderey, Corros. Sci., 33 (1992) 475 [12] R J Cinderey and G T Burstein, Corros. Sci., 33 (1992) 493 [13] R J Cinderey and G T Burstein, Corros. Sci., 33 (1992) 499 [14] G T Burstein and C Liu, Corros. Sci., 37 (1995) 1151 [15] M P F Sutcliffe, R Combarieu, M Repoux and P Montmitonnet, Wear, 254 (2003) 65 Figures and tables (shown separately on following pages) 7 Fresh aluminium surfaces in oil Figure 1 Upper: schematic diagram of the guillotine electrode assembly for experiments with lubricants. (a) working electrode (aluminium wire) sleeved in PTFE; (b) PVC tube with agar gel for reference electrode; (c) steel blade; (d) carriage made of aluminium alloy; (e) spring; (f) upward direction of the guillotine when the sample is being cut; (g) steel framework; (h) test lubricant in PTFE cell; (i) PTFE block; (j) PTFE block for sample feeding. The diagram shows the guillotine in its activated position, with the sharp edge of the blade approaching the protruding aluminium wire. Lower: The guillotine blade showing the cutting edge and the relative position of sample to be cut. 8 Fresh aluminium surfaces in oil -1 C potential, V(SCE) -1.1 B -1.2 A C -1.3 B -1.4 -1.5 -2 10 -1 10 0 10 1 10 2 10 A 3 10 4 10 5 10 6 10 time, ms Figure 2 Open-circuit potential vs. time transients of fresh aluminium surfaces after guillotining in three lubricant solutions: Somentor 32 (A), Somentor 32 + 0.5 wt% lauric acid (B) and Somentor 32 with 1.0 wt% lauric acid (C). 9 Fresh aluminium surfaces in oil Table 1 Comparison of effects of lauric acid on some repassivation parameters. Solution Somentor 32 Somentor 32 Somentor 32 + 0.5 wt % + 1.0 wt % lauric acid lauric acid Potential at 1000 ms, V(SCE) -1.39 -1.34 -1.32 Evolution time for potential –1.35V(SCE), ms 2050 780 500 10