Workshop/Assessment Task

advertisement

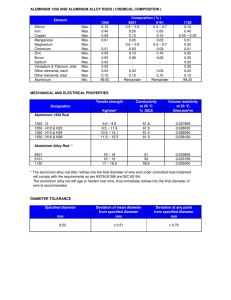

Workshop/Assessment Task Unit/Topic: STS Performance Criteria: AQF Unit & PC: CNCCT1001 2.3 MEM12024A 1.2, 2.1, 2.2 MEM16006A 1.2 MEM07007C 4.2 MEM12006C 2.3 Cooltools Student Name: Teacher: Class: Date: Time: 15 mins Assessment Event: Total Mark: Calculating speed, feed and depth of cut /8 Q1 From the table below what is the fastest surface speed recommended to turn aluminium ? Recommended surface speeds for turning Material type Meters per min (MPM) Steel (tough) 15–18 Mild steel 30–38 Cast iron (medium) 18–24 Stainless steels 23-40 Bronzes 24–45 Aluminium 75–105 Brass 90-210 _105____MPM (1 Mark) Q2 Calculate the rotational speed for a lathe (n) if the workpiece diameter =20mm and the cutting speed Vc = 30 m/min. (Steel) n = Vc/ π x d d= __0.02__m π = 3.14 n=__30__/(_3.14_x_0.02_) n=_____ 478 ____rev/min (3 Marks) Page 1 of 2 Workshop/Assessment Task Unit/Topic: STS Performance Criteria: AQF Unit & PC: CNCCT1001 2.3 MEM12024A 1.2, 2.1, 2.2 MEM16006A 1.2 MEM07007C 4.2 MEM12006C 2.3 Cooltools Student Name: Teacher: Class: Date: Time: 15 mins Assessment Event: Total Mark: Calculating speed, feed and depth of cut /8 Q3 When roughing a bar of aluminium we want to reduce the diameter in a bar from 25mm to 23mm diameter in one cut. What is the depth of cut ? Depth of Cut (d) = (Original Diameter Do – Feed Diameter Df )/ 2 d=( Do - Df )/ 2 d=(_25_- _23_)/2 (2 Marks) d=____1.0____mm Q4 From the table below a) What feedrate should be chosen to cut aluminium as fast as you can? __________0.75 mm/Rev b) What feedrate should be chosen to get the best finish in aluminium? _________________0.13 mm/Rev (2 Marks) Page 2 of 2