P345 - World Journal of Engineering

advertisement

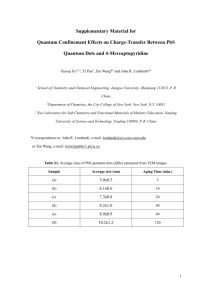

World Journal Of Engineering APPLICATION OF QUASI-TERNARY InAsSbP COMPOUND SEMICONDUCTORS FOR THE GROWTH OF QUANTUM SIZE OBJECTS ON InAs (100) SUBSTRATE Karen Gambaryan 1, *, Vladimir Aroutiounian 1, Vardan Harutyunyan 1, Torsten Boeck 2, Jan Schmidtbauer 2 and Roman Bansen 2 1 Department of Physics of Semiconductors and Microelectronics, Yerevan State University, 1 A. Manoogian, Yerevan, 0025 Armenia. ( * E-mail: kgambaryan@ysu.am ) 2 Leibnitz Institute for Crystal Growth (IKZ), 2 Max-Born-str., Berlin, 12489 Germany. Introduction A large research effort has been devoted to quantum dots (QDs), the quantum wires, QD chains, quantum rings, nanoholes and pits [1-8] due to their modified density of states, fascinating optoelectronic properties and device applications for lasers, photodetectors and other electronic devices. Among quantum size objects fabrication techniques, the self-organized StranskiKrastanow method is an important one by which dislocation-free nanostructures can be produced. Extensive experimental results suggest that surface morphologies are relying on growth conditions and matrix materials. On the basis of an atomistic model, it is shown that the energy change due to the step formation is negative or positive depending upon the sign of the misfit. The step formation energy can even be negative for compressive misfit stress in the heterolayer, while it is definitely positive for tensile misfit stress. Narrow band-gap III–V semiconductor materials as InAs, GaSb, InSb and their alloys are particularly interesting and useful since they are potentially promising to access mid– and far infrared wavelength regions and should provide the next generation of semiconductor devices for applications such as infrared gas sensors, molecular spectroscopy and thermal imaging, as well as thermophotovoltaic cells. In this paper we present an example of InAsSbP quaternary lens-shape and ellipsoidal QDs growth on InAs (100) substrates by liquid phase epitaxy (LPE). Experimental procedures The InAsSbP quantum-size objects are grown from the thin liquid phase using a LPE slide-boat crucible. The technological know-how to obtain a very thin (~100200 μm in height) working liquid phase was developed and applied. To ensure a high purity of the structures, the entire growth process is performed under the pure hydrogen atmosphere. The InAs (100) substrates have an 11 mm diameter, are undoped, with a background electron concentration of n=2×1016 cm-3. The initial growth temperature were chosen within T=540-560oC. To expect the strain-induced QDs formation, the undoped and supersaturated by antimony and phosphorus liquid phase was used to provide a different sign of lattice mismatch up to 2% between the InAs substrate and InAsSbP wetting layer. To initiate the growth of QDs, a supersaturation of the liquid phase is developed by decreasing the initial growth temperature up to 2oC at the slower ramp rate. To study the QDs morphology, size, shape and distribution density the high resolution Scanning Electron Microscope (SEM-EDXA–FEI Nova 600–Dual Beam) and atomic force microscope (AFM–Asylum Research MFP-3D) are used. Results and discussion A series of QDs structures were grown at the different initial growth temperatures and the liquid phase compositions, as well as at the different in height liquid phases. The optimal technological conditions were chosen for the growth of lens-shape and the ellipsoidal QDs, quantum rings, QDs/nanopits cooperative structures in InAsSbP quasi-ternary material system. In Fig. 1 the AFM – (A, B) and HR-SEM – (C, D) images of the InAsSbP lens-shape and ellipsoidal QDs grown by LPE on InAs (100) substrate are presented. From these figures the bimodal growth mode is quite visible, i.e. QDs massive consists of relatively uniform distributed small QDs in sufficiently large (~300 μm2) area with the more low density and relatively big QDs. Statistical explorations shown that the small QDs average density ranges from 3 to 9×109 cm-2, with heights and widths dimensions from 0.8 nm to 15 nm and 10 nm to 40 nm, respectively. Otherwise, the less density and big QDs average diameter ranges from 40 to 80 nm. In Fig 2 is also presented an example of InAsSbP quantum dot molecule in the form of QD/nanopits cooperative structure taken from our previous work [3]. Our detailed analysis shown that small QDs are mainly lens-shape, but the bigger ones – ellipsoidal, and that the elongation occurs mainly in [010] direction. Note, that the interesting transformation of the QDs histograms and the distribution function’s shape, i.e. 345 World Journal Of Engineering dependence of the QDs number versus their average diameter, was detected (Fig. 3). In particularly, the small QDs distribution is well fitted by the GramCharlier function (Lifshitz-Slezov-like distribution with the “left” asymmetry), but ellipsoidal QDs – by the Gaussian. (A) (B) active surface, and (ii) p-InAsSbP/n-InAs diode heterostructures with QDs inside p-n junction spatial charge region. Conclusion Thus, we have presented an example of the InAsSbP quaternary lens-shape and ellipsoidal QDs grown by LPE on InAs (100) substrate. Bimodal growth mechanism for the QDs was observed. It was shown that during the growth an elongation of QDs and their shape transformation from lens-shape to ellipsoidal are occurred. The small QDs distribution is well fitted by the GramCharlier function, but ellipsoidal QDs – by the Gaussian. The results of our study can be used for the fabrication of novel QDs-based semiconductor devices for several midinfrared applications. Acknowledgments (C) (D) Fig. 1. AFM – A, B and HR-SEM – C, D images of the InAsSbP lens-shape and ellipsoidal QDs grown by LPE on InAs (100) substrate. Fig. 2. HR-SEM image of the InAsSbP QD molecule in the form of QD/nanopits cooperative structure. Fig. 3. Number of QDs versus their average diameter. On the base of researches presented in this paper a two type of quantum dot mid-infrared photodetectors are fabricated: (i) photoconductive cells with QDs on the This work was performed in the frame of German Academic Exchange Service Award (2010) and in part by a Research Grant from the Armenian National Science and Education Fund (ANSEF, 2011) based in New York, USA. References 1. Gambaryan, K. M., Aroutiounian, V. M. and Harutyunyan, V. G. Infrared Physics and Technology, 54 (2011) 114. 2. Marquardt, O., Gambaryan, K. M., Aroutiounian, V. M., Hickel, T. and Neugebauer, J. In Proc.: Villa Conference on Interactions among Nanostructures (VCIAN-2010), June 21–25, 2010, Santorini, Greece, p. 36. 3. Gambaryan, K. M. Nanoscale Research Letters, 5 (2010) 587. 4. Gambaryan, K. M., Aroutiounian, V. M., Harutyunyan, V. G., Marquardt, O. and O’Reilly, E. P. In Proc: Villa Conference on Energy, Materials and Nanotechnology, April 21-25, 2011, Las Vegas, Nevada, USA, p.p. 260-261. 5. Dvoyan, K. G., Hayrapetyan, D. B., Kazaryan, E. M. and Tshantshapanyan, A. A. Nanoscale Research Letters, 2 (2007) 601. 6. Aroutiounian, V. M., Gambaryan, K. M. and Soukiassian, P. Surface Science, 604 (2010) 1127. 7. Moiseev, K. D., Mikhailova, M. P., Parkhomenko, Ya. A., et al. Proc. of SPIE: Quantum dots, particles and nanoclusters-VI, v. 7224, issue 6, 25-28 January, 2009, San Jose, USA. 8. Gambaryan, K. M., Aroutiounian, V. M., Boeck, T., Schulze, M. and Soukiassian. P. G. Journal of Physics D: Applied Physics (FTC), 41 (2008) 162004. 346