Additional Materials 1 - Philosophical Transactions of the Royal

advertisement

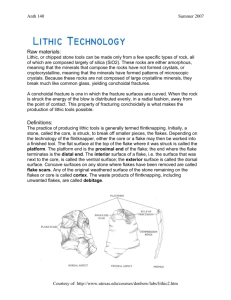

ELECTRONIC SUPPORTING MATERIALS, SECTION 1 PART ONE: FROM PRIMATES TO MODERN HUMANS Wynn (2002) has suggested that with the advent of bifaces in the palaeontological record beginning about 1.4 mya, a cognitive change from the apes can be seen with the fact that symmetry begins to be imposed on a modified object through modifying one edge of a biface so it will be comparable to the other edge (but see Noble & Davidson (1996) for a contrary viewpoint). Cognitively, Wynn argues, this required linking shape recognition (which may be part of the cognitive repertoire of the apes) with the spatially framed task of knapping a biface (which does not occur among the apes). Though his argument about symmetry as an indicator of cognitive difference between the apes and the evolving hominids is intriguing, it has the weakness of simply treating in isolation one aspect of artefact production from an individual, selectionist viewpoint (“What might the perceptual saliency of symmetry have been good for? [...] Could symmetry have become so salient a pattern for mate assessment that it intruded into other shape recognition domains?” (p. 399)), rather than relating symmetry to an evolving cognitive/conceptual representation for which it is just one aspect. Absence of symmetry in Oldowan tools (Mode 1)1 is taken by Wynn to mean that nothing beyond than the cognitive abilities of apes is necessary for Oldowan tool production. However, experimental work demonstrates that the areas of brain activation during simple flint knapping “are those that have undergone the greatest expansion in hominid evolution (Deacon 1997)” (Stout, Toth, & Schick 2000: 1222), and that the skills involved “are as reflective of human mental uniqueness as more ‘cognitive’ behaviours like visualization and language” (Stout 2002: 421). Though a chimpanzee (Kanzi, Pan paniscus) was taught to strike cobbles together to break then into pieces, he was unable to learn the 90 angle necessary for producing flakes (Lawn & Marshall 1979, Cotterell & Kamminga 1987). Even more pronounced evidence of cognitive differences between chimpanzees and humans is provided by the bifaces with clear evidence of symmetry that are used on a regular basis from around 500,000 bp. Wynn argues that these bifaces exhibit “(1) congruency; (2) three-dimensional symmetries and (3) broken symmetry” (p. 395). He suggests that for three-dimensional symmetries “one must somehow hold in mind viewpoints that are not available at that moment, and for the finest symmetries, viewpoints that are not directly available at all (oblique cross sections)” (p. 397). His comment invokes the importance of working memory (Masters & Maxwell 2002, Stone 2002), and Wynn notes “one could posit that evolutionary developments in working memory … are the basis for the emergence of the handaxe knappers’ ability to coordinate shape, spatial, and procedural information into a plan of action” (Wynn 2002: 430). 1 Rather than referring to types of stone tools, a number of authors follow the technological distinctions made by Clark (1977: 23, Table 5): “Mode 1: chopper–tools and flakes,” “Mode 2: bifacially flaked hand-axes,” “Mode 3: flake tools from prepared cores,” “Mode 4: punch-struck blades with steep retouch” and “Mode 5: microlithic components of composite artefacts”. REFERENCES Clark, G. 1977. World prehistory in new perspective. Cambridge: Cambridge University Press. Cotterell, B., & J. Kamminga. 1987. The formation of flakes. Amer. Antiq. 52, 675-708. Deacon, T. W. 1997. The symbolic species: The co-evolution of language and the brain. New York: Norton. Lawn, B. R., & D. B. Marshall. 1979. in Lithic use wear analysis. (B. Hayden, ed.), pp. 63-82. San Diego: Academic Press. Masters, R., & J. Maxwell. 2002. Was early man caught knapping during the cognitive (r)evolution? Behav. Brain Sci. 25, 413. Noble, W., & I. Davidson. 1996. Human evolution, language and mind: A psychological and archaeological inquiry. Cambridge: Cambridge University Press. Stout, D. 2002. Thinking and doing in cognitive archaeology: Giving skill its due. Behav. Brain Sci. 25, 421-422. Stout, D., N. Toth, & K. Schick. 2000. Stone tool-making and brain activation: Position emission tomograpy (PET) studies. J. Archaeol. Sci. 27, 1215-1223. Wynn, T. 2002. Archaeology and cognitive evolution. Behav. Brain Sci. 25, 389-438. ELECTRONIC SUPPORTING MATERIALS, SECTION 2 2. WORKING MEMORY IN CHIMPANZEES (PAN PANISCUS) (a) Direct Evidence The action requires identification of a stone (or other hard object) suitable to be used as an anvil, placing a nut on the anvil, and finally hitting the nut with a suitably shaped stone that serves as a hammer stone. Cognitively, three components must be conceptually linked – the anvil, the nut and the hammer stone -- and the nut-cracking action must be conceived of in the proper sequence – the anvil is placed on the ground, a nut is placed on the anvil and then the nut is struck with a hammer stone. Though other tools are made and used by chimpanzees (and other non-human primates), none of them require this complex a sequence of actions. Other actions use single object tools (e.g., termite sticks, sponges, and so on) with functionality derived directly from either the form or the material properties of the object. Only nut cracking requires functionality of a tool to be derived from the relationship of one object to another. The conceptual relationship linking anvil to hammerstone that gives rise to the function of nut cracking is not a phylogenetic trait as hammerstones used by chimpanzees for nut cracking have pitted surfaces similar to hammerstones used by modern-day Tanzanians for cracking palm nuts (McGrew 1992). Nut cracking is carried out in a manner similar to the actions used by chimpanzees by a number of modern human groups (de Beaune 2004 and references therein), hence we may assume that the cognitive requirements for carrying the sequence of actions involved in nut cracking were present in a common ancestor for Pan and Homo. Nut cracking, then, provides us with a starting point from which we can assess changes in working memory that developed in the evolution of Homo as part of the evolutionary development of the hominids leading to modern Homo sapiens. We can do so by considering the conceptual requirements for a time-dependent sequence of artefacts whose initial production required increasingly complex cognitive/conceptual abilities that may also relate to a parallel development of language-based communication systems dependent upon symbolizing behaviour. The cognitive abilities that made possible the uniqueness of ourselves as “the only species capable of communicating with an articulated oral language and creating symbolic ideational cultures” (d'Errico et al. 2003: 2) are also the cognitive capacities that made possible the increasingly sophisticated technologies and conceptualizations about form and production of form that underlie evolutionary changes in the conceptual complexity of artefacts and artefact assemblages during evolution leading to modern Homo sapiens. Nut cracking is not a simple task for chimpanzees (Matsuzawa 1996, Hayashi, Mizuno, & Matsuzawa 2005). It is a learned task, hence transmitted in a social context, especially from biological mother to biological offspring. As simple as it may appear to us, from a chimpanzee perspective it pushes the envelope of what chimpanzees can cognize. Data from a 16-year study on nut cracking among the wild-living chimpanzees at Bossou, Guinea, shows that about ¼ (7 out of 29) of the adult chimpanzees never learned to crack nuts, despite extensive observation of other adults cracking nuts.2 There appears to be a “cognitive window” from about 3 to 5 years of age during which learning takes place: “If not learnt by the end of this period, the skill will not be acquired…” (Biro et al. 2003: 216). No chimpanzee younger than 3 years of age was observed to crack nuts.3 Prior to age 3, cognitive development has not progressed sufficiently to allow conceptualization of a task that involves three objects.4 Four developmental stages are involved in learning to crack nuts: (1) manipulation of singleobjects, which begins around one year of age, (2) object association manipulation with two objects, which begins around two years of age, (3) performance of multiple actions such as first placing a nut on an anvil and then hitting it with a hand, which starts around three years of age and (4) putting together the sequence of placing a nut on an anvil, holding a stone hammer and then hitting the nut with a stone hammer so as to crack it open (Matsuzawa 1994). The 4th stage is the cognitive “bottleneck” for learning nut cracking; that is, conceptually being able to link three objects (anvil, nut and hammerstone) into a single action sequence (place nut on anvil, hold hammerstone, hit nut with hammerstone). Chimpanzees that fail to learn to crack nuts are only able to conceptualize two of these objects at a time as part of an action sequence: a nut may be placed on the ground and hit with a hammerstone, or a nut is placed on the anvil and then hit with a fist. Inability to learn the task is all the more profound when we take into account the fact that the artefacts involved in nut cracking provide a memory scaffold for the task since the objects are in the visual field of the chimpanzee, and other chimpanzees who are doing the sequence correctly can be observed. Performance in nut cracking suggests that the short term working memory of chimpanzees is on the order of 2 ± 1. This estimate receives confirmation from other data and experiments (token combinations, gesture combinations, object manipulation, number recall) relevant to estimating the working memory capacity of chimpanzees (see review in Read 2006). All of these data are consistent with a short term working memory of size 2. The experiment on recall memory required a chimpanzee to remember the location of 5 numbers shown on a computer 2 Experimental conditions for learning nut cracking have obtained similar proportions. In a group of 16 semi-captive chimpanzees released on a natural island in Liberia, only 13 learned to crack nuts after one of the chimpanzees was observed to be cracking nuts (Hannah & McGrew 1987). In one group of five captive chimpanzees that were being taught to crack nuts via human exemplars, only three learned to crack nuts (Sumita et al. 1985) and in another attempt to teach three chimpanzees to crack nuts only two learned to do so (Hayashi, Mizuno, & Matsuzawa 2005). 3 A similar pattern is reported for the chimpanzees at Taï National Park in Côte d’Ivoire, where chimpanzees begin to pound nuts on the ground at age two, then only succeed in cracking open a nut by age three, and only become proficient by age 4 (Boesch & Boesch-Achermann 2000). 4 It should be noted that three distinct objects are involved with nut cracking at Bossou since the anvil is a loose stone. The stone anvil must be made stable; for example, by using a small rock as a wedge (Matsuzawa 1994), though this method has only been observed infrequently. In contrast, the chimpanzees at Taï National Park use fixed objects such as surface roots or flat rock outcroppings for anvils and have never been observed to use loose stones as anvils (Boesch & Boesch 1983). Thus nut cracking at Taï only requires manipulation of two objects, a cognitively less demanding task, which would account for the fact that at Taï “all members of the community crack nuts (Boesch, personal communication)” (Matsuzawa 2003: 385) whereas 25% of the chimpanzees at Bossou do not learn to crack nuts. Interestingly, cracking of palm nuts by Capuchin monkeys (Cebus libidinosus) in Brazil is again based on using fixed objects as anvils (Fragaszy et al. 2004, Visalberghi et al. 2007), thus also suggesting that nut cracking with fixed object anvils is cognitively less demanding than the kind of nut cracking that occurs at Bossou. screen by first touching the screen location of the smallest number (which make the screen go blank) and then identify the location of the remaining numbers in ordinal order. This experiment comes closest to the kind of recall experiments used with human subjects for estimating the size of working memory.5 These data were, however, misinterpreted as showing a short term working memory of size 5 (Kawai & Matsuzawa 2000b, a) due to failure to take into account the fact that although 5 numbers were involved, the first choice did not require recall and the last choice is fixed, so there were only 3 independent choices. The chimpanzee used in the experiment (Ai) was only correct about 65% of the time on the third choice, which is not statistically different from a random choice given the number of trials. Hence Ai was only able to recall the ordinal order for two numbers, thus implying a short term working memory of size 2. This is consistent with the fact that Ai was the only one of three chimpanzees who could not learn to crack nuts (Hayashi, Mizuno, & Matsuzawa 2005). REFERENCES Biro, D., N. Inoue-Nakamura, R. Tonooka, G. Yamakoshi, C. Sousa, & T. Matsuzawa. 2003. Cultural innovation and transmission of tool use in wild chimpanzees: Evidence from field experiments. Animal Cognition 6, 213-223. de Beaune, S. A. 2004. The invention of technology. Current Anthropology 45, 139-162. Boesch, C. & H. Boesch. 1983. Optimisation of nut-cracking with natural hammers by wild chimpanzees. Behaviour 83, 265-286. Boesch, C. & H. Boesch-Achermann. 2000. The chimpanzees of the Taï Forest: Behavioural ecology and evolution. Oxford: Oxford University Press. d'Errico, F., C. Henshilwood, G. Lawson, M. Vanhaeren, A.-M. Tillier, M. Soressi, F. Bresson, b. Maureille, A. Nowell, J. Lakarra, L. Backwell, & M. Julien. 2003. Archaeological evidence for the emergence of language symbolism, and music -- An alternative multidisciplinary perspective. J. World Prehistory 17, 1-70. Fragaszy, E., P. Izar, E. Visalberghi, E. Ottoni, & M. Gomes de Oliveira. Wild capuchin monkeys (Cebus libidinousus) use anvils and stone pounding tools. Am. J. Primatol. 64, 359-366. Hannah, A., & W. C. McGrew. 1987. Chimpanzees using stones to crack open oil palm nuts in Liberia. Primates 28, 31-46. Hayashi, M., Y. Mizuno, & T. Matsuzawa. 2005. How does stone-tool use emerge? Introduction of stones and nuts to naïve chimpanzees in captivity. Primates 46, 91102. Hauser, M. D., N. Chomsky, & W. T. Fitch. 2002. The faculty of language: What is it, who has it and how did it evolve? Science 298, 1569-1579. Kawai, N., & T. Matsuzawa. 2000a. "Magical number 5" in a chimpanzee. Behav. Brain Sci. 24, 127-128. Kawai, N., & T. Matsuzawa. 2000b. Numerical memory span in a chimpanzee. Nature 403, 39-40. 5 Chimpanzees can learn to match number tokens from 1 to 9 with the size of a collection, but only with extensive training. Unlike the conceptual development that takes place with a human child learning numbers, learning one number does not make it any easier for a chimpanzee to learn another number (Hauser, Chomsky, & Fitch 2002). Matsuzawa, T. 1994. Field experiments on use of stone tools by chimpanzees in the wild, in Chimpanzee cultures. (R. W. Wrangham, W. C. McGrew, F. B. M. de Waal, & P. G. Heltne, eds.), pp. 351-370. Cambridge: Harvard University Press. Matsuzawa, T. 1996. Chimpanzee intelligence in nature and in captivity: Isomorphism of symbol use and tool use, in Great ape societies, (W. C. McGrew, L. F. Marchant, & T. Nishida, eds.), pp. 196-209, Cambridge: Cambridge University Press. Matsuzawa, T. 2003. Koshima monkeys and Bossou chimpanzees: Long-term research on culture in nonhuman primates, in Animal social complexity, (F. B. M. de Waal & P. L. Tyack, eds.), pp. 374-387. Cambridge: Harvard University Press. McGrew, W. C. 1992. Chimpanzee material culture: Implications for human evolution. Cambridge: Cambridge University Press. Read, D. 2006. Working memory: A cognitive limit to non-human primate recursive thinking prior to hominid evolution? CogSci 2006 Proceeding 2674-2679. Sumita, K., J. Kitahara-Frjsch, & K. Norikoshi. 1985. The acquisition of stone-tool use in captive chimpanzees. Primates 26, 168-181. Visalberghi, E., D. Fragaszy, E. Ottoni, P. Izar, M. G. de Oliveira, & F. R. D. Andrade. 2007. Characteristics of hammer stones and anvils used by wild bearded Capuchin monkeys (Cebus libidinosus) to crack open palm nuts. Amer. J. Phys. Anthrop. 132, 426-444. ELECTRONIC SUPPORTING MATERIALS, SECTION 3 2. MEMORY IN CHIMPANZEES (PAN PANISCUS) (b) Indirect Evidence For Homo sapiens, working memory development begins around 7 months of age and continues until puberty, around 12 years of age. No single study has measured the pattern and rate of development of working memory over this time span since working memory must be measured in different ways according to the age of the developing child. For our purposes here, we have had to do a meta-analysis based on several studies that have considered the longitudinal rate of development of working memory over a portion of the time span. We integrated together (and tested for longitudinal consistency in rate of development of the working memory) 12 data sets to develop a composite pattern for the growth development of working memory in Homo sapiens, as follows. The most extensive, and highly consistent, longitudinal study available in the literature is based on a time delay response for infants from 7.5 to 12 months of age (Diamond & Doar 1989). For these data, working memory increases linearly with age (r = 0.99), hence they were used to establish a predicted a growth curve for working memory, assuming a linear trend until puberty. Other data sets, since they were based on different measures of working memory, were then rescaled so that the mean of the data set -- mean age and mean measurement of working memory -- falls on the predicted linear trend for that mean age. This permits the growth rate for working memory in a data set – based on a different measure of working memory and a different age interval than the baseline data – to be compared both to the baseline data and to the growth rate for working memory for all other data sets. Finally, the working memory scale (y –axis in a plot of working memory against age) was rescaled to a 0 to 7 point scale for the age span from 0 to 12 years of age based on Miller’s estimate of 7 ± 2 for the size of short term working memory (STWM) in human adults. Growth rates for working memory for most of the data sets are based on synchronic comparison across different age classes. The degree of consistency in growth rates across the studies is remarkable (see Figure 1), especially given the variety of experimental conditions and different choices for measuring working memory that have been utilized.6 As can be seen from Figure 1, assuming working memory develops at essentially the same rate in Pan as in Homo, the data on Homo imply that STWM = 2 is achieved around 3 – 4 years of age, precisely the age period for which nut cracking behaviour begins to appear (when it appears!) in Pan. Thus both the direct evidence on working memory for Pan and data on the development of working memory in Homo are consistent with assigning STWM = 2 to Pan. REFERENCES Diamond, A. & B. Doar. 1989. The performance of human infants on a measure of frontal cortex function, the delayed-response task. Dev. Psychobiol. 22, 271-294. 6 Only one study (Kemps et al. 2000) is inconsistent with the predicted linear trend and deviates in a manner (rapid rate of growth of working memory) that if projected either forward or backward would not be consistent with either the age at which working memory begins or ends its development. Kemps, E., S. De Rammelaere, & T. Desmet. 2000. The development of working memory: Exploring the complementarity of two models. J. Exp. Psychol. 77, 89-109. ELECTRONIC SUPPORTING MATERIALS, SECTION 4 Concept: Object attribute; Action: repeated The attribute to be used for termite catching, namely the branch without side branches or leaves, is already present on the object. Side branch or leaf removal may be done repetitively; that is, the same action takes place but in a manner such that one instance of removal is conceptually independent of another instance of removal. In other words, the order of the repetition does not affect the outcome of the repeated action. Other examples would include the use of a mass of leaves bunched or mashed together and used as a sponge. The logic of Stage i attributes is of the form: If A then B; e.g., if an object is long and then (A) then it may be used for termite catching (B). The logic of Stage i tools associates an attribute(s) of an object and the functionality the attribute provides for the task at hand (B). Clearly, STWM = 2 suffices for Stage i tools. ELECTRONIC SUPPORTING MATERIALS, SECTION 5 Concept: relationship between objects More than one dyadic relationship, R, may be employed; e.g. using a small stone under one edge of the anvil to stabilize the anvil. Memory scaffolding occurs if the objects are both visible. The logic is of the form: If A is R related to B then C; for example, nut cracking, C, can occur when objects A and B are related to each other as anvil and hammerstone. Nut cracking may lead to stone debris due to either hammerstones or anvils breaking or chipping during nutcracking (Mercader, Panger, & Boesch 2002), though there is no evidence that the debris is ever used for any task. REFERENCES Mercader, J., M. Panger, & C. Boesch. 2002. Excavation of a chimpanzee stone tool site in the African rainforest. Science 296, 1452-1455. ELECTRONIC SUPPORTING MATERIALS, SECTION 6 (ii) Concept: imposed attribute; Action: repeated; Dimensionality: none (unknown dating, > 2.6 mbp) Examples would be a sharpened stick or bone, a piece of debris from a cracked or shattered rock with a functional edge, and so on. This is a hypothetical category for the moment as there are no non-human primate tools made under natural conditions that satisfy the condition that the attribute giving the object its functionality is imposed on the object. Stone artifacts that are simply debris from breaking one rock against another would be difficult to identify as artifacts (that is, conceptualized as an object with functionality (Read 2007), especially if produced on an “as needed” basis and not accumulated in a single location. Though not produced under natural conditions, making objects of this sort is within the cognitive ability of chimpanzees as shown by Nicholas Toth’s work on teaching Kanzi (Pan paniscus) to break rocks by striking one against the other (Toth et al. 1993). However, Kanzi neither seemed to understand the angle needed for flaking nor was it evident what he actually comprehended about the task (de Beaune 2004). The failure of chimpanzees under natural conditions to produce stone debris with edges that were used for cutting may just be due the fact that chimpanzees can use canines and incisors for cutting tasks (Wynn & McGrew 1989), but the fact that chimpanzees neither modify stones nor hammer stones for nut cracking suggests that the task of conceptualizing both the action of one object striking another and keeping in mind the goal of producing stone edge with a sharp edge may be pushing the envelope of chimpanzee cognitive abilities. REFERENCES de Beaune, S. A. 2004. The invention of technology. Current Anthropology 45,139-162. Read, D. 2007. Artifact classification: A conceptual and methodological approach. Walnut Creek: Left Coast Press. Toth, N., K. Schick, S. Savage-Rumbaugh, R. A. Sevcik, & D. Rumbaugh. 1993. Pan the tool-maker. J. Archaeol. Sci.20, 81-91. Wynn, T. & W. C. McGrew. 1989. An ape's view of the Oldowan. Man, New Series 24, 383-398. ELECTRONIC SUPPORTING MATERIALS, SECTION 7 Concept: Flaking; Action: repetition; Dimensionality: 0 dimensional (2.6 mbp) In more modern contexts, flakes that are simply used on the basis of the suitability of a flake edge for the task at hand are often referred to as “utilized flakes” and patterning arises not through flake production but through selection of flakes suitable for the task at hand. Patterning induced through use selection can be determined from the relationship of a utilized edge to the overall geometry of the flake (Decker 1976, Read & Russell 1996). The earliest stone artifacts associated with hominids (e.g., Kada Gona (Ethiopia) dating to 2.6 MA and Hadar, Omo (Ethiopia) and Lokalalei (Kenya) dating to around 2.4 – 2.3 Ma (Semaw 2000, Delagnes & Roche 2005 and references therein) all demonstrate that the mechanics of conchoidal fracturing as a means to produce flakes is part of the repertoire of the knappers at these locations. Most of the material (99%) has been classified as débitage (including broken and whole flakes). The cores, though few in number ”were … very well-flaked, suggesting experienced knapping skills and mastery of the mechanics of conchoidal fracture by their makers” (Semaw 2000: 1205). The repetitive nature of flaking on cores (but without overall patterning to the flaking; see Figure 6, (2000) can be seen in the fact that “cores were exhaustively flaked with negative impression of several generations of scars present” (p. 1207). The other early sites (Hadar, Omo and Lokalalei) are similar in the range of stone material: mostly débitage, some flakes and a few cores (Semaw 2000). One of these sites, Lokalalei 2C, was produced by knappers with considerable skill. The knapping was “geared towards the production of flakes … probably intentionally produced [for cutting] … Cores clearly fall into the category of waste” (Delagnes & Roche 2005: 466). Flakes were divided by the authors into simple and organized débitage, the former distinguished by the fact that it represents knapping that “does not involve a repetitive technological principle” whereas the latter “is characterized by strong technical rules” with the flaking “organized into successive series [of flake removals]” that involve repetitive actions (2005: 465). Repetitive flaking seems to be dependent on, and a consequence of, having a flat surface allowing for a striking angle < 90, thereby making it possible for a series of flakes to be removed. Though aware of the importance of a striking angle < 90, the knappers only “had the cognitive abilities to exploit angles when encountered but not to create new ones” (2005: 467, emphasis added) and reverted to simple débitage in “response to the difficulty experienced by the knappers in exploiting cobbles … owing to their inappropriate shapes” (2005: 467). In contrast to Lokalalei 2C, Lokalalei 1 is characterized by repeated, but not repetitive, flaking of cobbles (2005). REFERENCES Decker, D. 1976. "A typology for the Chevelon flaked lithic implements," in Chevelon archaeological research project, Monograph II, (F. T. Plog, J. Hill, and D. Read, eds.), pp. 92-106. Los Angeles: Department of Anthropology, UCLA. Delagnes, A. & H. Roche. 2005. Late Pliocene hominid knapping skills: The case of Lokalalei 2C, West Turkana, Kenya. J. Hum. Evol. 48, 435-472. Read, D. & G. Russell. 1996. A method for taxonomic typology construction and an example: Utilized flakes. Amer. Antiq. 61, 663-684. Semaw, S. 2000. The world's oldest stone artefacts from Gona, Ethiopia: Their implications for understanding stone technology and patterns of human evolution between 2.6-1.5 million years ago. J. Archaeol. Sci. 27, 1197-1214. ELECTRONIC SUPPORTING MATERIALS, SECTION 8 (iv) Concept: edge; Action: iteration; Dimensionality: 1 dimensional (2.0 mbp) = Mode 1 Repetition may be represented as a string of identical actions. Each action calls upon an immediate feedback loop between striking the pebble, removing the flake, and judging the effect. And for the manufacture of bifacial edge-flaked tools, the string is itself repeated on both sides of the pebble. The basic structure of such knapping is that of a two-level hierarchy or partonomy: a. percussion points are seen to make up a line, and b. a line is seen to consist of such points. There are at least two control loops involved, one between each act of percussion and its immediate results, and one between each act of percussion and the last/next one. Repetitive flaking becomes iterative flaking as part of this process of linking the surfaces and the boundary into a functional whole. With iteration, a major, conceptual change is introduced into flint knapping since the desired object is no longer simply a fragment removed from a cobble, but can be formed (in this case, 1– dimensionally) through a sequence of flake removals in which each removal contributes to the desired attribute and its functionality. Iteration is a simple form of recursion that is a precursor to algorithmic recursion in which the output of an algorithm is used as the input to a second (or subsequent) use of that algorithm. (We will see the introduction of algorithmic recursion in flint knapping with blade technology, below). Iteration, as it is used in the production of an Oldowan chopper, uses working memory scaffolding (via the current form of the core) as a way to direct the next knapping blow to the core, rather than requiring that the iteration itself be kept in working memory as a recursive process. The knapping only requires repeating the same action with the last flaking scar on the core directing where the next knapping blow should take place. The knapper takes advantage of the characteristics of the cobble during this process. As noted by Pigeot “le tranchant est placé là où le galet, par sa forme, le permet” (“the edge is located on the cobble there, where the form of the cobble allows it”) (Pigeot 1991: 180). The method of producing the edge is through iteration, namely repeated flaking in which each subsequent flake removal is based on the previous flake removal and is not simply a series of flake removals made possible by the form of the cobble or cobble fragment as in the case of the Lokalalei 2C ‘organized débitage’. The edge is formed by conceptually transforming repetitive flaking into iterative flaking aimed at imposing a topology consisting with an edge that is the boundary between two surfaces, and it is this topology that gives the Oldowan chopper its functionality. Conceptualizing the surface left behind by repetitive flaking as part of a topology opens the way, conceptually, to modify the surface so as to increase the functionality of the topology that gives rise to the desired functionality. REFERENCES Pigeot, N. 1991. Reflexions sur l'histoire technique de l'homme: De l'évolution cognitive à l'évolution culturelle. Paléo 3, 167-200. ELECTRONIC SUPPORTING MATERIALS, SECTION 9 Concept: Closed curve; Action: iteration; Dimensionality: edge as a generative element (1.5 mbp) = Mode 2 The form of the closed curve would likely have followed the form of the cobble, as Pigeot noted for an edge, before it becomes a closed curve. We would expect, then, that early “bifaces” would be distinguished primarily by flaking that identifies a closed boundary for the two surfaces (where portions of the surface may be just the surface arising from breaking a cobble into large pieces – see left side of Figure A): “Many (but not all) of these “bifaces” were made by first detaching a very large flake from a bouldersized core using a two-handed hammering technique” (Jones 1981). The knapper then modified this large flake by trimming around the margins (usually onto both faces of the flake, hence the term biface)” (Wynn 2002: 394). Flaking will occur around the perimeter of the object so as to give it an edge (see right side of Figure A): “Preferences are suggested to have existed for a circumferential working edge” (White 1995: 18). QuickTime™ and a TIFF (LZW) decompressor are needed to see this picture. QuickTime™ and a TIFF (LZW) decompressor are needed to see this picture. Figure A: Left side: Cleaver from Olduvai (1.4 mya). Flake removals determine the side edges of the cleaver. Right side: Handaxe from West Natron, Tanzania (1.4 mya). Flake scars determine the edge that circumscribe the hand axe (modified from Figures 4 and 5 in Wynn 2002). For the early bifaces, symmetry may simply be an unintended by-product of the process of constructing an edge to serve as a boundary that makes the “biface” a biface. If the knapper used one edge as a “model” for the other edge, then the biface will tend to be symmetrical. There is no need to assume that the knapper had a shape in mind prior to constructing the biface and so there will be variation in shape. If the edge of a chopper is just extended around the chopper, then the shape would either be an oval if the working part of the edge as it is being constructed joins smoothly with the starting point of the edge, or the intersection would be pointed if the intersection were not a smooth curve. Thus bifaces formed with an edge that encircles the object would tend to either be oval (possibly with end of the oval large than the other depending on the properties of the cobble) or oval on one end and more-or-less pointed on the other. The knapper need not have the final shape in mind, but rather only needs to conceptualize the process for making the shape: to continue constructing the edge until it intersects with itself. The shape will emerge from this process. The edge becomes a generator of a more complex form through the simple expediency of extending the edge until it circles back on the starting point of the edge. To the extent that the knapper uses the already formed edge as a model for the edge being formed, the biface will take on a more symmetrical shape (see right side of Figure A). In addition, the shape of the recovered hand axe is not simply the shape it had at the time it was made, but is also due to its use history (Nowell 2002 and references therein). Stage 5, though it appears to be qualitatively different than Stage 4 since two dimensions are involved, begins by simply extending the process of producing an edge until the edge intersects itself. The technique for so doing is more complex than just forming an edge as the blank must be suitable for an edge to be extended around it. If the knapper is constrained by the properties of the blank as to where an edge can be located, then the challenge to the knapper may lie more in producing a suitable blank and less in the execution of the edge that defines the bifaces.7 REFERENCES Jones, P. 1981. Experimental implement manufacture and use: A case study from Olduvai Gorge, Tanzania, in The emergence of man. (J. Young, E. Jope, & K. Oakley, eds.), London: The Royal Society and the British Academy. Nowell, A. 2002. Coincidental factors of handaxe morphology. Behav. Brain Sci. 25, 413-414. White, M. 1995. Raw material and biface variability in southern Britain: A preliminary examination. Lithics 145, 1-20. Wynn, T. 2002. Archaeology and cognitive evolution. Behav. Brain Sci. 25, 389-438. 7 If the biface is not ‘sculpted’ from a cobble but is formed by extending an edge as in Figure A, then the blank must be amenable to transforming a continuous edge into a perimeter; that may lead us to speculate whether in such cases the “bottleneck” between choppers and bifaces may be less the biface per se, rather than the technique of producing a blank suitable for making a biface ELECTRONIC SUPPORTING MATERIALS, SECTION 10 Concept: Surface; Action: iteration; Dimensionality: 2 dimensional (500,000 bp) = Mode 2 This transition may at first sight seem somewhat arbitrary. In effect, when flaking in order to create an edge, the tool-maker also creates a surface. Distinguishing between edge-tools and surface-tools is all a question of identifying the intention and/or the topological conception of the tool-maker. Although an edge-tool may show a surface that is the result of flaking, the real difference resides in whether or not the tool-maker attempted to control the shape of the tool as a whole. Such control implies the wish to be economical with the raw materials, as well as the conceptualization of the function of the tool in terms of its entire shape. The resulting tools are true bifaces in the sense that both faces of the pebble have entirely been shaped. In passing, the useful part of the edge is extended to encompass the whole of the tool’s perimeter. In a sense, the transition is thus between the biface as seen from the edge and the biface as seen from the two surfaces concerned; it is conceptual rather than technical. Once surfaces were cognized, tool-making inherently became a matter of surfaces, whereas until that moment it was entirely a matter of edges. At that point in the development, the distinction between the tool and the flake, between object and product, disappears. Both are seen as products of the shaping process, as well as bifacial objects that may be subjected to further flaking. This cognitive/conceptual change permits the toolmaker to strive to maintain the same strike platforms all through the exploitation of a piece of flint or stone. It eventually resulted in more standardized, better quality tools with more regular cutting edges and a more economic use of raw materials. As control over the production increases, the form towards which the knapper strives becomes more clearly defined, while the distance between it and the final product is reduced. It is at that point that the “débitage facial” appears alongside edge-flakes. Initially, again, whether such “débitage facial” is unifacial or bifacial is mainly determined by the shape of the stone object involved - i.e. surfaces are perceived, but volumes are not yet. But with increasing control over flaking, the original shape of the raw material becomes less and less important. The invention of the surface as a concept seems to involve two changes in procedure. Firstly, as in Stage 5, the knapper implements a long string of identical events (i.e. iteratively flaking the edge all around the pebble), each of which is conceived so that once the whole string is completed, the knapper is back at the beginning. By returning to the beginning, the knapper has effectively circumscribed a surface. And secondly, once this is done, there remains no cortex in the middle of the circular edge. To achieve that, the knapper in practice modifies each flake only marginally - making it somewhat bigger so that it stretches from the edge to the centre of the (now circular) line that is the result of iteratively linking a set of identical flaking actions. A slight change in percussion angle allows the knapper to “fill” the surface at the same time as circumscribing it. The knapper has conceptually introduced a “third level” effect alongside the immediate effect of the blow. Not only does each blow create a stretch of cutting edge, but the set of blows together also has the effect of creating a fully circumscribed surface. And not only does the change in percussion angle enlarge the size of each flake, but the totality of flakes thus removed covers the whole surface to be decorticated. In practice, this implies that the knapper acknowledges that there is a hierarchical relationship between each individual action and the total set of actions, and that that hierarchy has three levels: point, line and surface.8 Apart from the conceptual steps outlined above, it involves the following new ones: percussion points are also seen to relate to flaking surfaces (which are only really controlled at the edge) and flaking surfaces relate to percussion points, the location of the set of percussion points relate to the shape of the flake surfaces in order to control a larger surface.9 But to assert that the knapper fully cognizes the existence of surfaces, and manipulates them, one last step is needed: recognizing as such the upper level of the hierarchy that has thus been created. This, again, can only be shown to be the case when and if the knapper is able to invert the procedure, i.e. when he or she is able not only to clear a surface by circumscribing an area and then filling it, but also to clear a surface and then circumscribe it by retouching its edge. That ability is demonstrated by the practice of making flake and blade tools. 8 9 Or in the knapper’s terms: a sequence of percussions (caused by individual blows) in well-defined (adjacent) places creates an edge. An edge of a particular configuration (one which is closed) encloses a surface, and a set of particularly configured and specifically aimed percussions creates a surface. This is what Pigeot calls the “radial facial” technique. ELECTRONIC SUPPORTING MATERIALS, SECTION 11 (vi) Concept: Surface; Action: algorithm; Dimensionality: 2 dimensions (300,000 bp) = Mode 3 The Levallois method has considerable variability in its implementation, including different historical trajectories for the transition from the façonnage technology of bifaces/hand axes and the débitage technology of flake production (White & Ashton 2003 and references therein). The transition is not simply one of elaboration on existing concepts (as occurs between Stage v(a) and v(b)), but a more complex one that creates a new dynamic: Rather than evolving directly from handaxes (Rolland 1995, Tuffreau 1995) or arriving fully formed courtesy of immigrant African hominids (Foley and Lahr 1997), both of which would demand no proto-phase, prepared core technologies originated in situ within north-western Europe (at least) through a gradual transformation of existing core technologies and a fusion of elements of both façonnage and débitage. In short, the development of the full Levallois concept represents for us the erosion of boundaries between and the integration of two existing systems, the practical fusion of façonnage and débitage into a new dynamic. While the final purpose was undoubtedly the production of select flakes, in our view it cannot be considered exclusively in terms of débitage, as it contains an elaborate shaping phase clearly aimed at controlling the form of an inner volume. But neither is it a system of façonnage, as the shaping of the core is only a means to producing desired flake blanks. In the Levallois method the core is involved in a reflexive interplay of these two concepts, constantly morphing from structured shaping phases to production phases; the rigid distinction between operational schemas seen earlier collapses and constructs that had been conceptually separate merge into one unified and highly flexible concept. That the products of early Levallois technology were used unmodified and served to produce both scrapers and handaxes (with minimal modification) and that, in the wake of its emergence, handaxes tended to phase out in some regions serves to demonstrate the nature of this fusion and the fundamental restructuring of technology that underpins it. However, standard systems of façonnage and débitage do not disappear as redundant technologies but continue to exist alongside Levallois technology at various temporal and spatial scales (White & Ashton 2003: 605). Conceptually, the Levallois method brings together existing conceptual units (débitage and façonnage techniques) and produces from them a new concept; that is, it involves the generation of a new and richer techniques rather than the transformation of existing techniques: “the fusion of principles taken from two distinct operational systems, that characterizes the Middle Palaeolithic technology, lead[s] to far greater variation and flexibility in both core reduction and tool production than that witnessed in the Lower Palaeolithic” and involves “an innovative conceptual leap” (see also Foley & Lahr 2003, White & Ashton 2003: 606). The Levallois method as a new concept draws our attention to other domains that also involve generating new concepts from already existing concepts. One of these is the conceptual development of a system of kin relations based on generating new kin relations from existing concepts such as a “mother relation,” a “father relation” and/or a “sibling relation” (Read, Lane, & van der Leeuw In Press). Each of these must have arisen through a Darwinian selection process through behavioural interaction (and the “mother relation,” at least, may be part of the cognitive repertoire of the macaques (Dasser 1988)). But the conceptual ability to combine relations together to generate a new relation (such as constructing the “mother of mother” relation from an already cognized mother relation or the “brother of mother” relation from an already cognized brother relation and mother relation) had far reaching consequences as the construction process was conceptual, hence not dependent upon prior behaviour (Read, Lane, and van der Leeuw In Press). In a comparable manner, the Levallois method is generated by combining together two existing technologies derived from direct experience with knapping (e.g., the conchoidal fracture as the basis for the débitage method; forming and extending an edge that becomes the boundary of two surfaces as the basis for the façonnage method) into a new method that is neither simply derived from knapping nor dependent on first developing new knapping techniques prior to the appearance of the method (see Figure B). QuickTime™ and a TIFF (LZW) decompressor are needed to see this picture. Figure B: Illustration of the concepts involved in the Levallois method of flaking. From Figure 5 in White & Ashton 2003, based on Boëda 1995. Our suggestion is obviously highly speculative, but is consistent with the argument that the development of the Levallois methods cannot be disassociated from changes taking place in the social milieu: “the origins of Levallois technology might be underwritten by changes in the way in which systems of flake production were used in the social sphere, perhaps becoming more critical to the construction of social life” (White & Ashton 2003). Those changes in the social life may relate to redefining what constitutes a social relation between individuals that was part of the conceptual development of systems of kin relations (Read, Lane, and van der Leeuw In Press). From a cognitive viewpoint the two developments – one in the area of knapping and the other in the area of kin relations – seem to share commonality at the abstract level of the neurological changes in brain functioning that make possible the formation of a new concept out of already existing concepts in a generative rather than a transformational manner. If so, it is possible that the Levallois method with its algorithmic formulation as a technique may have depended on lateral transfer of brain function from one domain (social relations) to another (stone knapping). This argument is consistent with the long stasis for Stage v(b) and the relative rapid appearance of Stage vi as a distinct method for the production of flakes. The “cognitive bottleneck” was not overcome through increased experience and skill development through knapping but through neurological changes responding to developments in the kinship domain that led to neurological capacities that were not modular but open ended with regard to the domains where the capacities could be expressed and utilized.10 REFERENCES Boëda, E. 1995. Levallois: A volumetric construction, methods, a technique, in The definition and interpretation of Levallois technology, (H. L. Dibble & O. Bar-Yosef, eds.), pp. 41-67. Madison: Prehistory Press. Dasser, V. 1988. Mapping social concepts in monkeys, in Machiavellian intelligence: Social expertise and the evolution of intellect in monkeys, apes, and humans. (R. W. Byrne & A. Whiten, eds.), New York: Oxford University Press. Foley, R. & M. M. Lahr. 1997. Mode 3 technologies and the evolution of modern humans. Camb. Archaeol. J. 7, 3-36. Foley, R. & M. M. Lahr. 2003. On stony ground: Lithic technology, human evolution, and the emergence of culture. Evol. Anthrop. 12, 109-122. Read, D., D. Lane, and S. van der Leeuw. In Press. "The innovation innovation," in Complexity perspectives on innovation and social change, (D. Lane, D. Pumain, S. van der Leeuw, & G. West, eds.). Berlin: Springer Verlag. Rolland, N. 1995. Levallois technique emergence: Single or multiple? A review of the Euro-African record, in The definition and interpretation of Levallois technology, (H. L. Dibble & O. Bar-Yosef, eds.), pp. 333-359. Madison: Prehistory Press. Tuffreau, A. 1995. The variability of Levallois technology in northern France and neighboring areas, in The definition and interpretation of Levallois technology, (H. L. Dibble & O. Bar-Yosef, eds.), Madison: Prehistory Press. 10 That is, the relative ‘stasis’ may be due to the complexity of conceptually combining ‘façonnage’ and ‘débitage’, a conceptual complexity that may have been resolved in a different domain and was then exapted at the neurological level for the similar problem of conceptually combining ‘façonnage’ and ‘débitage’ together in a generative manner to produce a new concept (Boëda 1995) and not just a new technique (see Figure B). White, M., and N. Ashton. 2003. Lower Palaeolithic core technology and the origins of the Levallois method in north-western Europe. Current Anthrop. 44, 598-609. ELECTRONIC SUPPORTING MATERIALS, SECTION 12 (vii) Concept: Intersection of Planes; Action: Recursion; Dimensionality: 3 dimensions (> 50,000 bp) = Mode 4 Whereas the Levallois technique exploits the volume by knapping on two cross-cutting planes and creates flake tools with essentially one (round) edge where two planes meet, the techniques that truly conceive of volumes knap at the intersection of three planes and thus create long blade tools with three edges, at each of which two out of the blade’s three planes meet. Or to paraphrase Boëda (1990), the Upper Palaeolithic nucleus is a volume in the true sense; it is prepared in different ways, but it always consists of two or three crests which guarantee an optimal exploitation of the nucleus because the flaking reduces the volume everywhere in turn. Pigeot adds that even more important in her eyes is the fact that the volume that is so defined is exploited on the smaller of its surfaces, creating backed blades, so that the volume literally is more important than the surface, and the management of the core volumetric rather than planar. That point is first reached with the Gravettian and Magdalenian traditions of the Upper Palaeolithic.11 In the earlier flaking techniques the striking surface and the surface from which the flakes are to be removed intersect at a sharp angle. This implies that with each removal the surface available for removing the next flake becomes smaller. With the introduction of the blade techniques, however, the knapper prepares a true striking surface at more or less right angles to the exploited surface, so that that the length of a blade is no longer as directly dependent on its place in the removal sequence. Although conceptually and economically very efficient, this approach requires the mastering of new techniques, soft percussion flaking among them. As a result, a whole new range of tools is invented.12 REFERENCES Boëda, E. 1990. De la surface au volume: analyse des conceptions des débitages Levallois et laminaires, in Paléolithique moyen récent et Paléolithique supérieur ancien en Europe. Ruptures et transitions: examen critique des documents archéologiques, (C. Farizy, ed.), pp. 63-68. Nemours: Mémoires du Musée de Préhistoire d’Ile de France, 3. 11 12 This change in perspective hinges on a reinterpretation of the materials from Rocourt, Roc de Combe and Arcy sur Cure. Boëda views the Rocourt materials as distinct from the Levallois techniques in the sense that although its volumetric conception is similar to that of the Levallois technique, the exploitation of the nuclei is truly volumetric. Pigeot, in arguing that the shift from exploiting the largest surface (the most tempting and potentially the most rewarding, but the most difficult) to exploiting the smaller surface is the best way to distinguish between the two conceptions, shifts the boundary and includes not only the materials from Rocourt, but also those of the two other sites, in the Middle Palaeolithic. Innumerable colleagues have noted that this development occurs more or less at the same time as the introduction of rock art, the production of bone tools and leather objects, new hunting methods and even language. However interesting the conjunction of these innovations might be, it is not the topic of this paper, and we have therefore refrained from discussing it in any way. ELECTRONIC SUPPORTING MATERIALS, SECTION 13 (d) Implications of change in STWM Until now, we have essentially focused on the acquisition or development of the cognitive capabilities from the perspective of what is needed to apply a range of specific ways to make stone tools, and we have related them to a specific vision on the development of the Working Memory. In the next part of this chapter, we will move beyond that. But before we do so, we need to take stock and highlight some of the implications of the developments outlined thus far. In particular, we want to reformulate in general terms some of the ‘tools for thought’ acquired in the process of developing the three-dimensional volumetric cognitive apparatus inherent in the ‘prismatic blade industries’. These include (1) the ability to handle a much more complex set of control loops, (2) the development of conceptual hierarchies and partonomies, (3) the sequencing of different parts of the chaîne opératoire (4) the extension of the reach of the working memory, and (5) the redefinition of the relationship between the object as a whole and its parts. We will discuss each of these in turn, as they are of essential importance for our understanding of what happens in the Neolithic. Arlan (1992) remarks that the first requirement of toolmaking is necessarily the capacity to reverse the direction of a sequence of events in the mind, as the identification of a sequence of cause-and-effect depends on it. This involves the creation of a control loop13 between observations and conceptualizations, so that one may identify and label the different stages of a sequence of events and store them independently, whilst assigning to their sequence a meaning all of itself. To (re)create the transformation or sequence at will, the individual must also be able to retrieve the whole sequence associated with the desired result, to “wind it back” to its beginning, and to “replay” it in the appropriate order. And to understand the dynamics of cause and effect, the individual must be able to play sequences backwards and forwards in an interactive way, and to retrieve (parts of) sequences that are associated with any of the stages of transformation or actions concerned. The act of winding such a sequence back implies at least a STWM of 4 if the forward sequence is AB (as that has to be held in working memory while one conceptualizes BA). If the forward sequence is ABC then a STWM of 6 would, roughly speaking, be needed – less if we take into account chunking and memory scaffolding. But for such understanding it is also necessary that the individual be capable of observing differences between causal chains, and to generate variations by mentally or physically inserting operations, removing or modifying them. That in turn requires the capacity to associate or dissociate different strings of events, on the basis of an assessment of relevant similarities and differences. Edge-flaked tools (Stage iv) require that the flaking action is repeated in an iterative, linear fashion. Such iteration may be represented as a string of identical actions. Each action calls upon an immediate feedback loop between striking the pebble, removing the 13 We will here use the term “control loop” instead of the more common “feed-back” or “feed-forward” loop because it seems to us that feed-back and feed-forward are always combined in monitoring the actions undertaken as part of a “chaîne opératoire” and their effects. flake, and judging the effect. We have seen that the basic structure of such knapping is that of a two-level hierarchy and partonomy, in which percussion points are seen to make up a line, and a line is seen to consist of such points. There are at least two control loops involved, one between each act of percussion and its immediate results, and one between each act of percussion and the last/next one, the basis for iteration. The ‘invention’ of the surface (Stages v(a) and v(b)) as a concept seems to involve two changes in procedure. Firstly, the knapper manages to implement a long string of identical events that is conceived so that once the whole string is completed, the knapper has effectively circumscribed a surface (Stage v(a)). And secondly, once this is done, there remains no cortex in the middle of the circular edge (Stage v(b)). To achieve that, the knapper marginally modifies each flake. In both cases, the knapper has conceptually introduced a ‘third level effect’ alongside the immediate effect of the blow. Not only does each blow create a stretch of cutting edge, but the set of blows together also has the effect of creating (controlling?) a fully circumscribed surface. And not only does the change in percussion angle enlarge the size of each flake, but the totality of flakes thus removed covers the whole surface to be decorticated. In practice, this implies that the knapper acknowledges that there is a hierarchical relationship between each individual action and the total set of actions, and that that hierarchy has three levels: point, line and surface.14 Introducing the third level of the hierarchy also makes the set of control loops more complex, adding a loop between percussion angle and strike point to monitor flake surface, one which links individual flake configurations to the total surface, and one which links all the individual percussion points to achieve the correct spatial circumscription of the surface15. This would correspond to STWM = 5, consistent with knapping based on conceptualization of the three level hierarchy and the two control loops. Pigeot (1991: 180-184) stresses a number of the many interesting consequences of this shift, notably in the areas of tool standardization, tool quality and the economics of raw materials. Another hierarchy is introduced, between different kinds of flakes, which one might call “surface flakes” and “edge flakes”. This distinction in turn implies a number of other acquisitions of a cognitive nature. Henceforth, flake- and blade tools exist alongside core tools. By implication, the size and shape of flakes and blades becomes important. The role of the flake also changes from that of reject to that of the tool, which removes a cognitive obstacle, the idea that the chaîne opératoire consists of a single linear progression transforming a lump of raw material into a tool. Now, the core and the flakes are seen as equal from a functional point of view. That has several consequences: Firstly, it fundamentally denies the hierarchical relationship between tool and flake (as object and waste) that was implicit in the approach to core tools, proving that that hierarchy is cognized, as shown by the further development of the ‘façonnage’ technique for the forming of a flake. Secondly, if flakes are transformed into tools, this implies the identification of the flakes as objects. Thirdly, it signifies that a hierarchical relationship 14 15 Or in the knapper’s terms: a sequence of percussions (caused by individual blows) in well-defined (adjacent) places creates an edge. An edge of a particular configuration (one which is closed) encloses a surface (Stage v(a)), and a set of particularly configured and specifically aimed percussions creates a surface (Stage v(b)). And there may be many more, as we have only taken the most immediate consequences and prerequisites of each act of percussion into account. between many (flakes) and one (core) is cognized, even though that awareness is limited to the fact that parts may be removed from a whole, and does not (yet) include the idea that parts may constitute a whole16. Fourthly, the change implies awareness of the analogy between, on the one hand, the relationship between a core and the flakes removed from it and, on the other, that between the flake and the retouches removed from it. In other words, not only objects but also relationships may be hierarchised. In our stress on the spatial aspect of the cognitive development illustrated by tool making, we have accorded less attention to the temporal side of the matter. Yet, the growing number of steps involved in the chaîne opératoire is another means to monitor the evolution of the cognitive and technical capacities of human beings. The essential capability to be acquired seems to be the capacity to anticipate parts of the chaîne opératoire and to create the right conditions for them to be implemented and controlled. The introduction of the “débitage facial envahissant” implies that the knapper has to look several steps ahead, and to closely integrate his actions during these steps, in order to create the right conditions for the removal of the main flakes (Stages vi and vii). Such “integrated sequences” are initially relatively short and their nature is to a very important degree determined by the initial shape of the pebble which is to be transformed into a set of flakes (Stage vi). The products are therefore quite varied. This will remain so for as long as the surface from which the flakes are to be struck is the largest surface available on the core. Beginning with the prismatic blade industries (Stage vii), toolmaking is technically more difficult, requires closer control and cannot be varied so easily because the physical constraints are much more limiting. From the sequencing point of view, it implies a much more stringent separation between “preparation” and “exploitation”. In fact, a whole series of preparatory steps is conceived and undertaken to subsequently facilitate the longest possible sequence of uninterrupted blade removal, hence our characterization of the prismatic blade industries as recursive. The use of the volume as a concept does not imply anything else than the stretching of the capacity to hierarchize. Once hierarchies of objects and relationships are available as conceptual tools, and can be linked to form three-level chains, extending them to include four levels is not fundamentally different. Surfaces are now conceived as derivatives of volumes: each volume can be conceived as made up of an infinity of surfaces, each surface an infinity of lines and each line an infinity of points. However unsurprising this development may in itself be, it has an important consequence: the discovery of both scale, embeddedness and generativity. REFERENCES Arlan, H. 1992. Self-organising networks: Weak, strong and intentional. The role of their underdetermination. La Nuova Critica N.S. 19-20, 51-70. 16 We also see this as the basis for the fact that the blade technology is recursive; recursion is a form of unwinding, as if the whole (the complete nodule) is conceptualized as already composed of blades that fit together to make the nodule and the technique is one of unwinding how the nodule is conceptualize into its constituent blades. Pigeot, N. 1991. Reflexions sur l'histoire technique de l'homme: De l'évolution cognitive à l'évolution culturelle. Paléo 3, 167-200.