VST-SPE-OAC-24000-1029

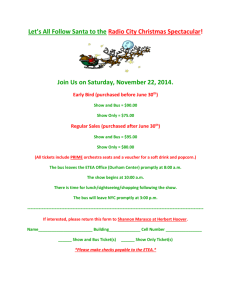

advertisement

VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 1 VST VLT SURVEY TELESCOPE DISTRIBUTED CONTROL SYSTEMS DESIGN SPECIFICATIONS Doc. No.: VST-SPE-OAC-24000-1029 Issue: 1.0 Pages: 21 Date: 09.11.00 File Name: VST-SPE-OAC-24000-1029-1.0 Activity Names System analysis, functionalities & Document design Contents by Document Preparation Document Supervision & Check Task Management Documentation and Quality Control Manager Task Responsibility D.Mancini, C.Molfese D.Mancini, C.Molfese D.Mancini, C.Molfese D.Mancini, V.Fiume Garelli D.Mancini V. Fiume Garelli D.Mancini mancini@na.astro.it Questions and Remarks on contents C.Molfese – molfese@na.astro.it – phone:+39 081 5575557 – fax: +39 081456710 Signature VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 2 CHANGE RECORD Issue Date 1.0 09.11.2000 Section/Paragrafh Affected Reason/Initiation/Documents/Remarks First release VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 3 TABLE OF CONTENTS 1 INTRODUCTION ........................................................................................................................................ 5 1.1 1.2 1.3 1.4 1.5 1.6 2 PURPOSE .............................................................................................................................................. 5 SCOPE .................................................................................................................................................. 5 DOCUMENT STRUCTURE DESIGN............................................................................................................ 5 REFERENCE DOCUMENTS ...................................................................................................................... 5 APPLICABLE DOCUMENTS ...................................................................................................................... 5 ABBREVIATIONS AND ACRONYMS ............................................................................................................ 5 GENERAL DESCRIPTION ........................................................................................................................ 7 3 CUSTOM MODULE DEVELOPMENT AND RELATED MICROCONTROLLER PLATFORM SELECTION ................................................................................................................................................. 9 4 CANBUS#1 DESIGN SPECIFICATION .................................................................................................. 11 4.1 DESCRIPTION ...................................................................................................................................... 11 4.2 FUNCTIONAL REQUIREMENTS ............................................................................................................... 12 4.2.1 CAN Bus Interface Board ........................................................................................................... 12 4.2.2 Motor Cooling Controller ............................................................................................................ 12 4.2.3 Temperature Acquisition Module ............................................................................................... 12 4.3 PERFORMANCE REQUIREMENTS ........................................................................................................... 13 4.3.1 CAN Bus Interface Board ........................................................................................................... 13 4.3.2 Motor Cooling Controller ............................................................................................................ 13 4.3.3 Temperature Acquisition Module ............................................................................................... 13 5 CANBUS#2 DESIGN SPECIFICATION .................................................................................................. 14 5.1 DESCRIPTION ...................................................................................................................................... 14 5.2 FUNCTIONAL REQUIREMENTS ............................................................................................................... 15 5.2.1 CAN Bus Interface Board ........................................................................................................... 15 5.2.2 Motor Cooling Controller ............................................................................................................ 15 5.2.3 Temperature Acquisition Module ............................................................................................... 15 5.3 PERFORMANCE REQUIREMENTS ........................................................................................................... 15 5.3.1 CAN Bus Interface Board ........................................................................................................... 15 5.3.2 Motor Cooling Controller ............................................................................................................ 15 5.3.3 Temperature Acquisition Module ............................................................................................... 15 6 CANBUS#3 DESIGN SPECIFICATION .................................................................................................. 16 6.1 DESCRIPTION ...................................................................................................................................... 16 6.2 FUNCTIONAL REQUIREMENTS ............................................................................................................... 16 6.2.1 CAN Bus Interface Board ........................................................................................................... 16 6.2.2 Astatic Lever Controller .............................................................................................................. 16 6.3 PERFORMANCE REQUIREMENTS ........................................................................................................... 17 6.3.1 CAN Bus Interface Board ........................................................................................................... 17 6.3.2 Astatic Lever Controller .............................................................................................................. 17 7 CANBUS#4 DESIGN SPECIFICATION .................................................................................................. 18 7.1 7.2 DESCRIPTION ...................................................................................................................................... 18 FUNCTIONAL REQUIREMENTS ............................................................................................................... 19 VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 4 7.2.1 CAN Bus Interface Board ........................................................................................................... 19 7.2.2 Motor Cooling Controller ............................................................................................................ 19 7.2.3 Temperature Acquisition Module ............................................................................................... 19 7.3 PERFORMANCE REQUIREMENTS ........................................................................................................... 19 7.3.1 CAN Bus Interface Board ........................................................................................................... 19 7.3.2 Motor Cooling Controller ............................................................................................................ 19 7.3.3 Temperature Acquisition Module ............................................................................................... 19 8 HARDWARE COMPONENTS DESIGN SPECIFICATIONS ................................................................... 20 8.1 8.2 8.3 8.4 CAN BUS I/F BOARD ........................................................................................................................... 20 ASTATIC LEVER CONTROLLER .............................................................................................................. 21 MOTOR COOLING CONTROLLER ........................................................................................................... 21 TEMPERATURE ACQUISITION MODULE .................................................................................................. 21 TABLES & FIGURES Fig. 3.1 - Microcontrolled Module for CANBus General Architecture .............................................................. 10 Fig. 4.1 - CANBUS#1 Configuration ................................................................................................................ 11 Fig. 5.1 - CANBUS#2 Configuration ................................................................................................................ 14 Fig. 6.1 - CANBUS#3 Configuration ................................................................................................................ 16 Fig. 7.1 - CANBUS#4 Configuration ................................................................................................................ 18 VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 5 1 INTRODUCTION 1.1 PURPOSE This document reports the design specification of the distributed control systems based on CAN Bus that are envisaged for the VST. The document is to be intended as a guideline for hardware detailed design and development. 1.2 SCOPE This Document is applicable to the development of VST Telescope distributed control systems based on CAN Bus. 1.3 DOCUMENT STRUCTURE DESIGN In the first part of the document a general description of distributed control systems envisaged for VST Telescope is given. Information about custom development activities and microcontroller platform selection are in chapter 3. Description of each CAN Bus Control System and of its functional and performance requirements are indicated in the document. Design specifications of commercial and custom module are given in the chapter 8. 1.4 REFERENCE DOCUMENTS [1] VST-TRE-OAC-24000-1008, VST Control Hardware 1.5 APPLICABLE DOCUMENTS [1] VLT-INS-ESO-01000-0001, Directive for Preparation of Technical Specifications [2] VLT-SPE-ESO-11410-0674, Technical Specification for the Opto-Mechanical Parts of the Cassegrain Adapter-Rotators for the Very Large Telescope [3] VLT-SPE-ESO-10000-0006, VLT Observatory Requirements for Nasmyth Instruments [4] VLT-SPE-ESO-10000-0017, General Safety – Requirements for Scientific Instruments [5] VLT-TRE-ESO-00000-0001, VLT Maintenance Concept [6] VLT-TRE-ESO-00000-0467, Requirements for Safety Analyses 1.6 ABBREVIATIONS AND ACRONYMS A/D ADC ADP APCS Analog-to-Digital conversion Atmospheric Dispersion Corrector Adapter Axial and Radial Pads Control System VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 6 AZ Azimuth CAB#x Cabinet n.x CIR Central Intensity Ratio CORR Corrector D/A Digital-to-Analog conversion DER Derotator DMA Direct Memory Access EL Elevation EMIF Electro-Magnetic Interference Filter ESO European Southern Observatory FEA Finite Element Analysis FEE Front End Electronics GESS General Emergency Stop System HBS Hydrostatic Bearing System HPCS Hexapod Positioning Control System LCU Local Control Unit LESS Local Emergency Stop System LSB Lowest Significant Bit LUT Look Up Table OAC Osservatorio Astronomico di Capodimonte PHA Preliminary Hazard Analysis PHL Preliminary Hazard List PI Proportional-Integrative Controller RMS Root Mean Square SCP Service Connection Point SHA Sub-System Hazard Analysis TBC To Be Confirmed TBD To Be Defined TBU To Be Updated TCS Telescope Control Software TWG Technology Working Group UD Under Definition VLT Very Large Telescope VST VLT Survey Telescope VME Versa Module Eurocard WS WorkStation VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 7 2 GENERAL DESCRIPTION For the VST Telescope four distributed control systems, driven through CAN Busses, are envisaged for the control/acquisition of the following aspects: M1 Axial and Radial Pads control Motors cooling system and temperature acquisition Telescope structure temperature acquisition The CAN Busses and the related control functions are here listed: CANBUS#1: AZ Motors cooling system, AZ Motors temperature acquisition, AZ structure temperature acquisition (connected to LCU#1) CANBUS#2: ALT Motors cooling system, ALT Motors temperature acquisition, AZ structure temperature acquisition (connected to LCU#2) CANBUS#3: M1 Axial and Radial Pads control (connected to LCU#3) CANBUS#4: ROT Motors cooling system, ROT Motors temperature acquisition, ALT structure temperature acquisition (connected to LCU#3) Each CAN Bus will be connected to one LCU by means of TEWS DATENTECHNIK TPMC816 2 Channel CAN Bus PMC Module as recommended by ESO. This module is suitable to be fitted into the PCI Mezzanine socket available on the Motorola VME 2604 CPU Card, envisaged for the LCUs. The availability of driver S/W ESO for the integration of this module into the Motorola CPU Card is being checked. Another solution to connect the CAN Bus with LCUs is based on the VME-CAN4 Intelligent CAN Bus I/F Board for VME Bus, manufactured by ESD; the S/W development support for this card is based on standard VxWorks drivers, but no ESO drivers should be available. Both commercial items are suitable to implement the CAN Bus I/F Board, but the former should be preferred, because better software supported. The features of the TPMC816 module and the ones of the VME-CAN4 board are reported in 8.1. The integration of the CAN Bus I/F into the LCU (PMC Module or VME Card) has been preferred to the one based on CAN Bus I/F modules connecting CAN Bus to RS-232 serial Interface, as described in [1], for the following two reasons: More powerful: this solution allows to exploit the whole transmission rate available with the CAN Bus (1 Mbit/s; this through-put value is much greater than the one actually requested by the application). More compact and easy to be integrated This board will be the master of the single CANBus network and can address the slaves modules to send configuration parameters or to request data. The address mechanism is based on the acceptance filtering capability. All CAN implementations provide some hardware acceptance filters to relieve the microcontroller from the task of filtering those messages which are needed from those which are not of interest. The address space managed by the acceptance filter is equal to 127 devices (sufficient for VST application), but it can also be expanded allocating one or more bytes of the data field of the CANBus standard packet as auxiliary address. This theoretical number of devices can be connected at the same time is derived by the CAN Bus data link protocol, but is also limited by the drive capability of the electronic device; so line drivers are to be selected carefully. Furthermore the use of signal repeater will be evaluated if necessary. VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 8 The physical layer is based on a twisted pair for data transmission; two other wires are present to distribute 12Vdc power to all modules connected to the network. The maximum data rate envisaged for the CANBus is equal to 1 Mbit/s. The power supply for the electronics envisaged for the modules will be provided by the CAN Bus; one DCDC converter for each module will perform +12/+5 [V] conversion. The power supply for all the actuators, sensors and the electronics connected after the insulation barrier will be distributed by a Field Power Bus. On the CAN Bus the connection of the three kinds of modules is envisaged: 108 Astatic Lever Controller (CAN Bus#3) 10 Motor Cooling Controller (CAN Bus#1-2-4) 20 (TBC) Temperature Acquisition Module (CAN Bus#1-2-4) All the mentioned modules will be provided with microcontroller for communication protocol management and to control the hardware devices present on the module. From the LCU, via serial I/F and CAN Bus, the functioning parameters are communicated to one module; then the module will implement the closed loop control locally without other intervention of the LCUs. The Astatic Lever Controller and the Motor Cooling Controller will be custom developed as indicated in point 3 of the document. The Temperature Acquisition Module will be implemented by means of commercial solution based on the CAN-CPT100/4 four analog thermal input module, manufactured by ESD; whose characteristics are reported in 8.4. VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 9 3 CUSTOM MODULE DEVELOPMENT AND RELATED MICROCONTROLLER PLATFORM SELECTION To implement the Astatic Lever Controllers and Motor Cooling Controllers, the development of application specific solution is an obliged choice, because no commercial solution able to fulfill completely the application requirements is available. A semi-custom solution based on commercial modules providing connection between CAN Bus and standard analog input/output, together with a minimum of custom electronics for field sensors/actuators connection, leads to a very expensive solution with a low level of integration; this can be critical especially for the implementation of the Astatic Lever Controllers, due to the large number of this kind of modules and due to the limited room available for their accommodation under the primary mirror. The microcontroller platform selected to implement the custom modules is the PIC controller by Microchip. The PIC has been preferred to other commercial platform, such as Siemens, Hitachi, ST Microlectronics for the following reasons: It is better suited for custom developments with low number of pieces to be manufactured The people of OAC involved in the development activities already know the use of PIC It is well supported by development kit for CAN Bus application, using the MCP2510 CAN Bus Communication Controller The following aspects are very effective in terms of reduction of time/risks of the project The following PIC development tools will be employed: - Programmer: PICSTART PLUS or PROMATE II - Emulator: MPLAB-ICE or equivalent - MCP2510 Can Development’s kit, providing both S/W support libraries and CAN I/F evaluation board - In-circuit debugger: MPLAB-ICD - ANSI C Compiler by third party such as CCS, Hi-tech and IAR The PIC component family chosen for the application is the 16F87x, a flash memory microcontroller providing program memory that ranges from 2k to 8k bytes. This component with flash memory will be employed during the development activities because it allows fast programming time (no erasing process is needed) and it allows also the use of the in-circuit debugger; both aspects are speeding up the development time. For the implementation of the final version of the firmware, the 16C6x microcontrollers OTP (one time programmable) family, equivalent to the flash one, will be employed; this components are cost effective and more reliable, concerning memory erasing problems. All the firmware will be written in ANSI C language. OAC TWG will be in charge of the custom modules design and prototype manufacturing. All aspects of functionality, concerning also reliability and EMI/EMC, will be tested before the production of all module electronic boards. The manufacturing will be carried out by specialized companies by means of automatic pick-and-place machines; automatic electrical test, aimed at verifying the mounting and soldering problems, and manual functional tests will be finally performed. The manufactured modules will include a sufficient number of spare module for the maintenance of the subsystems. VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 10 A general architecture diagram of a microcontrolled module for CAN Bus is depicted in the picture Fig. 3.1. The microcontroller is the PIC 16C6x (16F87x for development activities only) by Microchip. It has integrated inside ALU, ROM for firmware storage and RAM for program execution. The CAN Bus Communication Controller for protocol management is the MCP2510 by Microchip, implementing full CAN 2.0 A and B, at 1 Mbit/s of transmission rate. The following components are also present on the module: CANBus and RS-232 line drivers; optoisolated driver for motors or electrovalves activation; optoisolated serial ADC and conditioning electronics to interface external analog sensors, such as temperature sensors and load cells. CANBus Power Lines CANBus Data Lines +12V. GND RS-232 Line drivers and Receiver DC/DC Converter CAN Bus Line drivers and Receiver MCP2510 CAN Communication Controller +5V. PIC 16C6x (16F87x) Microcontroller Serial Comm. Controller ROM ALU RAM I/O Ports from Field Power BUS Optoisolated DAC and Power Drivers Optoisolated ADC and Conditioning Electronics To Electromechanical Devices From Sensors (Temperature sensors; Load cells) Fig. 3.1 – Microcontrolled Module for CANBus General Architecture PICmicro MCU Overview (Note by Microchip) Microchip PICmicro MCUs combine high-performance, low-cost, and small package size, offering the best price/performance ratio in the industry. More than 120 million of these devices ship each year to costsensitive consumer products, computer peripherals, office automation, automotive control systems, security and telecommunication applications. Microchip offers four families of 8-bit MCUs to best fit your needs: PIC16C5X 12-bit program word, PIC16CXXX 14-bit program word, PIC17CXXX 16-bit program word, PIC18CXXX enhanced 16-bit program word and PIC12CXXX 8-pin 12-bit/14-bit program word MCU families. All families offer OTP, low-voltage and low-power options, with a variety of package options. Selected members are available in ROM, EEPROM or reprogrammable Flash versions. The widely-accepted PIC16C5X, PIC16CXXX and PIC17CXXX MCU families employ a modified RISC architecture. Microchip pioneered the use of RISC architecture to obtain high speed and instruction efficiency. VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 11 4 CANBUS#1 DESIGN SPECIFICATION 4.1 DESCRIPTION The CANBUS#1 will be connected to LCU#1 and will have to perform the following tasks: AZ Motors cooling system AZ Motors temperature acquisition AZ structure temperature acquisition The CANBUS#1 configuration will be based on the following items: CAN Bus I/F Board Motor Cooling Controller (performing motor temperature acquisition as well) Temperature Acquisition Module The CANBUS#1 configuration is represented in Fig. 4.1. CAN Bus I/F Board CAN Bus Motor Cooling Controller Motor Cooling Controller Motor Cooling Controller Motor Cooling Controller LCU#1 Electro valve In Out1 ... Electro valve Temperature sensors Out2 In Out1 ... In Out2 ... Electro valve Temperature sensors Out1 Electro valve Temperature sensors Out2 In CAN Bus Temperature Acquisition Module ... Temperature sensors Fig. 4.1 - CANBUS#1 Configuration Temperature Acquisition Module Temperature sensors Out1 ... Temperature sensors Out2 VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 12 4.2 FUNCTIONAL REQUIREMENTS 4.2.1 CAN Bus Interface Board The functional requirements to be fulfilled by the CAN Bus I/F Board are the following: Implementation of one CAN interface Implementation of the physical and data link layer according to the ISO 11898 Implementation of the data link layer according to the CAN 2.0 B standard Addressing capability, as unique master of the network, to communicate with all connected CAN nodes, to send configuration parameter and to acquire data and status information Galvanic insulation of the CAN from LCU, by means of opto-couplers and insulated DC-DC Converters 4.2.2 Motor Cooling Controller The Motor Cooling Controller is devoted to implement the closed loop control of the temperature of the main axes and rotator motors. The temperature are acquired from several sensors by means ADC and conditioning electronics present on the module. The cooling liquid flow is controlled with an electrovalve powered by an electronic driver. More details about the motor cooling system are given [1]. Each controller will be based on the following components: Microcontroller CAN Bus Communication controller CAN Bus Interface drivers ADC and conditioning electronics for temperature sensors Optoinsulated Electrovalve driver RS-232 serial port for monitoring and debugging functions The functional requirements to be fulfilled by the Motor Cooling Controller are the following: Control of the cooling liquid electrovalve by means of linear regulator firmware implemented Acquisition of temperatures from the sensors Implementation of the physical and data link layer according to the ISO 11898 Implementation of the data link layer according to the CAN 2.0 B standard Implementation of monitoring and debugging functions via CAN Bus and local RS-232 serial port Galvanic insulation of electrovalve and sensors, by means of opto-couplers and insulated DC-DC Converters 4.2.3 Temperature Acquisition Module The Temperature Acquisition Module is aimed at telescope temperature acquisition. The following main components will be present on this module: Microcontroller CAN Bus Communication controller CAN Bus Interface drivers ADC and conditioning electronics for temperature sensors RS-232 serial port for monitoring and debugging functions The functional requirements to be fulfilled by the Temperature Acquisition Module are the following: VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 13 Acquisition of temperatures from sensors Implementation of the physical and data link layer according to the ISO 11898 Implementation of the data link layer according to the CAN 2.0 B standard Implementation of monitoring and debugging functions via CAN Bus and local RS-232 serial port Galvanic insulation of sensors, by means of opto-couplers and insulated DC-DC Converters 4.3 PERFORMANCE REQUIREMENTS 4.3.1 CAN Bus Interface Board The performance requirements to be fulfilled by the CAN Bus I/F Board are the following: Data rate: 1 Mbit/s Power supply provided to the CAN interface: +12 V. 4.3.2 Motor Cooling Controller Electrovalve type to be controlled: TBD; maximum requested flow rate: 12 [l/min] Electrovalve electrical characteristics: Power Supply voltage: 24[Vdc] Maximum current: TBD Temperature sensors type: PT100 mod: TBD Temperature acquisition performances: Temperature range: from –15 to +50 [°C] Overall Accuracy: +/- 0.1 [°C] Electrical I/F: 4-wires connection Temperature control accuracy: better than +/-1.5 [°C] 4.3.3 Temperature Acquisition Module Temperature sensors type: PT100 mod: TBD Temperature acquisition performances: Temperature range: from –10 to +30 [°C] Overall Accuracy: +/-0.1 [°C] Electrical I/F: 4-wires connection VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 14 5 CANBUS#2 DESIGN SPECIFICATION 5.1 DESCRIPTION The CANBUS#2 will be connected to LCU#2 and will have to perform the following tasks: ALT Motors cooling system ALT Motors temperature acquisition AZ structure temperature acquisition The CANBUS#2 configuration will be based on the following items: CAN Bus I/F Board Motor Cooling Controller (performing motor temperature acquisition as well) Temperature Acquisition Module The CANBUS#2 configuration is represented in Fig. 5.1. CAN Bus I/F Board CAN Bus Motor Cooling Controller Motor Cooling Controller Motor Cooling Controller Motor Cooling Controller LCU#2 Electro valve In Out1 ... Electro valve Temperature sensors Out2 In Out1 ... Electro valve Temperature sensors In Out2 Out1 ... Electro valve Temperature sensors In Out2 CAN Bus Temperature Acquisition Module Temperature sensors ... Temperature Acquisition Module Temperature sensors Fig. 5.1 - CANBUS#2 Configuration Out1 ... Temperature sensors Out2 VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 15 5.2 FUNCTIONAL REQUIREMENTS 5.2.1 CAN Bus Interface Board See paragraph 4.2.1. 5.2.2 Motor Cooling Controller See paragraph 4.2.2. 5.2.3 Temperature Acquisition Module See paragraph 4.2.3. 5.3 PERFORMANCE REQUIREMENTS 5.3.1 CAN Bus Interface Board See paragraph 4.3.1. 5.3.2 Motor Cooling Controller See paragraph 4.3.2. 5.3.3 Temperature Acquisition Module See paragraph 4.3.3. VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 16 6 CANBUS#3 DESIGN SPECIFICATION 6.1 DESCRIPTION The CANBUS#3 will be connected to LCU#3 and will have to perform the following tasks: M1 Axial and Radial Pads control The CANBUS#3 configuration will be based on the following items: CAN Bus I/F Board Astatic Lever Controller The CANBUS#3 configuration is represented in Fig. 6.1. CAN Bus I/F Board CAN Bus Field Power Bus Astatic Lever Controller #1 Field Power Bus Astatic Lever Controller #1 .... LCU#3 R L Load Limit Cell DC Motor sw itches and Tacho M1 Axial and Radial Pads R L Load Limit Cell DC Motor sw itches and Tacho Fig. 6.1 - CANBUS#3 Configuration 6.2 FUNCTIONAL REQUIREMENTS 6.2.1 CAN Bus Interface Board See paragraph 4.2.1. Two CAN I/F have to be provided. 6.2.2 Astatic Lever Controller The Astatic Lever Controller is devoted to the Astatic Pad DC Motor control; it will be based on: Microcontroller VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 17 CAN Bus Communication controller CAN Bus Interface drivers Opto-insulated Load Cell Interface Opto-insulated Tachometer Interface Opto-insulated DC Motor Driver Software Limit Switches interface RS-232 serial port for monitoring and debugging functions The functional requirements to be fulfilled by the Astatic Lever Controller are the following: Control of the applied force by means of linear regulator Control of the DC motor Acquisition of force from the load cell Acquisition of the end-switches status Acquisition of motor speed from the tachometer Implementation of the physical and data link layer according to the ISO 11898 Implementation of the data link layer according to the CAN 2.0 B standard Implementation of monitoring and debugging functions via CAN Bus and local RS-232 serial port Galvanic insulation of motor and sensors, by means of opto-couplers and insulated DC-DC Converters Provide electrical connection for Axial Pad Magnetic Blocker 6.3 PERFORMANCE REQUIREMENTS 6.3.1 CAN Bus Interface Board See paragraph 4.3.1. 6.3.2 Astatic Lever Controller DC Motor type to be controlled: FAULHABER DC MINIMOTOR mod.1841 16/5 1596:1 DC Motor electrical characteristics: Power Supply voltage: 24 [Vdc] Maximum Current: 300 [mA] Load Cell sensors type: LEBOW mod.3167-500 Force acquisition performances: Force range: 0-500 [N] TBC Overall Accuracy: TBD Max excitation voltage: 20 [Vdc] or 20 [Vac rms] Bridge nominal resistance: 350 [Ohm] Output at rated capacity: 2 [mV per V] VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 18 7 CANBUS#4 DESIGN SPECIFICATION 7.1 DESCRIPTION The CANBUS#4 will be connected to LCU#3 and will have to perform the following tasks: ROT Motors cooling system ROT Motors temperature acquisition ALT structure temperature acquisition The CANBUS#4 configuration will be based on the following items: CAN Bus I/F Board Motor Cooling Controller (performing motor temperature acquisition as well) Temperature Acquisition Module The CANBUS#4 configuration is represented in Fig. 7.1. CAN Bus I/F Board CAN Bus ROT Motor1 Cooling Controller LCU#3 Electro valve In Out1 ROT Motor 2 Cooling Controller ... Electro valve Temperature sensors Out2 In Out1 Temperature Acquisition Module ... Temperature Acquisition Module ... Temperature sensors Temperature sensors Out2 Fig. 7.1 - CANBUS#4 Configuration Temperature sensors VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 19 7.2 FUNCTIONAL REQUIREMENTS 7.2.1 CAN Bus Interface Board See paragraph 4.2.1. Two CAN I/F have to be provided. 7.2.2 Motor Cooling Controller See paragraph 4.2.2. 7.2.3 Temperature Acquisition Module See paragraph 4.2.3. 7.3 PERFORMANCE REQUIREMENTS 7.3.1 CAN Bus Interface Board See paragraph 4.3.1. 7.3.2 Motor Cooling Controller See paragraph 4.3.2. 7.3.3 Temperature Acquisition Module See paragraph 4.3.3. VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 20 8 HARDWARE COMPONENTS DESIGN SPECIFICATIONS 8.1 CAN BUS I/F BOARD In this paragraph the features of TEWS DATENTECHNIK TPMC816 2 Channels CAN Bus PMC Module and the ESD VME-CAN4 Intelligent CAN Bus I/F Board for VME Bus are reported. TEWS DATENTECHNIK TPMC816 2 Channels CAN Bus PMC Module Features - Standard single-width 32-bit PMC module conforming to IEEE P 1386.1 - PCI 2.1 compliant interface - CAN Bus I/F based on Intel 82527 chipset - Supporting CAN Specification 2.0 part A and B - Max tranfer rate equal to 1 Mbit/s - Phisical interface CAN High Speed (according to ISO 11898) and modified RS485 per channel - Phisical I/F optically insulated from CAN Controller by onboard DC/DC converter per channel OS support -VxWorks -pSOS -OS-9 ESD VME-CAN4 Intelligent CAN Bus I/F Board for VME Bus. Intelligent CAN Controllers - Full CAN controller by integrated firmware for any identifier - Each channel with separate micro controller (68331/20Mhz) and its own CAN controller (SAJ1000) - Lossless data exchange with VMEbus via Shared RAM and FIFOs CAN Layer - CAN layer according to ISO 11898 with 9-pole DSUBs or DeviceNet interface - Data transfer rate up to 1 Mbit/s - Each channel electrically isolated by optocouplers CAN Protocol Support - CAL/CMS and CANopen - DeviceNet - SDS Smart Distributed System - Multi-Net support OS support -VxWorks -LynxOS -OS-9 -UNIX VST Project Technology Working Group Osservatorio Astronomico di Capodimonte Napoli Date: 09.11.2000 Page: 21 8.2 ASTATIC LEVER CONTROLLER The Astatic Lever Controller is devoted to the Astatic Pad DC Motor control; it will be custom developed and based on: Microcontroller for communication with CAN Bus CAN Bus Interface drivers Opto-insulated Load Cell Interface Opto-insulated Tachometer Interface Opto-insulated DC Motor Driver Software Limit Switches interface RS-232 serial port for monitoring and debugging functions Two limit switches will be provided. The Limit Switches are read out by the microcontroller and are used to avoid out of range actuator movement. 8.3 MOTOR COOLING CONTROLLER The Motor Cooling Controller will be custom developed and devoted to implement the closed loop control of the temperature of the main axes and rotator motors. The temperature are acquired from several sensors by means ADC and conditioning electronics present on the module. The cooling liquid flow is controlled with an electrovalve powered by an electronic driver. Each controller will be based on the following components: Microcontroller for communication with CAN Bus CAN Bus Interface drivers ADC and conditioning electronics for temperature sensors Optoinsulated Electrovalve driver RS-232 serial port for monitoring and debugging functions 8.4 TEMPERATURE ACQUISITION MODULE In this paragraph the features of ESD CAN-CPT100/4 module implementing the Temperature Acquisition Module are described. - Num. of input sensors: 4 Sensors type: PT100 A/D Converter resolution: 12 bits Linearity error: +/- 1 LSB Max sampling rate: 2.5 kHz/channel Module operating voltage: 24 [Vdc] CAN Layer ISO 11898, 1 Mbit/s