Quiz: TQM

advertisement

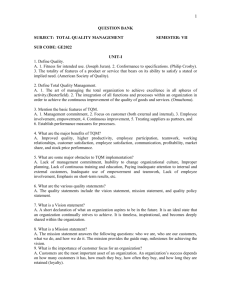

Quiz: TQM - Managerial 1. TQM is about meeting quality expectations defined by a. b. c. d. e. 2. The quality of services is often defined by perceptions that are highly a. b. c. d. e. 3. Poka-yoke Kaizen*** Kanban Muda Automation Quality at the source involves a. b. c. d. e. 5. Subjective*** Reliable Regarded Defined Tangible The Japanese term for continuous improvement is a. b. c. d. e. 4. Marketing Top management The sales force The customer*** The quality control group Discarding defective items after production Inspecting goods after they are produced Sending defective products back for rework Inspection of raw materials Identifying quality problems at the source and correcting them*** Giving workers responsibility for seeking out quality problems and correcting them is a. Continuous improvement b. c. d. e. 6. Studying business practices of companies considered “best in class” is called a. b. c. d. e. 7. They are given a bonus They are allowed to participate in competitive bidding Their contract is renewed They are nominated for an award Their materials do not have to be inspected upon arrival*** Which of the following is not an important cost of poor quality? a. b. c. d. e. 9. Pairwise comparison Benchmarking*** Competition Dreamscaping Discouraging Under TQM, if suppliers meet preset quality standards a. b. c. d. e. 8. Passing the buck Brainstorming Employee empowerment*** Employee involvement Product recalls Litigation resulting from product liability issues Loss of business Overhead*** Dissatisfied customers Quality planning, employee training in quality measurement, and cost of maintaining records of information and data related to quality are example of what type of costs. a. b. c. d. e. Internal failure External failure Appraisal Prevention*** Replacement 10. Costs of quality inspections, testing, test equipment, and labs are examples of what type of costs. a. b. c. d. e. 11. Machine downtime due to failures in the process, scrap, and rework are examples of what type of costs. a. b. c. d. e. 12. Scrap Litigation costs resulting from product liability issues*** Rework Quality inspections Employee training Warranty claims, customer complaints, and costs of litigation are examples of what type of costs. a. b. c. d. e. 14. Internal failure*** External failure Appraisal Prevention Replacement External failure costs include a. b. c. d. e. 13. Internal failure External failure Appraisal*** Prevention Replacement Internal failure External failure*** Appraisal Prevention Replacement The plan-do-study-act cycle is often called the a. b. c. d. e. 15. A useful tool for translating customers’ everyday language into specific technical requirements is a. b. c. d. e. 16. Translating scores into specific product characteristics Evaluating how the product compares with its major competitors Setting specific goals to address the specified problems Identifying important customer requirements*** Numerically scoring customer requirements based on their importance In using quality function deployment, one way to find out precisely what features customers want in the product is a. b. c. d. e. 18. Quality function deployment*** Quality circles Quality of design Scatter diagrams Cause-and-effect diagrams Quality function deployment begins by a. b. c. d. e. 17. TQM activity approach Deming wheel*** Continuous improvement cycle Quality circle Action wheel Interviewing the company sales force Analyzing the changes in features historically Asking top management Talking to process engineers Conducting focus groups*** The important thing in quality function deployment competitive evaluation is a. b. c. To evaluate the financial strength of competitors To identify customer requirements that should be pursued and how we fare relative to our competitors*** Speed of introduction d. e. 19. The strength of the relationship between customer requirements and product characteristics is shown in the a. b. c. d. e. 20. Checklists Scatter diagrams Pareto analysis Cause-and-effect diagrams*** Flowcharts Cause-and-effect diagrams are often called a. b. c. d. e. 23. Determining how to advertise Setting targets for our own product*** Determining how to attack our competitors’ products Designing the product Comparing results with past sales What quality control tool resembles a "fishbone?" a. b. c. d. e. 22. Trade-off matrix Product matrix Relationship matrix*** Strength matrix Inverse matrix The last step in constructing the house of quality includes a. b. c. d. e. 21. The number of competitors Knowing our product well Checklists Scatter diagrams Pareto analysis Fishbone diagrams*** Histograms What is a schematic diagram of the sequence of steps involved in an operation or process? a. b. c. d. e. 24. What tool is useful in helping everyone develop a clear picture of how an operation or process works? a. b. c. d. e. 25. Number of occurrences of these defects.*** Relative importance of these defects. Attributes of these defects. Costs of these defects. Visibility of these defects. Scatter diagrams are particularly useful in detecting the degree of linear relationship between two variables. This linear relationship is also called a. b. c. d. e. 27. Control chart Pareto analysis Checklist Flowchart*** Scatter diagram A checklist is a list of common defects and a. b. c. d. e. 26. Checklist Control chart Scatter diagram Flow chart*** Process chart Correlation*** Heteroscedasticity Agreement Disagreement Causality A technique used to identify quality problems based on their degree of importance is a. b. Deming Pareto*** c. d. e. 28. A chart showing the number of defects that result from different causes would be used in a. b. c. d. e. 29. Scatter diagram Control chart Histogram*** Flow chart Process chart Who is often referred to as the father of quality control? a. b. c. d. e. 31. Pareto analysis*** Flowcharts Cause-and-effect diagrams Benchmarking Control charts Which of the following shows the frequency distribution of observed values of a variable. a. b. c. d. e. 30. Davis Crosby Juran W. Edwards Deming*** Joseph Juran Philip Crosby Martin Marietta Count Pareto Deming pointed out that 85% of quality problems are caused by a. b. c. d. e. Worker error Numerical quotas Processes and systems*** Carelessness Suppliers 32. What did Deming believe is the key to improving quality? a. b. c. d. e. 33. Which of the following is not attributed to Philip Crosby? a. b. c. d. e. 34. The concept of the quality trilogy*** The phrase “Do it right the first time.” Stressed the idea of prevention of defects The notion of zero defects The phrase “Quality is free.” The most important factor in the success or failure of TQM efforts is a. b. c. d. e. 35. Employee training Process design Properly functioning equipment Having good suppliers Improving the system*** Getting started quickly The use of statistical process control The genuineness of the organization’s commitment*** The use of cause-and-effect diagrams Employee training A company cannot achieve high quality if a. b. c. d. e. Marketing understands the changing needs and wants of customers by working closely with them Finance translates general definitions of quality into vague dollar terms*** Accounting has accurate costing methods Engineering properly translates customer requirements into specific engineering terms Human resources hires employees with skills necessary to work in a TQM environment Homework: TQM - Managerial 1. Is the goal of Six Sigma quality realistic for services such as Blockbuster Video Stores? A goal of Six Sigma can also be used for services. The one area where Six Sigma maybe difficult is that many aspects of service quality are based upon customer perception--for example--the courtesy of the clerk. In spite of all efforts, someone may perceive that the clerk was not courteous. But in spite of this problem, every effort should be made to attain Six Sigma in both manufacturing and service settings. 2. The typical computerized word processing package is loaded with poka-yokes. List three. Are there any others you wish the packages had? When exiting the word processor, a prompt asks whether or not you want to save the document. (ii) Many word processors will make backup files at various points in time. (iii) Many word processors will automatically correct certain words when they are misspelled, such as “the.” Word processors have made tremendous strides in this area. Although it would be nice if the word processor checked the form of a word like “to,” too,” and “two.” 3. Shingo told a story of a poka-yoke he developed to make sure that operators avoided the mistake of putting less than the required four springs in a push button device. The existing method involved assemblers taking individual springs from a box containing several hundred, and then placing two of them behind an ON button and two more behind an OFF button. How could you pokayoke this operation? One common poka-yoke is part kitting. By kitting individual boxes of four springs, operators could make sure no springs remain in the box after the assembly operations. Exercise: TQM - Managerial Consider the following basic definition of service quality: Excellent quality Good quality Poor quality Very poor quality = = = = you you you you would would would would highly recommend this service recommend this service not recommend using this service recommend against using this service Choose one of the following service situations: Auto brake job Executive search firm Financial planning Used car sales Landscaping Federal Express Temporary office help agency Public utility (elec. or gas) Trash pickup-city or private U.S. Army combat unit Pet grooming Hospital emergency room Purchasing dept. in mfg firm Information systems department American Express Card Catered wedding Computer repair Theme park U.S. Postal Service State auto license bureau Movie theater Nursing care Dome stadium Pre-school Gambling casino Barber/beauty shop Security service Photo developing One-day training seminar City police department Rock concert Travel agent Interior decorating Car wash Airline Defense attorney Dry cleaner Accounting firm Bank checking account Mexican restaurant Newspaper Student copy service ......or choose any other service not on the list ( but check with the me for an OK). Specific Service Chosen: Explain All Your Answers – “Yes” or “No” is not acceptable. 1. Is there a physical product involved? Which is dominant, the product or the service? Physical products involved in airlines and restaurants are food and seating. 2. How unique or how standardized is the product and/or service from the same company from one time to the next? A car wash is standardized, while an emergency room visit is customized. 3. Give three specific examples of characteristics of the product and/or service that would determine how well the quality of the service is rated. Speed, courtesy, taste, comfort, etc. 4. Is the customer involved in the production and delivery of the service? How? The customer is typically involved in the service industry. They come to place the order – make their selections – and then wait for the service. For example, they are part of production and delivery when they are getting a haircut – decide what to have done and have it done. 5. What is an example of a critical defect? a major defect? a minor defect? Critical defect is the worst possible problem (i.e. plane crash, food poisoning, hair falls out). Major defect is a bad problem, but not as bad as a critical defect (i.e. hair turns orange, plane is stuck on runway for hours and runs out of food and drinks). Minor defect is just a small problem (i.e. plane is a few minutes late, wrong change is given) 6. Give two or more examples of the cost(s) of a defect for the company? A defect may mean payments for a lawsuit settlement, lost customers, and the cost of repairing the item. 7. After the service is delivered, is corrective action possible? restitution? Many times both are possible. The wrong hair color can be fixed. We can give a refund of the cost of the hair coloring. 8. Is service quality most affected by the contact employee, by technology, or by management? Explain your choice. It depends on the service chosen. 9. Is service quality the same as customer satisfaction? They are not the same. Service quality factors can affect satisfaction.