SIEMENS 36 F

advertisement

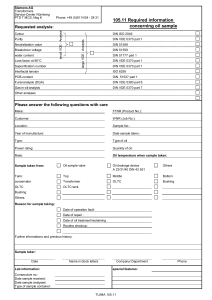

Transformer installation instructions 105. Insulating fluid 105.11 Notes concerning oil sample An oil sample is a major help in monitoring the quality of oil filled transformers and reactor coils. Great care should be taken when the sample is drawn off during transport to ensure that the test results represent the state of the transformer. Please note that we perform and charge for a KWIKSKRENE test every oil sample in order to protect our equipment from polychlorinated biphenyls. Please answer the following questions with care. Make: FTNR (Product No.): Customer: WNR (Job. No.): Location: Sample No.: Year of manufacture: Date sample taken: Type: Type of oil: Power rating: Oil temp. when sample taken: Transformation: Load when sample taken: No. Of operations of tap changer: Sample taken from: Oil sample tap Oil drainage device. A 22/31/40 DIN 42 551 Tank: Top Load transfer switch: LT tank Expansion tank: Transformer Middle Bottom LT Bushing pocked Transducer Execution: Reason for taking sample: Fill with new oil on: Quantity: (t) Topped up on: Quantity: (t) Fault on: Tests desired: See next page Test cerificate in German language Repaired on: English language Oil treatment on: French language Routine inspection: Further information and background: Sample taker: Date: Name in block capitals Company/Dept. Tel. Maintenance engineer responsible: Acceptance engineer responsible: Lab Information: Serial number.: Date sample received: Date sample analyzed: Type of sample vessel: Alle Rechte vorbehalten © Siemens AG 1997, EV LT SCN Special features: TUMA 105.11 1/2 06.97 de (Ersetzt TUMA 105.11 1/2 8.93 D) Transformer installation instructions General instructions concerning the taking of oil samples (See also Installation instruction TU MA 105.03) One liter of oil is required for an oil test; suitable sample bottles may be borrowed form corresponding Siemens AG branch office. For oil gas analysis, one liter of oil is required. * For a PCB test, at least 50 ml of oil is required. Tap-off point for oil gas analysis: normally top of tank Tap-off point for other tests: normally bottom of tank 1. Use clean 1-litre bottles with gas-tight closure to hold the sample. 2. Special aluminum bottles with plastic screw caps are generally used. The sample bottles must close so tightly that no air can be drawn in during cooling. 3. If glass bottles are used, the oil sample should not be drawn off unless you are sure that the temperature of the sample is higher than or equal to the storage or dispatch temperature. If not, please consult the test laboratory. 4. Samples for gas analysis should always be taken using the overflow method. The operations described under 5 and 7 below should be carried out quickly and without interruption so as to prevent the sample from coming into contact with the atmosphere as far as possible. 5. Method of drawing oil from the oil sample tap Screw onto the tap o coupling element with seal, hose fitting and oil proof hose (30 to 50 cm long) turn the tap on and fill the outer vessel with 2 to 3 liters of oil (from the outlet pipe).Insert the hose in the bottle so that its end is just short of the bottom of the bottle. Turn the tap on and fill the bottle from the bottom upwards, slowly at first and then quickly until two or three times the content of the bottle have overflowed into the outer vessel. Finally, reduce the flow from the tap and, with oil still flowing, pull the bottle downwards off the hose. Seal the bottle immediately. 6. Method of drawing oil from the drainage device A22/31/40 DIN 42 551; this method is not suitable for gas analysis. Put the outer vessel (5) under the oil outlet. Use an open-ended spanner to unscrew the cap (contains some oil) Carefully unscrew the square-headed inner plug screw (6.2) until oil starts to flow from the outlet (6.3). Rinse the bottle with some oil. Screw the cap (6.1) back on by hand to stop the oil flow. Fill the bottle (4) almost full by opening the cap (6.1) again. Seal the bottle (4) and label it. 7. The method of drawing oil from the drainage device A22/32/40 DIN 42 551 with the aid of a length of hose is analogous to that described under 5 above, the drainage device being operated as described under 6 above. 8. Dispose the oil in the outer vessel in the proper way. Fig 1: Taking an oil sample with oil sample bottle and outer vessel 1 2 3 4 5 Transformer tank Oil sampling tap Hose Oil sample bottle Outer vessel Proposition for routine check Tests available: Test desired Aging state Dryness state Fault free PCBcontamination After occurrence of fault or damage Used oil Duty to mark ordinance under PCB banning ordinance Color DIN ISO 2049 Purity DIN VDE 0370 Part 1 Neutralization value DIN 51558 Saponification value DIN 51559 Loss factor at 90°C DIN VDE 0370 Part 1 Breakdown voltage DIN VDE 0370 Part 1 Water content DIN 51777 Part 1 Oil classification number required only when PCB < 50 ppm PCB-preliminary test* (KWIK-SKRENE quick test) 20 ppm PCB-preliminary test* (KWIK-SKRENE-quick test) 50 ppm PCB –content without DIN 51527 Part 1 Quick test PCB –content where quick test> 50 ppm DIN 51527 Part 1 HALOGEN- or chlorine content DIN 51577 Part 3 Total gas content Gas analysis Measuring the gas content and performance of gas analysis are possible only when the oil sample has been drawn off through a hose without bubbles (see Figs. 1a and 1c) * PCB-PCB tests in conformity with DIN 51 527, chlorine content tests in conformity with DIN 51577 and gas analysis can be performed in Nuremberg only. Alle Rechte vorbehalten © Siemens AG 1997, EV LT SCN TUMA 105.11 2/2 06.97 de (Ersetzt TUMA 105.11 1/2 8.93 D) Transformer installation instructions Siemens AG EV TWN QM Katzwanger Straße 150 D-90461 Nürnberg Siemens AG EV TBD FS Scharfenberger Str. 66 D-01131 Dresden Alle Rechte vorbehalten © Siemens AG 1997, EV LT SCN Siemens AG EV TWK QFM Hegelstraße 20 D-73230 Kirchheim/Teck Siemens AG EV TWK SCB Cruismannstraße 48 D-44807 Bochum - Riemke TUMA 105.11 2/2 06.97 de (Ersetzt TUMA 105.11 1/2 8.93 D)