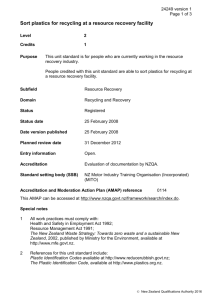

resourcestewardship-3

advertisement