Thomas Viggiano Summary:

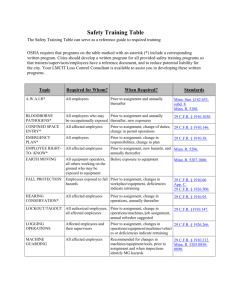

advertisement