-It is hard to store empty aluminum beverage cans and not let them

advertisement

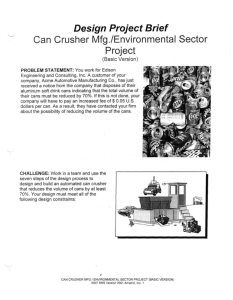

-It is hard to store empty aluminum beverage cans and not let them mount up and overflow your recycling bin. Inventors aim for classical American problems that when solved bring in a plethora of revenue. But when multitudes of possible solutions never really leave the shelves to fill homes it means that the problem has not really been solved. Our team came in to tackle a can-buyer’s problem much like this and vowed to prototype a working solution competitive in the American market. Of course maybe it wouldn’t take off or make millions but would give other engineering companies a run for their money while working with nothing but our school’s project lead the way. After running through multitudes of problems we decided to tackle that of the overload of used cans in home recycling bins. Our personal recycling bins- we noticedwere all overflowing with used cans. We found this curiously interesting and after conversing with classmates at school we realized something important. While everyone dislikes crushing sticky used cans no one but two people in our class has a can crusher for home use. This was our final deciding factor in choosing our problem statement. Because even though can crushers are already easy to use, cheap, and durable they are still not in use in every American home. This proves that there is something missing in today’s solutions. Ergo, it is hard to store aluminum beverage cans and not let them mount up and overflow your recycling bin. In order to justify this problem we didn’t just want to ask a handful of students but a variety of people of all ages and people from out of school as well. We wanted to make sure that the problem was an issue for others outside of our group of academy students. One hundred and twenty people were surveyed, questioned on their opinion of aluminum can buildup. What we came up with is a mass of data resulting in one common conclusion- that the buildup of cans is a widespread problem and although there are solutions in place to solve this; they have obviously not solved the problem since it is still a general issue. In addition to a public opinion we wanted an expert’s view on this issue as well. For this we consulted the experts we had previously spoken to. Their outlook on our situation was to make sure we made our prototype different somehow; so that it would stand out from the crowd and sell. We had mentioned including a container to attach to the can crusher that the extra liquid could leak into, and every expert contacted thought positively of this idea. As a group we decided that the extra trouble with building, maintaining, and cleaning this would be worth the trouble. This satisfied the group and made us on our way to a successful prototype. In order to produce a successful prototype there must be research done to make sure that the prototype is different and enhanced from past items. From the first to the last can crusher manufactured in history each one has emphasized a quality; each quality has made it sell in its own right but at the same time constrained the marketability. Upon completing research the compiled models were examined for best and worst qualities; these were noted in order to not reproduce negative features. Right after compiling model research we took it upon ourselves to briefly look up can crushing patents online. When creating our product we were aiming to make it as real as possible and this meant not recreating something previously patented. The models we looked up were all great prototypes. There was solutions to every market-target who used or crushed cans. Qualities such as pricing, material and what-the item-is-powered-by differed depending the market target. When targeting a large company the can crusher tends to move from man powered to electrical. In other cases they were also powered by hydraulics, but over all they seemed to agree upon not using one once of human force. With these higher-end crushers they also tended to be made of steel and geared towards lasting more than a decade. These quality features however show up in the price tag. Along with being an amazing can crusher it can really only be afforded by a company who uses a lot of cans. So if the market-target isn’t large companies then the other solution is making it geared towards use by the regular aluminum-can-purchasing Joe. These models still emphasize qualitative but relinquish features such as metal based or push-button use. All are human powered and are made of some type of plastic. With these models the trade-off is also the price tag. It can start at about ten dollars and these can also last many years. Sure they may take some effort to use and it may get tedious to do one after another after another, but you wont have to mess with crushing them with your foot; or your forehead in some people’s case. Our research brought us to a wealth of solutions. The first decision was in making the product for home use and not over engineering it to be powered by hydraulics or even electricity. Making it too expensive would be the first flaw in the design and we were aiming for home-use, not corporate. Next step in line was evaluating how many moving parts it would have. In our primary inventor drawing designs we decided to make a ratchet and pinion device that we could turn like a jack-in-the-box that would crush the cans without much needed force. After finishing the product however, we were left with a block of wood that we jammed down a cubic prism that crushed cans. This in turn worked out for the better and required much less effort than the product would have originally, made it less expensive, and required less maintenance. The first set of models we researched were made to crush one can at a time. This must have been intended for home use; but as previously stated, designing a feature just for a certain market-such as home owners- can harm sales instead of helping. Crushing one can at a time can become a tedious task. When you are a homeowner attempting to crush sixty cans after a party owning a multiple can crusher seems the better option. When considering it, it can take a quarter of the time crushing cans with a four-can can crusher. This simple reason kills sales for single-can can crushers. From this we learned not to overdo the number of cans to be crushed but also not undermine it. Most importantly we learned not to focus on a quality or feature so that it benefits a certain market output while underestimating another. Over engineering is another factor that needs to be watched out for. Making it too big or sturdy is something that also pushes away potential customers. Making a can crusher out of steel would be superfluous to the design due to the costly effect. Likewise making it out of thin plastic may lower the price significantly but it wouldn’t last more than a few uses. It is imperative to use the proper material and keep the price economical for its buyers. Along with over engineering comes Our efforts combined qualities so that we didn’t overemphasize any one in specific or underrate any either. In the end our product reached an equilibrium regarding features and kept the procedure as simple as one, two, three. Along with this simplicity we plan in making the price-tag according to most family’s budgets. We want the quality to stay great and lower the price as much as we can. Originally it was going to involve a ratchet and pinion mechanism that would raise the price and maintenance but as we went along it changed into this simple machine. By changing this it immediately reflected better results in our data. The results told us that the higher number of cans crushed- by using our new model- used less human force; which in turn meant that the older, lesscapable folks won’t have such a hard time crushing their cans. Like Cotie. All in all it is our hopes that can crushing turns to be a problem of the past. The extensive research shows that solutions today- although well-priced, of quality and aesthetic- are still missing something the customer wants. Further research and tests has brought us to our solid prototype that we hope holds what the customer is looking for. We feel our rugged design is perfect for any customer regardless of age; it is strong and durable yet light enough for grandma to go on a crushing spree. It may not be the new item seen in every home of America but it definitely solves the problem of overflowing cans in recycling bins. Joe Cotton Daniel Villanueva Patrick Hepner Can Crusher EDD Stephen Buchs 4.13.09 References Basic Multi Can Crusher 77703. (2007, July 2). Retrieved April 13, 2009, from http://www.thegreathardwarestore.com/ProductDetails.asp?ProductCode=58781 6&click=2744 CRI - Aluminum Recycling Rates. (n.d.). Retrieved April 13, 2009, from http://www.container-recycling.org/alum_rates.htm Can Crusher - Can Crusher @ As Seen On TV Guys Store. (n.d.). Retrieved April 13, 2009, from http://www.asseenontvguys.com/index.asp?PageAction=VIEWPROD&ProdID= 402 Can Manufacturers Institute. (n.d.). Retrieved April 13, 2009, from http://www.cancentral.com/funFacts.cfm EZ Can Crusher - Aluminum Can Crushers and Containers. (2008, December 18). Retrieved April 16, 2009, from http://recycal.stores.yahoo.net/ezcancrusher1.html Herkules HCR-3 Economy Bench Top Can Crusher. (n.d.). Retrieved April 13, 2009, from http://www.handsontools.com/Herkules%20HCR3%20Economy%20Bench%20Top%20Can%20Crusher_p_9307.html?utm_sour ce=googlebase&utm_medium=shopping&utm_term=Select&utm_content=Selec t&utm_campaign=broi&thissku=9307&site=google_base Monarch Power Can Crusher - Aluminum Can Crushers. (2008, April 30). Retrieved April 13, 2009, from http://www.recyclingsupply.com/mopocancr.html Other Kitchen Organizers - Multi-Can Aluminum Can Crusher. (2008, December 16). Retrieved April 13, 2009, from http://www.organizeit-online.com/multicanaluminum-crusher-p1066.html?m1track=googlebase&utm_campaign=export_feed&utm_medium=G oogle+Base&utm_source=googlebase&language=en&osCsid=46f894299fefa805 a43aa233185c3283#googlebase THE CRUSHER CAN CRUSHER Can lid with can crusher 30210 PACIFIC PRECISION METALS. (2008, October 8). Retrieved April 13, 2009, from http://www.acehardwaresuperstore.com/the-crusher-can-crusher-can-lid-withcan-crusher-p-57130.html?ref=42 Created at www.bibme.org