Survey of the Microbiological Examination of Fresh Cream Cakes

advertisement

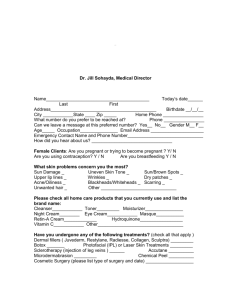

Report of the Cheshire, Cumbria, Greater Manchester, Lancashire and Merseyside Food Liaison Groups and FEMS North West Survey of the Microbiological Examination of Fresh Cream Cakes K Williamson, G Allen, F J Bolton FEMS North West Date of Report: 15 September 2008 Survey No: 804001 Introduction A wide variety of fresh cream cakes are consumed in the UK and outbreaks of food poisoning associated with cream cakes have been recorded worldwide, many due to Salmonella. Several local authorities have expressed concern relating to the frequency of high aerobic colony counts and unsatisfactory levels of indicator organisms in routine samples of cakes containing dairy cream. Poor hygiene practices have also been observed during inspection of premises retailing cream cakes in relation to temperature control, improper use of equipment and handling. Local authorities have also questioned whether the four hour temperature regulations exemption rule which is applicable to cream cakes could affect the microbiological quality, and whether category 3 of the PHLS ready to eat food guidelines (1) is suitable for assessing the microbiological quality of cakes filled with fresh cream. Hence the purpose of this survey was to determine and compare the microbiological quality of cream cakes sampled from refrigerated and ambient display units in a wide range of retail and catering premises. Additionally a questionnaire relating to premises, preparation and display conditions was analysed so that risk factors associated with microbiological quality and safety could be identified. Materials and Methods Sample Collection This survey was carried out as part of the Cheshire, Merseyside, Cumbria, Greater Manchester and Lancashire Food Liaison Groups sampling programme in coordination with FEMS-NW laboratories during March – June 2008. Additionally Flintshire participated from the North Wales Food Liaison Group. Samples of any type of cake containing dairy cream were purchased/sampled from a wide range of catering and retail premises. The cakes were served/collected from either refrigerated or ambient display in their usual retail packaging. The samples were placed in food grade plastic bags and transported to the laboratory at 0-8C. Information relating to premises, preparation and display unit was recorded onto a modified FEMS-NW request form (Appendix 1). KW/KLM (27/08) Page 1 of 9 Sample Examination A total of 571 cream cake samples were submitted by 42 North West authorities to their FEMS-NW testing laboratory (Appendix 2). Samples were examined using UKAS accredited test methods for aerobic colony count/g (ACC), Enterobacteriaceae/g, E. coli/g, Staphylococcus aureus/g, Bacillus cereus/g, Bacillus spp/g, L. monocytogenes/g, Listeria spp/g and for the detection of Salmonella/25g and Listeria/25g. Isolates of L. monocytogenes were referred to HPA, Colindale for epidemiological typing. Microbiology Results Table 1. Microbiology Results (n = 571) Detected Not detected <10, <20 ACC/g Enterobacteriaceae/g 292 557 564 E.coli/g S.aureus/g Bacillus cereus/g Bacillus spp(not B.cereus)/g L.monocytogenes/g/in 25g Listeria spp (total)/g/in 25g Salmonella in 25g 13 26 0 Table 2. 558 545 571 568 568 10,20-<102 102-<103 103-<104 104-<105 105-<106 106-<107 107-<108 >108 26 119 7 4 555 532 3 3 73 84 7 2 14 30 0 0 132 50 0 0 1 5 0 0 78 21 0 1 0 2 0 0 102 5 0 0 1 1 0 0 67 0 0 0 0 0 0 0 89 0 0 0 0 0 0 0 4 0 0 0 0 1 0 0 Relevant parameters in Category 3 of PHLS guidelines (1) Microbiological quality (cfu/g) unless stated Satisfactory <105 Aerobic colony count Acceptable Unsatisfactory 105 - <106 4 106 Unacceptable/Potentially Hazardous N/A 104 N/A 104 Enterobacteriaceae <100 100 - 10 E. coli <20 20 - <100 S. aureus <20 20 - <100 100 100 - <104 Bacillus cereus and other pathogenic Bacillus spp <103 103 - <104 104 - <105 105 Listeria monocytogenes <20 20 - <100 N/A Listeria spp (total) <20 20 - <100 100 100 N/A Salmonella N/A Not detected/25g Table 3. Microbiological results using microbiological guidelines (1) Satisfactory Acceptable 271 (47.5%) 131 (23%) Table 4. Detected/25g Unsatisfactory 166 (29%) Listeria spp. identification (n = 26) Identification L. monocytogenes L. innocua L. seeligeri KW/KLM (27/08) Category No. of isolates 13 8 5 Page 2 of 9 3 of the PHLS Unacceptable/potentially hazardous 3 (0.5%) Table 5. Listeria monocytogenes serotype (n = 13) Serotype 1/2a 4 1/2c 1/2b Not typable No. of isolates 6 2 2 1 2 Tables 1 and 3 summarise the microbiology results and demonstrate that 30% of samples were of unsatisfactory quality based on Category 3 of the PHLS guidelines (1). The ACC of >106 in 160/571 (28%) was the main cause of unsatisfactory results. Other unsatisfactory results were due to high levels of: Enterobacteriaceae 26/571 (4.5%), E. coli 7/571 (1.2%), Bacillus spp 4/571 (0.7%) and Staphylococcus aureus 3/571 (0.5%). Three samples were of unacceptable and potentially hazardous quality due to high levels of pathogenic Bacillus spp, (B. subtilis >105/g, B. cereus >105/g, and one sample with B. subtilis >105/g, and Staphylococcus aureus at >104/g). No samples were unsatisfactory due to Listeria spp and Salmonella was not detected in any of the samples. Listeria spp was detected at low levels in 26 (4.6%) samples with L. monocytogenes detected in 13 (2.3%) (10 at <10/g and 3 at 10-100/g). The most common serotype was 1/2a (6 isolates), as demonstrated in Table 5. Questionnaire results The questionnaire results were related to the microbiological quality in the following tables. Table 6. Q.1 Microbiological quality related to type of premises (n = 571) Baker (n=370) Café (n=54) Corner shop (n=6) Delicatessen (28) Local branded grocer (n=13) Market stall (n=10) Mobile vendor (n=1) Public house (n=3) Restaurant (n=10) Supermarket (n=68) Not stated (n=8) TOTAL (n=571) Satisfactory Acceptable Unsatisfactory 156 (42%) 29 (54%) 2 8 (28.5%) 7 (54%) 1 (10%) 1 2 5 (50%) 55 (81%) 5 99 (27%) 7 (13%) 1 7 (25%) 2 (15%) 4 (40%) 0 0 0 9 (13%) 2 113 (30.5%) 17 (31.5%) 3 13 (46.5%) 4 (31%) 5 (50%) 0 1 5 (50%) 4 (6%) 1 Unacceptable/potentially hazardous 2 (0.5%) 1 (1.5%) 0 0 0 0 0 0 0 0 0 271 (47.5%) 131 (23%) 166 (29%) 3 (0.5%) Market stalls and restaurants produced the highest proportion of unsatisfactory results (both 50%) although sample numbers were low (n = 10). In comparison 94% of the samples from supermarkets were acceptable/satisfactory. KW/KLM (27/08) Page 3 of 9 Table 7. Q2. Was the cream cake refrigerated? (n = 554) Yes No 537 17 Information not supplied 17 The majority of businesses (97%) served the cake from a refrigerated display. Table 8. Q.3. Microbiological quality – temperature of the display cabinet/area (n = 542) Refrigerated and displayed at 0-8oC (n=457) Refrigerated and displayed at >8oC (n=74) Not refrigerated and displayed at >8oC (n=11) Satisfactory Acceptable Unsatisfactory 220 (48%) 107 (23.5%) 128 (28%) Unacceptable/potentially hazardous 2 (0.5%) 32 (43%) 16 (22%) 25 (34%) 1 (1%) 5 (46%) 2 (18%) 4 (36%) 0 86% of the refrigerated display units were operating between 0-8C. An increase in unsatisfactory results was demonstated with an increase in display temperature. Table 9. Q.4. If not refrigerated, how long had the product been on display? (n = 17) Less than 4 hours 12 Greater than 4 hours 0 Information not supplied 5 From the information supplied no samples had been displayed/stored at ambient temperature for >4 hours. Table 10. Q.5. Microbiological quality – was the cream cake prepared on the premises? (n = 539) Yes (n=210) No (329) Satisfactory Acceptable Unsatisfactory 90 (43%) 160 (49%) 53 (25%) 71 (21.5%) 65 (31%) 97 (29.5%) Unacceptable/potentially hazardous 2 (1%) 1 (<1%) 68% of cream cakes prepared on the premises were satisfactory/acceptable and 70.5% when prepared offsite. Table 11. Q.6. Microbiology quality – how was the cream applied to the cream cake? (n = 209) Dispenser (n=48) Piped manually (n=146) Utensil (n=15) Satisfactory Acceptable Unsatisfactory 23 (48%) 58 (40%) 8 (53%) 8 (23.5%) 43 (29.5%) 2 (13%) 17 (28%) 43 (29.5%) 5 (33%) Unacceptable/potenti ally hazardous 0 2 (1%) 0 71.5% of cream cakes produced using a dispenser were satisfactory/acceptable, 69.5% when piped manually and 68.5% when utensils used. Sample numbers were too low to draw conclusions. Both of the unacceptable/potentially hazardous results were obtained from the manual piping method. KW/KLM (27/08) Page 4 of 9 Discussion The results of this study indicate that 30% of the samples were of unsatisfactory (29%) or unacceptable microbiological quality (0.5%) according to category 3 of the PHLS guidelines (1). The ACC was the parameter most often associated with unsatisfactory results however interpretation of the high ACC’s was limited in this study due to not identifying the predominant organism. Although a high ACC does not constitute a risk to health, it may sometimes indicate a general lack of hygiene. The frequency of the high ACC results is of concern. Category 3 allows an ACC of up to 106/g before being unsatisfactory and is supported as a valid and good indicator level because 94% of cream cakes from supermarkets were <106/g. If supermarkets can achieve this level, it has to be questioned why other premises cannot. For example only 70% of bakers were able to produce cream cakes with ACC’S <106/g. If category 2 had been used, 85% of supermarkets and only 50% of bakers would have produced satisfactory/acceptable cream cakes indicating that category 2 may be too stringent. One authority reported that high ACC’s were observed when the cream cakes were made offsite and transported, however this study does not support this view (Table 10). Unsatisfactory Enterobacteriaceae results were obtained from 4.5% of samples with the faecal indicator E. coli in 1.2% and Staphylococcus aureus in only 0.5%. Unsatisfactory results were often followed up by repeat sampling including a cream sample. However there is no cream category in the PHLS guidelines and no ACC parameter for cream in EC 2073 for samples from producers. This causes difficulty in interpretation of ACC’s and Enterobacteriaceae from cream at retail. EC 2073 food process criteria may be used to interpret Enterobacteriaceae counts in cream samples from the primary producer (<5/g = satisfactory) but again ACC’s would be difficult to interpret because of the lack of an ACC parameter. Hence although the ACC is a good hygiene indicator in cream cakes, there is a need to be able to interpret ACC and other indicators such as E. coli, Staphylococcus aureus and Bacillus spp in the bulk cream used to fill the cakes. The ACC and other indicator results for the bulk cream can only be used comparatively with the final cream cake product. The presence of Enterobacteriaceae, E. coli and Staphylococcus aureus in cream are indicators of post pasteurisation contamination and in cream cakes may also be derived from subsequent poor environmental and equipment cleaning or poor handling practices. Bacillus cereus and other Bacillus spp are common in milk and its endospores are able to survive pasteurisation. Some strains are also pschrotrophic and capable of growth in refrigerated cream. Although Bacillus food poisoning associated with cream is not frequently reported, three cream cake samples in this study contained unacceptable/ potentially hazardous levels of Bacillus spp (Table 1) and were of concern. The three unacceptable results were further investigated by the local authorities. There was no link established between the samples but all reported possible hygiene failures related to the handling of the bulk cream. In particular one authority reported that the cleaning of the Carpegiani cream dispenser was only carried out on the day following KW/KLM (27/08) Page 5 of 9 use. Although residual cream was maintained cooled in the refrigerated unit of the Carpegiani machine overnight, the cream in the exit piping and nozzles was at room temperature allowing bacterial growth. Subsequent cleaning was probably not sufficient to remove the high levels of Bacillus spp. Action – machine, piping and nozzles are now cleaned daily – problem resolved. It was also reported by one of the authorities that residual cream was refrigerated overnight and used again in further batches of cream cakes. Action – residual cream is now discarded at the end of each day of use – problem resolved. High moisture products such as cream cakes are likely to present food safety concerns as they will support the growth of a wide range of bacteria. There are a number of inherent factors and practices in cream cake production that increase the potential for cross contamination. These include potential contaminated areas, frequent handling, potential cross contamination from raw products such as eggs and potential cross contamination through the re-use of equipment such as piping bags and contaminated nozzles, etc. Further problems may also relate to temperature control because this study has also highlighted that 74/537 (14%) of refrigerated units were operating at >8.0C. In the past, cream filled confectionery were a common cause of food poisoning but the situation has improved with the use of refrigerated display counters. Although cream cakes sampled from ambient displays in this study were only at room temperature for less than 4 hours (as allowed by temperature regulation exemption rule), the microbiological quality was still worse than those from refrigerated displays. Hence, potential pathogens such as Staphylococcus with a minimum growth temperature of about 10C would multiply. Good catering/retail practice advice would therefore be to store cream cakes at 0-8C from process to retail. The control of temperature is essential in restricting the growth of bacteria thus minimising the risk of food poisoning. For high risk foods like cream and cream cakes, keeping them chilled is probably the single most important control in ensuring their safety. However even with good temperature control 2 samples in this study were potentially hazardous highlighting the need to monitor all risk factors carefully. Conclusion It is of concern that based on category 3 of the PHLS guidelines (1), 30% of samples examined in this study were unsatisfactory, predominantly caused by high ACC’s. The majority (94%) of samples collected from supermarkets were of satisfactory microbiological quality, indicating the need for careful risk assessments and hygiene inspections at other premises producing the higher proportion of unsatisfactory results (Table 6). Category 3 of the PHLS guidelines (1) is considered a suitable category for the interpretation of the microbiological quality of cream cakes and highlighting potential hygiene or cream supply problems. It is of concern that 14% of refrigerated display units were operating at >8.0C. KW/KLM (27/08) Page 6 of 9 The 4 hour temperature regulation exemption rule applicable for cream cakes is not be be encouraged, due to evidence that these samples produced more unsatisfactory results (Table 8). Future work Survey of the bulk cream used to fill cream cakes in order to establish if the poor final product quality is due to processing and handling or the cream supply and to identify the predominant organisms responsible for high ACC’s. References (1) Guidelines for microbiological quality of some ready to eat foods sampled at point of sale, PHLS, ACFDP, Communicable Disease and Public Health. Sept 2000, Vol .3, No.3: 163-167. KW/KLM (27/08) Page 7 of 9 Appendix 1 – Request Form KW/KLM (27/08) Page 8 of 9 Appendix 2 - Participants Authority Allerdale Carlisle Copeland Eden CUMBRIA TOTAL Chester Congleton Crewe & Nantwich Ellesmere Port & Neston Halton Macclesfield Vale Royal Warrington CHESHIRE TOTAL Bolton Bury Manchester Oldham Rochdale Salford Stockport Tameside Trafford Wigan GREATER MANCHESTER TOTAL Barrow Blackburn Blackpool Burnley Chorley Fylde Hyndburn Lancaster Pendle Preston Ribble Valley Rossendale South Lakes South Ribble West Lancs Wyre LANCASHIRE TOTAL Knowsley Liverpool St Helens Sefton Wirral MERSEYSIDE TOTAL Flintshire Wrexham NORTH WALES TOTAL Total for Cumbria, Cheshire, Greater Manchester, Lancashire, Merseyside, North Wales KW/KLM (27/08) Number of samples examined 9 12 8 10 39 13 6 11 9 18 11 10 2 80 12 12 0 15 10 12 16 20 18 19 134 10 11 14 0 20 14 18 16 8 12 16 11 19 4 25 20 218 8 4 20 45 6 83 17 0 17 Page 9 of 9 571