Hot Polymer Catches Carbon Dioxide Better

advertisement

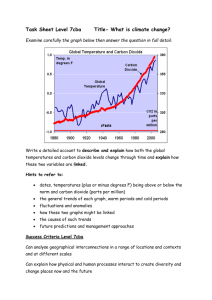

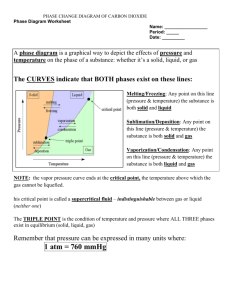

Web Site: ScienceDaily Magazine Page URL: http://www.sciencedaily.com/releases/2002/05/020531072522.htm Original Source: Los Alamos National Laboratory Date Posted: 2002-05-31 Hot Polymer Catches Carbon Dioxide Better LOS ALAMOS, NM, May 29, 2002 - A new and economical technology for the separation and capture of carbon dioxide from industrial processes could lead to a significant reduction in greenhouse-gas emissions to the atmosphere. Scientists at the Department of Energy's Los Alamos National Laboratory are developing a new high-temperature polymer membrane to separate and capture carbon dioxide, preventing its escape into the atmosphere. This work is part of the DOE Carbon Sequestration Program's mission to reduce the amount of carbon dioxide emitted into the environment from industrial processes. Growing concern about the potential worldwide environmental impacts, such as global warming and acidification of the oceans, from the vast amounts of carbon dioxide released from the combustion of fossil fuels prompts scientists to research and develop methods for carbon sequestration. National studies estimate approximately 30 percent of human-caused carbon dioxide emissions are a result of power-producing industries. At the American Geophysical Union conference today in Washington D.C., Jennifer Young, principal investigator for Los Alamos' carbon dioxide membrane separation project, presents data on a new polymeric-metallic membrane that is operationally stable at temperatures as high as 370 degrees Celsius. To date, polymer membranes commercially available for gas separation are limited to maximum operating temperatures of 150 degrees Celsius. Industrial processes that produce carbon dioxide operate at temperatures as high as 375 degrees Celsius, and to sequester, or capture, the carbon dioxide, it first must be separated from other gases. "Current technologies for separating carbon dioxide from other gases require that the gas stream be cooled to below 150 degrees Celsius, which reduces energy efficiency and increases the cost of separation and capture," said Young. "By making a membrane which functions at elevated temperatures, we increase the practicality and economic feasibility of using membranes in industrial settings." According to Young, developing an efficient and economically feasible membrane from membrane materials is difficult because the membrane materials are expensive, and there is a tradeoff between productivity and selectivity. On the other hand, less expensive commercially available polymer membranes are effective only up to 150 degrees Celsius. "Our approach is to improve upon conventional technology," said Young. "The most promising application of this technology in terms of the carbon sequestration program is the separation of hydrogen from carbon dioxide in synthesis gas; however, the technology is not limited to this particular gas pair. For example, it might also be useful in the separation of carbon dioxide from methane. " Young's team developed the high-temperature membrane based on the polymer polybenzimidazole, or PBI, combined with a porous metallic support. According to Young, the resulting composite membrane outperforms other high-temperature membranes in terms of selectivity for the separation of hydrogen from carbon dioxide; has the highest demonstrated operating temperature of polymer-based membranes, 370 degrees Celsius; is chemically resistant; and is easily processed. The unique combination of metallic support and polymer film to form thin-film composite membranes also allows the membrane to be effective at higher pressures than conventional membranes. Q1. Los Alamos National Laboratory で開発されている技術はどのようなものか簡潔に説明せよ。 Q2. この技術は現代社会においてどのような点で有益であるか簡潔に述べよ。 Q3. ここで紹介されている polymeric-metallic を述べよ。 Q4. 現在の二酸化酸素分離の問題点はどのようなものか。 membrane とこれまでの polymer membrane の特性の違い