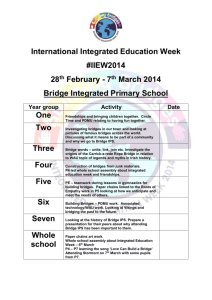

Taller Bridges

advertisement

FUTURE TRENDS IN DESIGN & CONSTRUCTION OF BRIDGES by Shiv Kumar, Director/IRICEN Synopsis The past decade has seen the bridge spans getting longer, the substructures getting taller and technology enabling construction of bridges in conditions that would previously have been considered impossible. The trends which have emerged indicate unprecedented developments in the bridge technology in above mentioned aspects as well as towards appearance. Introduction The past ten years has been a time of unprecedented developments both in the bridge technology as well as towards appearance. Perhaps, cost is the only thing preventing bridges from being built with spans several times longer than today’s recordbreakers. Technically, very long span bridges can be built with present-day materials. Spans are becoming larger and larger, e.g. the proposed 1315m long bridge on Chenab river in J & K Rail Link Project will have one of the longest arch span (480m) in the world. (Fig.1) Fig.1. Fig.1Proposed Proposedbridge BridgeononChenab ChenabRiver River 1 / 10 There are many reasons behind the trend. Consideration of the entire life cycle justify driving the span upwards. Society is also increasingly willing to pay for the convenience and aesthetics of long span bridges. Today’s construction costs are relatively less expensive than 20 years ago. The trend not only applies to cable- supported bridges but also other types of bridges as a major step has come through the building of the 330m-span box girder Shibanpo Bridge in Chongquing, China. To many engineers, long span bridges epitomize the ultimate in engineering achievement. The design and construction of long span bridges push the frontier in the engineering science. Cable-stayed bridges are increasingly encroaching on the type of spans traditionally associated with suspension bridges. The longest cable stayed bridge which has been constructed in the world is in Japan (Tatara – 890m span). (Fig.2) Fig. 2. Tatara Bridge 2 / 10 Only a decade later, the 1,000m barrier is soon going to be breached by both Stonecutters bridge in Hongkong and Sutong bridge in China and spans of 1,200m are already planned. One is also seeing a growth in smaller suspension bridges with spans of perhaps 100m to 500m. A few trends which are emerging as far as the design and construction of bridges is concerned are as under:- Architectural Appearance Appearance plays a far greater role in bridge design today than it did a few years ago. The general attitude towards bridges has changed greatly. Previously, bridges were seen as ‘a necessary evil’, the price that had to be paid for development. Now, a bridge is seen as a sculpture that people use to connect to each other. There is a much greater awareness of the importance of a bridge design that properly fits its setting. The emphasis on appearance has also led to a huge jump in the quality that clients are prepared to pay for. Thus, there is growing world wide awareness of the importance of visual aspects of design. e.g. Bow String Girder Bridge across Thane Creek in Mumbai region provides a visual treat to the rail commuters. (Fig.3) Fig. 3. Bow String Girder Bridge across Thane Creek 3 / 10 Placing greater importance on appearance has greatly heightened the role of architects in design. Sometimes a client wants an artist to dictate the design, the architect to interpret it and the engineer to make it work. Traditionally, bridges are cut into pieces, with bearings and joints introduced which make these bridges not only look ugly but also bad. Instead, far better solution would be to make use of the material properties as the reinforced concrete can handle the forces and it is unnecessary to cut the bridges into pieces and deprive them of their monolithic character. Today’s designers find themselves facing a dilemma. The ‘wow’ factor can come with something that is both original and simple in concept, such as the much-praised Gateshead Millennium Bridge (Fig.4) – which has won 37 awards so far, and is still winning them several years after opening. The balance is being tipped in favour of visual criteria over engineering. Fig. 4. Gateshead Millennium Bridge Changes in the business environment and responsibilities have led to a growth in design and build projects all over world which saves time and gives incentive to new ideas bearing in mind constructability but are subject to risk that the lowest tender may be ugly or boring. 4 / 10 Security hazard Today’s designs have a new threat to take into account. The concept of bridge security hardly existed a few years ago. Now, multi-hazard protection is growing in importance. Blast and earthquakes would be the obvious one. Greater understanding of behaviour in earthquakes has led to a massive increase in the armoury of tools to protect bridges. There have been parallel developments in recent years in areas such as the understanding of seismic activity, techniques for risk assessment and means of predicting seismic response. Solutions are being envisaged such as wrapping columns with glass fibre or carbon fibre which holds them together without increasing the stiffness. There have also been major developments in energy absorbing devices, bearings and the use of ‘structural fuses’ to dissipate energy without creating severe structural damage to the bridge. Seismic design has certainly come a long way and the philosophy has also changed significantly. By realizing that earthquake is not a force, but a deformation, the concept now is to provide sufficient capacity in deformation and allow the bridge to move under an earthquake, instead of trying to resist a force. Today’s designs emphasise how to keep the piers and pylons from losing capacity and the addition of loop reinforcement as one of the major advances in this direction. Increased Span Developments in cable technology have been assuming ever greater importance as spans of both suspension and cable-stayed bridges have increased. This technology is a key parameter to increasing the span. When you increase the span, the stay cables act like a sail. Manufacturers have made significant progress in recent years in reducing the size of strand systems and adding features such as helixes around the cables. Damping has also proved very important for long spans, with solutions such as tuned mass dampers and cross-cables or ‘aiguilles’ as used on the cable-stayed Pont de Normandie bridge in France. (Fig. 5) 5 / 10 Fig. 5. Pont de Normandie Bridge Today’s spinning equipment is competitive with preformed parallel wire strand systems. Which cable system has the lowest cost depends on factors such as the cost of the wire or strands, local labour costs and the contractor’s experience. New technology is still being developed, and synthetic cables will come eventually. One of the difficulties is that they are easy to destroy, though a solution may be to use steel top and bottom with the new material only installed out of reach. Taller Bridges Just as there have been developments above ground, so too have foundations moved ahead. There has been a quantum leap in the last decade from piles of 1.5m diameter up to ones as large as 4m and with a length of more than 100m. Equipment has been developed both for handling and driving these large piles, which has come about through a transfer of technology from the offshore industry to bridge building. In 6 / 10 foundations, large diameter drilled shafts of 3m diameter have been drilled to a depth of 68m. Improved equipment is not the only factor but such huge diameter holes also depend on improvements in drill hole stability. A third advance has come through an improvement in the ability to place higher quality concrete. Use of large diameter pile or drilled shafts has also made it possible to position the pile cap further above the river bed. Larger piles can have a long unsupported length enabling the footing to be constructed far closer to the water surface. It opens up the possibility of bridge foundations in much deeper waters. Getting stronger There is a lot still to be learned about materials such as ultra-high performance concrete. History shows that the introduction of a new material will only be successful if a new concept of structure to use that material can be developed. Let us refer to the use of stone to build arches. When steel was invented, long span trusses and box girders followed. High strength wires made suspension bridges possible. Together with concrete it made prestressed concrete, and therefore, long span concrete bridges possible. We are waiting to see if these new materials will revolutionise our bridges. Ultra-high performance materials such as VSL’s cementitious material Ductal have been introduced in the past ten years. It is a material that is nearer steel than concrete. Designers have to use it in a different way, using it as normal concrete would work out ten times too expensive. Huge progress has also been made in the development of standard materials such as concrete and steel, where a huge range of high strength or high performance products is now available, many developed to suit a particular application or environment. Engineers now have an enormous toolbox available to them in terms of material properties and characteristics. Precast Components Pre-cast foundation, abutment, pier and superstructure units enable construction of bridges not in years but in months and weeks. The benefits of pre-cast components in bridge construction enhance the philosophy of get in, get out, stay out e.g. the pre-cast bridge structure in San Juan, Puerto Rico (Fig. 6 ) was erected from the ground up in just 21 consecutive hours. 7 / 10 Fig. 6. The pre-cast bridge structure in San Juan, Puerto Rico In order to cut the construction time, the engineers at Lake Ray Hubbard Bridge in Dallas, USA, used pre-cast bent caps (Fig.7 & 8) for all the 43 pier caps reducing construction time from 8-9 days to 1 day for each pier cap. Pre-cast units eliminate costly field formwork as well as extend seasonal construction time. Fig. 7. Lake Ray Hubbard Bridge, USA Fig. 8 Lowering a pre-cast pier bent cap New materials Use of advanced composites started more than a decade ago. But although composite materials are beginning to be used on projects, they are still at an early stage. Even the stainless steel has been tried in bridges. When you have a new material, you tend to use it in the same way as you would use a traditional material. Today’s composite sections look exactly like steel sections. It will take a while before they find their own form, just like concrete bridges originally looked like wooden structures. There are many 8 / 10 different types of application for composites such as use in post-tensioning, plates and strips, FRP decks, stay cables, wraps to provide seismic protection and enclosures to protect structures. Some of the technology is used for repair, strengthening or rehabilitation; others for new construction. Examples include composite rods to replace the top mat of steel reinforcing bars, effectively increasing the cover to the steel, and for bridge decks. FRP bridge decks are gaining popularity in the USA. They have been proving especially successful for movable bridges because of their light weight. Increasing durability Such materials also offer the benefit of increased durability, a property that is being increasingly demanded by clients. The use of plastic ducts for cables has been an important development in this regard. Encapsulating the cable in plastic protects the ducts, and this has become widespread in a number of countries, although this approach is not universally accepted, e.g. it is not used in France. For some, the principle is that if water can enter, it can also leave. Introduction of enhanced protection through use of electrically isolated systems is a revolution. If the cable is electrically isolated, it is also possible to take measurements to ensure that the system is intact. Otherwise we are completely blind – with internal prestressing, we cannot see anything. Another aspect of this trend is that durability of concrete decks is now far more important than it used to be. A change in bridge deck design over the past ten years has implications for deck replacement that are not yet fully understood. In the traditional design, there would normally have been some kind of supporting structure, generally topped by a concrete deck, which could easily be replaced. But now in the modern bridge, the deck is part of the structure and is holding it up - a factor that could mean that in the future, deck replacement could become more complex and expensive. Conclusion In India, one cable stay bridge had been constructed spanning across railway track near Bangalore a few years ago. (Fig.9). Another one is now under construction at Chirayatand near Patna. There is a significant growth in demand for long span bridges. 9 / 10 Fig. 9 Cable Stay Bridge crossing at Railway Yard Eyes are turning to countries like China and Korea where major bridges are under construction and one will see a high level of expertise in a low cost country – that is certainly going to affect the economics of who does what. *** 10 / 10