Notes - Personal WWW Pages

advertisement

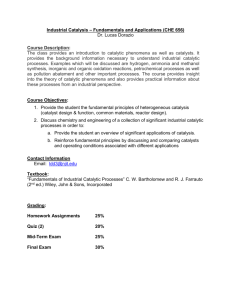

CH538: Molecular Catalysis Dr M.D. Spicer Contents 1. Introduction 1.1 What is a catalyst 1.2 Homogeneous vs Heterogeneous Catalysts 2. The Fundamentals of Catalytic Reactions 2.1 Tolman’s Rules 2.2 Organometallic Reactions 2.3 Construction of Catalytic Cycles 3. Case Studies 3.1 Catalytic Hydroformylation 3.1.1 Cobalt Catalysed Hydroformylation 3.1.2 Phosphine modified Hydroformylation 3.1.3 Rhodium Catalysed Hydroformylation 3.1.4 Comparisons 3.2 Wacker-Schmidt Aldehyde Synthesis 3.3 Olefin Hydrogenation by Wilkinson’s Catalyst 4. Immobilisation of Homogeneous Catalysts 5.1 Polymer Bound catalysts 5.2 Functionalised Inorganic supports 5. Biphasic Catalysis 5.1 Aqueous Biphasic Catalysts 5.2 Fluorous Biphasic Catalysts 6. Organocatalysis 7. Enzyme catalysts Assumed Background Knowledge: 3rd Year Inorganic Chemistry (Organometallics) Recommended Books: “Organometallic Chemistry”, G.O. Spessard and G.L. Miessler, Prentice Hall, 1997. “Applied Homogeneous Catalysis with Organometallic Compounds” Eds Cornils and Herrmann, VCH, 1|Page 1. Introduction 1.1 What is a Catalyst? There are many reactions in chemistry which are favourable thermodynamically, but which for various reasons occur at very slow rates. Consider the three very important reactions below: The Water Gas Shift Reaction H2O (g) + CO (g) H2 (g) + CO2 (g) ΔH = - 6.9 kcal mol-1 Alkene Hydrogenation CH3CH=CH2 (g) + H2 (g) CH3CH2CH3 (g) ΔH = -20.6 Kcal mol-1 Glucose Metabolism C6H12O6 + 6 O2 (g) 6 H2O (g) + 6 CO2 (g) ΔH = -688 Kcal mol-1 Potentially all these reactions should proceed, since the products are more stable than the starting materials. However, in practice none of the take place under ambient conditions. Each requires a catalyst because there is a kinetic barrier to the reaction taking place. The phenomenon of catalysis was first recognised over 150 years ago by Berzelius, who referred to the “catalytic power of substances” which were able to “awake affinities which are asleep at this temperature by their mere presence and not their own affinity”. 2|Page CH538: Molecular Catalysis Dr M.D. Spicer With our modern understanding of thermodynamics and equilibria, we now know that a catalyst is a substance which alters the rate at which a reaction reaches equilibrium, without altering the equilibrium distribution of reactants and products. For many years the action of catalysts was something of a mystery. Now, however we know that catalysts interact with the reactants to provide a reaction pathway with a significantly lower free energy of activation than the corresponding uncatalysed pathway. Consider the following diagram: The solid trace represents the un-catalysed reaction. It has a large activation energy, ΔG‡ which makes the reaction unlikely to occur. So although the products have lower free energy than the starting materials, there is no way of getting from one to the other. The dotted trace show the effect of adding a catalyst. A substrate-catalyst complex is formed, which then provides a much lower energy route (ΔGc‡ << ΔG‡) to the products of the reaction. This can pass through a number of intermediates and transition states. We will see examples of this phenomenon in action as we consider some catalytic reactions later in the course. 3|Page Catalysis is of great importance to the chemical industry – more than 60% of chemical products, and greater than 90% of chemical processes are based on catalytic reactions. In turn, the development of organometallic chemistry has been a key to the rapid growth of catalysis, and the award of Nobel Prizes to Ziegler and Natta (Olefin Polymerisation), Wilkinson and Fischer (Organometallic Chemistry) and most recently Grubbs, Schrock and Chauvin (Olefin Metathesis) are recognition of this fact. Consider the timeline below, which shows in parallel the development of organometallic chemistry and of the development and industrial use of homogeneous catalysis. 4|Page CH538: Molecular Catalysis Dr M.D. Spicer It can be seen that the discovery of ferrocene and the ensuing explosion of organoelement chemistry led to a huge expansion of catalytic chemistry in industrial processes. 1.2 Homogeneous vs Heterogeneous Catalysis. It was Sabatier who, in 1927, published the first classification of catalysts and used the terms homogeneous and heterogeneous. A heterogeneous catalyst exists in a separate phase to the reaction medium (most commonly as a solid in either a liquid or gaseous reaction medium). A homogeneous catalyst is miscible with (or dissolves in) the reaction medium, along with the reactants. In the early 20th Century catalysis was inextricably linked with large volume industrial processes, such as ammonia synthesis via the Haber process, coal hydrogenation, fat hardening, Fischer-Tropsch synthesis and mineral oil processing. These were all heterogeneous processes, and with the exception of the occasional use of Grignard and organozinc reagents and in the Mond process (extraction of Nickel via the carbonyl, [Ni(CO)4]), organometallics were almost unheard of in industrial processes. Furthermore, heterogeneous processes were also rare, partly for chemical and partly for engineering reasons. However, with the rapid development of organometallic chemistry in the latter part of the 20th century, homogeneous catalysis became far more important. Heterogeneous catalysts typically comprise of metals, metal oxides or metals finely dispersed on a supporting material to increase the surface area (e.g. rhodium on silica; palladium on charcoal). These are generally robust materials and so can be used at high temperature with either gaseous or liquid reaction media. By contrast, homogeneous catalysts are generally used in the liquid (solution) phase at much lower temperatures, since the catalysts tend to be sensitive, to some degree, to 5|Page heat. Reactions are often carried out at elevated pressure to a) increase the concentration of gaseous components in the reaction medium and b) to maintain highly volatile species in the liquid phase, thus rendering the process engineering more straightforward. The two classes of catalyst have both advantages and disadvantages and these are summarised in the table below: Homogeneous Heterogeneous Activity (vs metal content) High Variable Selectivity High Variable Mild (< 250 °C) Harsh (250 – 500 °C) Variable Long Sensitivity to poisoning Low High Diffusion Problems None May be important Catalyst recycling Expensive Not necessary Catalyst “Tuning” Possible Rarely Possible Mechanistic Understanding Possible Rarely Possible Reaction Conditions Catalyst Lifetime Let us consider these advantages and disadvantages in a little more detail. Activity and Selectivity: these often have an inverse relation in both homogeneous and heterogeneous catalysis. i.e. faster reactions are often less selective. So, although homogeneous catalysis has a major advantage in the high selectivities which can be achieved, this is sometimes at the expense of lower reaction rates. Selectivity normally arises in homogenous catalysis because a single molecular species is in present in solution and so there is only one type of reaction site for the substrate. This results in fewer side products from the reaction. On the other hand, reactions in heterogeneous catalysts occur at the non-ideal catalyst surface and so there can be many different reaction sites, leading to a decrease in selectivity. Produt Separation: This is the main disadvantage of homogeneous catalysis. Since the catalyst is in the same phase as the substrates and products, simple mechanical separation is not possible. Occasionally, if the product has a low molecular weight and boiling point then distillation of the product may be possible (e.g. CH3CHO from Pd 6|Page CH538: Molecular Catalysis Dr M.D. Spicer catalysed ethane oxidation). Even more rarely, if the product precipitates from solution (e.g. a polymer) then again separation is more practical. Catalyst Tuning: Homogeneous catalysts are much more readily modified in a controlled manner to give well defined variations in properties. This can be done in a number of ways: Change the metal type (e.g. Co to Rh) Change co-ligands (steric and electronic properties affect regioselectivity, and kinetics) Cation or anion additives Change solvent Such changes can greatly improve (or worsen) the performance of a catalyst system and is the focus of an enormous amount of academic and industrial research. Mechanistic Understanding: Homogeneous catalysts are far easier to study mechanistically for a number of reasons: Single active site Single reaction pathway Can be studied spectroscopically (in solution). Since the catalyst is uniformly dispersed in the medium, at a measurable concentration, it is usually possible to apply standard spectroscopic procedures to investigate these catalytic reactions. By contrast, the active sites of heterogeneous catalysts are on the surface of the catalyst, with the bulk of the material being inactive. Consequently, the active sites are at a low concentration. Furthermore, the characterisation of chemical species on a surface, except in very ideal circumstances, is extremely difficult. Thus, heterogeneous catalysts remain rather poorly understood. Other courses will cover the study and application of heterogeneous catalysts, while this course will focus on the understanding of molecular (homogeneous) catalysts. 7|Page 2. Fundamentals of Catalytic Reactions We will look at three systems as case studies showing how catalysts are developed, how mechanisms can be probed and the origin of selectivity. In order to make sense of catalytic reactions we need a basis on which to approach them. A set of rules have been developed, which when coupled with a knowledge of organometallic reactions can give us a great deal of insight into these processes. 2.1 Tolman’s Rules Tolman’s rules were developed in the early 1970s, based on the observation that the majority of well characterised transition metal organometallic complexes have either 16 or 18 valence electrons (although there are now plenty of exceptions, especially in the early transition elements) and this observation can be used in a predictive capacity. Rule 1: Diamagnetic organometallic complexes of the transition metals may exist in significant concentrations at moderate temperatures only if the valence shell contains 16 or 18 electrons. (N.B. significant concentration is defined as one which can be detected either spectroscopically or inferred from kinetics). Rule 2: Organometallic reactions proceed by a series of elementary steps involving only intermediates with 16 or 18 electrons. These rules, together with some basic organometallic reactions (summarised in the following section) allow us to propose mechanistic pathways which can be investigated and confirmed or ruled out experimentally. 2.2 Reactions of Organometallic Compounds Let us then consider the main classes of reactions undergone by organometallic compounds. You will have covered most of these in detail in the 3rd year Inorganic Chemistry course with Dr O’Hara, and you should consult his notes or an organometallic textbook if you need to refresh your memory. The table below shows the reaction types as pairs (which are essentially the reverse of each other) and highlights the changes in the number of valences electrons, the formal oxidation state of the metal and the coordination number of the metal which accompany the reaction. 8|Page CH538: Molecular Catalysis Reaction Type Dr M.D. Spicer Example NVE OS CN Lewis Acid dissociation 0 -2 -1 Lewis acid association 0 +2 +1 Lewis base dissociation -2 0 -1 Lewis Base association +2 0 +1 Reductive elimination -2 -2 -2 Oxidative addition +2 +2 +2 Insertion -2 0 -1 Elimination +2 0 +1 [HCoI(CO)4] [Rh(L)3(H)2Cl] H+ + [Co-I(CO)4][Rh(L)2(H)2Cl + L [Ir(H)2(L)2(CO)Cl] [Ir(L)2(CO)Cl] + H2 [Pt(L)2(H)Cl(C2H4)] [Pt(L)2(Et)Cl] As can be seen, these reactions all result in changes of -2, 0 or +2 valence electrons, supporting the assertion in Tolman’s rules that the component steps in catalytic reactions should proceed via intermediates with either 16 or 18 valence electrons. When we consider catalytic reactions, they can be split down into three main phases: Catalyst Activation: catalysts are required to be coordinatively unsaturated (i.e. have less than 18 valence electrons to allow a low energy path for the substrate to bind to the metal centre prior to reaction taking place. Other reagents may also require activation at the catalyst centre (e.g. H2, RX), usually by oxidative addition. Reaction at the Metal Centre: Various types of reaction, such as alkyl migration or migratory insertion, metallacycle formation, nucleophilic or electrophilic addition and halide or hydrogen abstraction are all common. These allow the activated substrate to be transformed at the metal centre. Release of Product from the Metal Centre: this most commonly occurs by either reductive elimination or by -, β-, or γ- hydride elimination. 2.3 Construction of Catalytic Cycles 9|Page By combining Tolman’s rules with our knowledge of organometallic reactions, we can propose a series of reactions which describe the action of the catalyst and other reagents on the substrate in order to generate the product. Such a series of recations is known asa catalytic cycle and should return to the starting catalyst or activated catalyst. Consider the example below which shows a simplified cycle for alkene hydrogenation using Wilkinson’s catalyst, [Rh(PPh3)3Cl] which illustrates the points above: Step 1: oxidative addition of H2 to the 16e- RhI complex. Step 2: coordination of alkene Step 3: migratory insertion of the alkene into the Rh – H bond Step 4: Reductive elimination of product with catalyst regeneration So a catalytic cycle can be regarded as a series of reaction steps such that during one cycle around the loop the substrate (reactant) is converted into the product. There is no net change in the catalyst itself (i.e. it is regenerated in the cycle). 10 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer 3. Case Studies 3.1 Catalytic Hydroformylation Catalytic hydroformylation (sometimes referred to as the oxo-reaction in older literature) was first discovered in 1938 by Otto Roelen (Ruhrchemie) and is one of the oldest processes still in use. It was used extensively during the second World War to generate aldehydes from alkenes, H2 and CO. The reaction may be summarised as follows: The catalysed reaction is the formation of butenal. Both the linear and branched isomers are formed. Subsequently, these can react further, depending on the precise conditions. The hydrogenation of butenal results in reduction to the corresponding alcohol, while aldol condensation, followed by reduction, results in formation of 2-ethylhexan-1-ol. The overall hydroformylation reaction (the first step above) is exothermic, with ΔH = -125 KJ mol-1 for propene and in the range -115 to -145 KJmol-1 for other alkenes. Despite being thermodynamically favourable under ambient conditions, it took a long time to realise this reaction experimentally, and eventually it was the use of metal carbonyl catalysts which yielded success. 11 | P a g e 12 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer Cobalt Catalysed Reaction. Although the process apparently uses a heterogeneous catalyst, a mixture of Co/SiO2/ThO2/MgO in a 30:66:2:2 ratio, it is almost certain that it is homogeneously catalysed. Under the reaction conditions cobalt carbonyl complexes are formed which are readily displaced from the silica-based support and which can catalyse the process. The mechanism of the homogeneous process has been extensively studied and a catalytic cycle has been proposed. We will look at this cycle in some detail, as this can help us to understand how the intricacies of such reactions can be unravelled. The Heck-Breslow Mechanism This is the accepted general mechanism for this process: So, let us dissect the reaction, step by step – this will give us an insight into each of the steps and how we assess whether a particular pathway is likely or not. 13 | P a g e Step 1. The pre-catalyst, HCo(CO)4 is readily formed from Co, CO and H2 under the reaction conditions (>100ºC, 300 bar pressure). It is an 18 electron complex and reasonably stable. This dissociates to give the 16 electron complex, HCo(CO)3 which is most probably the active catalyst: The concentration of HCo(CO)3 will be low, because the high pressure of CO will force the equilibrium to the left hand side. However, enough is present for catalysis to occur at a reasonable rate because of the high temperature at which the reaction is carried out – this overcomes the activation energy of the dissociation process. There are two possible structures of HCo(CO)3: From computational methods it is found that the structure on the left is most stable and thus more likely to occur. Step 2. Once the active catalyst is formed the next step is alkene binding to the metal centre to form an 18 electron complex once more. The bound alkene can have two possible orientations: The double bond can either lie in the equatorial plane (left) or perpendicular to the equatorial plane (right). While the structure on the left is slightly more stable (again from calculations) the one on the right has the correct orientation for the next step. Both will exist and will be able to interconvert with one another. Step 3. Alkene insertion – this takes place by a concerted process with a cyclic transition 14 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer state to give a 16 electron species which very rapidly picks up CO to form an 18 electron alkyl species: The “addition” of Co – H to the alkene is in an anti-Markovnikov sense (the cobalt is attached to the least substituted carbon), which will give rise to the linear aldehyde. The alternative Markovnikov addition is possible, but is more sterically hindered and so occurs to a lesser degree. β-hydride elimination is possible from the “untrapped” 16 electron intermediate, but the high partial pressure of CO drives the formation and stabilisation of the 18 electron RCo(CO)4 species, and so the elimination does not occur to any significant extent. Step 4. CO insertion – which in all likelihood is in fact alkyl migration. Calculations show that the rearrangement has a low activation energy and is slightly endothermic. The RC(O)Co(CO)4 species is the only intermediate which has been detected when the reaction is followed by infra-red spectroscopy. Step 5. This step is probably the rate limiting step. Three different possible processes by which hydrogen is activated and transferred to the acyl group have been suggested: a) Oxidative addition of H2 followed by reductive elimination of the aldehyde. 15 | P a g e b) A bimolecular reaction involving HCo(CO)4 and the acyl tricarbonyl intermediate followed by hydrogenation. c) Side on-bonding of H2 followed by a concerted elimination of the product and catalyst. It is not certain which process occurs. While the bimolecular process (b) has been observed to occur under normal conditions, the concentrations of the proposed reacting species under the catalytic conditions are so low that the reaction is unlikely to occur at a significant rate. Process (a) is probably most intuitive, but the oxidative addition of H2 to the metal centre has a high activation energy. Process (c), the formation of an η2dihydrogen complex followed a a four-centred rearrangement is a much lower energy process, and seems more likely that the other alternatives. This process is still used in industry, despite some fairly major drawbacks, namely Linear to branched ratio is never better than 4:1 The active catalyst is both unstable and hard to separate High pressure of CO (200-300 atm) make the plant expensive Phosphine Modified Cobalt Catalysed Hydroformylation In 1968 it was discovered (Shell) that addition of phosphine (and in particular P nBu3) to the reaction resulted in hydroformylation at a much lower pressure (ca 100 atm). The ratio of linear to branched isomers also improved to 9:1 and, as the modified catalyst, 16 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer HCo(PnBu3)(CO)3, was more stable, it was more easily separated from the reaction products. However, despite the advantages there were also drawbacks to this process. While the lower pressure is useful, the payback was that higher temperatures were required (160-200ºC). Furthermore, the alkene can also be hydrogenated under these conditions with about a 15% conversion by a process thought to proceed as shown below: The origin of the improved selectivity is most likely steric, the bulky phosphine (compared to CO) can influence the orientation of the alkene in the complex prior to the insertion into the Co-H bond. The different orientations lead to different transition states and thus to either linear or branched products. There is more steric repulsion in the transition state shown on the right hand side (indicated by the arrow) due to the bulk of the coordinated phosphine. Studies have shown that changing the phosphine influences both the rate and selectivity of the hydroformylation. There are two sources of influence, which may be summarised by saying that steric effects alter the selectivity, while electronic effects alter the reaction rates. Thus, the presence of more electron donating phosphines results in greater electron density at the metal, which in turn results in stronger M-CO bonds. This means that the intermediates are more stable, and alkyl migration/CO insertion step is less favourable and hence slower. 17 | P a g e When studying this reaction spectroscopically only phosphine substituted cobalt carbonyl complexes are observed (in contrast to the phosphine free reaction, no alkyl or acyl species are seen). It is thought that the reaction proceeds via a very similar mechanism to the phosphine free reaction, but this is by no means certain. Rhodium Catalysed Hydroformylation Naturally, since rhodium is in the same group as cobalt, chemists soon attempted the use of rhodium based catalysts in hydroformylation reactions. Under the conditions used for cobalt catalysed reactions (i.e. H2 + CO at high temperature and under high pressure) HRh(CO)4 forms rhodium carbonyl cluster compounds such as Rh4(CO)12. Under milder conditions it does catalyse hydroformylation (although the linear to branched ratio is low), but it is also a good hydrogenation catalyst which makes it unviable as a commercial catalyst. The addition of phosphines, however allows hydroformylation at close to atmospheric pressure and at moderate temperature. Use of the appropriate phosphine allows good linear to branched product ratios to be attained. There are a number of advantages of the rhodium/phosphine hydroformylation catalysts.. - Activity: the rhodium catalysts are 102 – 103 times more active than their cobalt counterparts. This means that less catalyst is required, thus outweighing the high cost of rhodium. - Conditions: the low pressures and temperatures required mean that the cost of the plant for production will be much lower - Selectivity: linear to branched ratios of 14:1 can be attained if a pure 1-alkene feed stock is used. - Hydrogenation: the rate of hydrogenation is low under these conditions, so good if the aldehyde is required. 18 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer Let us consider the mechanism of the reaction, which may be represented by the scheme below: The catalyst precursor can be either HRh(CO)(PPh3)3 or HRh(CO)2(PPh3)2, depending on the concentrations of CO and PPh3 in the reaction mixture, both of which give the same active catalyst, HRh(CO)(PPh3)2. In contrast to the cobalt catalysed process, the use of alkyl phoshines (such as PnBu3) renders the catalysts too inactive. The donation of electron density presumably stabilses the catalytic intermediates too much, preventing the reactions from proceeding. The ideal ligand appears to be triphenylphosphine (PPh3) which has a combination of appropriate electron donating ability and reasonable steric bulk, which gives an acceptable rate and leads to high selectivity for the linear aldehyde product. The various processes are compared in the table below. 19 | P a g e Phosphine Process Cobalt catalyst modified cobalt catalyst Rhodium phosphine catalyst Catalyst Precursor HCo(CO)4 HCo(CO)4 + PnBu3 HRh(CO)(PPh3)3 PR3 : Metal ratio - 2:1 50 : 1 to 100 : 1 Pressure (bar) 200 – 300 50 – 100 15 – 25 Temperature (ºC) 110 – 160 160 – 200 80 – 120 0.1 – 1.0 0.6 4:1 7:1 8 : 1 – 16 : 1 <2 15 5 5 5 2 Difficult Simple Catalyst Concentration 0.01 – 0.05 (% metal/olefin) Linear : branched ratio Alkene Hydrogenation (%) Higher B.Pt. Products (%) Catalyst Recovery 20 | P a g e Simple (for C3 and C4 alkenes) CH538: Molecular Catalysis Dr M.D. Spicer 3.2: Wacker-Smidt Aldehyde Synthesis Background Ethanal (acetaldehyde) is another commercially important precursor. It was originally prepared by the following method: This can be thought of as the hydration of ethyne (acetylene). It is a facile and high yielding reaction, but one which is fraught with difficulties. Acetylene is prepared by heating a hydrocarbon gas stream to high temperature (often in the presence of an electric discharge). This is an energy intensive process which is inefficient. Furthermore, acetylene is thermodynamically unstable and is an explosive hazard! So, there was a strong incentive to develop a more energy efficient and less hazardous process. The following stoichiometric reaction was known: In the 1950s, Smidt at Wacker Chemie developed a commercially viable process which is a modification of the above reaction, using a catalytic amount of palladium chloride (PdCl2) in the presence of CuCl2, HCl and O2 (which help to maintain the palladium in the correct oxidation state) as follows: Combining the three equations, the overall reaction can be considered to be: 21 | P a g e So, the stoichiometric process is rendered catalytic. This is an extremely atom-efficient reaction – the oxidation of ethane by oxygen! The acetaldehyde produced is converted to acetic acid or acetic anhydride. If the reaction is run in the presence of copper(II) acetate and KCl/KOAc then the resulting product is vinyl acetate, which is important as the precursor to polyvinyl acetate (PVA). For many years this was a highly important source of acetic acid, although latterly a rhodium catalysed synthesis from synthesis gas has become prevalent. One problem with the reaction was maintaining the plant, as the reaction mixture is extremely corrosive. The overall reaction may be summarised as shown below….. Under the reaction conditions (high concentration of Cl-), PdCl2 is converted to [PdCl4]2-. 22 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer Step (a) – involves the displacement of 2 chloride ligands by alkene and water. Step (b) is a nucleophlic attack of water on the alkene. The mechanism of this step is by no means certain, although it appears that there are two main options: 1. The attack of a non-coordinated water molecule, or 2. Insertion of alkene into a Pd – OH or Pd – OH2 bond. The observed rate law is consistent with both mechanisms, so in order to try and ascertain which is more likely a number of elegant experiments have been devised using isotopic labelling. The first was reported by Stille Cis-dideuterioethene undergoes hydroxy-palladation followed by CO insertion to give a lactam product. The deuterium atoms are trans- to one another in the product, which implies that an inversion of configuration has occurred. However, CO insertion is known to proceed with retention of configuration, so inversion must have occurred during the attack of H2O. This would imply that an external nucleophile has attacked the π-ligand (alkene). 23 | P a g e A second, similar, series of experiments were performed by Bäckvall and Åkermark. They took a trans-deuterioethylene complex of palladium and reacted it in the presence of a high concentration of chloride ions. The resulting product was an epoxide in which the deuterium atoms are cis to one another. The scheme below shows how this must occur: The trans-deuterioethylene complex again undergoes a nucleophilic attack by water leading to the hydroxyalkyl species. In the presence of a high concentration of chloride undergoes an SN2 cleavage reaction to give the threo-chlorohydrin product, with inversion of configuration. Finally, in order for the geometry to be correct for the displacement of chloride to give the epoxide it is necessary for a rotation about the C – C bond to occur. This results in the cis-deuterio epoxide as shown. So we have two pieces of evidence which support the external nucleophilic attack of a water molecule. However, there is also some evidence to suggest that this may not necessarily be the mechanism which occurs under the conditions most commonly used in the Wacker synthesis! A third, cleverly devised reaction, uses an allylic alcohol which prevents β-elimination and thus aldehyde formation from occurring. At high concentrations of chloride (as used in Bäckvall’s experiment) the external nucleophlic attack by water occurs, which 24 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer leads ultimately to the R-isomer, whereas, at low concentrations of chloride ion (similar to the conditions of the industrial process) an internal nucleophilic attack by coordinated water leads to observation of the S-isomer as shown in the following scheme: A great deal of effort has been expended in trying to understand this step of the reaction, but the fact that no firm conclusion can yet be drawn illustrates how difficult it can be, even in relatively simple systems, to obtain definitive answers to mechanistic questions. Setps (c), (d) and (e): these comprise of halogen loss (c), β-elimination (d) and olefin insertion (e). It might be thought that after step (d) the enol could be displaced from the metal centre followed by a tautomerisation to the aldehyde product as shown below. However, this is not the case. The evidence for this is that if the reaction is run in D2O there is no incorporation of deuterium into the product, which would be expected if the 25 | P a g e tautomerisation was taking place. So the metal based rearrangement (olefin insertion followed by elimination) seems more plausible. This reaction can also be used on a lab scale for the preparation of ketones. In addition, the reaction is selective, as terminal alkenes react very substantially quicker than internal alkenes, for instance: 3.3: Alkene Hydrogenation by Wilkinson’s Catalyst Wilkinson’s catalyst, [Rh(PPh3)3Cl], is a 16 electron square planar complex which is a highly useful catalyst for a number of reactions. We will consider briefly its use as a hydrogenation catalyst. It is able to catalytically add hydrogen across the double bond of an alkene at room temperature, 1 atmosphere pressure of H2 and at millimolar concentration of catalyst. In other words it is highly efficient. 26 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer A great deal of effort has been expended in trying to understand this catalytic reaction. It has been discovered that the rate of hydrogenation increases both with alkene concentration and with H2 pressure. This is shown in the figure below, which displays plots of reciprocal rate vs 1/[alkene] and vs 1/[H2] where the alkene is cyclohexene. The straight line plots confirm that the reaction rate is inverse first order with respect to both alkene and hydrogen concentration. The dependence of the rate on the catalyst concentration is somewhat more complex, and is subject to variation on addition of free PPh3. A number of rate laws have been advanced, for example: b[ PPh3 ] c[ PPh3 ] d [alkene] [ Rh ]total a dt [H 2 ] [alkene] 27 | P a g e The dependence of rate on addition of phosphine suggests that there are chemical reactions of the catalyst taking place. The catalytic solution have been studied extensively by spectroscopic means and the presence of a considerable number of species can be observed or inferred. The species identified thus far are: The concentrations of the hydride containing species increase with increasing H2 pressure (as might be expected), while the dimers decrease in concentration as the concentration of phosphine increases and at higher temperature. The dimer C is also a good hydrogenation catalyst, but is not particularly soluble and is very sensitive to O2 poisoning. Addition of small amounts of phosphine to the reaction give a small increase in rate of H2 uptake, but addition of large amounts of phosphine inhibit the reaction (see figure above). This is presumably because the excess phosphine inhibits the dissociation equilibria which are necessary for the catalyst to take up the alkene and for the reaction to proceed. Consider the catalytic cycle which has been proposed: 28 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer It can be seen that, in line with the number of observed complexes in this reaction, there are a large number of possible peripheral reactions that can be undergone by the catalyst. Many of these can be studied relatively easily. For instance, Halpern has studied the reactions of H2 with Wilkinson’s catalyst: At low PPh3 concentrations the phosphine dissociation process (1) dominates, and below 0.15M PPh3 the uptake of H2 by this species (reaction (4)) is preferred. However, at higher concentrations of PPh3 the direct reaction of H2 with Wilkinson’s catalyst (reaction (2)) is most important since equilibrium (1) is pushed back towards the starting material. The phosphine dissociated compound, [Rh(PPh3)2Cl] has not been observed to date, but the related PCy3 complex is known, demonstrating the feasibility of this reaction. Reaction (3) in the scheme has been very nicely followed by 31P NMR spectroscopy as shown in the figure below: 29 | P a g e The top spectrum is of [Rh(PPh3)3Cl]. There are two different PPh3 ligands in the complex, 2 which are mutually trans to one another and one which is trans to chlorine. The one trans to chlorine is seen as a doublet of triplets arising from coupling to 103Rh (I = ½, 100%) and to two 31P nuclei (I = ½, 100%). The two phosphine ligands which are mutually trans appear as a doublet of doublets due to coupling to 103Rh and to the other phosphine ligand. The spectra labelled B show what happens when H2 is introduced into the system. The starting complex is completely consumed and a new complex is formed. The difference 30 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer in the spectra at 30 °C and at -25 °C suggest dynamic exchange is taking place. It can be assumed that the following equilibrium is occurring: At 30 °C the exchange is fast and the unique phosphine ligand is being lost leaving a doublet due to coupling of the two equivalent,non-exchanging phosphines to 103Rh. The third, unique phosphine appears as a broad line – the coupling to Rh is disrupted by the exchange. At -25 °C the exchange is slowed and the full coupling is now seen. So we have confirmation of the exchange processes which are proposed in the catalytic cycle. The final spectrum shows the effect of bubbling N2 through the reaction mixture. The result is that the starting complex is partially reformed, suggesting that the hydride complex and H2 are in equilibria with one another, and that H2 is carried out of the system on the N2 stream. This implies that step (2) of the cycle is in fact an equilibrium. Step (6) of the reaction has also been the subject of considerable study. In particular, if an isotopic labelling experiment is performed using D2 instead of H2, and using cyclohexene as the alkene, while the main product is the expected d2-cyclohexane, products which include 0 – 4 deuterium atoms are obtained! This suggests that this step of the reaction is in fact an equilibrium as well. We can see again that the reactions are not as simple as they may seem at face value. There are many competing reactions which require careful control of concentrations of various reagents to ensure that the appropriate species are present for the most efficient catalytic reaction. It’s a detective puzzle, trying to track down all the pieces of information and putting them together to deduce a likely pathway for the reaction. 31 | P a g e 4. Immobilisation of Homogeneous Catalysts We have seen that, while there are many advantages to homogeneous catalysis in terms of selectivity, activity, tuneability and mechanistic understanding. However, the major stumbling block remains the problem of separation of the catalyst from the reaction products. One strategy which has been adopted to address this problem is to immobilise homogenous catalysts on solid phase supports. This allows the molecular nature of the catalyst to be retained, with all the advantages that entails, but also facilitates separation. A number of different types of support have been investigated and we will take a brief overview of these. 4.1 Polymer Bound Catalysts This was probably the first class of immobilised catalyst to be extensively studied and a vast array of systems has been investigated. Catalyst immobilisation is achieved by introducing appropriate metal ligating functions into an organic polymer. We will only consider phosphines, but a wide range of different ligand types have been used in this capacity. There are at least two different strategies which are used for introduction of these groups. 4.1.1 Modification of Pre-formed Polymers This is the most popular method. A commercially available polymer is treated to introduce ligating groups which then form complexes with metal ions in order to generate catalytically active species. The major advantage of this method is that the physical properties, such as pore size, surface area, swelling properties, are already known. Polystyrene (right) is most commonly used. It is readily available in several forms and it has limited chemical reactivity (enough to enable functionalisation, but not so much that it is damaged under catalytic conditions). There are three main classes of polystyrene which are used in this application: 32 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer (i) Uncrosslinked Polymers. These polymers are soluble, and hence apparently homogenous with the reaction mixture. However, they can be readily separated either by membrane filtration or by precipitation. (ii) Gel (or Microporous) Polymers. These have a low degree of cross-linking (typically < 2%). In organic solvents these swell to open up their internal volume to allow both solvents and reagents which allows reasonably high catalyst loading and efficient diffusion of reagents and products to catalytic sites. (iii) Macro-reticular (or Macro-porous) Polymers. These are polymers with a high degree of crosslinking (common commercially available examples have 20, 40 or 60% crosslinker) and have high surface areas. However, diffusion is highly restricted by the rigidity of the polymer and so the majority of the catalyst will be located on, or close to the surface. Some examples of phosphine functionalisation of polystyrene are shown below: Functionalisation requires in the first instance that the aromatic ring be substituted to allow appropriate reactivity. Aryl phosphines are generally prepared by either by reaction of aryl lithium or aryl Grignard reagents with halophosphines, or by reaction of 33 | P a g e lithium diphenylphosphide (LiPPh2) with an alkyl or aryl halide. Various examples are seen in the scheme above. It is also possible to do something similar with polyvinyl chloride (and indeed other polymers as well) : The substitution reactions are less efficient with PVC and the strong nucleophile used can also lead to polymer breakdown. 4.1.2. Polymerisation of Phosphine Containing Monomers A second approach is to prepare phosphine monomers which can then be polymerised. An example of this is: The catalyst loading is controlled by the ratio of styrene to diphenylstyrylphosphine and the degree of crosslinking by the amount of divinyl benzene added. A variety of metals can then be incorporated into these polymers. Such metal functionalised polymers are used in a range of catalytic reactions. These can be reasonably well characterised by a variety of analytical and structural techniques, although there is always some conjecture as to the exact nature of the active site. However, as the 34 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer catalytic reactions seem to proceed in much the same fashion as with the simple molecular catalysts it is generally assumed that very similar catalytic species are present. 4.1.2 Functionalised Inorganic Polymers Inorganic polymers have been used for a long time as a part of heterogeneous catalysts, and in more recent times have also been used to support homogeneous type catalysts as well. Examples of such polymers include Zeolites, clays, alumina and magnesia; however, the most widely used is silica. We will briefly look at how catalysts may be attached to silica surfaces. Silica, as you will know from other courses, has hydroxylgroups on the surfaces, and it is the chemistry of these groups which allows functionalisation. Two approaches may be used: (i) Direct Attachment. Here the metal complex is allowed to react directly with the surface hydroxide. For example: Here, molybdenum hexacarbonyl is reacted with the silica surface. Carbon monoxide is released and the Mo(CO)5 fragment is believed to insert into the O-H bond to form a surface bound carbonyl hydride. The problem with this approach, however, is that it is difficult to ascertain what the true nature of the surface bound species is. (ii) Attachment via a Spacer Group. This generally employs alkoxy-substituted organosilanes, which react with the suface Si – OH groups, eliminating an alcohol and covalently attaching to the surface. 35 | P a g e The metal complex is then added and is immobilised on the surface by exchanging a labile ligand with the surface bound phosphine. The main problem is controlling the distribution of the phosphine ligand on the silica particle surface. If there is a high concentration of ligand on the surface the metal complex may be tethered by two or even three surface bound phosphines, while if the concentration is low then maybe only one phosphine will bind to the metal. One way to circumvent this problem is to use a preformed metal complex instead. An example of this is: The triethoxysilane substituted phosphine ligand is complexed to rhodium, forming an analogue of Vaska’s complex, which is then immobilised on the silica surface. Since the orientations of the silane groups are essentially fixed, the metal complex will normally be transferred essentially unchanged to the silica surface and thus the identity of the catalytic species can be known with some degree of confidence. 5. Biphasic Catalysts As an alternative method of catalyst immobilisation it has fairly recently been discovered that, instead of a solid supported catalyst in either a liquid or gaseous medium, a liquid-liquid biphase can be used. In such a system the catalyst is in one liquid phase, while the substrates and products are in a second, immiscible, liquid phase. The process relies on transfer of substrate and product at the liquid-liquid interface. There are two main realisations of these types of processes, namely Aqueous Biphasic Catalysis and Fluorous Biphasic Catalysis. These will be considered in turn. 36 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer 5.1 Aqueous Biphasic Catalysis. As the name suggests, this method uses a homogeneous catalyst dissolved in water as a mobile phase, while the reactants and products are carried in an organic phase which is immiscible with water and in which the catalyst is insoluble. The catalyst is thus “immobilised” and rendered heterogeneous on what may be thought of as a liquid support. Also, the catalyst, though immobilised, is not anchored to a surface and thus loses none of the advantages of homogeneous catalysts, since it is a truly molecular species. In a truly biphasic system there should be no need for additives of any sort (e.g. phase transfer catalysts) to ensure phase separation. Normally the miscibility of the reactants and products is controlled by changes in temperature and pressure alone. In addition, the ease of separation enhances the ease of catalyst recycling. In order to generate water soluble catalysts, complexes bearing ligands with highly polar (often ionisable) functional groups are used. Some examples include: The polar substitutents such as carboxylates, sulfonates alcohols and ammonium salts enhance the solubility of the ligands and their complexes in water. In some casesthe number of groups can be increased to increase partition. Thus, triphenylphosphine can be sulfonated on either one (above, bottom right), two or three or the phenyl rings depending on the reaction conditions used. Also, variation of the spacers can also lead to improved solubility properties or separation of the two layers. The advantages of biphasic catalysis include: 37 | P a g e 1. Generally heating is not required (e.g. distillation) to separate the products, hence catalyst lifetimes are increased as less degradation occurs. This can also be helpful if sensitive organic groups are being used. 2. Catalyst leaching is not observed. With supported catalysts, because the complexes can be susceptible to ligand exchange, some leaching of the metal into the liquid phase can be observed. Because the catalyst is already in solution the problem does not exist in biphasic catalysis. 3. Easy separation of the pahses. However, the major disadvantage of aqueous biphasic catalysis arises when the substrate or product is moisture sensitive. Some types of catalyst are also moisture sensitive, and so certain types of reaction may be hard to do in aqueous media. Another drawback can be that many organics are not highly soluble in water, so problems of mixing and phase transfer can arise leading to slow reaction rates. The classic example of aqueous biphasic catalysis is the hydroformylation of ethene by a sulfonated analogue of the standard rhodium catalyst, with P(m-C6H4SO3Na)3 replacing PPh3. The reaction takes place in the aqueous layer. The reaction conditions and outcomes (selectivity etc) are similar, or slightly better than the standard rhodium system as shown in the table below. 38 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer Process Cobalt catalyst Phosphine modified cobalt catalyst Catalyst Precursor HCo(CO)4 HCo(CO)4 + PnBu3 HRh(CO)(PPh3)3 HRh(CO)(PAr3)3 (Ar = m-C6H4SO3Na) PR3 : Metal ratio - 2:1 50 : 1 to 100 : 1 50 : 1 to 100 : 1 Pressure (bar) 200 – 300 50 – 100 15 – 25 40 – 60 Temperature (ºC) 110 – 160 160 – 200 80 – 120 110 – 130 Catalyst Concentration (% metal/olefin) 0.1 – 1.0 0.6 0.01 – 0.05 0.001 – 1.0 Linear : branched ratio 4:1 7:1 8 : 1 – 16 : 1 7 : 1 – 19 : 1 Alkene Hydrogenation (%) <2 15 5 <2 Higher B.Pt. Products (%) 5 5 2 < 0.5 Catalyst Recovery Difficult Simple Simple (for C3 and C4 alkenes) Facile Rhodium phosphine catalyst Rhodium Phosphine Biphasic Catalyst 39 | P a g e 5.2 Fluorous Biphasic Catalysis (Short Perspective Article: R.H. Fish, Chem. Eur. J., 1999, 5(6), 1677-1680) This is an alternative to aqueous biphasic catalysis. Perfluorinated organic s make ideal carriers for the catalysts. They are poorly miscible with a range of organic solvents (e.g. toluene, THF, acetone, alcohols) and they are chemically rather inert, thus rarely react with either the catalyst or the substrate and product. So, the catalyst is dissolved in a suitable fluorous solvent. These are usually perfluorinated alkanes, ethers or tertiary amines, of types CF3(CF2)nCF3, N((CF2)nCF3)3, and O((CF2)nCF3)2. The organometallic complex can be solubilised in the fluorous phase by attachment of “fluorous ponytails”, (long fluorocarbon or hydrofluorocarbon chains) to ligands such as phosphines or diketonates: One problem which can arise with attachment of the fluorous ponytails is that the fluorinated hydrocarbons are highly electron withdrawing, which can lead to adverse effects on the reaction rates. This can be ameliorated by placing two or three methylene (CH2) groups between the ligand functionality and the fluorous ponytail to act as a buffer. An example of the use of fluorous biphasic catalysis is in the epoxidation of alkenes by a ruthenium tris(perfluoroheptyldiketonate) complex. The O2 and aldehyde are thought to react in the presence of the catalyst to give a peroxyacid performs the epoxidation. The big advantage of this reaction is that O2 is highly soluble in fluorocarbons. 40 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer 6. Organocatalysis. When we think of catalysts our thoughts invariably turn to transition metals and their complexes, which have dominated the scene for many decades. There have, however, been rapid advances in enzyme based catalysis in recent years. A third approach, namely Organocatalysis, has also become significant in the last decade or so. While organic catalysts have been known for some time, the term organocatalysis was coined by David MacMillan in 2000 (A Scot from Bothwell, now Prof at Princeton) and brought focus and impetus to the area of chemistry. As the name suggests, Organocatalysts are purely organic compounds (containing C, H and heteroatoms such as N, O, P and S) which are able to enhance reaction rates. Organocatalysis is not new. One of the first examples in the literature was reported by Justus von Liebig, one of the early fathers of organic chemistry, who described the reaction of cyanogen with water, catalysed by acetaldehyde (ethanal) to give oxamide The acetaldehyde catalyst presumably activates the carbon atoms to nucleophilic attack by water. The work of MacMillan has raised the profile of organocatalysis and has brought focus to research in this area of chemistry. Organocatalysts have a number of significant advantages over metal based catalysts. 1. They are robust. This is in contrast to many organometallic catalysts which are typically air or moisture sensitive. Organocatalysts are normally inert to both O2 and H2O. Consequently, inert atmosphere conditions and dry solvents are unnecessary making manipulation much more straightforward. 2. They are inexpensive. Precious metal catalysts (with Rh/Ir/Pt etc..) are typically between £50 and £500 per gram. Organocatalysts are mostly less that £10 per gram (and often much less). 3. They are readily available – Most organocatalysts can be bought “off the shelf”, and thus little or no synthesis is required. In contrast only the most basic transition metal 41 | P a g e catalysts can be purchased (and at considerable expense), so normally they will need to be prepared. 4. Low molecular weight This means that only a small mass of material is required. 5. Low product contamination – Organocatalysts are easily separated from unreacted reagents and from the products by chromatography. – metal catalysts are less easily separated and are prone to leaving trace contaminants, which are undesirable, especially in pharmaceutical products! 6. Chiral catalysts are readily available from the “chiral pool”. These are cheap and abundant sources of pure chiral materials. 7. Most have low toxicity. Organocatalyst Classes. Organocatalysts fall into two broad classes, those which operate by the formation of covalent bonds, and those which operate by non-covalent interactions (such as hydrogen bonding). We will concentrate on the former type. Most organocatalysts of this class react by one of four general mechanistic types shown in schematic cycles in the figure on the left (where A = Acid, B = Base, S = Substrate, P = Product). In Lewis base catalysis, the catalyst is a Lewis base which can react with the substrate to form an intermediate. This is then converted to the product and is lost, regenerating the catalyst. For reasons of time, and the fact that they predominate, we will consider Lewis base catalysts in a bit more detail. In particular there are three major types of Lewis base catalyst: 42 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer 1. Iminium Catalysis. Iminium catalysis can be summed up in the scheme below. The condensation of a secondary amine/ammonium salt with an aldehyde or ketone gives rise to an iminium salt. The original carbonyl carbon is now activated towards nucleophilic attack. An example of such a reaction is the piperidine catalysed Knoevenagel Condensation: The mechanism can be summarised as follows: 2. Enamine Catalysis. Secondary amines (below) can also catalyse reactions via enamine formation. The enamine is formed by deprotonation of an iminium ion. These enamines can react with electrophiles or undergo pericylic reactions. 43 | P a g e An example of an enamine reaction is shown below: The key mechanistic step can be summarised as follows: The proline forms an enamine with the ketone which is then sufficiently activated to react with the lighly electrondeficient alkene 3. Carbene Catalysis. The so called N-heterocyclic carbenes, which are derived from heterocyclic salts such as imidazolium (left), triazolium (centre) or thiazolium (right) salts by deprotonation (below) are relatively stable and active catalysts in a range of reactions. The catalysts work by nucleophilic reaction with a variety of substrates, including aldehydes as shown below: 44 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer An example of an imidazolium catalysed reaction is the benzoin condensation: The mechanism can be summarised as follows: The N-heterocyclic carbene acts as a nucleophile towards the aldehyde to form the 2substituted imidazolium salt, which rearranges to the very electron rich N,N’-alkene. This in turn is a good nucleophile for the second aldehyde and leads to the coupling product. Finally, the product dissociates to regenerate the carbene catalyst. In all of the examples we have seen, the key is the reversible formation of a C-C bond. 45 | P a g e 4. Enzyme Organocatalysts. It should be noted that many (metal-free) enzyme catalysts behave in a very similar fashion to these organocatalysts. An example is shown on the right. This is a comparison of the catalytic mechanisms of the class I aldolase enzymes and the proline catalysed aldol reaction. It can be seen that the steps are completely in parallel. It is thought that enzyme catalysts will inspire new generations of organocatalysts, while mechanistic insights from the small molecule analogues will aid understanding of the enzymatic processes. A synergistic relationship. 5. Chiral Organocatalysis. By far the most important reactions in this class are the proline catalysed reactions. Proline (right) is a naturally occurring, enantiomerically pure chiral compound which is cheap ( < 30 pence per gram) and readily available. It is able to support both iminium and enamine type reactions. A second type of readily available chiral catalysts are the imidazolidinone catalysts (right), which are prepared in a one-pot reaction from readily available and enantiomerically pure amino acids. 46 | P a g e CH538: Molecular Catalysis Dr M.D. Spicer The chiral induction arises from the control of transition states. In the case of proline reactions this arises by hydrogen bonding from the acid to the substrate: In the case of the imidazolidinones, steric effects and π-π interactions between the proximal aryl group and the substrate control the stereochemistry of the intermediate: The intermediate on the left is stabilised in preference to the one on the right because of π-π interactions between the phenyl group and the alkene on the substrate. This controls the face which is attackedin the next step and thus the handedness of the chiral centre generated. 47 | P a g e