Development Plan for a Lead-Carbon-Fiber Low

advertisement

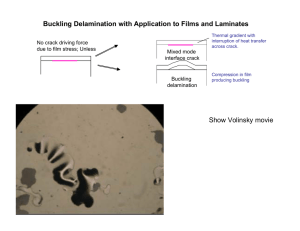

Development Plan for a Lead-Carbon-Fiber Low-CTE Laminate Goal: Develop a laminate of carbon fiber and lead foils, with a total of thickness of 20% to 25% (TBD) radiation lengths and a CTE that closely matches that of silicon. To minimize the thickness and amount of low-Z material, we prefer to use prepreg sheets of carbon-fiber and cure them together with the lead foils. If this does not work, a backup solution is to use finished carbon-fiber sheets laminated with lead using room-temperature-cure adhesive. This program should be completed by the time of the GLAST PDR (August 2001). The first step, to test the concept, should be completed by about the end of June 2000, so that we can know whether we are proceeding in the right direction. 1) Test the concept: Very quickly find small quantities of lead sheet and graphite fiber prepregs in the right range of properties, and design a simple 3 to 5 layer sandwich sample (about 5cm by 5cm maybe, the exact value of the CTE is not so important). Have that sample built and model it for CTE. Then run a CTE test (2 directions, 0 and 90 degrees, at least) to validate the modeling. Finally run a thermal cycling test, looking for fatigue induced delamination. The primary goals are to uncover any unexpected difficulties in manufacturing, to find out if delamination is critical, and to validate the modeling 2) Talk to composite manufacturers and materials specialists to uncover any other possible issues with lead/GFRP layered composites (such as long term chemical interactions, electro-chemical corrosion issues, etc.). 3) Examine and discuss with manufacturers health risk issues related to this use of lead (most manufacturers will take this very seriously). 4) Further discuss manufacturing with composite manufacturers. As a result of this we would narrow down the possible selections of fiber and matrix systems (i.e. epoxies vs cyanates, cure temperatures, etc...)., and get a better feel for manufacturing parameters (pressure, temperature, fiber volume content that can be achieved, fabrics VS unitape, etc.). 5) Based on what was learned above, down-select to one (or two at most) fiber/matrix systems for the layering and get cost, delivery, and material property information from suppliers and/or literature. 6) Repeat the design/optimization calculations based on the selected fiber/matrix system(s), and design a SuperGLAST converter. Here we need some final input on the desired radiation lengths. 7) Have at least one sample built, but preferably 5 or 10 samples produced in separate batches so that we get some idea of repeatability in manufacturing (which is always an concern with composites). 8) Test those samples for CTE (two directions minimum) and creep, and temperature cycle them to check for delamination. It may be useful to perform some other mechanical strength test as well, mostly to get a feel for the margin of safety to delamination (maybe a 3-point bend test). 9) If the approach is viable, get quotations for multiple manufacturers for production quantities of SuperGlast converters. 10) Select one or two vendor(s) and order a few samples from them to validate their process. This of course can be avoided if the same manufacturer is used in development and production.