IMO Type 1 21000-Litre Hydrogen Peroxide Tank

advertisement

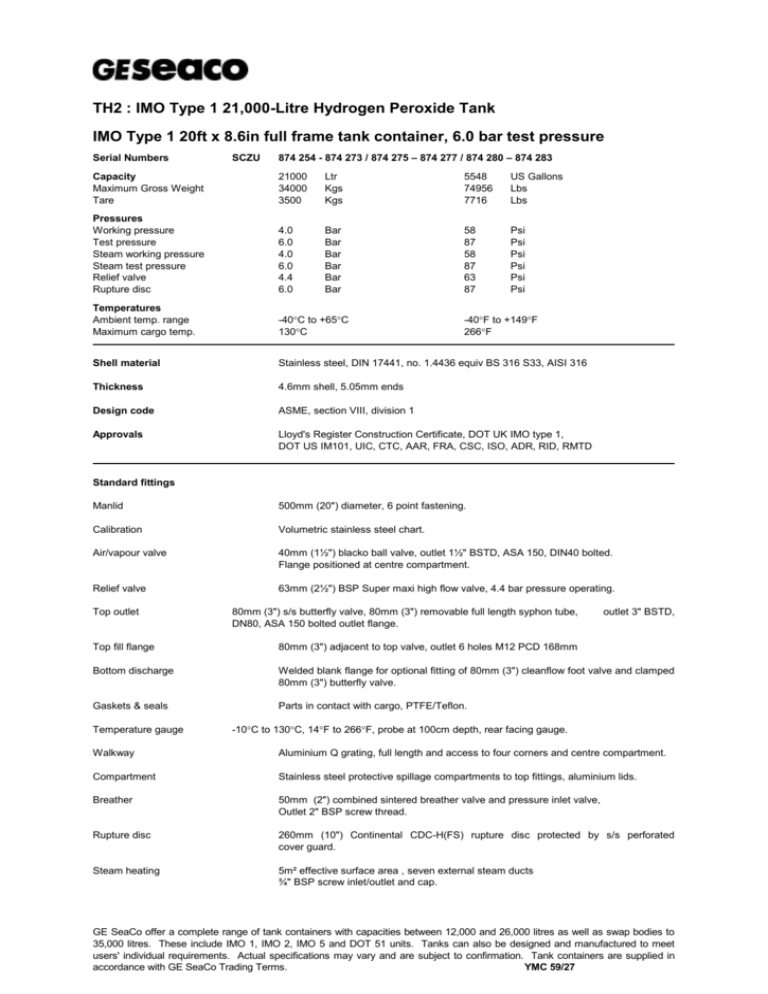

TH2 : IMO Type 1 21,000-Litre Hydrogen Peroxide Tank IMO Type 1 20ft x 8.6in full frame tank container, 6.0 bar test pressure Serial Numbers SCZU 874 254 - 874 273 / 874 275 – 874 277 / 874 280 – 874 283 Capacity Maximum Gross Weight Tare 21000 34000 3500 Ltr Kgs Kgs 5548 74956 7716 US Gallons Lbs Lbs Pressures Working pressure Test pressure Steam working pressure Steam test pressure Relief valve Rupture disc 4.0 6.0 4.0 6.0 4.4 6.0 Bar Bar Bar Bar Bar Bar 58 87 58 87 63 87 Psi Psi Psi Psi Psi Psi Temperatures Ambient temp. range Maximum cargo temp. -40C to +65C 130C Shell material Stainless steel, DIN 17441, no. 1.4436 equiv BS 316 S33, AISI 316 Thickness 4.6mm shell, 5.05mm ends Design code ASME, section VIII, division 1 Approvals Lloyd's Register Construction Certificate, DOT UK IMO type 1, DOT US IM101, UIC, CTC, AAR, FRA, CSC, ISO, ADR, RID, RMTD -40F to +149F 266F Standard fittings Manlid 500mm (20") diameter, 6 point fastening. Calibration Volumetric stainless steel chart. Air/vapour valve 40mm (1½") blacko ball valve, outlet 1½" BSTD, ASA 150, DIN40 bolted. Flange positioned at centre compartment. Relief valve 63mm (2½") BSP Super maxi high flow valve, 4.4 bar pressure operating. Top outlet 80mm (3") s/s butterfly valve, 80mm (3") removable full length syphon tube, DN80, ASA 150 bolted outlet flange. outlet 3" BSTD, Top fill flange 80mm (3") adjacent to top valve, outlet 6 holes M12 PCD 168mm Bottom discharge Welded blank flange for optional fitting of 80mm (3") cleanflow foot valve and clamped 80mm (3") butterfly valve. Gaskets & seals Parts in contact with cargo, PTFE/Teflon. Temperature gauge -10C to 130C, 14F to 266F, probe at 100cm depth, rear facing gauge. Walkway Aluminium Q grating, full length and access to four corners and centre compartment. Compartment Stainless steel protective spillage compartments to top fittings, aluminium lids. Breather 50mm (2") combined sintered breather valve and pressure inlet valve, Outlet 2" BSP screw thread. Rupture disc 260mm (10") Continental CDC-H(FS) rupture disc protected by s/s perforated cover guard. Steam heating 5m² effective surface area , seven external steam ducts ¾" BSP screw inlet/outlet and cap. GE SeaCo offer a complete range of tank containers with capacities between 12,000 and 26,000 litres as well as swap bodies to 35,000 litres. These include IMO 1, IMO 2, IMO 5 and DOT 51 units. Tanks can also be designed and manufactured to meet users' individual requirements. Actual specifications may vary and are subject to confirmation. Tank containers are supplied in accordance with GE SeaCo Trading Terms. YMC 59/27