Operating a Chip Spreader

advertisement

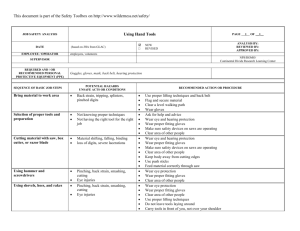

JOB SAFETY ANALYSIS (JSA) Job: Chip Spreader Dept.: Road & Bridge Date: 9.3.10 Supervisor: Joe Carter JSA No. #4 New Revised Analysis Performed By: Road & Bridge Employees & Safety Coordinator Approved by: Joe Carter Operator: Operators & Laborers Note: Item 1. 2. 3. Required/Recommended Personal Protective Equipment (PPE): Safety Vest, safety-toed boots should be worn at all times. Appropriate gloves should be worn as needed. Hard hat protection required as needed. Sequence of Basic Job Steps Potential Incident/Hazard Recommended Notes - *While working outdoors dehydration is always a problem - drink adequate amountsSafe Job Procedure of water. Pre-trip inspection: oil, anti-freeze, 2 *Spills/oil & fuel on hands & clothing *Wear protective clothing (coveralls) *Wear appropriate clothing for weather conditions hydraulic belts, 5 chains, levers *Pinch point or have change of clothes available *When working outside whatever the season sun screen is advised *Slip, trip & fall *Wear appropriate gloves Operation: Driver( lights, beacon, levels *Injury due to contact with traffic, *Certified flagger at site *Back strain *Awareness/condition of work area, & controls) overhead lines, mail boxed, bridges, *Traffic control signage obstacles culverts, etc. *Awareness/all *3 point contacthazards Operation: Hopper operator (levels & *Injury points to driver *Awareness/watch for driver *Pinch *Wear appropriate gloves *Proper bending & controls) *Injury due to contact with traffic, *Certified flagger atlifting site technique overhead lines, mail boxes, bridges, *Traffic control signage culverts, etc. *Awareness/all hazards *Pinch points *Wear appropriate gloves 4. Operations: Operator hooking up truck (levers, contact with driver/hand signals or radio *Injury due to contact with traffic, and other hazards (same as above) *Pinch points *Slip, trip & fall *Back injury *Certified flagger on site *Traffic control signage *Awareness/ of all hazards *Awareness/ pinch points *Wear appropriate gloves *Awareness/footing *Use proper bending & lifting technique 5. Parking & shutdown of equipment *Slip, trip & fall/exiting *Post operation accidents *Awareness of footing *Maintain 3 point contact