Service Waste

Manufacturing and Service waste

The original seven muda are:

Transport (moving products that is not actually required to perform the processing)

Inventory (all components, work in process and finished product not being processed)

Motion (people or equipment moving or walking more than is required to perform the processing)

Waiting (waiting for the next production step)

Overproduction (production ahead of demand)

Over Processing (resulting from poor tool or product design creating activity)

Defects (the effort involved in inspecting for and fixing defects)

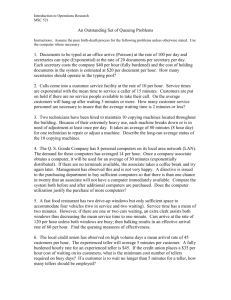

Service Waste

The Biggest Challenge in Service: Learning to Recognize Waste

• Waste 1: Overprocessing – adding more value than your customer would pay for. Do you know what your customer wants? Have you allowed NVA to creep into the process?

• Waste 2: Transportation – excessive movement of materials or information. Paperwork loop-backs are especially wasteful. Cut the hand-offs in half and you cut the queue time in half.

• Waste 3: Motion – excessive movement of people. Multiple computers or drives, multiple keystrokes, poor office setup or workstation arrangements.

• Waste 4: Inventory – WIP exceeding customer needs causes NVA waiting, longer lead times. Look for piles of requests, callers on hold, people in line. Excess WIP is often overproduction.

• Waste 5: Waiting time between processes. Since much service work is invisible, mapping techniques are essential for finding delays. [See Diagram: Process Map]

• Waste 6: Defect – anything that does NOT meet customer needs. Missing information, missed deadlines.

Misinformation in a process results in re-work. Mapping shows how corrections are done.

• Waste 7: Overproduction – production over what is needed for immediate use.

One redefinition of these wastes for service operations by

Bicheno and Holweg (2009) is as follows:

Delay on the part of customers waiting for service, for delivery, in queues, for response, not arriving as promised.

The customer’s time may seem free to the provider, but when she takes custom elsewhere the pain begins.

2. Duplication. Having to re-enter data, repeat details on forms, copy information across, answer queries from several sources within the same organisation.

3. Unnecessary Movement. Queuing several times, lack of one-stop, poor ergonomics in the service encounter.

4. Unclear communication, and the wastes of seeking clarification, confusion over product or service use, wasting time finding a location that may result in misuse or duplication.

5. Incorrect inventory. Being out-of-stock, unable to get exactly what was required, substitute products or services.

6. An opportunity lost to retain or win customers, a failure to establish rapport, ignoring customers, unfriendliness, and rudeness.

7. Errors in the service transaction, product defects in the product-service bundle, lost or damaged goods.