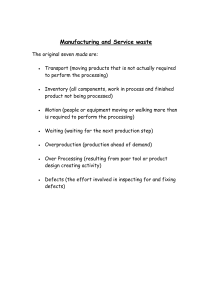

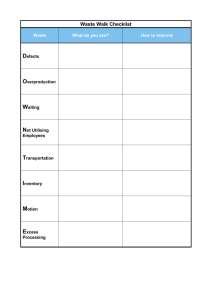

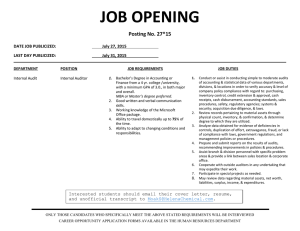

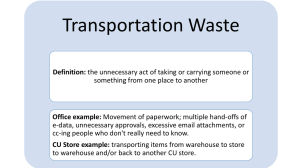

Eight Areas of Waste CHAPTER 7 Waste (Definition) A situation in which something valuable is not being used or is being used in a way that is not appropriate or effective (Merriam-Webster Dictionary) Eight Areas of Waste Overproduction Waiting Transporting Unnecessary Paperwork or Processing Unnecessary Inventory Excess Motion Defects Underutilized Employees Overproduction refers to the production of a given output in excess of what is required. To address this, organizations perform cycle counts and physical counts, build/rent and use climate-controlled facilities, implement access controls, and in general build an infrastructure to address overproduction Waiting is the delayed action that happens until some other productive action is done on the item produced The auditor can help the organization by examining what is happening, where, why, and by whom, then recommending improvements to the process that will allow production to occur more evenly. Transporting refers to the action of moving an item from one location to another Transportation waste is the unnecessary movement of parts, excessive handling of materials, or shuffling of inventory to get access to the correct components. Eliminating transportation waste requires a focus on the flow of materials, machines, and people. Unnecessary Paperwork or Processing While the concept and vision of workplaces where paper is redundant for routine tasks like documentation, bookkeeping, and communication has a lot of merit, the reality is that we still use paper for a multitude of reasons. Ways to eliminate or greatly reduce the use of paper in the workplace: Convert documents into digital form Adopt digital signatures to digitally sign documents rather than relying exclusively on manual signatures on paper documents. Employ some technologies like: E-forms (electronic form) to create, integrate, manage, and route forms and data with other processing systems Workflow applications to route information and documents Web servers to host the process, receive submitted data, store documents, and manage information Unnecessary Inventory Excess products, materials, parts, and documentation not being processed immediately, or ahead of requirements, constitute unnecessary inventory. Why manage inventories: It incur carrying costs It ties up needed capital Susceptible to damage, obsolete, and being lost/stolen The goal should always be to maintain a balance between the future demand and the inventory on hand. Excess Motion Superfluous activities or additional steps in the required minimum number of steps to achieve a stated purpose and to deliver a product or service Main cause: Poorly designed work environment Use spaghetti diagram to track routing through factories and other types of workplace to identify inefficiency within the flow of the system Why it becomes a concern? every action is paid causes wear and tear on people and machines requires time to be completed Employees’ disability time off May increase workers’ compensation insurance premiums Spaghetti Diagram Defects a physical problem that causes something to be less valuable, effective, healthy, etc., something that causes weakness or failure and an imperfection that impairs worth or utility (MerriamWebster) Defects prompt the need to rework the item to correct the error made, so the organization must then spend additional resources to correct and deliver an acceptable product or service as initially expected. Internal auditors should ascertain as best they can what the expectations are in the first place, then comparing the end result to that standard. Underutilized Employees Employees are instructed to perform activities beneath their capabilities, or they are prevented from being employed in positions where their capabilities would be better utilized. Business leaders should: i. Perform skill assessments in their organizations to identify the entity’s present and future needs. ii. Collect information about the skills and competencies of their workers to perform a gap analysis. iii. The information gathered should inform their training and development programs, their hiring practices, outsourcing/cosourcing plans, and alignment of strategic plans with resource availability. Internal auditors should audit employee engagement as it influences productivity, retention, customer satisfaction, and the quality of internal controls. Identifying, Assessing, and Preventing the Occurrence of Muda I. Identify the auditable universe in the organization. consists of all auditable entities, accounts, programs, processes, and systems relevant to the organization II. This audit universe should be reviewed and updated periodically to assess the risk level of each of these items, which in turn informs the priority that should be given to each of them and to schedule the review. III. Perform audits at the beginning of the entire cycle This way auditors can check the system development life cycle, check the feasibility studies, planning documents, bidding and contracting process, vendor selection procedures, and the process to embed internal controls in the design. examine these Eight Areas of Waste from a prospective perspective and anticipate their occurrence and their impact on the organization Using the Eight Areas of Waste during Internal Audits Standard Areas of Waste Achievement of the organization’s strategic objectives Any of the Eight Areas of Waste occurring en masse over extended periods of time can limit the organization’s ability to achieve its expansion goals, profitability objectives, and accomplishment of its mission. Reliability and integrity of financial and operational information Excessive waiting during the financial reporting cycle can delay the timely publication of financial reports. Defects in accounting transactions, or notes to the financial statements can result in costly restatements and significant decreases in stock price. Using the Eight Areas of Waste during Internal Audits Standard Areas of Waste Effectiveness and efficiency of operations and programs Any of the Eight Areas of Waste will limit the organization’s effectiveness and efficiency. By eroding the efficiency of operations, they can collectively limit the ability to achieve organizational objectives. Safeguarding of assets Misusing limited financial resources and increasing the need for operating capital due to waste is contrary to the concept of safeguarding assets. Unskilled workers are more likely to be inefficient in their transportation planning, motion assessment, and inventory management, and cause more defects to occur. Furthermore, by not having the skills to perform their duties, they may engage in waiting as they try to figure out how to get the work done. Table 7.2 Using the Eight Areas of Waste during Internal Audits Standard Areas of Waste Compliance with laws, regulations, policies, procedures, and contracts There are many ways that noncompliance can occur, based on specific laws, regulations and internal expectations. Environmental laws frown upon excessive waste, which is caused by overproduction and defects. Compliance with clean air regulations are hindered by idling vehicles, excessive transport, and vehicles carrying heavier loads due to overproduction and inventory accumulation. Workplace safety laws, and in-house ergonomics expectations would be compromised through excessive motion. “The most dangerous kind of waste is the waste we do not recognize.” - SHIGEO SHINGO