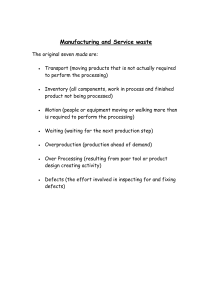

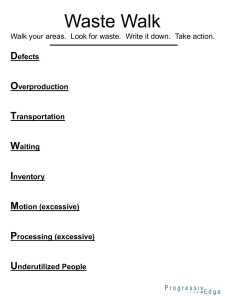

Waste Chapter 3 Waste (muda) Anything other than the minimum amount of resources (material, labor, parts, equipment, time) absolutely necessary to add value to a product or service. Value-added Anything that directly adds value to the product or services as seen or experienced by the customer Non-value added Waste (should be eliminated) Necessary non-value added Non-value added, but necessary and hard to eliminate (e.g., planning, scheduling, purchasing, quality control, etc.) Toyota’s Seven Wastes Overproduction Waiting time Transportation Processing Inventory Motion (non-work) Defects (Sometimes also included: Human potential) Overproduction Overproduction Solution: Produce only on demand Waiting Waiting Solution: Discourage “busy work” so waiting can be identified. Eliminate sources of waiting • Setup time • Equipment breakdown • Erratic schedules • Large-batch production • Defects Transportation Transportation Solutions: •Rearrange facility layout to shorten distances • Coordinate stages of process • Use good housekeeping • Improve transportation methods Spaghetti Chart Patient Rooms Nurse station 60+ trips per patient to get supplies or enter information Solutions: • Rearrange facility layout to shorten distances • Rearrange or alter stages of the process • Use good housekeeping • Improve transportation methods John Processing Dealer Faxes Order Paper Order Created 4% of orders lost Order Sits In Fax In Box 0 to 4 hours 2 hours on average Order Sits In Clerk’s In Box Internal Mail Delivers Fax 0.5 to 1.5 hours 1 hour on average 1% of orders lost 0 to 2 hours 1 hour on average Clerk Processes Order 5 minutes 10 to 45 minutes 20 minutes on average Dealer Receives Order Transport Firm Delivers Order 1 to 3 hours 2 hours on average No history of lost, damaged, or incorrect deliveries Inspector Checks Order Worker Picks Order 2 minutes 0.5% of orders incorrect YES Is Item In Stock? NO Clerk Notifies = value-added activity Dealer and Passes Order On to Plant Processing Dealer Faxes Order Paper Order Created 4% of orders lost Solution: Analyze steps; identify non-value added ones; try to eliminate them Order Sits In Fax In Box 0 to 4 hours 2 hours on average Order Sits In Clerk’s In Box Internal Mail Delivers Fax 0.5 to 1.5 hours 1 hour on average 1% of orders lost 0 to 2 hours 1 hour on average Clerk Processes Order 5 minutes 10 to 45 minutes 20 minutes on average Dealer Receives Order Transport Firm Delivers Order 1 to 3 hours 2 hours on average No history of lost, damaged, or incorrect deliveries Inspector Checks Order Worker Picks Order 2 minutes 0.5% of orders incorrect YES Is Item In Stock? NO Clerk Notifies = value-added activity Dealer and Passes Order On to Plant Inventory Inventory (the “Flower of all Evil”) Flower: Inventory Root: Bad management practices Inventory Solutions • Produce only what is required or demanded • Produce in small batches • Procure in small batches • Eliminate the reasons for inventories; e.g., Inventory Reasons for inventory • • • • • Uncertain demand Product defects Equipment breakdown Erratic schedules Poor housekeeping/inventory control Motion (non-work) Motion (non-work) Solutions • Improve facility layout • Improve process and job design • Clean up and organize workplace Defects Defects Solutions • Implement a system to preclude defects (pokayoke) • Implement system to immediately identify and rectify defects (source inspection) Wastes: each company defines its own Canon’s nine wastes operations (motion) work-in-process (inventory) defects equipment (procurement and operation) expenses (personnel, materials, tools, etc.) indirect labor (management functions) planning (inappropriate methods, machinery, purchasing) human resources (people given tasks better done by machines; not given tasks that require judgment and creativity) startup (setup/changeover time) Waste of Human Talent Most everyone has ideas about improvements that could be put to good use. Seldom are these ideas valued, solicited, or implemented Necessary, nonvalue-added Planning Scheduling Purchasing Quality Inspection Process/equipment changeover Equipment preventive maintenance/repair Others? Can these be eliminated?