Using LEAN Continuous Improvement to Strengthen Contact Centre

advertisement

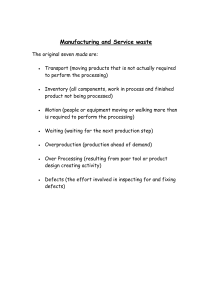

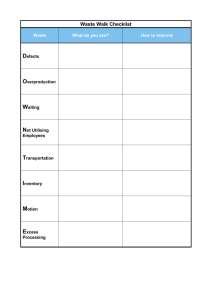

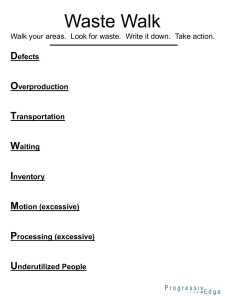

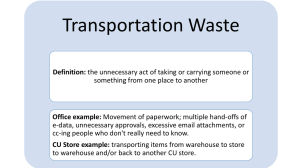

Using LEAN Continuous Improvement to Strengthen Contact Centre Performance Part 3 of 4 “Identifying Waste In Your Contact Centre” An important part of Customer Value is determining whether tasks to deliver products or services are “Value Added” (VA) or non-value added (NVA). A simple definition of VA is “anything that consumes resources that the customer would be willing to pay for”. Waste is an NVA task that consumes resources but does NOT create customer value. Resources can mean people’s time, materials, equipment, space or money. The 7 original wastes are defined by “T-I-M-W-O-O-D” - Transportation, Inventory, Motion, Waiting, Overproduction, Over-processing, and Defects. Recently, LEAN practitioners have added “Staff” (underutilization of) and “Safety” to the original seven wastes, for a total of nine wastes. While these original seven wastes were initially defined in a manufacturing environment, the concepts apply to a contact centre as well. The following table illustrates each type of waste in a contact centre: WASTE Transportation Inventory Motion Waiting Overproduction Over-processing Defects Staff Safety Manufacturing Movement of Materials, Product Accumulation of Materials, WIP, Product Movement of people or body parts Waiting to do work Typically refers to … Contact Center Movement of Work (ie a call), or information Inventory of Information, Accumulation of Work (in progress), or lack of product inventory (short stock) Movement of people or body parts Contact Center Example Call Transfer, Escalation Easy to find info, # Calls in queue, ACW (after call work), Call backs Looking for information, copying or faxing, escalating to manager Waiting to do work Not ready status, waiting for work, call transfers, waiting for up stream response More inventory than required More agents than required Lower productivity ratios Changes to product "form fit Time spent on call that does not create Long scripts, answering questions not feel" but does not create value customer value asked, jumping to conclusions, pushing work back onto customers Errors, repairs, inspection of Actions not aligned with customers Inaccurate information, incorrect product or subassembly expectations transfer or routing Not making use of the skills of Not making use of the skills of employees Employees could improve scripts, employees process, or suggest ideas Process of workplace risks to Workplace processes pose risks to Unrealistic expectations of employees health and well employees health and well being productivity or skills (without required being training) causing stress 9 Wastes – “T I M W O O D” + “SS” A more detailed description of each type of waste is as follows: 1. Transportation – any unnecessary movement of materials or work. A key offender of transportation waste in contact centres is “call1 transfers”, and “escalations” as these tasks directly inconvenience the customer. Another example might be mailing the customer product literature, when the option of a web page link exists. Caution – it is important to note that the preferred method of providing information to the customer should be based on what the customer needs (values), not what is convenient for the organization. 1 “Call” refers to all forms of contact including telephone calls, emails, fax, chats and social media. ©2013 MasterKey Business Solutions Inc. 1 Using LEAN Continuous Improvement to Strengthen Contact Centre Performance 2. Inventory – while inventory originally referred to products or materials in a manufacturing process, inventory in a contact centre is typically defined as an accumulation of work (in progress) as illustrated by increasing queue sizes. This can be measured through metrics like “average # of calls in queue”, and “after call work”. Also, in a contact centre where physical products are ordered, inventory waste can be due to “lack of available products (i.e. inventory)” to provide or ship to customers. 3. Motion – any unnecessary movement of people. This can range from an agent trying to find something in/on their desk or computer, to having to go to the printer, or photocopier, or manager (in the case of an escalation). Motion can also apply to making the customer “move” – for example, asking them to call another phone number, or asking them to fax something to you (especially when your company already has the information), or asking them to go to a (different) location for face-face service. 4. Waiting – often applies to a customer stuck in an IVR2 system, or an agent either in a non-productive status, waiting for the next call, or waiting for an up-stream request for information or authorization. Waiting can also apply directly to the customer (e.g. call transfers and escalations create wait times for the customer). 5. Overproduction – while overproduction is a result of producing more product than is required by the customer (demand), overproduction has a different meaning in a contact centre because of its real time, transactional service characteristics. Overproduction translates to staffing more agents than is required for the demand at any given time. Having more capacity than is required is considered as wasteful, and leads to other forms of waste like waiting. It is important to note that overproduction (or overcapacity in the case of a contact centre) often hides waste and inefficiency as this extra capacity allows agents to work in a nonoptimal manner undetected. 6. Over-processing – Over-processing in a manufacturing environment typically refers to additional touch time as a result of an ineffective or error-prone process. In a contact centre environment, over-processing means spending more time and resources on a call than the customer deems necessary (i.e. it does not create value for the customer). 7. Defects – Errors in the product, service or contact centre operations or processes. An error can be defined as “a product, service, or process that is not working as per expectations set with the customer”. 8. Staff – by not making use of employee’s knowledge, wisdom, and creativity (especially on the “front line”) the customer’s time is wasted due to lost opportunities to reduce errors and speed up the process. A key principle of LEAN is employee empowerment (with trust and respect); this leads to greater employee engagement. 9. Safety – working in an unsafe work environment causes unexpected time off due to injury and/or health issues (creating inefficiencies which are wasteful). A common health risk in contact centres is “overburden” which causes stress, time off, and unbalanced teams. Stay tuned for this upcoming blog! Part 4 of 4 - “A 5 Step Process to Strengthen Contact Centre Performance” 2 Interactive Voice Response system. ©2013 MasterKey Business Solutions Inc. 2