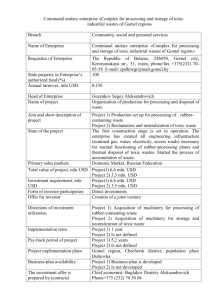

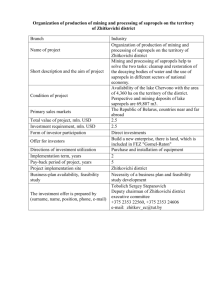

Паспорт

advertisement

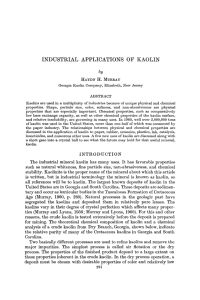

Investment proposal 1. Project name: Sanitary ware production with capacity 200 thousand pcs. per annum in Uzbekistan 2. Project Initiator: Joint Stock Company “Uzbuildingmaterils” - www.uzsm.uz 3. Local market demand: Due to high demand in a high quality sanitary ware, the project assumes to sell 60% of produced goods to the local market. 4. Export market: 40% of goods are expected to export to neighboring counties, and CIS (Russia, Kazakhstan, Tajikistan, Turkmenistan, Afghanistan and others). 5. Demand in raw materials (materials and components), including the ones manufactured in Uzbekistan and imported raw materials: all raw materials required for sanitary ware production, such as kaolin, silica sand, feldspar, dolomite, are available in Uzbekistan, excluding zirconium. 6. Manufacturers of sanitary ware in Uzbekistan and region: there is only enterprise in the Uzbekistan specialized in sanitary ware production is a Stock Company “Kulol” with production capacity of 25000 pcs. per year. There are no other production facilities in Central Asian region manufacturing the identical goods that promotes the perspectives for Uzbekistan of its potential sale in the region. Over 150000 psc. of sanitary ware are imported to Uzbekistan annually. The ceramic units were imported for over 2178,3 thousand USD to Uzbekistan in 2008. The country’s annual demand in sanitary ware is not less than 160000 psc. (bowls, lavatory, bidet and others), and it is regularly growing. The cost of sanitary ware on the market depends on quality and design: lavatory pan set – 80-400 US dollars, washing stand – 60-200 US dollars. 7. Required land area including the land intended for production capacities, engineer infrastructure (m2/ hectare): 10-15 thousand sq.m. are already available in FIEZ. 8. - Required engineering provision: branch railway construction; 3,5 thousand cubic meters/year water supply; 2,7 mln. K.W.H./year power supply; 1,3 mln. cubic meters/year gas supply; sewerage (thousand cubic meters/year). 9. Project costs: 17,6 mln. USD; the estimated project costs depend on the chosen equipment. Proposed technological line charges are the following: - sanitary ware production equipment - 7 mln. USD - construction and installation works - 4 mln. USD - other costs and works - 6,6 mln. USD Project financing: foreign direct investments 10. Terms of Project implementation: 24 months after financing started. 11. New jobs: 63 people including: management-8, engininring-10, and workers – 45. 12. Annual production: 200 thousand units per year (6,22 mln. USD). - for local market - 120 thousand units (3,7 mln. USD); - for export - 80 thousand units (2,48 mln. USD). 13. Annual volume of earnings for project implementation is 5.6 mln. US dollars. 14. Raw materials located in Uzbekistan are applied for sanitary ware production (kaolin of Angren deposit, silica sand of Djeyron deposit, feldspar of Lyangar deposit), except zirconium. - Angren kaolin-coal open-pit-mine is located in middle part of Angren valley in 80 km to the southeast from kaolin-coal open-pit-mine Tashkent City and connected with Tashkent with Angren railway branch. Kaolin investigated resources are located in the territory of operated coal pit and could be withdrawn together with coal. - Aparkat kaolin-coal open-pit-mine is located in 5 km to the west from operating coal open pitmine and in 3,7 km to the north from Angren Station. According to the detailed data, kaolin clay resources are 390 mln. ton. Kaolin clay annual production: 0,3-0,5 mln. ton. The specific weight of clay: 1,9 – 2 t/m3. The main raw material for facing ceramic tiles production are kaolin derived clays which represent mottled kaolin clay, that is fat with rare quartz seeds. Derived kaolin consists of large amount of fine-dispersed quartz undersized through sieve of 10000 holes/cm2 while enrichment process. Grain-size composition of derived kaolin: fraction 2- 0,05 mm (sand) - 26-38,4% 0,5-0,005 mm (dust) – 16,8-44,9% and less than 0,005 mm (clay) – 38,6-81,9% - Angren derived kaolin is a raw material with fireproof (refractoriness is 1580-1620˚ C), low dispersive, semi acid, moderate or average plastic, kaolinite clay, and low-grade of gross-grained inclusions in form of quartz, rock debris, low-sensitive to drying. - Feldspar concentrate of Lyangar deposit is the product of enriched and crashed granites and gabbro. The amount of oxide alkaline metals is 7.8 – 8.5%. - Silica sand Djeroy silica sand deposit is located in Tamdin district, Navoi region, 14 km southward of Tamdimbulak administration centre, 60 km to the northeast from Zarafshan connected by main highways. The nearest railroad station is Yangi Zarafshan. Silica sands of Djeroy deposit comply with local standards and are free-milling. It is not developed nowadays. 15. Brief description of production technology: mass preparation, glaze preparation, molding, drying, glazing, burning. 16. Condition of development and appraisal of project construction documents. Construction documents will be developed after the approval of equipment supplier and feasibility study development.