Asphalt Paving JSA/SWMS: Safety Analysis & Hazard Control

advertisement

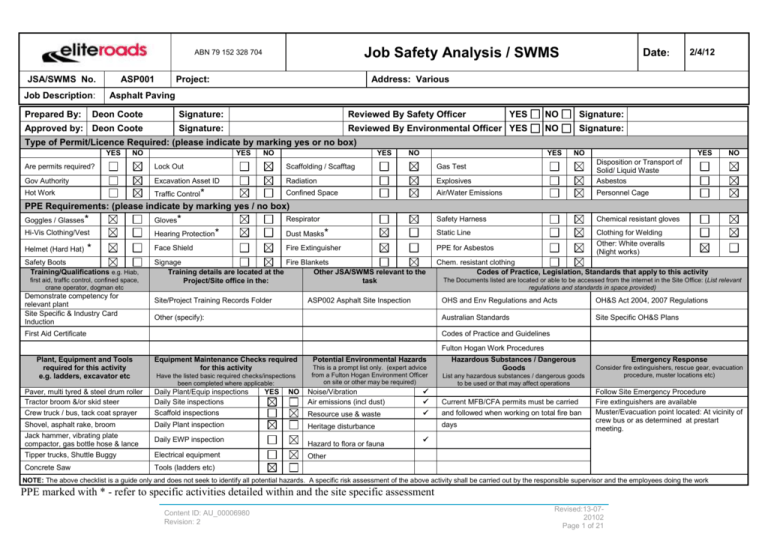

Job Safety Analysis / SWMS ABN 79 152 328 704 JSA/SWMS No. Job Description: Prepared By: ASP001 Project: Date: 2/4/12 Address: Various Asphalt Paving Deon Coote Signature: Reviewed By Safety Officer YES NO Signature: Approved by: Deon Coote Signature: Reviewed By Environmental Officer YES NO Signature: Type of Permit/Licence Required: (please indicate by marking yes or no box) YES NO YES NO YES NO YES NO YES Are permits required? Lock Out Scaffolding / Scafftag Gas Test Gov Authority Excavation Asset ID Radiation Explosives Disposition or Transport of Solid/ Liquid Waste Asbestos Hot Work Traffic Control* Confined Space Air/Water Emissions Personnel Cage NO PPE Requirements: (please indicate by marking yes / no box) Goggles / Glasses* Gloves* Respirator Safety Harness Chemical resistant gloves Hi-Vis Clothing/Vest Hearing Protection* Dust Masks* Static Line Clothing for Welding Face Shield Fire Extinguisher PPE for Asbestos Other: White overalls (Night works) Helmet (Hard Hat) * Safety Boots Training/Qualifications e.g. Hiab, first aid, traffic control, confined space, crane operator, dogman etc Demonstrate competency for relevant plant Site Specific & Industry Card Induction Signage Fire Blankets Training details are located at the Other JSA/SWMS relevant to the Project/Site office in the: task Site/Project Training Records Folder ASP002 Asphalt Site Inspection Other (specify): First Aid Certificate Chem. resistant clothing Codes of Practice, Legislation, Standards that apply to this activity The Documents listed are located or able to be accessed from the internet in the Site Office: (List relevant regulations and standards in space provided) OHS and Env Regulations and Acts OH&S Act 2004, 2007 Regulations Australian Standards Site Specific OH&S Plans Codes of Practice and Guidelines Fulton Hogan Work Procedures Plant, Equipment and Tools required for this activity e.g. ladders, excavator etc Equipment Maintenance Checks required for this activity Have the listed basic required checks/inspections been completed where applicable: Potential Environmental Hazards This is a prompt list only. (expert advice from a Fulton Hogan Environment Officer on site or other may be required) Hazardous Substances / Dangerous Goods List any hazardous substances / dangerous goods to be used or that may affect operations Noise/Vibration Air emissions (incl dust) Current MFB/CFA permits must be carried Scaffold inspections Resource use & waste and followed when working on total fire ban Shovel, asphalt rake, broom Jack hammer, vibrating plate compactor, gas bottle hose & lance Tipper trucks, Shuttle Buggy Daily Plant inspection Heritage disturbance Concrete Saw Tools (ladders etc) Paver, multi tyred & steel drum roller Tractor broom &/or skid steer Daily Plant/Equip inspections Daily Site inspections Crew truck / bus, tack coat sprayer Daily EWP inspection Electrical equipment YES NO Hazard to flora or fauna days Emergency Response Consider fire extinguishers, rescue gear, evacuation procedure, muster locations etc) Follow Site Emergency Procedure Fire extinguishers are available Muster/Evacuation point located: At vicinity of crew bus or as determined at prestart meeting. Other NOTE: The above checklist is a guide only and does not seek to identify all potential hazards. A specific risk assessment of the above activity shall be carried out by the responsible supervisor and the employees doing the work PPE marked with * - refer to specific activities detailed within and the site specific assessment Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 1 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. 1 ASP001 Project: Job Safety Analysis / SWMS Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. Mobilisation to Site POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Collisions with public road users 11 H Arrive at site – park vehicles Site hazards – pits, ditches, culverts, soft edges, drop offs ledges, environmental flora/fauna, other traffic 4L 3 4 2/4/12 Address: Various 2 Date: Where traffic control is required, ensure that it is implemented prior to commencing works As per Traffic Management SWMS (see site specific risk assessment for risk score) Carry out daily pre-start toolbox, complete site specific induction and review the SMWS relevant to activities Site environment / job plan not understood Content ID: AU_00006980 Revision: 2 11 H Adhere to all road rules Give sufficient warning using vehicle indicators Park legally and out of the path of traffic Attach and activate amber flashing light to warn traffic users Drive to the conditions Ensure traffic management plan is approved and implemented where required Familiarise yourself with site Identify safe parking area which maintains safe distance from embankments, ditches, soft edges, vulnerable flora/fauna and allows safe access to and from work vehicles Park equipment on level sealed ground Avoid parking within a 10m radius of stormwater entry points Ensure spill kits are available & representative trained Residual Risk Score 8M Drivers 1L Drivers Operators As per Traffic Management SWMS Check that the traffic control has been implemented in accordance with the traffic management plan and crew members are fully aware / understand paving plan & traffic control plan Engagement and feedback from all crew members Acknowledgement “sign off” Revised:13-0720102 Page 2 of 21 PERSON RESPONSIBLE Nominate the person who will action the controls Foreman / Crew manager 6L All Foreman / Crew manager & Subcontractors ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. 5 ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. Conducting general duties whilst on site POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Working in exposed environment Initial Risk Score 7M REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard 8M Working around machinery – onsite traffic 12 H Public traffic Content ID: AU_00006980 Revision: 2 Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls All Visitors Correct PPE in accordance with PPE procedure including sun hat, long sleeved shirt,& sunscreen Provide cool water on site and drink regularly. All personnel on site to wear approved high visibility clothing. For night works and Vic Roads works approved reflective vests must be worn. 5L Crew members Adopt Vehicle Movement guidelines – 3m front and rear clearance, 1 m side clearance all mobile plant. 5 m clearance all sides of skid steer except front A truck controller shall be appointed for all reversing vehicles with restricted rear vision & all trucks tipping into the paver. All personnel on site to wear approved high visibility clothing. For night works and Vic Roads works approved reflective vests must be worn. Mobile phones must not be used whilst operating mobile plant or within the active work area. Refer to Mobile Telephone Policy 6L Crew manager / engineer Crew members 6L Crew manager / engineer Crew members Maintain clearance to traffic in accordance with site specific induction Ensure that traffic control has been implemented in accordance with the traffic management plan. Appoint a traffic control stop/slow Revised:13-0720102 Page 3 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls spotter to control traffic where there is a need for mobile plant to cross active traffic lanes or roads. All personnel on site to wear approved high visibility clothing. For night works and Vic Roads works approved reflective vests must be worn When crossing the road cross at traffic control points wherever possible If it isn’t possible to cross at a traffic control point then before crossing the road - STOP, LOOK, LISTEN and THINK: 8M Pedestrians Content ID: AU_00006980 Revision: 2 STOP one step back from the kerb or well back on the shoulder of the road if there is no footpath. LOOK in all directions for approaching traffic. LISTEN in all directions for approaching traffic. THINK about whether it is safe to cross the road – when the road is clear or all traffic has stopped. When crossing, walk straight across the road. Keep LOOKING and LISTENING for traffic while crossing Ensure that the traffic management plan covers management of pedestrian traffic where required. Plant operators and spotters to remain Revised:13-0720102 Page 4 of 21 6L Crew manager / engineer Crew members ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Content ID: AU_00006980 Revision: 2 vigilant of errant pedestrians and personnel. Where pedestrian crossings are within work site either shut the pedestrian crossing or make the crossing safe for pedestrian use. Revised:13-0720102 Page 5 of 21 Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. 6 ASP001 Project: Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. Night works Job Safety Analysis / SWMS POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Low visibility Initial Risk Score 12 H REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Fatigue 12 H Low visibility hazard must be emphasized in toolbox meeting Sufficient site lighting for job where required when street lighting absent or insufficient to perform work safely White overalls with reflective tape Fit all plant with plant task lighting Red/Green light batons to be used for guiding all reversing vehicles or constant radio contact to be maintained whilst reversing. Minimum 10 hours break required between shifts Adhere to good fatigue management practices: o Get a good session of sleep prior to commencing shift. o Avoid alcohol use in between shifts. o Report all medication which may have side affects of drowsiness (on label). o Report to foreman/supervisor when symptoms of fatigue affect safe operation. Content ID: AU_00006980 Revision: 2 Program works to conclude within 10 hour shifts. Where this is not achieved give due consideration to breaks and subsequent shift durations. Revised:13-0720102 Page 6 of 21 Residual Risk Score 8M 8M PERSON RESPONSIBLE Nominate the person who will action the controls Crew manager / Project Manager / engineer Crew manager / engineer Crew members ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Profiling (if required) Refer to Profiling SWMS Refer to Profiling SWMS 8 Clean pavement surface with rotary broom or suction sweeper. Hand broom may also be used for tight areas or joints Refer to suction sweeper SWMS (if used) Manual Handling Refer to suction sweeper SWMS Use mechanical means where ever practical Warm up exercises, correct posture, and correct technique Take regular breaks/rotate work Wear dust mask if conditions require Wear gloves if conditions require. 5L 10 2/4/12 Address: Various 7 9 Date: Remove raised reflective pavement markers (cat’s eyes) – this may be done with a pick or loader bucket Set out paver runs and levels (line mark with paint) Dust/debris 4L Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls Crew manager / engineer Crew members Subcontractor 3L 1L Crew manager / engineer Crew members Use mechanical means where ever practical Warm up exercises, correct posture, and correct technique Eye protection where required Respiratory protection where required Assess adjacent obstructions, parked vehicles, traffic etc for risk of flying debris/dust and remove obstruction or place traffic control measures to mitigate risk Projectile cat’s eye 2L Wear eye protection 1L Crew members Manual handling 4L Ensure that extension arm is used with paint can to minimise bending of the back Wear eye protection when cleaning spray nozzles 1L Crew manager / engineer Crew members Do not wrap string around fingers. Release tension in string line when vehicles crossing 3L Crew manager / engineer Crew members Entanglement with string line (if construction traffic entangles with string line) Content ID: AU_00006980 Revision: 2 5L Revised:13-0720102 Page 7 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. 11 ASP001 Project: Job Safety Analysis / SWMS 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. Jack hammering POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Noise 4L Hearing protection must be worn 1L PERSON RESPONSIBLE Nominate the person who will action the controls Crew members Debris 4L Wear eye protection 1L Crew members Vibration 4L Wear Anti-vibration gloves 1L Crew members Manual Handling 9M Maintain good manual handling techniques Attend manual handling training Rotate duties Take rest breaks as required 2L Crew members Long sleaved clothing, safety footwear, gloves and eye protection. Handle chemical in accordance with material safety data sheet Assess adjacent obstructions, parked vehicles, traffic etc for risk of contamination and remove obstruction or place traffic control measures to mitigate risk 1L Crew members 12 Date: Tack coating (including use of hand lance) Chemical exposure during hand spraying – eye, skin 2L Residual Risk Score Ground personnel 8M Maintain vigilance for ground personnel during spray run. Sound horn twice before commencing spraying. Maintain clearance distance and stop if clearance distances are breached 6L Crew members Truck when hand lancing for large areas – being pulled along by truck or becoming entangled in hose 5L Appoint spotter/hose handler who also guides movement of sprayer 3L Crew members Contact with overhead structures / trees 7M Refer to pre-start site inspection (obstructions identified & eliminated or 3L Crew manager / engineer Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 8 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Job Safety Analysis / SWMS Project: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Falling from cab 4L Runoff and spills 4L 13 Date: Laying asphalt with paver which is filled from tipper. Some manual laying using shovels & rakes required. Some cleaning may be required at the front of the paver Manual handling 9M Reversing vehicles with restricted rear vision (tipping asphalt into paver) 12 H Content ID: AU_00006980 Revision: 2 Residual Risk Score mitigated) Appoint spotter where required PERSON RESPONSIBLE Nominate the person who will action the controls Crew members Always use three points of contract when entering and exiting vehicle, do not jump Always face vehicle when entering and exiting Do not use steering wheel as hand hold 1L Crew members Ensure spill kit is on truck Do not spray if rain is likely Do not overspray or allow emulsion to pool in areas Use splash boards if necessary Park away from pits and culverts 1L Crew members Use mechanical means where ever practical Warm up exercises, correct posture, and correct technique Take regular breaks/rotate work Wear gloves as required 2L Crew members All trucks to have completed a company induction before arriving at job site. All trucks to complete an operators prestart checklist & be fitted with reversing beepers & rotating flashing beacon Do no reverse into hopper until under the guidance of the Tipman in the yellow / green vest Maintain contact with Tipman via Two 8M Drivers Crew members Revised:13-0720102 Page 9 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Overhead obstructions 12 H Content ID: AU_00006980 Revision: 2 Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls way Radio or the use of hand signals Reverse at walking pace Sound horn to warn people of your presence Always use mirrors and look in direction of travel No ground personnel permitted in front of paver when truck reversing Refer to Vehicle Movement Procedure Treat all powerlines as live Strictly follow directions of Spotter Maintain radio contact with Tipman / Spotter. Maintain a minimum clearance of 6.4 to 3.0 metres if an OCEI trained spotter is in place Lower the body of the truck immediately after tipping. (Not to drive off with the body up unless directed by tipman/spotter) Take special precautions in wet weather or damp conditions to avoid arcing Assess the work to determine if work can be safely carried out without encroaching on the No Go Zone (anywhere within 3m of the power line). Notify Client if the work cannot be completed outside the No Go Zone Ensure that all persons working on site are made aware of the location of each line and the minimum clearances, during the site induction Advise all site personnel to be Revised:13-0720102 Page 10 of 21 8M Drivers Crew members Spotters ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Working with hot mix (hand laying when required i.e. unable to lay with paver) 2L Moving parts / entanglement – paver 10 H Fumes 7M Content ID: AU_00006980 Revision: 2 Residual Risk Score constantly aware of the danger of overhead power lines (look up and live!) Mark the location of overhead power lines by placing out yellow traffic cones Ensure that all persons working on site are made aware of the location of other overhead obstructions such as tree branches or canopies during the site induction Long sleeved clothing, protective footwear Handle hot mix with shovel or mechanical aid No direct contact. If need to directly touch hot mix, wear protective gloves Wear gloves as required PERSON RESPONSIBLE Nominate the person who will action the controls Crew Manager / Foreman 1L Crew members Do not clear hopper with shovel whilst slat conveyor is operational Do not raise or lower hopper wings without first checking for the presence of workers Stay clear of augers Spotter required to watch for vehicle movement whilst crew member cleans front of paver Wear gloves as required 5L Crew members Spotter Ensure mix is at the specified temperature to avoid excessive fuming Wear supplied P2 respirators as req. 3L Crew members Drivers Supply plant personnel Revised:13-0720102 Page 11 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score 4L REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Do not use excessive release agent in hopper or in truck bodies Do not touch any part of the paver which may be hot Wear riggers gloves if contact with hot surfaces is necessary Carry out with two people wherever possible Heat from side of roller wherever possible Roller to maintain a min 1.5 m clearance Roller to travel no quicker than ground personnel Roller to stop when directed or if contact lost with ground personnel Ensure regulator and hose connections are sound and well maintained Point gas torch away from personnel when lighting and when alight Do not leave torch unattended when gas torch is alight Crew members must be familiar with location of nearest extinguishers On days of total fire bans or working within 2 metres of combustible goods, an observer with a fire extinguisher is required Maintain safe distance from edge of drop off (assess and communicate distance during toolbox and site risk assessment meeting). Select low amplitude. Use vibrating plate or smaller roller Heating joints – using hand lance in front of roller Roller traffic 11 H Gas torch 11 H 15 2/4/12 Address: Various Hot surfaces 14 Date: Compact with steel roller, pneumatic (multi tyred) roller and vibrating plate. Vehicle turnover (eg drop offs, steep grade >~10% cross fall) 11 H Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 12 of 21 Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls 1L Crew members 8M Crew members 8M Crew members 8M Crew members ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Job Safety Analysis / SWMS Project: Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Longitudinal steep grades - vehicle turnover/run away 11 H Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls near drop offs All rollers to be fitted with ROPS Seatbelts to be worn at all times For rollers which are not hydrostatically driven: 8M Crew members o Select correct gear before ascending or descending. o Do not attempt to change gear. o Do not descend grades with gear in neutral position Noise Striking people on site 7M 11 H Refer to plant noise rating and adopt hearing protection if deemed mandatory 3L Crew members Ensure rotating flashing beacon is on Do not roll up too close behind paver Sound horn to warn people of your presence Always use mirrors and look in direction of travel When using worker to assist cleaning the drum, always move away from the worker 8M Crew members 8M Crew members Collisions with other plant and vehicles 11 H Content ID: AU_00006980 Revision: 2 Activate amber flashing light Always check mirrors and look in direction of travel Ensure Operators Checklist has been completed Adhere to Vehicle Movement Procedure Revised:13-0720102 Page 13 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. 16 ASP001 Job Safety Analysis / SWMS Project: Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. Raking & shovelling POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Manual Handling Initial Risk Score 10 H REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Hot Asphalt 4L Slips, trips and falls Being struck by moving machinery and vehicles 7M 11 H Content ID: AU_00006980 Revision: 2 Use skid steer loader to pick up and spread asphalt when possible Ensure shovels and rakes are in good condition before use Warm up muscles prior to work Place feet apart and assure adequate footing Use legs to drive shovel into mix Bend your legs, keep your back straight Hold shovel close to body Shift feet with load, do not twist body Do not overload the shovel beyond your physical capacity Keep shovel and rake lubricated with release agent Use shovel to spread large amounts of asphalt prior to raking; do no push large amounts of asphalt with rake Wear long sleeves and long pants Take precaution when tossing asphalt not to spray on fellow workers Don’t touch or pick up asphalt with hands Avoid crossing screed Wear lace up steel cap boots at all times Watch where you are walking Do not run or rush Ensure pits are covered Do not use mobile phone Check for oncoming vehicles or plant prior to moving Remain alert to vehicle and plant movements around you Revised:13-0720102 Page 14 of 21 Residual Risk Score 5L PERSON RESPONSIBLE Nominate the person who will action the controls Crew members 2L Crew members 3L Crew members 6L Crew members ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Fatigue 8M 17 Date: Parking of mobile plant at the completion of work Animal bites and or stings 5L Public traffic – hazard to the public 7M o o o Content ID: AU_00006980 Revision: 2 Do not walk behind reversing plant Remain clear of operating plant if your presence is not required Do not walk between reversing trucks and the paver Remain in operator’s view when working around plant Do not rely on operators to see you, remain vigilant Minimum 10 hours break required between shifts Rotate roles as required based on site and environmental conditions Wear long clothing Do not venture into long grass Do not intentionally aggravate or pursue insects or animals with the potential to cause harm Park in accordance with signed parking requirements & mobile plant and equipment procedure Make sure that the parked width of the vehicle is not impinging the safe passage of traffic through the roadway This may require the removal of any attachments/equipment which is protruding into the roadway If there is no signed parking, then on roads where the signed speed is: <60km/hr – park with care and abide with all parking signage. >60 km/hr – vehicles must be parked with a 3 metre clearance to all traffic. >80 km/hr – vehicles must be parked Revised:13-0720102 Page 15 of 21 Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls 6L Crew members 3L Crew members 3L Crew members ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls with a 6 metre clearance to all traffic Theft 9M 18 Density Testing As per testing SWMS Radioactive source 19 Clean up site & reload equipment Manual handling 7M Floats 20 Demobilise traffic controls if required As per Traffic Management SWMS Working Outdoors in the Cold Hypothermia / Cold Stress Dehydration M7 Content ID: AU_00006980 Revision: 2 As per testing SWMS All site personnel to stay clear of area when being tested ARPANSA Code of Practice and Safety Guide Portable Density / Moisture Gauges Containing Radioactive Sources to be followed Operator to be licensed Use mechanical means where ever practical Use good manual handling technique and team lift where required 3L Crew members Subcontractor / FH Subcontractor / FH All Personnel Wear appropriate PPE that is warm, light weight and water proof as to allow for freedom of movement. Including gloves. Rotate staff if able and plan works in relation to weather forecast L3 Keep supplies of clean cool water within work area taking time to drink at least two glasses of water every hour L3 Revised:13-0720102 Page 16 of 21 Crew manager Crew members Lab personnel Crew members Refer to SWMS for loading and unloading plant As per Traffic Management SWMS M7 Working Outdoors in the Heat 2L Park in accordance with mobile plant and equipment procedure Do not leave loose items or equipment trailers onsite overnight unless they are in a secured compound All Personnel ABN 79 152 328 704 JSA/SWMS No. Job Description: STEP NO. ASP001 Project: Job Safety Analysis / SWMS Date: 2/4/12 Address: Various Asphalt Paving JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Appropriate Clothing M7 particularly in hot weather. Rotate staff if able or ensure adequate breaks. Ensure that appropriate clothing is worn during the job and enforce that hats and sunscreen is worn when in direct exposure Residual Risk Score L3 PERSON RESPONSIBLE Nominate the person who will action the controls All Personnel Note *Operating plant (paver, levels, rollers) is not considered a manual handling task and therefore do not require the use of gloves unless maintenance, lubricating or refuelling processes are undertaken STEP NO. JOB STEP List the steps required to perform the task in the sequence they are carried out. POTENTIAL HAZARDS/RISKS Against each step list the potential / risk hazards that could cause injury / damage when the task step is performed. Initial Risk Score REQUIRED HAZARD CONTROL For each hazard identified, list the control measures required to eliminate or minimise the risk of the hazard Additional site specific risks Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 17 of 21 Residual Risk Score PERSON RESPONSIBLE Nominate the person who will action the controls ABN 79 152 328 704 JSA/SWMS No. Job Description: ASP001 Project: Job Safety Analysis / SWMS Address: Various Asphalt Paving The steps which are considered to determine the most appropriate control measures are as follows 1. 2. 3. 4. 5. Elimination - eliminate the work practice, material, plant equipment responsible for the hazard Substitution - substitute the work practice, materials, plant, equipment for a safer alternative Engineering Control - re-design the work practice use of materials, plant or equipment to attain a safer alternative Administrative Control - changing the deployment of personnel to reduce exposure (job rotation, training, etc) Protective Equipment for Personnel - select appropriate equipment/apparel to reduce risk/exposure Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 18 of 21 Date: 2/4/12 ABN 79 152 328 704 JSA/SWMS No. ASP001 Job Safety Analysis / SWMS Project: Vic Roads Contract No. 8208 Date: 2/4/12 Address: Various Arterial Roads within South Western Victoria Job Description: Asphalt Paving I certify by my signature below that I have had attended, understood and been given the opportunity to comment on the content of the JSA/SWMS and I am aware of: the risks involved in the work and the control measures required to control those risks. I agree to implement those control measures as I perform the work my obligation to perform tasks in a safe and appropriate manner my duty and responsibility to maintain a safe work environment as detailed in this JSA/SWMS Name Content ID: AU_00006980 Revision: 2 Company/Division Signature Date / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / Revised:13-0720102 Page 19 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: ASP001 Job Safety Analysis / SWMS Project: Vic Roads Contract No. 8208 Date: 2/4/12 Address: Various Arterial Roads within South Western Victoria Asphalt Paving Risk Assessment Matrix (RAM) To be used during Risk Assessment in the creation of a JSEA/SWMS for an activity as per Section 4. of the JSEA/SWMS Procedure Step 1 - Determine the probability of an event occurring PROBABILITY COMMENT VERY LIKELY A 70% OR GREATER CHANCE THAT THIS WILL HAPPEN POSSIBLE A 50% TO 70% CHANCE THAT THIS WILL HAPPEN (2) UNLIKELY A 20% TO 50% CHANCE THAT THIS WILL HAPPEN (1) EXTREMELY UNLIKELY A 10% OR LESS CHANCE THAT THIS WILL HAPPEN Step 2 - Assess the most likely consequence of the event CONSEQUENCE SAFETY ENVIRONMENT MINOR FAC or MTI Vehicle Incident Up to $10,000 damage MODERATE LTI e.g. Fall from height, Falling objects, Plant collision (plant/people), vehicle rollover Up to $100,000 damage MAJOR As above Fatality Structural collapse More than $100,000 damage Step 3 - Determine the level of risk: LOW = .Green_, MEDIUM = Isolated community complaints (<5) Impact confined to site Requiring action/control but with minimal impact Several community complaints (5-10) Local media interest Off-site impact contained (e.g.: spill on impermeable area) Possible infringement notice Multiple community complaints (>10) Regional media interest Off-site impact uncontained (e.g.: polluted waterway groundwater, drain) Possible prosecution _Orange_, HIGH = _Red__ MINOR MODERATE MAJOR MEDIUM (9) HIGH (10) HIGH (12) POSSIBLE LOW (4) MEDIUM (7) HIGH (11) UNLIKELY LOW (2) LOW (5) MEDIUM (8) EXTREMELY UNLIKELY LOW (1) LOW (3) LOW (6) MATRIX VERY LIKLEY RISK PARAMETERS HIGH [10 – 12]The activity MUST NOT proceed. Alternate work methods must be identified MED [7 – 9] The activity can proceed so long as the highest level and most appropriate risk control measures have been identified and implemented LOW [1 - 6] The activity may proceed with normal supervision after implementing the control measures Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 20 of 21 ABN 79 152 328 704 JSA/SWMS No. Job Description: ASP001 Job Safety Analysis / SWMS Project: Vic Roads Contract No. 8208 Date: 2/4/12 Address: Various Arterial Roads within South Western Victoria Asphalt Paving Content ID: AU_00006980 Revision: 2 Revised:13-0720102 Page 21 of 21