29_SWP_Mini-prep_KT

advertisement

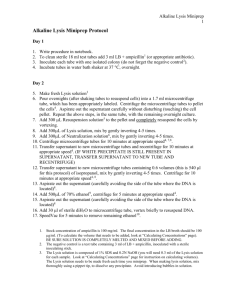

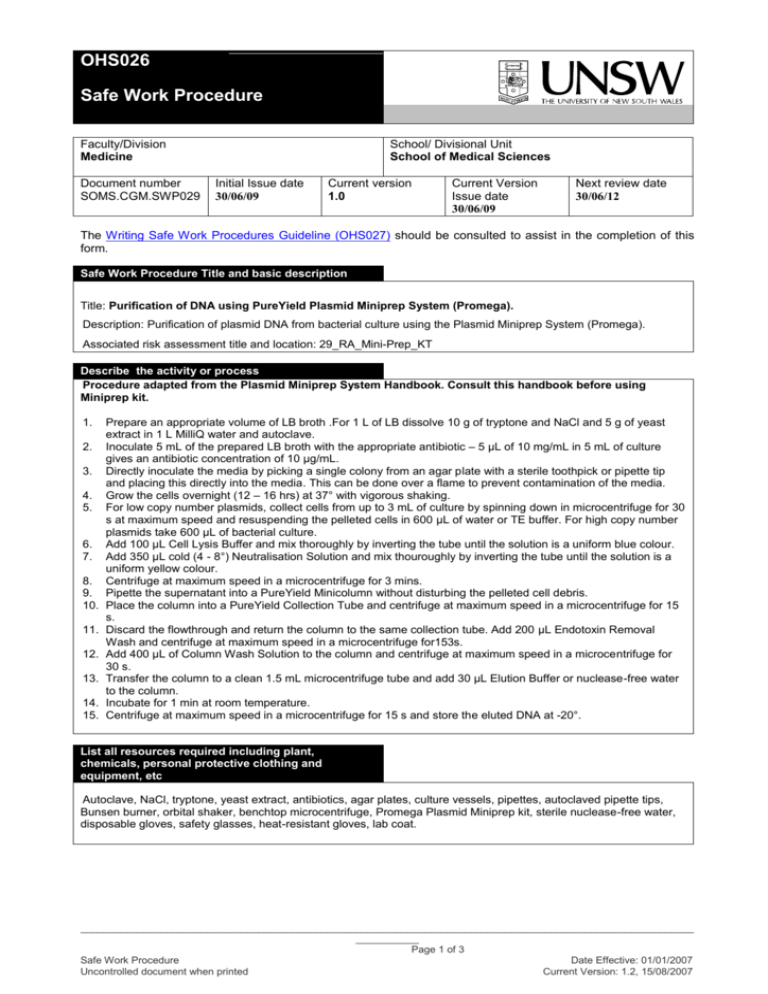

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP029 School/ Divisional Unit School of Medical Sciences Initial Issue date 30/06/09 Current version 1.0 Current Version Issue date 30/06/09 Next review date 30/06/12 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Purification of DNA using PureYield Plasmid Miniprep System (Promega). Description: Purification of plasmid DNA from bacterial culture using the Plasmid Miniprep System (Promega). Associated risk assessment title and location: 29_RA_Mini-Prep_KT Describe the activity or process Procedure adapted from the Plasmid Miniprep System Handbook. Consult this handbook before using Miniprep kit. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Prepare an appropriate volume of LB broth .For 1 L of LB dissolve 10 g of tryptone and NaCl and 5 g of yeast extract in 1 L MilliQ water and autoclave. Inoculate 5 mL of the prepared LB broth with the appropriate antibiotic – 5 µL of 10 mg/mL in 5 mL of culture gives an antibiotic concentration of 10 µg/mL. Directly inoculate the media by picking a single colony from an agar plate with a sterile toothpick or pipette tip and placing this directly into the media. This can be done over a flame to prevent contamination of the media. Grow the cells overnight (12 – 16 hrs) at 37° with vigorous shaking. For low copy number plasmids, collect cells from up to 3 mL of culture by spinning down in microcentrifuge for 30 s at maximum speed and resuspending the pelleted cells in 600 µL of water or TE buffer. For high copy number plasmids take 600 µL of bacterial culture. Add 100 µL Cell Lysis Buffer and mix thoroughly by inverting the tube until the solution is a uniform blue colour. Add 350 µL cold (4 - 8°) Neutralisation Solution and mix thouroughly by inverting the tube until the solution is a uniform yellow colour. Centrifuge at maximum speed in a microcentrifuge for 3 mins. Pipette the supernatant into a PureYield Minicolumn without disturbing the pelleted cell debris. Place the column into a PureYield Collection Tube and centrifuge at maximum speed in a microcentrifuge for 15 s. Discard the flowthrough and return the column to the same collection tube. Add 200 µL Endotoxin Removal Wash and centrifuge at maximum speed in a microcentrifuge for153s. Add 400 µL of Column Wash Solution to the column and centrifuge at maximum speed in a microcentrifuge for 30 s. Transfer the column to a clean 1.5 mL microcentrifuge tube and add 30 µL Elution Buffer or nuclease-free water to the column. Incubate for 1 min at room temperature. Centrifuge at maximum speed in a microcentrifuge for 15 s and store the eluted DNA at -20°. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Autoclave, NaCl, tryptone, yeast extract, antibiotics, agar plates, culture vessels, pipettes, autoclaved pipette tips, Bunsen burner, orbital shaker, benchtop microcentrifuge, Promega Plasmid Miniprep kit, sterile nuclease-free water, disposable gloves, safety glasses, heat-resistant gloves, lab coat. ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required Autoclave – risk of burns; injury from incorrect operation of autoclave. Only individuals who have been trained in the correct use of the autoclave should perform this operation. Do not remove items from autoclave until they’ve cooled to a safe temperature. Use appropriate protective equipment when handling hot items, including heat-resistant gloves. Burns from Bunsen burner – only leave the Bunsen burning while in use. When no longer required turn off the gas. Turn the Bunsen onto the more visible safety flame when not directly using it. Microcentrifuge – risk of mechanical injury. Ensure rotor is correctly screwed in before use. Ensure centrifuge is balanced and the lid is firmly screwed in place. Orbital shaker incubator – risk of mechanical injury. Ensure shaking has stopped before opening the incubator. Bacteria – risk of contamination from cultured bacteria. Always wear PPE when handling bacteria. Open agar plates or culture vessels where bacteria have been grown for the minimum time required. Dispose of contaminated waste correctly. Ethanol – flammable, risk of burns. Do not dispense ethanol near an open flame or source of ignition. Isopropanol – flammable, risk of burns. Do not dispense isopropanol near an open flame or source of ignition. List emergency shutdown instructions In the event of an electrical emergency turn the centrifuge off at the unit/power point or, if it is unsafe to do so, hit the “Laboratory Power Emergency Shutdown” button. In case of a fire, immediately turn gas off at the tap. Fire extinguishers are located in the laboratory. Please notify the Laboratory Manager (Renee Szokolai x58497) of any incidents. List clean up and waste disposal requirements For solid waste: 1. Seal plates using parafilm. 2. Place in biological waste bin to be autoclaved. For liquid waste: 1. Decant media into an appropriately sized screw-top plastic bottle. 2. Decontaminate media by adding Betadine antiseptic solution or bleach (4%) solution. 3. Leave the waste to disinfect for approximately 15 minutes. 4. Pour the waste into a large, 20L waste container for later collection. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects Australian Standard AS2243.3-2002. Safety in laboratories. Part 3: Microbiological aspects and containment facilities. Australian Standard AS2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. Australian Standard AS2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection UNSW Hazardous Waste Disposal Procedure Safe Work Procedure Form (OHS026) Supervisory approval, training, and review Supervisor: Peter Gunning Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to Lab, Training in SWP ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007