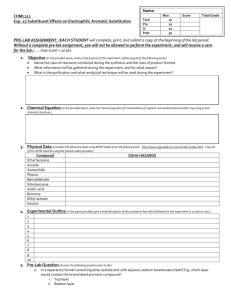

Electrophilic Aromatic Substitution of Vanillin

advertisement

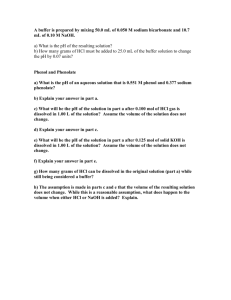

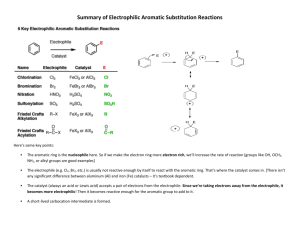

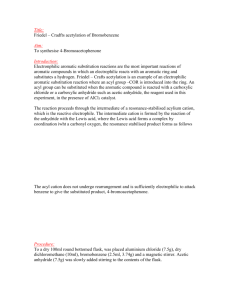

Chemistry 243 Lab Electrophilic Aromatic Iodination of Vanillin Introduction: Substitution on an aromatic ring is a two step process called Electrophilic Aromatic Substitution (EAS). The first step is addition across a pi bond in the aromatic ring resulting in a resonance stabilized carbocation intermediate. The second step is elimination of the extra hydrogen to regain the aromatic structure. This mechanism allows us to predict regioselectivity (o,p director or m director) and relative reactivity (activating or deactivating) based upon whether substituents already on the ring are electron donating or electron withdrawing. Halogenation of the benzene ring is typically carried out with elemental halogen (Br2, Cl2, I2) and a metal catalyst. Although iodine is relatively harmless, bromine is a volatile liquid which can cause serious burns to the eyes and skin in both gas and liquid form as well as potentially severe to fatal respiratory irritation. Chlorine is a gas at room temperature (bp = -34C) that can also cause serious and even fatal respiratory problems. Clearly, bromine and chlorine should not see much use in the undergraduate laboratory. However, the EAS mechanism in general and halogenation in particular are important tools of the organic synthetic chemist. As mentioned in chapter 15, iodine has a relatively low reactivity towards EAS. As a result, powerful oxidizing agents (nitric acid, et al) are frequently used to effect this reaction. If the aromatic structure contains several strong electron donating groups, then the addition is easier, can be difficult to control the regioselectivity and sometimes polyiodination is achieved. In this experiment, you will use sodium iodide as your source of iodine and common bleach (sodium hypochlorite: NaOCl) as an oxidizing agent. The solvent will be aqueous alcohol. The green benefits of this method include milder oxidizers (bleach instead of nitric acid) and more environmentally friendly solvents (water and alcohol instead of halogenated liquids). I. Table of Reagents and Products name of m.w. mL density compound used (g/mL) vanillin 152.15 NaI 149.9 NaOCl (5.25%) 74.4 product 278.05 Limiting reagent - grams used moles used ratio of moles theory used 1.078 - - - ________________________________________________ O O I NaI OH OMe NaOCl OH OMe Safety Precautions: Sodium hypochlorite is household bleach. It may bleach or otherwise damage your clothing/hair/skin. Methanol and ethanol are flammable. Procedure: Reaction: 1. In a 100 mL round bottom flask containing a magnetic stir bar, dissolve 1.0 g of vanillin in 20 mL of ethanol. Add 1.17 g of NaI, then cool to 0 C with ice water bath. 2. Use a separatory funnel to add 11 mL of aqueous sodium hypochlorite solution (5.25% w/w) dropwise to the stirred reaction mixture of a period of 10 minutes. The color should change from pale yellow to red-brown. 3. After the addition is complete, allow mixture to warm to room temperature and continue stirring another 10 minutes. Workup and Isolation: 4. Add 10 mL of sodium thiosulfate (10% w/w), then acidify with 10% HCl. Use litmus paper to monitor pH. 6 mL is typically required. At this point, your compound should precipitate out of solution. 5. Remove the ethanol from the suspension by letting it evaporate overnight. Water should still be present. 6. Cool the flask in an ice bath for ten minutes, then collect the precipitate by vacuum filtration. Wash well with ice cold water, then a small amount (a few mL at most) of cold ethanol. Continue to draw air through the crude product to help dry it for several minutes. Record the mass of the crude product. 7. Recrystallize your crude product using a solvent mixture of isopropyl alcohol and water. Do this by dissolving your product in barely enough 2-propanol to do the job in a 100 mL Erlenmeyer flask. While continuing to heat it. Add enough hot water to make the mixture become cloudy, then more hot isopropanol to generate a clear (though colored) solution. 8. Remove the flask from the heat, allow to cool to room temperature, then place in an ice bath for a few minutes to maximize crystal recovery. 9. Collect by vacuum filtration again drawing air through the product for a few minutes to facilitate drying. Characterization 10. Take the mass and mp of your product (literature value = 183-185C). Questions 1. What are the products of these reactions? Br2 FeBr3 NBS, heat HOOH O CH3CH2Cl AlCl3 NO2 NaOCH3 heat Br C(CH3)3 + O CH3CH2CCl C(CH3)3 HNO3 H2SO4 1. AlCl3 2. H2O 2. Design a synthesis for each of the following using benzene or toluene as your only aromatic source. Show all intermediates and reagents for each step. Cl NO2 NH3 NO2 OCH3 CH2Br Br