General Trail Types - Peoria Area Mountain Bike Association

advertisement

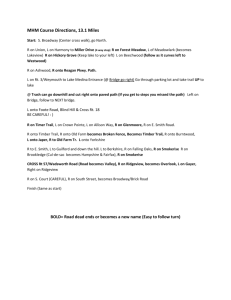

Trails, Water Crossing Bridges, and Technical Trail Features: Standards, Definitions, and Examples Peoria Area Mountain Bike Association, Inc. Terry Carter, President November 18, 2004 Introduction The following is a compilation of standards, definitions, and examples of trails and trail features found in the world of mountain biking put together by the Peoria Area Mountain Bike Association. This document is to serve as an educational resource for trailcare groups, land managers, mountain bike trail users, and the general public. This document is meant to serve as a starting block to create official standards and proposals for structures within any trail system. General Trail Types Groomed Corridor Trail (Easy Access)– This trail type has a wide (20” to 48” or wider) natural surface tread. This trail type has a wide, tall, cleared corridor. This trail type is suitable for most trail users. This trail type allows for more than one user abreast in the corridor. Few technical trail features (TTF), if any, would be found on this trail type. This trail type has long, straight sight lines, gradual grades, and smooth terrain. This trail type can be designed to allow for gasoline powered All Terrain Vehicles for land manager access to areas of the trail system or property. Corridors of this trail type are often mowed and / or groomed. This trail type offers a feeling of being “near” nature. Positive attributes: Long sight lines allow for trail users to make eye contact long before reaching one another. Smooth, gradual trail tread allows for beginning trail users to easily use the trail without fear of injury. Allows easy access to areas within the property. Evacuating an ill or injured user requires less time and effort. Negative attributes: Wide, open, long stretches of smooth terrain trail promote excessive speeds. This trail type can actually add to conflict between trail user types due to speed and ability differences. This trail type offers little or no challenge for more seasoned, experienced trail users (other than increased speed). This trail type calls for constant maintenance due to it’s wide tread needing more drainage attention and the mowing and grooming of corridors. Maintenance is less labor intensive due to the possible use of powered machinery. This trail type is difficult to reroute, repair, or eliminate. Primitive Corridor Trail (Limited Access) – This trail type typically has a narrow (12” to 24”) natural surface tread. This trail type allows for single file use only. This trail type has a narrow, proximal corridor, just wide enough in places to allow passage by trail users. Technical trail features (TTF) are easily added to this trail type. This trail type is suitable for more advanced knowledgeable trail users. Short straight stretches, tight curves, switchbacks, and rough terrain define this trail type. Grades within this trail type can be more abrupt and distinct than those found on Groomed Corridor Trail. This trail type can be easily adapted to serve specific trail user types (i.e. horses, bikers, and XC skiers). Corridors of this trail type are rarely groomed, except for the clearing of deadfall and/or the cutting back of invasive plants. This trail type offers a feeling of being “part of” nature. 36" or 48" primitive corridor trails are not uncommon. Primitive corridor trail can be built with mechanized machines in certain circumstances. Some experienced, professional operators, like Rich Edwards of IMBA, can full bench a 24" tread, scraping the fill he's used as a construction platform as he moves through, but this is a honed skill. 36" equals the minimum width you can achieve with a walk-behind skid steer, 48" the minimum with a Sweco. Positive attributes: If built correctly, this trail type requires minimal maintenance. Tight, twisty trail corridors promote slow travel speeds reducing user conflict. This trail type offers challenge to more experienced trail users. Technical trail features can add to said challenge and attraction of this trail type. This trail type is easily rerouted, repaired, or eliminated. Negative attributes: The majority of construction is done with hand tools. The majority of maintenance must be done by foot, horse, or bicycle. The majority of maintenance must be done by hand tools or small gas powered equipment. Evacuating an ill or injured user takes more time and effort. Trail Features and Bridges (overview) The TTF’s described in this document are of both natural and constructed types. They are not mutually exclusive of each other. Many natural features can be built upon to include wooden constructed features. Natural material may even be manipulated to form TTF’s without the use of connectors such as screws, bolts, and nails. Even the types of features and structures themselves are not exclusive. You may want to place a teeter-totter in the middle of a bog bridge, or skinny, or place an “A” frame structure before a constructed drop off. Designers and builders are only restricted by their imagination and a relative margin of safety. A few points need to be reiterated. This document, in no way, covers all aspects of technical trail features. It is not intended to be a blanket standard for any advocacy group and/or land manager. It is to provide information that can lead to the development of standards and acceptable practices by advocacy groups and their particular land managers. Water crossing bridges have been included in this manual because they have many similarities to TTF’s. The bridges alluded to by this document are intended for stream crossings of no more than 30 feet in length, and intended for foot and bike traffic only. Larger bridges, or those intended for ATV or horse traffic, will need to be researched and engineered for their specific purpose. The United States Forest Service is a great resource for information concerning all recreational bridge construction. Rails to trails organizations also have a wide knowledge base for bridges. Here are two resources: http://www.fs.fed.us/eng/structures/ - USFS online guide to bridges and structures http://members.fortunecity.com/railtrails/Org/bridges.htm – A rails to trails bridge resource Definitions: “A” frame: Two ladder ramps, planks, or planed logs, placed in an “A” configuration to provide an “up and over” type trail feature. Berm: Pile of dirt used to help negotiate turns or used as a dirt jump. Not used often in trail building, but when used, must provide for proper drainage. Bog Bridges: Often called “skinnies” by bikers. They are long planks or planed logs placed on sleepers or sills, to provide access over boggy, sensitive, or wet areas. These offer challenges to bikers by testing their balance and hand/eye coordination. Differing widths and heights provide differing levels of challenge. Dirt Jump: Pile of dirt used by bikers to jump, with varied elevation gain or loss, from one trail tread to another. Drop off (Drop): Log, dirt, or rock feature where there is a perpendicular, vertical drop from one trail tread to the following trail tread. Ladder Ramp (Ladder): Wooden stringers with plank rungs used by mountain bikers to create technical trail features such as skinnies, A frames, drops, or teeter-totters. Log Pile: Logs secured in a stacked, triangular shape to provide a challenging “up and over” type trail feature for bicyclists. North Shore: The area of Vancouver, British Columbia with which TTF type riding is most associated. Now synonymous with this type of riding. Rock Garden: A section of trail where either a naturally occurring or planned and constructed group of larger rocks is located. Rocks can range from baseball size up. Teeter-Totter: Not unlike the child playground ride. A plank or ladder placed on a fulcrum so that the rider enters on the lower end and as they ride up and over the fulcrum, the teeter-totter drops to the other side where the rider can then exit. Water Crossing Bridges (General) Locate bridge crossings to minimize disturbance to streambeds and banks. Those sections of the waterway that are straight and where banks are stable are preferred for crossings. Construct bridges across streams to top of the bank. This minimizes erosion of stream banks and sedimentation of streams. For bridges requiring supports in contact with the stream, in aquatic environmentally sensitive areas, pile supported structures are preferred over slabs or floats. Primitive corridor trails and the bridges and TTF’s associated with them should be constructed manually with materials and equipment that can be transported by work crews. Bridges exceeding the 4-foot height rule (explained in the TTF section) from tread of bridge to the ground surface below shall have alternate safety methods (i.e. railings). Bridges must be of an approved design. Submitted designs with this proposal may include heavy and medium timber construction and steel girder / timber tread types or other design as seen fit by the land manager. Technical Trail Features (General) Mountain bike advocacy groups and land managers alike, are concerned with the durability, design, safety, and surface finish of the TTF. TTFs must exceed the minimum strength and stability standard established by the Whistler Trail Standards and International Mountain Bike Association. It should be capable of supporting a centered vertical load of 440 lb. and a horizontal load of a 180-lb. adult leaning against the constructed feature with less than 2 inches of displacement. (Whistler Trail Standards) The structure should be built and finished to minimize potential injury to a falling rider. Make riders fall early: By placing a narrow section or difficult turn at the start, while the TTF is still close to the ground (known as a gateway or qualifier), the inexperienced rider will dismount early, before the TTF is high above the ground where the rider might be more prone to injury from a fall. (Example: place a 4 inch wide gateway less than one foot off the ground as a gateway to a 12 inch wide section 3 feet off the ground.) Make the most difficult section easily visible from the entry: By placing the difficult section in view, the rider can make an informed decision whether or not to attempt said TTF BEFORE already having entered the structure. Avoid wide, easy entrances leading to high, narrow, exposed features. Height is to be measured vertically to the lowest point within 3 feet adjacent to the TTF. Height restrictions on TTF’s shall be negotiated between the advocacy group and the land manager. Tread width is defined as the amount of flat tread available for bike tires. Tread width of TTF’s shall be negotiated between the advocacy group and the land manager. The approach to the TTF should be on dry, stable ground. This will help prevent water and mud from being deposited on the TTF, causing slippery conditions. Examples of TTFs: Drops, skinnys, teeter totters, A frames, ladder ramps and bridges, log piles, dirt jumps. Construction Practices for Water Crossing Bridges and TTF’s Cross bracing of vertical members is required. TTF’s should never be mounted or attached to living trees. Three acceptable means of attachment are nuts and bolts, galvanized deck screws, and ring shank nails. Two thirds of the nail or screw length shall penetrate the stringer. Loading on a member should be done so that the shear strength of the attachment device is not what is exclusively relied upon. Deck planks must be spaced so that body parts are not able to penetrate between them. An appropriate spacing is ½ to ¾ inch to promote drainage of water and mud. Deck planks should not overhang stringers by more than 3 inches. Deck planking material should be durable wood that is naturally resistant to moisture, decay, sun, heat, cold, and insects. Examples include Oak, Ash, Hickory, Hedge, and Locust. Environmentally friendly, commercially treated woods can be used for support structures and tread surfaces. When used for tread surfaces, a non-slip coating or covering should be used (i.e. expanded diamond lathe, exterior non-slip paint, scoring surface with chainsaw, etc). Wooden pallet material, scrap lumber, plywood, pine, maple, or any other soft wood should not be used for any construction. Finished surfaces should have no protrusions or excessively sharp edges. Dead trees, logs, and stumps shall not be used unless found to be of sufficient size or type of wood to withstand deterioration (i.e. Oak, Hedge, Locust, etc) Rough sawn or hand prepared wood is preferred and will blend into primitive locations better than commercial lumber. Owners of portable saw mills are a good source of rough sawn slabs. As stated previously, connectors shall be nuts and bolts, deck screws, or ring shank nails. All connectors shall be weather resistant and of sturdy design. Natural Material Technical Trail Features (General) Natural Material Technical Trail Features may include, but are not limited to, rock gardens, dirt jumps, log piles, single logs, balance beams, bog bridges, berms, or drops. Mountain bike advocacy groups and land managers alike are concerned with the durability, design, and safety of any trail feature. All natural material technical trail features will be constructed of naturally occurring woodland material (i.e. logs, rock, dirt). The feature should be created and maintained to minimize potential injury to a falling rider. Make any difficult section easily visible from the entry: By placing the difficult section in view, the rider can make an informed decision whether or not to attempt said trail feature BEFORE already having entered the section of trail. All natural material technical trail features shall adhere to the general TTF policies stated previously. Log Obstacles General Fallen logs should not be used as a speed control device. In fact, logs across the path may encourage cyclists to ride faster to jump them. Trail users have been known to give trail workers grief for removing 3-foot high logs, so almost any size log can be in play. However, erosion and multiple paths can develop around the end of deadfall that obstructs the trail. One of PAMBA’s trailbuilding goals is to minimize the impact on the landscape. If fallen logs divert riders off the established tread, our impact increases. This should cause review of said obstacle and possible restructuring, addition of an optional line, or removal. Log obstacles should have clear, visible approach and exit areas, as not to surprise approaching trail users. Fall zone, entrance, and exit policies shall be adhered to. Only solid, secure deadfall should be used. Deadfall that is unacceptable due to rot, sharp edges, inconsistent diameter or shape, shall be removed from the trail tread. Be sure to account for water flow. Single Logs Some trail users view a fallen tree as a welcome challenge. Single logs with a diameter of less than 10 inches need not have an alternate route to avoid crossing them. Single logs with a diameter of more than 10 inches can appear as insurmountable barriers and users will go around, even if this requires leaving the trail. A route without obstructions to avoid larger logs should be provided. Single logs that have been chosen to remain in the trail tread shall be completely touching the ground, assured as not to roll, and possibly debarked. Log Piles A pile or ramp of logs can serve as an enjoyable challenge for mountain bicyclists. All log pile type obstacles should have an alternate route that provides users with an obstacle free option to avoid the log pile. Mountain bikers need to understand that throwing a bunch of rotting logs and twigs at an obstructing log and calling it trail maintenance is improper and careless trail construction. Log piles should be of solid, well thought out design. Logs and deadfall used for pile building should be solid, not rotted, and of consistent shape and diameter. A well-built log pile will use at least 6-inch diameter logs. The base logs of each side of the pile should be anchored into the ground, the desired method being to sink them into a shallow trench. The option of wiring logs together to form the pile may be considered. Thick, strong baling wire can be used toward the ends of the logs. No wire should be allowed on the actual tread area, and the wire ends should be securely wrapped together and tucked out of sight. Log piles that show signs of excessive rotting or incohesiveness shall be either rebuilt or removed from the trail tread. Balance Beams Balance beams made from deadfall can provide a unique challenge. Logs placed lengthwise next to the trail can provide this service. For some users the log will function as a balance beam, while others will use it as a bench to rest on. It's important to set these logs into the ground so they don't roll. These logs should be placed upslope of the trail where they won't impede drainage. These logs may remain rounded or may be planed on the top surface to provide varying tread types. Drops and steps Drops and steps can be constructed of many trail building materials such as, lumber, logs, rocks, and dirt. Large logs, ladder ramps, or rocks can be used to construct short steps or drop-offs. Rock drops will require considerably less maintenance than those of log or lumber construction. Log steps or drops must consist of slower rotting wood types. Dirt is placed behind the log to create the tread of the step or drop. Dirt contact will cause eventual rotting, causing the step to be more easily ridden as the log deteriorates. Eventually the log will cease to be a step and will be removed or replaced. These types of additions can provide challenges to riders in an area without much natural terrain difficulties. A six-inch-to-a-foot drop is appropriate for most users. Drops of over 10 feet are not uncommon in some areas. The advocacy group and the land manager must negotiate limitations to height and construction practices. Dirt used for placement behind logs or rocks should come from a borrow pile or pit clear from the trail tread, as not to be a hazard (i.e. removing dirt from the exit side of the step or drop is a bad idea). Make sure the step or drop fits with the overall flow of the trail. Use steps and drops in, at least, bike-length series in an area where riders won't be taken by surprise. Transitions are important: a tight turn following a step is awkward. The landing area on drops (also known as a type of “transition”) may need to be sloped downward toward the exit of the area. Drops to flat surfaces provide substantial shock force to bike and rider. Rock Construction (General) Solid rocks of proper size will be used for construction of natural material technical trail features. Flat rocks may be used to “armor” a section of trail that is prone to persistently muddy or wet conditions. Many times a trail can be routed as to end up at a naturally occurring technical trail feature, such as a rock drop, or rock garden. Do not stray from sound, practical trail building techniques in order to reach such a location. Do not be guilty of “tunnel vision”. Recognized resources such as IMBA and USFS trail-building guidelines shall be referenced during all construction using rock as a material. Fall Zone Standards Fall Zone is defined as the area adjacent to a technical trail feature that the rider may deviate into should they fail to negotiate the feature (Whistler Trail Standards). The fall zone should include the sides of the trail, the bottom of descents, and both interior and exterior of all corners. Careful review of the area surrounding the feature and the removal of all obvious hazards can aid in the reduction and avoidance of injuries. Hazards may include branches, stumps, rocks, and other debris. The fall zone shall be cleared of hazards to a minimum of 3 feet on all sides of technical features that are up to 1 foot in height. A minimum clearing of 5 feet shall be kept on TTF’s that exceed 1 foot in height. Clearing of fall zones includes, but is not limited to: cutting or digging out any sharp objects, trimming tree branches back to trunk of tree, stump removal. The fall zone should NOT be cleared of foliage entirely. Total clearing does not help define the intended trail tread. Local species that do not present a thorn or poison threat should be encouraged to grow. The primary focus for fall zone clearing should be on trails that are considered to be “more difficult”. This would be where a user might be honing his or her skills and abilities and their falling skills may not be perfected yet. Maintenance Standards for Primitive Corridor Trails and Natural Material Technical Trail Features (Whistler Trail Standards) Trained personnel, from the advocacy group or the land management entity, twice per year will inspect primitive corridor trails and the trail features within them. Acceptable training level will be IMBA trail building school completion, US Forest Service trail construction training, or local equivalent. All bridges, log piles, etc. will be inspected during the trail inspection or whenever the advocacy group or land manager are notified of items that may require inspection. Inspections will also be done if any of the following triggers arise: short cutting of turns or switchbacks, trail drifting or sliding, vegetation cover loss, trail proliferation (widening or braiding), trail incisions (ruts greater than 4 inch depth), deterioration of bridges or trail features. Mitigation measures may include trail hardening, water flow diversion techniques, trail relocation or reroute. Compiled and composed by: Terry S. Carter, President and Founder of the Peoria Area Mountain Bike Association, Inc., Peoria, Illinois Dates of initial production: May – November, 2004. Technical assistance and editing provided by: Scott Frey and Rita Nygren, Expert Trail Designers, Wisconsin Off Road Bicycle Association Scott Linnenburger, IMBA Trailcare Crew member and Trail Solutions Coordinator, International Mountain Bike Association Scott Whitaker, Southern Illinois IMBA State Representative, Gateway Off Road Cyclists Shawn McKinney, President, Illinois Mountain Bike Coalition and Springfield Area Mountain Bike Association Bibliography: 10 Tips to Building a Ladder Bridge, International Mountain Bike Association, Boulder, Colorado Bent and Bog Bridge Construction, United States Forrest Service Building Better Trails, International Mountain Bike Association, Boulder, Colorado Bump, Jump, and Berm Trail Proposal to Army Corps of Engineers, Peoria Area Mountain Bike Association, Peoria, Illinois Construction Guidelines for Wooden Technical Trail Features, International Mountain Bike Association, Boulder, Colorado Log Construction and Placement, United States Forrest Service Trail Bridge Catalog, United States Forrest Service Trail Solutions: IMBA’s Guide to Building Sweet Singetrack, International Mountain Bike Association, Boulder, Colorado Using Logs to Add Challenge, International Mountain Bike Association, Boulder, Colorado Whistler Trail Standards, Environmental and Technical Trail Features, Resort Municipality of Whistler