Recommendations for cleaning routines in a Food Technology room

advertisement

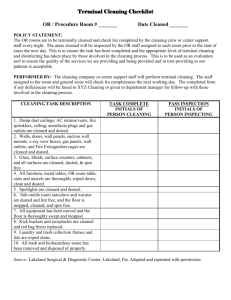

Recommendations for cleaning routines in a Food Technology room. This is based on and adapted from good practice in the Food Industry. References: Managing Food Safety-Engel, McDonald & Nash-Published by Chadwick House-The Chartered Institute of Environmental health. Food Safety First Principles-Chartered Institute of Environmental Health. Industry Guide to Good Hygiene Practices-Chadwick House Group-Useful document that clarifies the legal requirements. Food Safety-First Principles-Claire Nash-C.I.E.H. BS4163:2007. Industry Guides to Good Hygienic Practice-Chartered Institute of Environmental Health. Cleaning Activity Wipe over work surfaces at the start of the day, use an antibacterial spray. Washing up equipment and utensils. Disinfection of equipmentchopping boards, work surfaces, handles to doors and refrigerators, taps, switches, cloths and mops. Why is this necessary? Overnight cleaning may have sprayed bacteria (E coli) up onto work surfaces. Pupil’s bags may have been put onto work surface when ingredients are being delivered. Night classes may have used room and not cleaned properly. To remove food debris from the equipment, to remove grease and dirt. To prevent cross contamination. To prevent cross contamination. Who is responsible? Technician. How often? Before a food preparation activity in a lessonprobably 5 times a day. Comments Pupils to wash, teacher and technician to check. Every practical lesson. Technician. Daily. Water is not usually hot enough for this process. Standards need to be monitored. Very difficult to do after every lessontime and variety of activities in a may day make this impractical. -1 –Buckinghamshire School Improvement Service If this is only done with a detergent it will not kill pathogenic bacteria. Must be done with a sanitizer. Must not be allowed to taint food that is prepared on that work surface. Washing food room floor at the end of the school day. To prevent a build up of dirt and grime on the floor, to keep floor looking clean and reduce bacteria to a safer level. To prevent cross contamination. Contract cleaners or site team. Daily Technician Daily Cleaning aprons To stop cross contamination from previous class. Technician. After each practical lesson. Hand washing and drying. To stop transfer of bacteria from hands onto food. All-pupils, teacher and technician. Coming into the room. After handling raw & cooked food, emptying the bin, touching ears, hair, nose, mouth. Cleaning of food storage units-fridges & cupboards, checking dates of foods and how long student dishes have been in fridge. A separate sink in the food preparation area for hand washing is a legal requirement in all food preparation areas. Disposable paper towels for drying hands. -2 –Buckinghamshire School Improvement Service Pupils may have mixed up raw and cooked foods or cooked dishes due to lack of storage space. Pupils must name and date all food that goes into fridges. Aprons must be of a material that can be sprayed and wiped down quickly. If aprons are a fabric that cannot be cleaned in this way, they must be washed daily. If hand towels are used they must be laundered and replaced after each lesson to prevent cross contamination between classes. Who uses the room? What should we insist on? Personnel Food Technology Teachers. Technician Pupils Contract or outside cleaners Other teaching staff Night classes Parents Association who may use rooms. Public who may hire facilities Training or communication protocols. Must write policy based on sound food hygiene and safety theory and practice. Food Hygiene level 2 certificate as a minimum. Communicate, train, check understanding, supervise and monitor in all cleaning activities. Food Hygiene level 2 recommended. Induction training through initial practical activities. Educate all in delivery of food to room so bags don’t go tables, pupils are tasting/eating foods and cleaning up after themselves. A Food Hygiene Qualification as appropriate-maybe for pupils who choose for GCSE. Communicate policy and expectations. May need to negotiate some jobs. Monitor and check standards. Staff /other teaching colleagues must be aware of and be able to adhere the hygiene checklist. Staff who want to teach food preparation should also have a level 2 Food Hygiene qualification and be capable and competent to run a food preparation activity safely with a class of pupils. Teaching staff should be required to submit a Risk Assessment and lesson plan that satisfies the Head teacher and the Subject leader. Written policy of expectations given to Adult Education Department and tutors. See agreement for use by outside agencies. Written list of expectations probably most appropriate here based on basic HACCP principles. See agreement for use by outside agencies Written communications and expectations-probably to go out with contract of hire of facilities. A document based on basic HACCP principles would set out clearly how the room should be left. It may be necessary to add extra cleaning costs required from site team to ensure rooms are ready for food preparation the next day. See agreement for use by outside agencies Food Hygiene Level 2 training can be provided by the Local Authority. For courses go to www.bucksgfl.org.uk and click on the Design & Technology part of the site. Information about dates costs, locations and how to book courses are all on that website. -3 –Buckinghamshire School Improvement Service Cleaning activities frequency General. It is essential to remember that we are legally responsible for all the food that is prepared in our rooms. If any of the food that is prepared in our Food Technology rooms makes someone ill, we are responsible. If an incident is the result of negligence on our part, whether it be the result poor cleaning routines or food storage we could be liable to prosecution. It is therefore essential that we have efficient and effective cleaning routines in place and that these are monitored and documented. More detail about cleaning for Food Preparation areas and frequency can be found in the Industry Guides produced by the: Chartered Institute for Environmental Health, Chadwick House Group, Chadwick Court, 15, Hatfields London SE1 8DJ 0171 827 5882. The guide to Markets and Fairs pg 130 has a sample cleaning schedule and the Retail Guide has a section on compliance and effective cleaning pf 42 onwards. The employer is responsible for working out a timetable for cleaning schedules. In most schools this will be devolved to the Subject Leader or Head of Department. A good cleaning schedule should identify: The item or area to be cleaned Frequency or cleaning required Method, including the chemicals to use, the protective clothing to wear and the safety precautions to take. Staff involved, including the name of the person responsible for checking that the cleaning has been carried out effectively. For chemicals to use please refer to Control of Substances Hazardous to Health Regulations (COSHH) regulations-these will probably be with the Health & Safety Officer/Site Manager. Using cleaning materials that are kept solely for the Food areas. These should be stored separately from food and in secure units/cabinets so that pupils cannot access. Mops must be disinfected overnight and only used in the food rooms. Cloths should be cleaned after each days cleaning either on a boil wash (95۫c) in the machine or use disposable cloths that are thrown away after each days use. The washing machine in the department should only be used for Food Technology items such as dish cloths, tea towels, tablecloths etc. Items that are heavily soiled with mud from outdoor activities should not be washed in the same machine. Washing temperatures, although high, are not high enough to destroy bacteria and spores that exist in mud and could cause a risk if transferred to food via cleaning cloths. -4 –Buckinghamshire School Improvement Service After each task. ‘Clean as you go’ should be applied to general food preparation tasks, such as handling and preparing raw meat, fruit and vegetables. Washing up of food preparation equipment in hot water and detergent and drying with a clean tea towel. (Leaving to dry is seldom an option in a busy Food Technology area). After each lesson. Dish cloths and tea towels should be washed on the hottest wash possible in the machine (usually 95۫c). Aprons should be washed if necessary or wiped with anti-bacterial cleaner. All food preparation surfaces wiped with anti bacterial cleaner. Food waste bins should be emptied. Daily Floors-swept (to remove food pieces), sweep under static tables and work units mop with hot water and detergent. A steam cleaner or ‘mechanical floor scrubbing machine’ may also be used-if this occurs there will still need to be some cleaning of the edges around the room as these are not reached by such machines. Door and fridge handles cleaned with anti bacterial cleaner. Sinks and taps, including hand washing sink washed with anti bacterial cleaner ,disinfected. Bins and their lids should be disinfected at the end of the day. Three times a week Windowsills washed with hot water and detergent. Weekly Fridge seals cleaned with disinfectant and sanitiser. Food storage cupboards checked for spilt foods. Any debris cleaned and shelves washed with hot water and detergent or sanitiser. Splash backs of sinks. Light switches should be cleaned. Half Termly Cookers pulled out and cleaned; brush away dropped food items and wash with hot water and disinfectant, sides cleaned with disinfectant. The inside of all cupboards in the Food Technology room should be washed and dried thoroughly. Extractor fans vacuumed to remove loose dust, dismantled and washed. Tiles and walls to be washed with detergent. Fridges pulled out swept and washed with hot water and disinfectant. This should include a thorough clean of the sides of the units where food often falls between the cooker or fridge and the unit. Windows should be cleaned. Deep Cleaning. -5 –Buckinghamshire School Improvement Service Where cleaning routines have been neglected there should be a ‘deep clean’ of the Food Technology area so that food preparation activities can resume in a clean and hygienic environment. There are cleaning companies that the Local Authority uses and their contact details can be obtained from Robert Myatt at County Hall in Aylesbury, contact details rmyatt@buckscc.gov.uk 01296 383620. Such a cleaning operations should include a thorough clean of: Work surfaces. All flooring and walls including behind all appliances. Ceilings. Doors and handles. Light fittings Fans and extractors Windows and windowsills. Ovens and microwaves. The surfaces and insides of all cupboards and shelving units-including under sink cupboards, food storage cupboards and shelves, food preparation areas, equipment storage cupboards/shelves and folders textbooks storage. Example of document for other users of the Food Technology room. This document can be used as the basis of an agreement for the use of the room. It is essential that we are confident that the rooms are fit to prepare food in at all times. It is an unnecessary burden on teaching staff and technicians if the standards of cleaning of equipment and the room are not adhered to when the rooms are used other groups. Food Technology Rooms. Agreement for use by outside agencies. The Food Technology room is an important teaching environment. As a department we insist on high standards of cleaning and cleanliness. If rooms are not left in a state that means food preparation activities can take place at all times, this places an extra burden on teaching staff and the teaching and learning experience of the pupils is compromised. It is important to us that the pupils have high standards set and that these standards are exemplified at all times. To this end can you please ensure that the following tasks are carried out and checked by the hirer. Dish cloths and tea towels will not normally be supplied. These must be provided by the hirer. These can be hired at extra cost (to cover laundering costs and technician time) through negotiation. It is suggested that the hirer and a member of the site team check and sign these together at the end of the hiring period. -6 –Buckinghamshire School Improvement Service Agreement for use of Food Technology room. Task Person responsible Checked Hirer Site team Fridges Any spillages inside the fridge should be cleaned. Door handles to be cleaned with sanitizer or anti bacterial cleaner. The temperature of the fridge should be below 5۫c. Hirer Door handles and switches, should be cleaned at the end of the session with anti bacterial cleaner. Hirer Work surfaces/food preparation areas- washed on a ‘clean as you go’ basis. Washed with hot water and detergent with anti bacterial cleaner or disinfected at the end of the hiring period. Hirer FloorsFloors-swept. Hirer Floors-to be cleaned by the site team. (Wet mopped with disinfectant and hot (above 82۫C) water. A steam cleaner or ‘mechanical floor scrubbing machine’ may also be used-if this occurs there will still need to be some cleaning of the edges around the room as these are not reached by such machines.) Sinks and taps, including hand washing sink washed with anti bacterial cleaner or disinfected. Site Team Bins and their lids should be disinfected. Hirer Small food preparation equipment-in unit drawers. Should be washed in hot water and detergent and dried and placed back in the correct drawers. There is a list of the equipment that should be in each drawer. Please check that units are correct. Hirer Hirer Hirer Large Food preparation equipment-e.g. Food Processors, Food mixers. Wash with hot water and detergent, dry and put away. These may be locked away in a storage cupboard and if these are needed prior arrangement may need to be made. Any person who uses this equipment should be competent and safe to use it. The school cannot be help responsible for any accident that occurs in the use of this equipment. -7 –Buckinghamshire School Improvement Service