Module 6: Field Emission Display

advertisement

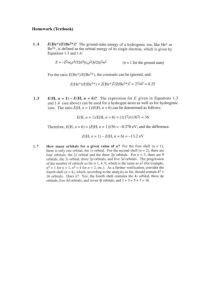

Module 6: Field Emission Display 6.1. Introduction Field emission devices (FEDs), sometimes referred to as old cathode field emission devices, can be thought of as a thin-profile cathode ray tube (CRT). Like a CRT display, it generates electrons and steers them to collide with a phosphor coated screen. The CRT uses large, hot-cathode emitters, usually referred to as electron guns. The FED uses a large number (>1000) of submicrometer emitters for each pixel. Another difference is that a CRT relies on complex steering mechanisms to guide electrons along long paths (~0.5 to 1.0 meters). The simplest incarnation of the FED focuses automatically, relying simply on the proximity of the guns to the screen across a cell gap of ~100 mms. When an electric field is applied between the anode and cathode, electrons are extracted from the microtip (see figure below). These electrons are then accelerated toward a phosphor coated anode. A gate voltage of 20 to 60 Volts is used to control the flow of electrons, turning a particular set of microtips on or off. Analogous to a CRT, chemical elements that are doped in the phosphor material are excited by the colliding electrons. Simply put, the electrons bombard the phosphor, transfer their energy to the atoms, raising their electrons to a higher energy level where they remain a very short time. When the electrons revert back to the ground state, energy is released in terms of visible light. The cold cathode phenomena is based on an extremely high field strength at the microtip. The tips can be extremely small (<50 nm). A field on the order of 50 V/mm is developed. At this high field intensity, electrons exhibit tunneling, a phenomena which allows them to pass throught the surface barrier. Note, unlike CRTs, a terminal energy boost is not needed for FEDs. 6.2. History The FED originated at Stanford Resources International in the early 1970's. Originally, initial efforts used an ultra-vacuum in the area of 10-9 Torr. Later, it was demonstrated to work in vacuums comparable to CRTs (10-6). The early work at Stanford Resources was initiated by Charles Spindt and his field emitter arrays became known as Spindt Cathodes. In the 1980's, the research and development and manufacturing infrastructure on FEDs were picked up again when some of the fundamental problems were worked out by researchers. 6.3. The Physics of Field Emission Displays A FED is analogous to a CRT in the sense that it liberates electrons from a cathode, the electrons are accelerated through a vacuum and the electrons impinge on phosphor to generate light through the cathodoluminescent process. For FEDs, the electron source is a cathode consisting of a large array of microtips that liberate electrons through the field emission of a CRT. Field emission typically occurs when an electric field >50 V/mm is applied across the tip. This large electric field enables electrons to tunnel (quantum mechanics) from the metal surface into the vacuum. This phenomena can be modeled by the Fowler-Nordheim equation: where a and b are constants, I is the electron current and V is the applied voltage at the surface. To create the necessary electric fields to liberate electrons (>5,000 V/mm), the emitter tip should be as small as possible (<<1 mm) so the electron spacing is as small as possible. To reduce the voltage required for field emission, it is desirable to have a material with a small and stable work function. The Fowler-Nordheim equation demonstrates the work function on current. It is vital to control the surface chemistry of the microtip material, and to maintain a high quality vacuum during the life of the display. The work function g is extremely sensitive to adsorbates, with most adsorbates increasing the work function. Many microtip technology utilizes molybdenum. Molybdenum (Mo) provides a mechanically robust tip. Molybdenum-oxide (MoO2) is reduced to Mo metal in low atmospheres at temperature as low as 300 degrees Celcius. Certain tip materials such as cesium coated tips have demonstrated very low turn-on voltages but the stability of alkali tips is poor. There is a large amount of work on diamond films, which can have a low work function and chemically stable surface. Silicon based emitters are also being explored. The first demonstration of a FED was by Spindt at Stanford Resources in the late 1960's. The basic steps in the Spindt fabrication process begins with high angle evaporation of a lift off layer, followed by the vertical evaporation of the tip material. As the vertically evaporated material builds up on the edges of the emitter hole, the hole closes off, with the tip formed in the emitter hole. The height of the tip is controlled by the thickness of the dielectric layer, the gate hole diameter, the aspect ratio of the tip metal used, and the substrate deposition temperature. The tip height with respect to the top of the gate is important in controlling emission efficiency. It has been determined that the optimal position for the tip is near the top of the gate. After the tip evaporation is complete, the top layer of the overburden metal is removed by a lift off process of etching away the superficial layer. Originally, the Spindt tip has an aluminum (Al) metal for the lift-off layer but more recently changed to aluminum oxide (Al2O3). The major problems with the early FED devices include: arcs which cause tip destruction. low electron emission efficiency. spatial non-uniformity. temporal non-uniformity (flicker). The positive attributes of the early FED devices were low operating voltage due to small tip diameter and the small electrode spacing which reduces tip damage due to ion sputtering. The first devices that Spindt discussed possessed constant currentvoltage characteristics for an array of tips for over 75,000 hours in an actively pumped vacuum chamber operating between 10-7 to 10-9 Torr. Many of the problematic issues mentioned above were solved at Laboratorie d'Electronique de Technologie et d'Instrumentation (LETI). A company Pixel in 1992 set out to commercialize this LETI FED technology. The Pixel (LETI) cathode structure consists of a multitude of emitter tips (>1500 tips/pixel), the lateral resistive layer, and a metal mesh structure which defines the sub-pixel array. For a 6 inch diagonal display, the multiplicity of tips (200 million) provides much redundancy. This redundancy improves the spatial and temporal uniformity. Both the standard deviation of the microtip sharpness plays a critical role in emission efficiency, from the curvature in the Fowler-Nordheim equation in the low voltage region. The ratio of the standard deviation to mean tip sharpness is about 10% in average panels. The resistive layers limits the device currents. The vertical resistive layer eliminates the uncontrollable cathode currents and exploding microtips, resisting the emitter currents to acceptable levels. The vertical resistive layer, along with microtip redundancy, provide long term uniform emission. Although this vertical resistive layer provides a partial solution of achieving a robust cathode, pinholes, thermal breakdown, or electrical breakdown in the amorphous silicon resistor can still result in catastrophic failure for the tip. The LETI configuration solves this problem by mesh cathode conductor and locates the microtips within the spaces in the mesh. This changed the path of current flow through the resistive layer from vertical to lateral. This eliminated the problem of pinhole shorts. The longer lateral resistive path operates under lower thermal stress compared to the shorter vertical resistor leading to a more robust cathode. The phosphor screen (anode) is a crucial component of the FED. The LETI display implements a switched anode scheme for producing a full color image. The phosphor is defined in columns in this scheme, with all the red tied together, all the green tied together and all the blue tied together. For each video frame, red, green and blue images are sequentially displayed with red, green and blue components tied together in time rather than spatially. This temporal color scheme is argued to be easier to manufacture. The switched anode triples the number of tips/pixel because dedicated tips for red, green and blue are not required. The switched anode releases the alignment between anode and cathode since specified microtips are not aligned to a specific color. The color spacing of the anode and cathode (200mm) provides proximetry focusing to the appropriate color. The negative impact to using a field sequential display is that the data rate is three times that of a frame sequential device. In order to avoid color breakup it must be >60 Hz. The primary criteria which influences the quality and the ease of manufacture of the phosphor screen are: acceleration voltage used by the display. phosphor deposition technique. Most conventional cathode ray tubes, cathodoluminescent based, operate at extremely high voltages. The CRT phosphors that are currently in use have been optimized for high voltage and low current density (few mA/cm 2). The use of high voltage (>3KV) allows the backside aluminization of the phosphor screen. Many CRT phosphors lose 50% of their initial efficiency (200 C/cm 2) electron dose due to Coulombic aging. FEDs require higher current densities to obtain comparable brightness. There is also much interest in using novel materials or new deposition techniques for low voltage phosphors. Doped semiconductor nanocrystals (30 -70 Angstroms in diameter) have demonstrated photoluminescent quantum efficiencies as large as 18% at room temperature with decay time of <10 ns. While there has been little work evaluating these materials for cathodoluminescent applications, the small diameter, short decay time and high quantum efficiency make these materials attractive for low voltage, high current density applications. Thin-film phosphors are also under investigation for low voltage applications because of the short electron mean-free path. The realization of thin-film phosphors with efficiencies equivalent to bulk phosphors at low voltages would be considered a major milestone for FED display technology. FEDs require high vacuum conditions with great reliability. Vacuum technology has been developed for many years; however, it is oriented toward applications involving macroscale devices. For FED devices, the vacuum technology base is not so useful because FED put unusual constraints on handling outgassing effects and conducting molecular gases to the appropriate pumping equipment. A FED display has a rectangular cross-section (length L, width b and thickness a) and outgasses at a rate Q(t0), then the pressure can be modeled by the following differential equation: where P(x,t) is the pressure inside the panel as a function of the spatial dimension x and time t. The dimension x is the distance from the pumping source of speed s. The value of Bn is the ratio brak rysunku where with m being the mass of the gas molecule and T the absolute temperature. The above expression demonstrates that when the space a between the anode and cathode is very small, the pressure can increase by several orders of magnitude. If a pumping source is capable of maintaining a vacuum of ~10 -8 T, then a vacuum at a location a centimeter away from the source could be 10 -5 T, when the separation distance between the anode and cathode is the distance of that for FED displays (100 - 500 mm). Up to this point, we have spent a significant amount of time on FED technology that was derived from the early work of Spindt. It was reviewed earlier that electron emission relies on electrons with enough energy to overcome the hurdle presented by the surface on the use of an electric field to lower the barrier to the extent that comparatively unenergetic electrons can escape through tunneling. Another method to engineer an acceptable level of electron emission is simply by employing a material for the emitter that has a low barrier of work function. The Fowler-Nordheim equation predicts that electron emission is strongly dependent on the work function (energy barrier height). For molybdenum, the work function is roughly 4.5 eV. If, for example, a material could be identified to have a work function of 0.2 eV, the electron emission could increase by several orders of magnitude. Unfortunately, for the alkali case cesium and cesium oxide, the ability to lose an electron efficiently usually comes at the expense of the overall stability of the material. The general rule of thumb is that the atomic arrangement is such that the outer electrons are easily lost, the general result is that the atoms are loosely bound to each other and therefore do not form a highly stable material. The poor stability manifests itself in a comparatively high free energy and high vapor pressure, enabling the material to be extremely mobile. This is a detriment to almost any electronic device. Also, materials with loosely bound electrons adsorb on insulating surfaces tend to lead to low voltage surface breakdown. Grids, gates and electrodes with monolayers of low work function gases start to emit electrons to more positively charge locations. Materials with high vapor pressures also lead to gaseousconduction mechanisms between the electrodes at different potentials. Conduction is detrimental in the devices leading to an avalanche condition, which develops into an arc that destroys the device. Diamond possesses very strong bonding as demonstrated by its high melting temperature, low vapor pressure, extreme hardness and high thermal conductivity (~20 x 103 W/mK). Diamond has been shown to have a negative electron affinity, which means that the conduction band is above the vacuum level. Diamond also has a low work function, between 0.2 - 0.3 eV. The diamond has a face-centered-cubic (fcc) crystal structure with two atoms per primitive unit cell. The measured cubic edge is 3.567 Angstroms. The figure below shows a band diagram for diamond as compared to a material with a positive electron affinity. The bandgap for diamond is approximately 5.5 eV and the conduction band E c is above the vacuum level (Evac). The difference between the conduction band and the vacuum level is the electron affinity X. For diamond, the affinity is negative. The relationship for (III) crystalline direction is such that an electron in the conduction band near the surface would prefer to leave the crystal by lowering its energy and liberating itself. This is the escaped electron we have been looking for. One must keep in mind a common misconception - the electron affinity is not the work function which is the barrier presented to electrons at the Fermi energy level E f. the work function is always positive, in order not to violate the 2nd Law of Thermodynamics. The band diagram for diamond demonstrates some very valuable properties, including the ability to emit electrons very easily. The current predicted by the band diagram is not very high. The free concentration in a perfect diamond crystal is very low due to the high-energy bandgap. No one has yet proven an n-type single crystal diamond with low dopant-activation energy. The primary source of free carriers in diamond comes from the graphite phase. The ease with which free carriers can escape the diamond surface is readily observed in the laboratory. The typical curve for diamond for current vs. applied field and is about three orders of magnitude lower than that required for traditional emitter materials used in the Spindt-tip configuration. This enables more trade-offs from the engineering perspective such as trade-offs between low turn-on voltage and producability issues such as lithography requirements, power and cost. The simple diamond LED structure is shown below. There are several advantages to the structure: no lithography is required beyond that necessary for pixel definition. printed circuit board techniques can be used. lithography is no longer a cost problem because lithography is simple