Limestone - scawtite review

advertisement

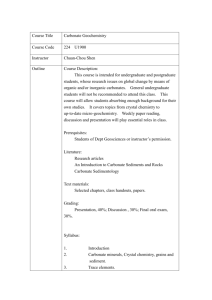

Influence of carbonate on cement Introduction Scawtite (Ca7(Si6O18)(CO3).2H2O) is a calcium-silicate-carbonate-hydrate that forms sporadically in calcium silicate or cement systems when exposed to carbonate and temperature. Pure scawtite contains 5.80% CO2 (Luke et al.) or 5.28% CO2 (Kalousek and Nelson). In other words, 1% CO2 corresponds to 19% scawtite and as such small amounts of CO2, i.e. 1 to 2% will yield large amounts of scawtite. Publications that mention the formation of scawtite or carbonate phases formed due to carbonation are listed in the reference section. Table 1, gives a general synopsis of the testing parameters, systems and stability temperatures at which scawtite was observed as well as CO 2 concentrations and performance characteristics. Table 1. Conditions observed for scawtite formation and performance criteria if noted. Ref Harker Kalousek and Nelson Cement Temp (°C) CO2 (%) CaO-SiO2-H2O-CO2 140 - 300 175 - 300 stoichiometric 0.34-0.37 1.32 – 1.74 350 0.9 – 2.0 Good performance DATA PROVIDED Trace – enhance properties Major – poor performance DATA PROVIDED 240 Class G 240 Trace Portland Cement or Class J 215-315 300 CaO-MgO-SiO2-H2O (Class J + chrysotile) Eilers et al. None determined None determined Class J Class J Roy et al. Taylor (Review) Gallus et al. Performance Field of stability Negligible Scawtite formed in equilibrium with gyrolite or truscottite Increases with CO2 content Trace amounts scawtite Trace to major amounts of a carbonate phase Presence observed Minor (10-30%) C2S-S Luke et al. Scawtite Formation 350 Up to 350 Minor amounts < 10% (carbonate) Trace - major None determined None determined (Implication that trace amounts of scawtite gives improved strength) None determined Compressive strength low but satisfactory and decreased over time. Permeability satisfactory. The data indicate that scawtite can form in the temperature range from 140-315°C at concentrations from 0.9 to <10% CO2 from trace to major amounts and that it can to some extent impact the compressive strength an permeability. The data is specific to the various testing parameters and it is not clear as to where the limits are in terms of carbonate addition, temperature and poor performance. Synopsis of papers relating to the effect of carbonate on cement and scawtite formation: Harker investigated the parameters necessary for formation of scawtite using reagent grade chemicals and found it to form at temperatures between 140 and 300ºC. The study suggests that at lower temperatures calcite reacts with tobermorite to form scawtite and with increasing temperature, the scawtite then reacts to give xonotlite and calcite. Eilers et al. indicates that scawtite, can be formed at temperatures between 215 and 315ºC on adding sodium carbonate, sodium bicarbonate or calcium carbonate at less than 10% presumably by weight of cement to Portland cements containing 35% silica. Scawtite, in trace to minor amounts, is reported to enhance the performance of cement whereas major amounts are related to lower strength and increased permeability. The results furthermore suggest that scawtite forms in the presence of xonotlite which conflicts somewhat with Harker’s data and could relate to the effect of other components such as alumina or alkalis in the cement, as indicated by Taylor and Roy. Luke et al. shows that the amount of scawtite formed corresponds approximately to the amount of CO2 present and formed at concentrations as low as 0.9 to 2.1% carbonate at 350ºC. Gallus et al. also noted the formation of scawtite 240ºC in geothermal dry steam wells having 5000 ppm CO2 content and was associated with gradual decrease in compressive strength over time although over the 2 year study strengths were still apparently acceptable. It is also of note that in this study, a Class J cement was used and Luke et al. reported that Class J cement tended to contain small amounts of carbonate. Kalousek and Nelson, on a study of C2S-S cements showed negligible amounts of scawtite when the CO2 content was 0.37% or less whereas at 1.32 and 1.74% CO2, scawtite was observed over the 175-300°C temperature range. At 175–200°C scawtite formed in equilibrium with gyrolite and at 250–300°C scawtite was in equilibrium with truscottite. Scawtite apparently formed in total replacement of xonotlite at these temperatures. Roy et al. observed scawtite in a CaOMgO-SiO2-H2O system at 300°C and 10,000 psi and noted that the material containing a mixture of scawtite and xonotlite was stronger than the material containing pure xonotlite. References Eilers L.H., Nelson, E.B. and Moran, L.K.: “High Temperature Cement Compositions Pectolite, Scawtite, Truscottite or Xonotlite Which Do You Want?” paper SPE 9286 presented at the 55th Annual Fall Technical Conference and Exhibition, Dallas, Texas, USA (September 21-24, 1980) Gallus, J.P., Pyle, D.E. and Moran, L.K.: “Physical and Chemical Properties of Cement Exposed to Geothermal Dry Steam,” paper SPE 7876 presented at the International Symposium on Oilfield and Geothermal Chemistry, Houston, Texas, USA (January 2224, 1979). Harker, R.I.: “Scawtite and Its Synthesis,” Mineral Mag., Vol. 34 (268) 1965, pp 232236. Kalousek, G.L. and Nelson, E.B.: “Hydrothermal Reactions of Dicalcium Silicate and Silica,” Cem. Concr. Res., Vol. 8, 1978, pp 283-290. Luke, K., Taylor, H.F.W. and Kalousek, G.L.: “Some Factors Affecting Formation of Truscottite and Xonotlite at 300 - 350ºC,” Cem. Concr. Res., Vol. 11 (2), 1981, pp197203. Roy, D.M., White, E.I., Langton, C.A. and Gruzteck, M.W.: “Potential New High Temperature Cements for Geothermal Wells,” paper SPE 7677 presented at the International Symposium on Oilfield and Geothermal Chemistry, Houston, Texas, USA (January 22-24, 1979). Taylor, H.F.W. and Roy D.M.: “Structure and Composition of Hydrates,” 7th International Congress on the Chemistry of Cement, Vol. 1, 1980, pII-2/1