Statistical Process Control Exam: Charts & Analysis

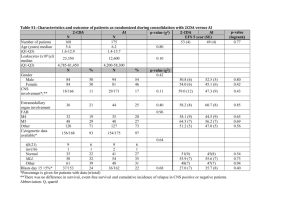

advertisement

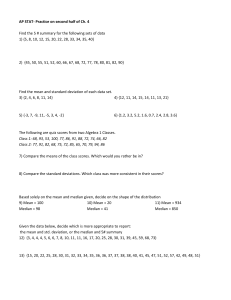

Statistical Process Controls: Please solve and submit the following questions (50 points). 1. A major record-of-the-month club collected data on the reasons for returned shipments during a quarter. Results are: wrong selection, 50,000; refused, 195,000; wrong address, 68,000; order canceled, 5,000; and other, 15,000. Construct a Pareto diagram and recommend what are the major problems that demand investment. Pareto Chart of Reason 350000 100 300000 totals 200000 60 150000 40 Percent 80 250000 100000 20 50000 0 reason Count Percent Cum % Refused 195000 58.6 58.6 Wr. Add 68000 20.4 79.0 Wr. Sel. 50000 15.0 94.0 Other 15000 4.5 98.5 Ord Can 5000 1.5 100.0 0 It does appear that communication is the largest issue in the organization. The customers are refusing their orders as 60% of our total losses because we are apparently not getting them proper service. We also have the wrong addresses for 20% of our customers with issues and 50,000 we have the wrong address for. Communication with the customer is apparently the largest flaw in need of most investment. 2. Calculate the average, median, mode, range, and standard deviation for each group of numbers. (a) 50, 45, 55, 55, 45, 50, 55, 45, 55 N N* C1 Variable C1 Mean 9 SE Mean StDev Minimum 0 50.56 1.55 4.64 Q1 Median 45.00 45.00 Q3 Maximum 50.00 55.00 55.00 Range 10.00 MODE = 45 (b) 89,87,88,83,86,82,84 Variable C1 N 7 N* 0 Mean 85.571 Variable C1 Maximum 89.000 SE Mean 0.997 Range 7.000 StDev 2.637 Minimum 82.000 Q1 83.000 Median 86.000 Q3 88.000 Mode = 83 (c) 11,17,14,12,12,14,14,15,17,17 Variable C1 N 10 N* 0 Variable C1 Maximum 17.000 Mean 14.300 SE Mean 0.700 Range 6.000 Mode 13 StDev 2.214 Minimum 11.000 Q1 12.000 Median 14.000 Q3 17.000 (d) 16,25,18,17,16,21,14 Variable C1 N 7 N* 0 Mean 18.14 Variable C1 Range 11.00 mode 17 SE Mean 1.40 StDev 3.72 Minimum 14.00 Q1 16.00 Median 17.00 Q3 21.00 Maximum 25.00 (e) 45,39,42,42,43 Variable C1 N 5 N* 0 Variable C1 Maximum 45.000 Mean 42.200 Range 6.000 SE Mean 0.970 Mode 42 StDev 2.168 Minimum 39.000 Q1 40.500 Median 42.000 Q3 44.000 3. Control charts for X and R are to be established on a certain dimension part, measured in millimeters. Data were collected in subgroup sizes of 6 and are given below. Calculate the trial central line and control limits. Assume assignable causes and revise the central line and limits. ----------------------------------------------------------------------------------------------------------Subgroup Subgroup Number X R Number X R -----------------------------------------------------------------------------------------------------------1 20.35 0.34 14 20.41 0.36 2 20.40 0.36 15 20.45 0.34 3 20.36 0.32 16 20.34 0.36 4 20.65 0.36 17 20.36 0.37 5 20.20 0.36 18 20.42 0.73 6 20.40 0.35 19 20.50 0.38 7 20.43 0.31 20 20.31 0.35 8 20.37 0.34 21 20.39 0.38 9 20.48 0.30 22 20.39 0.33 10 20.42 0.37 23 20.40 0.32 11 20.39 0.29 24 20.41 0.34 12 20.38 0.30 25 20.40 0.30 13 20.40 0.33 ----------------------------------------------------------------------------------------------------------- Xbar-R Chart of X U C L=20.6556 Sample M ean 20.6 20.5 _ _ X=20.4004 20.4 20.3 20.2 LC L=20.1452 1 2 3 Sample 4 5 1 U C L=0.4320 Sample Range 0.4 0.3 _ R=0.2156 0.2 0.1 0.0 LC L=0 1 2 3 Sample 4 5 4. The following table gives the average and range in kilograms for tensile tests on an improved plastic cord. The subgroup size is 4. Determine the trial central line and control limits. If any points are out of control, assume assignable causes, and determine the revised limits and central line. Xbar-R Chart of X Sample Mean 520 U C L=519.75 500 _ _ X=482.52 480 460 LC L=445.29 440 1 2 3 4 Sample 5 6 7 Sample Range 60 U C L=58.29 45 30 _ R=25.55 15 0 LC L=0 1 2 3 4 Sample 5 6 7 5. The Get-Well Hospital has completed a quality improvement project on the time to admit a patient using: XC- and R charts. They now wish to monitor the activity using median and range charts. Determine the central line and control limits with the latest data in minutes, as given here. Xbar-R Chart of XBar Sample M ean 6.8 U C L=6.759 6.4 _ _ X=6.064 6.0 5.6 LC L=5.369 5.2 1 2 3 4 5 6 7 8 Sample 2.0 Sample Range U C L=1.748 1.5 1.0 _ R=0.679 0.5 0.0 LC L=0 1 2 3 4 5 Sample 6 7 8 6. The viscosity of a liquid is checked every half hour during one three-shift day. What does the run chart indicate? Data are 39, 42,38,37,41,40,36,35,37,36, 39,34,38,36,32,37,35,34,33,35,32,38,34,37,35,35, 34, 31, 33, 35, 32, 36,31,29,33,32,31,30,32, and 29. Run Chart of C1 42 40 C1 38 36 34 32 30 1 5 Number of runs about median: Expected number of runs: Longest run about median: A pprox P-Value for Clustering: A pprox P-Value for Mixtures: 10 14 20.20000 7 0.01917 0.98083 15 20 25 Observation Number of runs up or down: Expected number of runs: Longest run up or down: A pprox P-Value for Trends: A pprox P-Value for Oscillation: 30 35 40 26 26.33333 4 0.44910 0.55090 The viscosity of the liquid appears to be dropping over time from the average. If this deterioration trend continues, then the liquid will have to be replaced to prevent damage to equipment. 7. Determine the trial central line and control limits for a p chart using the following data, which are for the payment of dental insurance claims. Plot the values on graph paper and determine if the process is stable. If there are any out -of-control points, assume an assignable cause and determine the revised central line and control limits. P Chart of No. N.C 0.07 1 0.06 Proportion 0.05 0.04 UCL=0.04016 0.03 _ P=0.01747 0.02 0.01 0.00 LCL=0 1 3 5 7 9 11 13 15 Sample 17 19 21 23 25 P Chart of No. N.C 0.04 UCL=0.03676 Proportion 0.03 0.02 _ P=0.01542 0.01 0.00 LCL=0 1 8. 3 5 7 9 11 13 15 Sample 17 19 21 23 Determine the trial limits and revised control limits for a u chart using the data in the table for the surface finish of rolls of white paper. Assume any out -of-control points have assignable causes. U Chart of Total N.C 6 5 Sample Count Per Unit 1 1 UCL=5.043 4 _ U=3.315 3 2 LCL=1.588 1 1 1 0 1 4 7 10 13 16 Sample 19 22 25 28 Tests performed with unequal sample sizes U Chart of Total N.C UCL=5.097 Sample Count Per Unit 5 4 _ U=3.358 3 2 LCL=1.620 1 1 3 5 7 9 11 13 Sample Tests performed with unequal sample sizes 15 17 19 21 23 9. A quality technician has collected data on the count of rivet nonconformities in four meters travel trailers. After 30 trailers, the total count of nonconformities is 316. Trial control limits have been determined and a comparison with the data shows no out-of-control points. What is the recommendation for the central line and the revised control limits for a count of nonconformities chart? If the data has been compared to the original data done for testing and all of the data indicates there are no out of spec process controls, then the revised control limits will have to be moved to fit the newly gathered data for the next run. If the nonconformities occurred on the low side of the spectrum, then move the revised control limits lower. If the phenomenon occurred on the high side, then move the control limits up. 10. By means of a scatter diagram, determine if a relationship, exists between product temperatures and percent foam for a soft drink. Scatterplot of temp vs foam 50.0 47.5 temp 45.0 42.5 40.0 37.5 35.0 15 20 25 30 foam 35 40 45 From the look of the graph of Product Temperature VS Foam, the data indicates that there is a correlation between the temperature and the percentage of foam in the product. My suggestion if foam is a deterrent to a quality end product, is to add equipment that would eliminate air entrapment to the liquid in the beginning or add coolers to the process to control the temperature of the product.