Isola Werke (UK) Ltd

advertisement

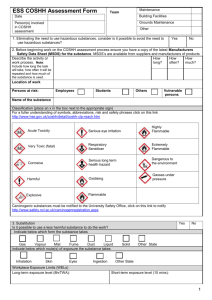

Selwyn College Risk Management Procedure Control of Substances Hazardous to Health (COSHH) Objectives Responsibilities of the Maintenance Manager, Head Housekeeper, Catering Manager and Head Gardener May 2012 RMP/16 Issue: 1 To identify the health hazards to staff and others from substances. To make an assessment of the degree of risk associated with each hazard in relation to inhalation, skin contact/absorption and ingestion. To determine and implement measures and procedures to control the risks. To meet legal requirements. To ensure that: All hazardous substances used are identified. Material Safety Data Sheets are obtained for each product used in their Department. A copy of each data sheet is passed to the H&S Officer. COSHH assessments are completed for each category held in their Department. Each assessment record adequately covers the scope of usage for each substance. Copies of all assessments are given to the HR & Health & Safety Officer. COSHH assessments are reviewed annually. All specified safety equipment is provided. Any specified maintenance checks are implemented and recorded. Staff are instructed on the hazards, risks and safety measures, as identified in the assessment records. Staff are working to the identified safety standards by means of regular monitoring inspections and audits. Maintenance Manager To ensure that: Planned maintenance is performed on the LEV system by suitably trained staff. Records of planned maintenance are kept for 5 years. H&S Officer To ensure that: The LEV system is examined and tested by a competent person at 14 month intervals. Records of any health surveillance records are maintained for 40 years. Records of all staff training are maintained. Employees To: Immediately report to their Head of Department any contact with chemicals. Follow instructions on the safe use of chemicals at all times. Report to their Head of Department any defects in safety equipment or working arrangements. Ventilation System Examinations and tests shall be performed at 14 month intervals. Routine maintenance checks should be completed on the dust extraction system and records of all maintenance kept. The Maintenance Manager will keep records of all training provided to staff completing routine maintenance checks on the LEV system. Selwyn College Risk Management Procedure Control of Substances Hazardous to Health (COSHH) May 2012 RMP/16 Issue: 1 COSHH Assessments General risk assessments shall be used to identify whether COSHH assessments have been prepared and are being implemented. COSHH assessments shall be prepared by relevant Heads of Departments for each category of substance used in their Department, using the assessment categories given in RMP/16c. Instructions on how to complete an assessment are given in document reference no. RMP/16a. The assessment form can be found at RMP/16b. The following aspects are relevant to completion of the record: Record No: An identifiable number for each assessment. Amendment No: An identifiable number which records the assessment has been amended to include additional substances and working methods. This allows the original record to be retained for any civil litigation purposes in the future. COSHH assessments shall be reviewed annually and also following any incident or case of ill-health. Material Safety Data Sheets Information and Training Contractors Substance Inventory Assessment Inventory Material safety data sheets should be obtained for all substances. Data sheets will not be available for all hazardous substances, e.g. substances produced from inadvertent mixing of substances, ozone released from laser printers and photocopiers. The data sheets relevant to each department should be referenced with a unique number, (e.g. A1, A2, B1, B2 etc.) and filed in alphabetical order. Information on hazards, assessments and control measures shall be brought to the attention of employees. Staff appointed to prepare assessments shall attend a specific training course. Where applicable, contractors shall provide details of their assessments before their work commences. Any alterations from the agreed working method, or substances used may only take place following a risk assessment review of the proposed changes. Each Head of Department will keep an inventory (RMP/16d) of all substances used in their Department. The Assessment Reference indicates the COSHH assessment record(s) for each substance. D.S. Ref. indicates the unique reference number of the health and safety data sheet for each substance. Each Head of Department will keep an inventory (RMP/16/d) of all COSHH assessments completed for their Department. Each Assessment Reference (e.g. SM/1) is unique, to identify: The nature of substance and method of usage, e.g. SM The risk level and associated safety standard, e.g. 1 Selwyn College Risk Management Procedure Control of Substances Hazardous to Health (COSHH) Trial Use of Substances PPE Training RPE Provision and Training May 2012 RMP/16 Issue: 1 The format is given at document no. RMP/16g. This allows usage of new substances pending incorporation into an assessment record. Substance trail use should only be authorised and documented by a Head of Department. All staff using chemicals must adhere to the instructions given to them regarding the use of any PPE. The PPE will be identified by suitably trained staff in COSHH assessments. The format is given in document RMP/13a. The Maintenance Manager will keep records of all COSHH toolbox talks provided to Maintenance Staff. The HR Officer will keep records of all other basic COSHH training and COSHH Assessment training. The requirement for RPE will be determined in project risk assessments. Staff will be provided with all RPE identified in risk assessments. Staff will be provided with appropriate training in the use and storage of RPE for each project. Employee Health Surveillance All employee health surveillance will be recorded in the form RMP/16f. This will be only relevant: Where health surveillance is identified in a COSHH assessment. If an employee reports health concerns when or immediately after using substances. Heads of Departments will keep chemical data sheets for all chemicals held their department. Data sheets will be brought to the attention of employees and be readily available in the event of an emergency. Duplicate copies of all data sheets will be held by HR & Health & Safety Officer’s and also in the Porters’ Lodge. Records of all LEV planned maintenance shall be kept by the Maintenance Manager. Records of all LEV examination and tests shall be kept by the H&S Officer. Records Monitoring Review and This procedure will be reviewed annually by members of the H&S Working Group.