toshiba cambridge research centre

advertisement

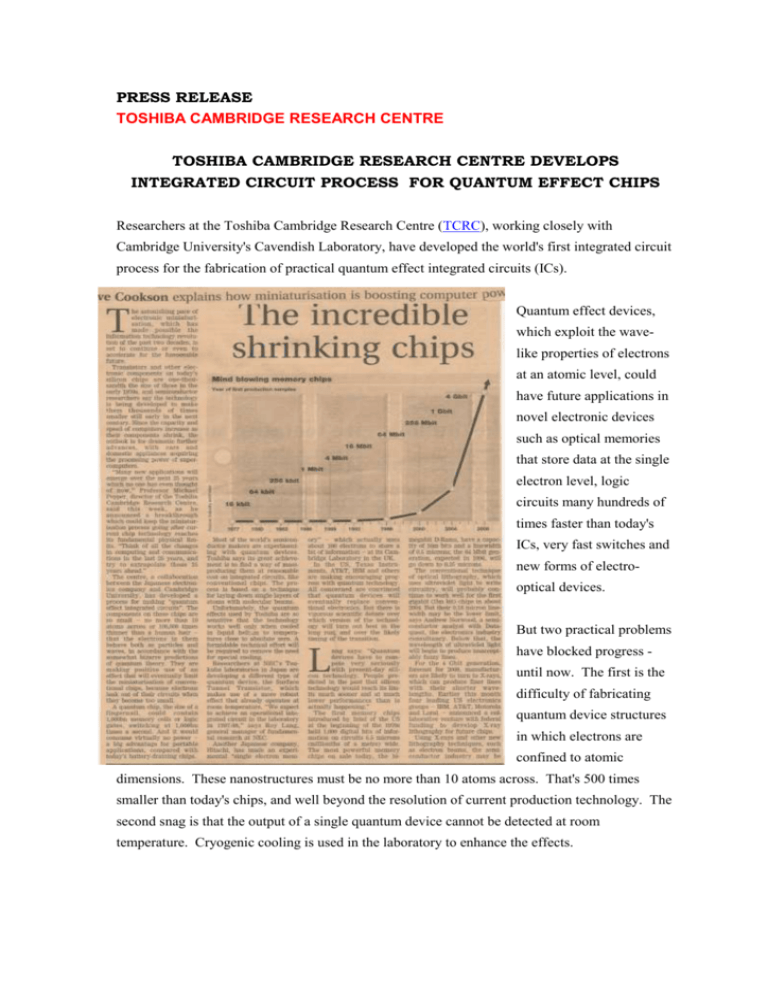

PRESS RELEASE TOSHIBA CAMBRIDGE RESEARCH CENTRE TOSHIBA CAMBRIDGE RESEARCH CENTRE DEVELOPS INTEGRATED CIRCUIT PROCESS FOR QUANTUM EFFECT CHIPS Researchers at the Toshiba Cambridge Research Centre (TCRC), working closely with Cambridge University's Cavendish Laboratory, have developed the world's first integrated circuit process for the fabrication of practical quantum effect integrated circuits (ICs). Quantum effect devices, which exploit the wavelike properties of electrons at an atomic level, could have future applications in novel electronic devices such as optical memories that store data at the single electron level, logic circuits many hundreds of times faster than today's ICs, very fast switches and new forms of electrooptical devices. But two practical problems have blocked progress until now. The first is the difficulty of fabricating quantum device structures in which electrons are confined to atomic dimensions. These nanostructures must be no more than 10 atoms across. That's 500 times smaller than today's chips, and well beyond the resolution of current production technology. The second snag is that the output of a single quantum device cannot be detected at room temperature. Cryogenic cooling is used in the laboratory to enhance the effects. The development of a practical IC process by the TCRC-Cavendish team promises a solution to both problems. Their achievement compares with the transition, in the late 1950's from discrete transistor devices to integrated circuits. Similarly, present-day nanostructures are produced on a laboratory scale, as discrete devices, using electron beam machines to define features. But this is a slow and expensive process. Now, the progress of the research has shown that quantum ICs can be fabricated on a wafer scale, just like conventional integrated circuits. Instead of diffusing impurities into the semiconductor materials, the research workers build up a sandwich structure of semiconductor layers from a base substrate. A first semiconductor layer is deposited using Molecular Beam Epitaxy (MBE) and this is followed by subsequent patterning and MBE regrowth stages to form individual devices and circuits. Conventional photo-lithography is used to define non-critical dimensions and separate individual ICs. A crucial stage in this process is the ability to regrow semiconductor layers, a technique that will be greatly assisted by a new vacuum cleaning chamber, recently connected to the MBE facility. Essentially, the first MBE-grown layers are used to define the devices in the regrown layers. Professor Michael Pepper, managing director of TCRC and Professor of Physics at Cambridge University, comments: "We have shown that full wafer scale processing is possible, just as with present day silicon devices. Moreover our technology, based on advanced MBE techniques, is highly manufacturable and could readily be transferred to a production environment." According to Professor Pepper this advance is significant for three reasons. "Firstly, we can now combine a variety of interesting quantum effect devices into integrated circuit structures to produce powerful new functions. For example, we could combine quantum logic devices with optical memories in a single device. The flexibility of the technology permits a wide range of device design." "Secondly, the technology allows us to produce a stronger confinement of electrons. This increases quantum effects and current output. If greater currents are required, we can also combine the outputs of parallel arrays of quantum structures. Together, these two effects may well be sufficient to permit device operation at room temperature". "Thirdly, our technology could have spin-offs in conventional silicon chip fabrication. We have shown how the process of integration can be continued down to the near atomic level. Conventional IC silicon processes are fast approaching a fundamental limit - set by the wavelength of light. But we have shown how these limitations can be overcome". More immediately, projects are underway which utilise this process technology to fabricate experimental devices in which electrons are confined in progressively fewer dimensions. For example, on dimensional thread-like structures - called quantum wires - have potential applications in novel forms of lasers. And zero dimensional nanostructures, or quantum dots, can be used in optical memories in which information is stored by switching the energy state of a single electron. The research workers have now fabricated 3, 2, 1 and zero dimensional devices using a combination of MBE regrowth technology and a novel electron squeezing technique, previously developed by Professor Pepper. Work at TCRC also could lead to the development of multilayer integrated circuits in which devices are stacked on top of each other to increase packing densities. Present work is based around III-V semiconductors, such as gallium arsenide and gallium aluminium arsenide. But these fabrication techniques could be extended to silicon, and are compatible with modern chip technology, as well as indium-based compounds used for many optoelectronic applications. There is world wide interest in quantum devices and many companies and academic institutions have active research programmes. In the UK the Engineering and Physical Sciences Research Council has sponsored work in Universities including many projects in the Cavendish Laboratory. The breakthrough announced today should increase this international level of interest and activity in the development of quantum technology as a source of new concepts and devices for applications in the next century.