Hints for cleaning and sterilization of surgical instruments

advertisement

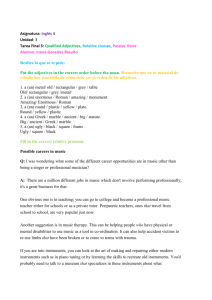

CHIRURGISCHE INSTRUMENTE MEDIZINTECHNIK Information about processing/reprocessing of reusable surgical instruments GENERAL PROCESSING CLEANING DISINFECTION INSPECTION STERILIZATION MATERIALS SILVER USEFUL LIFE WARNING DISPOSABLE INSTRUMENTS Surgical instruments are manufactured for surgical procedures and must not be used for other purposes. The attending surgeon and/or the hospital is/are responsible for selecting the proper instrumentation as well as for training of and providing sufficient information to the surgical staff. The instruments supplied by Bernhard Hermle GmbH comply with the EC Directive 93/42/EEC and correspond to Class 1 (Rule 6). Surgical instruments must be CLEANED and STERILISED prior to the first and each subsequent use. They must NOT be sterilised in their original packaging. Only use validated device and product-specific procedures in all processing steps and also follow the respective laws of your country. Cleaning may be performed manually, mechanically or by ultrasound. Articulated instruments (scissors and clamps) must be cleaned in their opened position and all instruments must be arranged in a single layer, i.e. not be stacked on top of each other. Do not use metal brushes or metal sponge pads. Arrange the instruments in such a way that no areas are left unwashed. Hollow instruments (e.g. cannulas) must be treated with extra care. They must not be allowed to dry out and must be rinsed IMMEDIATELY after use. Cleaning solutions must be used according to the manufacturer’s instructions and replaced with fresh solution on a regular basis. Prepare and use the disinfectant solutions as specified in the manufacturer’s instructions. Dry the instruments after disinfection. Inspect the instruments for cleanliness, proper functioning, wear and damage. Instruments in technically perfect condition may be wrapped or placed in trays. We recommend steam sterilisation with fractionated vacuum. Sterilise at 134 °C and a pressure of 3 bar for at least 5 minutes. Follow the instructions and recommendations of the device manufacturer. Surgical instruments are made of stainless steel (rust-resistant steel alloys) in accordance with DIN 7153-1. The following material numbers are primarily used: 1.4021 (X20Cr13) 1.4024 (X15Cr13) 1.4034 (X46Cr13) 1.4104 (X14CrMoS17) 1.4116 (X50CrMoV15) 1.4117 (X38CrMoV15) 1.4301 (X5CrNi18-10) 1.4305 (X8CrNiS18-9) 1.4310 (X12CrNi17 7) 1.4401 (X5CrNiMo17-12-2) 1.4197 (X22CrMoNiS13-01) The applied solutions and chemicals must be appropriate for these stainless steel materials and must be used according to the manufacturer’s instructions. Follow the indicated immersion times, concentrations and recommended usage times. Some cannulas and probes in our product line are made of pure silver. Do not place silver cannulas and silver probes into normal saline solution, since prolonged contact may lead to discoloration. Surgical instruments made of stainless steel (and silver) are generally suitable for a large number of reprocessing cycles. It must, however, be noted that each chemical, manual, mechanical and/or thermal treatment might put stress on the material. This is why the surgeon is required to inspect each instrument for surface changes such as corrosion or other changes prior to each use. Any suitable care products should be applied in a very thin layer following cleaning and prior to sterilisation and must be biocompatible and approved for sterilisation. We reject any responsibility for reusing instruments that were used in patients with Creutzfeldt-Jakob disease or HIV infection. Even if these infections are merely suspected, we recommend that the utilised instruments be destroyed. Instruments intended for SINGLE USE must never be processed or reprocessed. Information about instrument processing and care is provided on the following website: http://www.a-k-i.org Bernhard Hermle GmbH Beethovenstr. 24 D-78532 Tuttlingen Germany Telephone +49 7461-8530 Fax +49 7461-3063 Email: Hermle.Medizintechnik@t-online.de Internet: www.hermle-medizintechnik.de Edition: 2016-01