Attrition of Dolomitic Limestone Calcine in a Spouted Fluidized Bed

advertisement

Attrition of Dolomitic Lime in a Fluidized-Bed Reactor at High

Temperature

Miloslav Hartman,* Karel Svoboda, Michael Pohořelý, Michal Šyc, Michal Jeremiáš

Institute of Chemical Process Fundamentals, Academy of Sciences of the Czech Republic,

Rozvojová 135,165 02 Prague 6-Suchdol, Czech Republic

Corresponding author: Miloslav Hartman, e-mail: hartman@icpf.cas.cz

Received

The results of an experimental study on the rate of attrition of lime catalyst/sorbent in a

high-temperature, turbulent fluidized bed with quartz sand are presented. Batchwise

measurements were conducted at 850oC in an electrically heated gasification reactor of an

inner diameter of 5.1 cm with three sizes (450, 715, and 1060 µm) of high-grade, dolomitic

lime. In addition to the influence of the particle size, the effect of operating (elapsed) time

was investigated at different superficial gas velocities. Assuming that the attrition rate decays

exponentially with time, a simple mechanistic model is presented which makes it possible to

correlate the measured experimental data. The course of the attrition of lime particles is

described as a function of the elapsed time, the excess gas velocity, and the particle size. The

present approach and the results may be applicable to the attrition of high-grade, dolomitic

lime, particularly in fluidized gasification of biomass.

Keywords: dolomitic lime; attrition; fluidized bed; catalytic gasification

2

Introduction

As has been well-established, a fluidized bed with particles of an alkaline solid, such

as is produced by the calcination of limestone or dolomite, can effectively remove unwanted

acidic gases like SOx, HCl, H2S, and COS from the gaseous phase at high temperature

(Hartman & Couhlin, 1976; Hartman & Svoboda, 1985; Hartman & Trnka, 1993, 2002;

Hartman et al., 1979, 1988, 1991, 1994a, 2000, 2002). It is apparent that under operating

conditions typical of fluidized-bed combustion, the carbonate rock first undergoes thermal

decomposition and then starts further reacting. During the processing, sorbent particles are

subject to thermal shock possibly causing their fragmentation and subsequent detrimental

elutriation out of the contacting bed. The continuous and vigorous movement of the fluidized

solids (Yates, 1983; Kunii & Levenspiel, 1991; Gupta & Sathiyamoorthy, 1999) causes their

significant comminution (pulverization). Nevertheless, this phenomenon may lead to the

favorable removal of the very dense layer of the reaction products, which are preferentially

formed and accumulate at the outer surface of particles in the course of sulfation (Hartman &

Couhlin, 1976; Hartman et al., 1988; Lee et al., 1993; Scala & Salatino, 2010; Yao et al.,

2010).

A promising route to reduce the direct use of fossil fuels is biomass gasification

(Knoef 2005; Higman & Burgt, 2008). In this aspect, biomass is usually viewed as any

organic material of plant origin. Gasification involves the partial oxidation of biomass at a

high temperature by heating in the environment of air, oxygen, and/or steam. The produced

combustible gas can be burned to generate heat or electricity, or processed into chemicals and

various gaseous or liquid fuels. However, prior to any use of the product (fuel) gas, a number

of undesirable impurities, both inorganic and organic, need to be removed from the gas (e.g.,

dust (ash), nitrogen compounds, sulfur compounds, metal compounds, and tar).

3

Tar(s) can hardly be defined by a simple specific term. They are usually taken as

viscous, complex organic mixtures mainly composed, for example, of (higher) aromatic

hydrocarbons, heterocyclic compounds, phenolic compounds, and other constituents. These

tars are carcinogens, have corrosive effects, can plug the pores of filters, and also reduce the

overall efficiency of a process. In general, tars can be eliminated from the fuel gas by a

number of methods, for example, by physical, thermal cracking, and catalytic tar removal

processes (Knoef, 2005; Higman & Burgt, 2008). Catalytic methods also impede the

occurrence of methane in the product gas. Catalysts can be used within (in situ) or outside the

gasifier (downstream).

The main groups of catalysts for tar elimination are based on alkaline earth metal

oxides (CaO and/or MgO), alkali metals, and nickel (Sutton et al., 2001). According to

another classification (Abu El-Rub et al., 2004), based upon the catalyst production method,

the catalysts fall into two groups: relatively inexpensive minerals [e.g., (calcined) limestone,

magnesites, dolomites, olivine, clay minerals, and iron ores] and synthetic catalysts (e.g.,

char, fluid catalytic cracking catalysts, activated alumina, and alkali metal- and transition

metal- based catalysts).

In our ongoing research into catalytic biomass gasification (in situ) in a fluidized bed,

we have been employing particulate (calcined) dolomite/limestone rocks. Calcined dolomites

are generally considered as very promising active catalysts for tar elimination (Gil et al.,

1999; Corella et al, 2002). Moreover, dolomite carbonates are inexpensive and abundant rocks

which can be, after use, disposed of without difficulty. However, a significant problem with

the use of dolomite/limestone calcines lies in their possible friability/fragility. Their particles

are quite soft and can have a tendency to break.

4

Characteristics and terminology of limestone and magnesite rocks

Limestone is rather a general term for any rock containing more than 80% of calcium

carbonate and magnesium carbonate (Boynton, 1980; Oates, 1998). Amongst their numerous

minor (trace) components (impurities), silica, alumina, iron oxides and alkali metals are the

most common. Many ways of classifying limestone rocks have been suggested to describe

their nature. Such classifications can be based, for example, on the average grain size, the

micro-structure, the texture, the principal impurities, or on the carbonate content and the

Ca/Mg ratio. The classification of limestone rocks based upon the contents of their principal

carbonate components is presented in Table 1.

By the term “calcination of limestone or magnesite”, it is routinely understood its

thermal conversion, usually under oxidizing conditions, into quicklime (CaO or MgO), which

is also often called more generally (burnt) lime or calcine. According to their precursors, they

may be classified into calcitic (high calcium), magnesian, or dolomitic lime. All lime is

crystalline or microcrystalline, although it usually appears to be amorphous to the unaided

eye. Both oxides possess virtually the same cubic crystal lattice with one exception: the MgO

crystals are slightly smaller, which accounts for the somewhat higher true density of

magnesian and dolomitic lime (3.5 – 3.6 g cm-3) compared to calcium oxide (3.2 – 3.4 g cm3

). Most commercial quicklime has a hardness of 2 to 3 on the Mohs scale. The values for

dolomitic lime lie in the range between 3 and 4 – 5. The porosity (relative volume of pores) of

quicklime varies widely from 20 to 55% depending on the parent carbonate rock and the

process conditions of calcination. The temperature at which the dissociation pressure of CO2

above CaCO3 reaches 101.325 kPa is a value between 898 and 902oC (Hartman & Trnka,

2002). The corresponding decomposition temperature for MgCO3 is between 400 – 550oC

5

(Hartman & Svoboda, 1985; Hartman & Martinovský, 1992). Experience indicates that all

dolomitic rocks decompose at higher temperatures than magnesium carbonate.

Comminution (pulverization) phenomena: scope and terminology

Catalyst attrition (scouring) and solid particle fragmentation were recognized as

important problems in the design and operation of many fluidized bed contacting units some

years ago (Forsythe & Hertwig, 1949; Lin et al., 1980; Arena et al., 1983; Ayazi Shamlou et

al., 1990). Different terms have been employed to describe the phenomena by which solids

undergo comminution/pulverization in fluidized beds (Scala et al., 1997, 2007; Chen et al.,

2008). “Primary fragmentation” occurs as a consequence of thermal stresses caused by rapid

heating of the particles and/or of internal pressure of the gases evolved by chemical reaction

(e.g., thermal decomposition). Both coarse and fine fragments can be generated in this way.

“Attrition by abrasion” yields fine, readily elutriable particulates due to surface wear and

collisions/contact with other particles and reactor internals. It reflects the resistance of the bed

particles to surface wear. “Percolation fragmentation” is brought about by loss of connectivity

in the very porous particle texture. “Secondary fragmentation” occurs due to particle-particle

collisions or particle impacts against the reactor walls or internals and generates coarser,

mostly nonelutriable fragments. All the comminution phenomena manifest themselves in

changes of the particle size distribution of bed solids and in unwanted elutriation of the

generated fines from the system. The extent as well as the sort of dominant pulverization

mechanism depends on the complex interplay (balance) between particle mechanical strength

and particle morphology and disruptive forces acting on the particles in suspension. Aside

from the chemical and thermal stresses (caused, for example, by cyclic heating and cooling of

the bed solids), fluid-dynamic-induced disruptive forces must always be taken into

6

consideration. The primary difficulty is that the behavior of the bulk of particulate materials

under actual operating conditions depends strongly upon the origin, formation and whole

history of the particles.

Although different attrition/fragmentation models are available in the literature (Lee et

al., 1993; Ayazi Shamlou et al., 1990; Chen et al., 2008; Cook et al., 1996) there is no

generally accepted description of particle breakage. Its precise mechanism is still a matter of

disagreement amongst researchers. As can be expected, the particle hardness provides a

general measure of the particle’s ability to resist wear and to its susceptibility to fracturing.

There is a relation between the particles’ tendency to fracture and the energy needed to break

the particles. Similarly, the extent of attrition, expressed as the size or weight reduction of

particles, can be related to the energy input into the given system. In general, spherical (and

smooth) particles are less likely to attrit than those irregularly shaped (and with a rough

surface). It is believed that porous particles (but not those very fragile) attrit less than

nonporous particles thanks to their higher resilience. Yao et al. (2010) confirmed that

fragmentation and attrition of limestone are strongly influenced by the hydrodynamic forces

in suspension and by the inventory of inert bed material. The results of Ayazi Shamlou et al.

(1990) indicate the attrition of bed material occurs in the core (bulk) of the bed rather than in

the grid (distributor) region. In case of excessive linear velocities of gas exiting into the bed,

attrition in the jetting zone should be also considered.

Dolomites are considered as the most promising inexpensive catalysts for tar

elimination from the fuel gas. The catalytic activity of these materials is higher than that of

calcite and magnesite calcines (Abu El-Rub et al., 2004). However, only a small amount of

knowledge is available on comminution of dolomitic limes in the fluidized bed. This work

embodies the authors’ efforts to narrow such a gap. The aim of this experimental study is to

7

explore and describe the rate of attrition of a particulate dolomitic lime in the turbulent

fluidized bed at high temperature.

Experimental

Methods and materials

Aside from chemical analyses and textural measurements of dolomitic lime particles,

two different sorts of experiments were carried out: (1) The point of minimum fluidization

was determined for the lime particles as well as for the inert, abrasion-resistant bed material

(quartz sand) at an elevated temperature. (2) At an elevated temperature, batch experiments

were conducted in order to explore attrition kinetics for precalcined samples originated from

high-grade, dolomitic limestone rock.

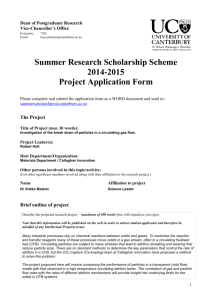

Apparatus

The experiments were performed in a turbulent fluidized-bed reactor constructed of

heat-resistant stainless steel. The apparatus was primarily designed and made for experimental

studies on biomass and plastic gasification. The bench-scale unit is schematically shown in

Fig. 1.

8

Fig. 1. Schematic diagram of a fluidized-bed reactor for the gasification and attrition

experiments. (1) container; (2) screw feeder; (3) motor with gear box; (4) pneumatic

transport; (5) cooler; (6) inlet of a gasification medium; (7) fluidized bed; (8) electric heating;

(9) freeboard region; (10) thermocouples; (11) gas sample withdrawal; (12) cyclone; (13)

container; (14) gas outlet; (15) feeding of the bed material.

9

The fluidized-bed reactor was constructed of a heat-resistant, stainless tube, 50 cm high and

5.1 cm in inner diameter. The upper part (freeboard) was built with a heat-resistant stainless

pipe 9.9 cm ID and 160 cm high. The fluidization gas distributor was a set of interchangeable

perforated plates 0.8 cm thick of different free area with orifices 0.49 mm in diameter

disposed on a triangular pitch. A linear air velocity through each opening was in the range 2530 m s-1 at 500 oC. The reactor was heated by means of several cylindrical segments of

electrical elements; its internal temperature was measured with the aid of a series of Pt-PtRh

thermocouples located throughout the height of reactor and kept constant by a PID controller.

The maximum operating temperature was as high as 1000oC. The flow rate of the fluidization

air was measured and controlled by mass flow controllers. Batches of bed material could be

introduced into the reactor through a feeding port at the top of the freeboard. A highefficiency cyclone and sintered brass filter separated elutriated fines from the fluidization gas

(air). The particulate samples could be withdrawn from both the bed and the separating

devices in order to measure the mass and particle size changes in the course of fluidization.

Materials

A high-grade, commercially available carbonate rock was employed in the present

work. This rock is a crystalline, high purity carbonate (according to Table 1) containing 37.5

wt.% CaO and 15.6 wt.% MgO whose loss on ignition (calcination) at 900oC amounts to 46.5

wt.%.

10

Table 1. Classification of limestone rocks based on the contents of their principal components /

carbonates (Boynton, 1980; Oates, 1998)

Rock

Amount /(wt %)

High calcium or chemicalgrade limestone

> 95 % CaCO3

High purity carbonate

> 95 % (CaCO3 + MgCO3)

Calcitic limestone

< 5 % MgCO3

Magnesian limestone

5 – 20 % MgCO3

Dolomitic limestone

20 – 40 % MgCO3

(High magnesium) dolomite

40 – 46 % MgCO3*

*

The stoichiometric value for CaMg(CO3)2 amounts to 45.72 wt % MgCO3, i.e., 21.86 wt %

MgO.

As it contains 32.7 wt.% MgCO3, it may be considered dolomitic limestone in light of Table

1.

The hand-picked stones from a commercial quarry, which contained no visible

inclusions, were crushed and sieved. The fractions investigated in this study comprised three

narrow size ranges: 400 – 500 µm (đp = 450 µm), 630 – 800 µm (đp = 715 µm), and 1000 –

1120 µm (đp = 1060 µm). Microscopic examination showed that the particles were sharpedged and of irregular shape. The dolomitic lime was prepared by thermal decomposition of

the carbonate at 900oC in a bed fluidized with air. Such mild conditions of calcination tend to

inhibit both primary fragmentation and unwanted sintering of the calcined particles. No

significant fragmentation of the decomposing solids was found when the conversion to lime

was complete. The calcined particles were sieved again and the narrow fractions of lime were

maintained in airtight containers. The irregular shape of the particles remained practically

unchanged by the calcination process. The chemical and physical characteristics of the lime

particles are presented in Tables 2 and 3.

11

Table 2. Chemical properties of dolomitic lime samples

Chemical

(wt %)

component

Chemical

(wt %)

component

CaO

70.1*

Fe2O3

0.054

MgO

29.2*

Cl

0.040

SiO2

0.29

K2O

0.028

Al2O3

0.24

SO3

0.024

*

On the basis of these values, the parent carbonate rock can be viewed as a high purity

carbonate and/or dolomitic limestone.

Table 3. Physical properties of dolomitic lime* and quartz sand samples

Sample

Guantity

Lime

Lime

Quartz sand

Sieve particle size/µm

400 – 500

1000 – 1120

250 – 360

Mean particle size/µm

450

1060

305

True solid density/(kg m-3)

2946

2941

2530

Particle density/(kg m-3)

1150

1148

2530

Pore volume/(m3 kg-1)

5.301 x 10-4

5.311 x 10-4

0

Fractional particle porosity

0.6096

0.6097

0

11.6

11.3

Specific BET surface

area/(m2 g-1)

*

Calcination took place in a fluidized bed at 900oC and in an oxidizing atmosphere with a

weight loss of 46.5 wt %. True and particle densities were determined by helium and

mercury displacement. The textural data for 630 – 800 µm particles occur between the

presented values.

According to the generally accepted classification of carbonate rocks in Table 1, our

lime can be taken as dolomitic one. A slightly different term follows from the classification of

calcined rocks based on the CaO/MgO weight ratio (Abu El-Rub et al., 2004): calcitic

dolomite lime in which CaO/MgO = 2.40. We prefer to adhere to the first term.

12

Round quartz sand was employed as an inert and attrition-resistant bed material. Its

particles were nearly isometric and fairly spherical. Basic physical properties of the sand

particles are shown in Table 3.

Procedures

The point of minimum fluidization of our particulate materials was determined by the

standard procedure from the dependence of bed pressure drop on air flow with the air velocity

gradually reduced from a well-fluidized state to packed (static) bed (Hartman & Coughlin,

1993; Hartman et al., 2007).

The parent lime sample in this experiment was high-grade, reactive lime formed by

calcining high-purity dolomitic limestone so that all the carbon dioxide was liberated and all

moisture removed. Attrition experiments were conducted in the fluidized-bed reactor using

the sieved, very narrow fractions of lime with a mean particle size of 450, 715, and 1060 µm.

Quick estimates of the terminal velocities (Hartman & Yates, 1993; Hartman et al., 1994) of

the lime and sand particles showed that no elutriation of such particles could occur in our

fluidization experiments. Therefore, the mass reduction of bed materials and the amount of

fines elutriated from the reactor (and captured by means of the cyclone and the filter) are

considered as a practical measure of the extent of attrition. Tests repeated under the same

operating conditions indicated that the extent of attrition could be determined with good

reproducibility within the range of 3 – 5%. It was also found that the attrition of quartz sand in

our experiments was not significant. To prevent hydration and recarbonation of the lime

particles in ambient air, the dried fluidization air was used; the collected samples were cooled

down in dessicators and weighed as quickly as possible.

13

In a typical attrition/gasification experiment, the reactor was preloaded with 1 kg of

sand which was fluidized under the preset gas flow rate and heated to the desired temperature

until a steady state was attained. Then, the 0.5 kg lime sample was introduced into the bed. By

collecting and weighing the elutriated fines, the course of attrition was measured.

Results and Discussion

Incipient fluidization at elevated temperature

The experimental measurements were conducted with three fractions of lime and with

the particles of sand (450, 715, 1060, and 305µm) at temperatures of 25 oC and 850oC. In this

temperature interval, the air density changes by a factor of 0.2655, whereas its viscosity

changes by a factor of 2.40. The sets of experimental data are shown in Table 4 and

demonstrate that the minimum fluidization velocity appreciably decreases with an increasing

operating temperature at ambient pressure.

Table 4. Experimental minimum fluidization velocities (Umf) of lime and sand samples in air

at different temperature (t) and ambient pressure*

Material

Mean particle size/(µm)

Lime

450

t/(oC)

Sand

715

1060

305

Umf/(cm s-1)

24-25

7.29

16.28

29.43

7.53

848-852

3.33

8.21

17.32

3.38

*

Physical properties of the solids are presented in Table 3.

These results indicate that the viscous energy losses in the bed predominate over the

kinetic energy losses (Hartman & Svoboda, 1986). In other words, the decrease of Umf with an

14

increasing temperature demonstrates that the increasing viscosity of the fluidizing gas is the

controlling factor under the flow conditions that have been employed (Remf = 0.07 – 21).

Attrition experiments

Analysis of the particle-size distributions of fresh and fluidized-for-an-hour lime

indicated that no significant primary fragmentation of the particles occurred. This is also

consistent with our results from the microscopic examinations of such solids. Thus, it may be

inferred that comminution of lime particles in this work was a consequence of the attrition by

abrasion rather than that of gross fragmentation.

Attrition tests were performed at 850oC in a batch mode with 450, 715, and 1060 µm

particles of dolomitic lime to explore the fluid energy-induced tendency towards attrition. As

is known, in the core of the fluidized bed, usually rapid particle motion is governed by the

flow of gas and bulk circulation of the bed material. The excess gas air velocities (U – Umf)

were varied in the range from 0.85 to 1.74 m s-1. In a recent work of ours (Hartman et al.,

2009) we developed a method that quite objectively determines the points of transition

between different flow (hydrodynamic) regimes of the fluid bed (bubbling/slugging/

turbulent/fast (dilute) bed). This method is based upon the concept of symmetry of the

sampled pressure fluctuating signal within the bed. Having employed this procedure, we

determined with a fair accuracy that our bed was operated in the regime(s) of intermediate or

full turbulence (turbulent bed). Unfortunately, it was hard to determine unequivocally the

point of transition between these two turbulent (sub)regimes. The operating time (elapsed

time of attrition) was varied between ten minutes and four hours. Statistical analysis was

performed on the basis of 75 experimental data points amassed with different particle sizes at

different excess gas velocities and at varying elapsed time of attrition.

15

1

w

0.8

0.6

0.4

0

1

2

3

4

h

Fig . 2. Decrease of the relative mass of dolomitic lime samples (w)

as a function of elapsed

time of attrition (). The symbols represent experimental data points measured at 850oC and

excess gas velocity U – Umf = 1.74 ms-1: initial mass of lime, mo = 559 g; mass of sand, ms =

1050 g. (O) Experimental data points measured with 450 µm lime particles, (●) experimental

data points measured with 1060 µm lime particles. The solid lines show the values predicted

by the model.

Fig. 2 presents a typical course of the relative mass of parent lime remaining in the bed

as a function of elapsed time. As can be seen, the lime mass decrease most rapidly in the

initial phases and the rate of decline gradually slows down with elapsed time. It appears that

rounding off (dislodgement) of originally sharp-edged lime solids considerably enhances

16

attrition in the early stages of this batch process. Nevertheless, the attrition process is not

likely to cease entirely. Very small bed weight reductions were still detected even after 15

hours of continuous fluidization. In light of this experimental finding, the concept of an

asymptotic minimum weight of parent solids remaining in a bed, which some researchers (Lee

et al., 1993; Cook et al., 1996) use in their attrition models, needs to be unequivocally

defined.

Particles with different extents of attrition were also examined with the aid of a

microscope. The results indicate that the original sharp edges of lime particles are rounded off

at first. Then, the attrition by abrasion due to collisions and surface wear gains ground. While

the sharp edges gradually disappear, the generally round shape of particles does not change

with time and their surface remains or becomes somewhat rough, possibly due to frequent

collisions. A limited number of samples of the fines elutriated from the bed, and collected by

the cyclone and filter, were subjected to particle-size characterization. Findings indicate that

the large majority of such particles is below 80 µm, which is in general agreement with the

corresponding results in the literature (Scala et al., 1997).

Three different sizes of parent lime particles (đp = 450, 715, and 1060 µm) were

employed to investigate the course of attrition at excess gas velocities in the range between

0.85 and 1.74 m s-1. A representative sample of the experimental measurements is shown in

this article in the graphical form, by way of illustration. However, all the amassed

experimental data were included in our effort to describe the measured results by means of the

proposed model. Figs. 2 and 3 show lime weight (mass) loss for various attrition times due to

continuing particle attrition.

17

1

w

0.9

0.8

0.7

0

1

2

3

h

4

Fig. 3. Decrease of the relative mass of dolomitic lime samples (w) as a function of elapsed

time of attrition (). The symbols represent experimental data points measured at 850oC and

excess gas velocity U – Umf = 0.85 ms-1: initial mass of lime, mo = 558 g; mass of sand, ms =

1051 g. (O) Experimental data points measured with 450 µm lime particles, (●) experimental

data points measured with 1060 µm lime particles. The solid lines show the values predicted

by the model.

As follows from the comparison of Figs. 2 and 3 and also as expected, the mass losses are

considerably greater when the superficial gas velocity is significantly increased. As also

shown in Figs. 2 and 3, weight losses of smaller particles are moderately higher than those of

larger particles under comparable operating conditions.

It should be noted that the origin and structure (texture) of original (fresh) particles can

strongly affect the course and extent of comminution. The breakage process of the suspended

particles can be viewed as an intricate interplay between mechanical (material) properties of

the solid and fluid-dynamic-induced disruptive forces within the bed. As pointed out in the

literature (Yao et al., 2010; Scala et al., 1997), the course of attrition of sulfated lime (a

mixture of CaSO4 and CaO) is similar to that of fresh lime, but its attrition rate is an order of

magnitude smaller than that of lime. On the other hand, the weight loss occurs much more

18

rapidly when the lime particles are wetted. Shattering and the soft surface of the hydrated lime

are most likely the cause of such enhanced attrition.

Mechanistic Model of Attrition

All the measured data suggest an exponential decline of the mass of attrited solids with

the elapsed time of fluidization. The rate of attrition (ra) can be defined as

ra = -

1

dw

___

_____

w

d

for w > 0

(1)

where w = m/mo is the relative mass of sample particles at a given instant of time ( ) and

dw/d is the rate of relative mass decrease of the sample at the same . In light of the twophase theory, all gas in excess above Umf passes through the bed in the form of “bubbles” and

these ascending gas pockets (tongues) can be viewed as a driving engine keeping the

suspended solids in more or less intensive continuous motion. The rate of such excess energy

supply to the bed by the gas above the condition of minimum fluidization is given by

Eexc = AΔpb (U - Umf)= m g (U - Umf )

(1a,b)

Thus, the excess gas velocity (U – Umf) is a useful measure of the energy being introduced

through the moving heterogeneities into the suspension (Yates, 1983; Ayazi Shamlou et al.,

1990).

Assuming that the rate of attrition is directly proportional to the excess gas velocity,

we can describe the course of attrition as follows

dw

_____

w

= - Ka (U – Umf) d

(2)

19

where Ka is the overall (effective) attrition rate constant. It is apparent that Ka depends

strongly upon a number of important material properties of solids such as impact strength,

wear hardness, particle size and particle shape, texture, and surface roughness. The excess gas

velocity (U – Umf) accounts for the influence of fluid-dynamic-induced forces on attrition.

Early experience indicated that Ka displays a tendency to decay exponentially with the

duration of fluidization experiments. Presuming that

Ka = a exp (- b )

(3)

and on substituting Eq. (3) into Eq. (2) we get

dw

_____

= - a (U – Umf) [ exp (- b ) ] d

(4)

w

Integration of Eq. (4) with the boundary condition

w=1

at

=0

(5)

gives the fractional amount of a parent sample remaining in the bed (w) as

a

ln w = ____ (U – Umf) { [ exp (- b ) ] – 1 }

b

(6)

and the rate of sample attrition (ra)

ra = a (U – Umf) exp (- b )

(7)

20

as functions of time.

Symbols a and b in Eqs. (3), (4), (6), and (7) represent by this time the unknown

parameters. The available measured data are the time series of values of w() for different

particle sizes and excess gas velocities. The parameters a and b were determined by a

nonlinear least-squares procedure which minimizes the sum of squares of the residuals.

Modified simplex minimization, which had proved successful in our previous work (Hartman

et al., 2010), was employed as the optimization method.

The computational results of the nonlinear regression fitting, and the statistical

evaluation based upon the Student’s t analysis are presented in Table 5.

Table 5. Effective rate parameters for attrition of dolomitic lime in turbulent fluidized bed a at

850oC [Eqs. (3), (4), (6), and (7)]

Mean particle size, đp/(µ m)

Quantity

450

715

1060

a x105/m-1

8.631

7.402

6.147

95 % confidence intervalb

+ 1.19 x 10-6

1.02 x 10-6

1.11 x 10-6

b x104/s-1

1.428

1.897

2.442

95 % confidence intervalb

+ 1.36 x 10-6

+ 1.62 x 10-6

+1.50 x 10-6

no. of exptl. points

25

26

24

The bed inventory was made up of silica sand (1050 g; dp = 250 – 360 µm) and lime (559 g

a)

in the initial state ( = 0)). b)Based upon the Student's t distribution.

The particle size is a relevant operating variable rather than a material property.

Thus, we believe that any practical model of attrition should make it possible to account for

this quantity. In attempt to extend the model also in this direction, the rate parameters given

Table 5 were regressed with respect to the particle size. The available data were correlated

by means of linear algebraic equations with the aid of a least-squares procedure:

21

a=-4.032x10-8 dp + 1.036x10-4

(8)

b=1.645x10-7 dp + 7.018x10-5

(9)

The particle size is given in μm and the respective regression factors (R2), amount to 0.993

and 0.986, respectively. Figs. 2 and 3 visualize a good correlation between the model

predictions and the experiments.

With respect to always-present differences in the operating conditions and particularly

in light of the varying origins (and consequently the properties) of the parent carbonate or

lime, it is not easy to compare the results of different researchers. Thus, any comparison

should be taken as approximate. Using a high calcium lime, Lee et al. (1993) explored the rate

of attrition at high superficial velocities in a similar manner to us. For 903 µm particles

fluidized with air for 2 h at U = 2 m s-1, the authors Lee et al. (1993) found by experiment that

the relative mass of particles decreased (from unity) to w = 0.78. The authors’ empirical

model estimates for these operating conditions a relative mass as large as w = 0.83. The

corresponding prediction of our model amounts to w = 0.69. In view of the fact that the

authors’ bed did not contain any hard particles (in contrast to ours), our somewhat higher rate

of attrition appears to be understandable. Therefore, we believe that our findings are in

general agreement with those of Lee et al. (1993) and the predictions of our model can be

considered as realistic.

It should be noted that attrition models available in the literature (Lee et al., 1993;

Cook et al.,1996) include as an important quantity, the minimum mass of solids below which

attrition may be neglected. Undoubtedly, this is a helpful attrition parameter, but its rigorous

definition and its determination by experiment are not unambiguous.

Of course, the attrition model developed in this work has the usual constraints and

should be applied with caution outside the range of the operating conditions for which it was

educed. Nevertheless, the model offers some practical features. For example, it provides, in

22

combination with suitable solids feeders, (Zheng et al., 1982; Pohořelý et al., 2004) essential

background information for the control of the amount of catalyst present within the bed

during fluidized gasification with effective limestone/dolomite-based catalysts. The model

parameters depend only on the material properties of solids and can be determined in simple

tests.

Model Predictions

As can be seen in Figs. 2 and 3, the original (initial) size of parent lime particles

significantly affects the course of the attrition curves. This influence embraces variation of the

minimum fluidization velocity with size of bed solids on one side and variation of the external

particle surface, exposed to attrition by abrasion, with solids size on the other side. While the

specific external particle surface is proportional to dp-1, the dependence of Umf on dp is more

involved (Hartman & Coughlin, 1993). Under the conditions of laminar flow, for small

Reynolds numbers, we have

Umf dp2

(for Remf < 1)

(10)

In highly turbulent flow, for large Reynolds numbers, it holds

Umf dp0.5

(for Remf > 1000)

(11)

In the flow regime transition conditions, the minimum fluidization velocity is proportional to

the solids diameter (dp) raised to a power in the range between 2 and 0.5:

23

Umf dp2 to dp0.5

(for 1 < Remf < 1000)

(12)

The attrition rate parameters a and b for different particles can be estimated by Eqs. (8) and

(9). As follows from Eq. (7), a greater value of a for the smaller particles indicates their more

rapid initial attrition than that of the larger solids at the same excess gas velocity.

Furthermore, a lesser value of b for the smaller particles demonstrates that their attrition rate

decays with time more slowly than that of the larger ones.In order to take a different look at

our results, we carried out systematic computations of the attrition rates. Some of the results

are plotted in Figs. 4 and 5. As visualized, the rate of attrition diminishes rapidly as the

attrition process progresses.

-3.5

-4.0

log ra

450 m

-4.5

1060 m

-5.0

-5.5

0

0.2

0.4

1-w

0.6

Fig . 4. Rate of attrition [ (-1/w)(dw/d) ] as a function of the relative mass of lime particles in

the bed (w). The lines show the model predictions for the respective lime fractions and for the

operating conditions as in Fig. 2.

24

-4.0

-4.5

450 m

log ra

-5.0

1060 m

-5.5

-6.0

0

0.1

0.2

0.3

1-w

Fig . 5. Rate of attrition [ (-1/w)(dw/d) ] as a function of the relative mass of lime particles in

the bed (w). The lines show the model predictions for the respective lime fractions and for the

operating conditions as in Fig. 3.

The presented curves also illustrate how the rate of attrition depends on the excess

gas velocity and particle size. The curves are very similar in shape to the lines describing an

entirely different process: the rate of sulfation of calcined limestone particles. As we reported

some years ago (Hartman et al., 1991), the sulfation rate also diminishes rapidly with the

increasing conversion of CaO to CaSO4. It is necessary to add that this is because of the

formation of a dense product shell (CaSO4 + CaO) on the particle surface. It was observed

that the attrition rate of the sulfation product is an order of magnitude smaller than that of lime

(CaO) under similar operating conditions.

25

Conclusions

The attrition rate of dolomitic lime in a turbulent fluidized bed with quartz sand can be

described in terms of a simple model. This mechanistic model is based upon experimental

observations that the rate of particle attrition decays exponentially with the elapsed time of

fluidization. Assuming a first-order dependency with respect to the excess gas velocity, the

model includes two rate constants: one of which (a) reflects the initial rate of attrition, while

the other (b) indicates how rapidly the attrition rate may decay with time. Particle size has a

significant effect on both rate constants, and therefore is also accounted for in the model. The

proposed model can be employed for batch and continuous processes with fluidized beds in

which attrition of dolomitic lime particles (mainly by surface abrasion) and subsequent

elutriation of fines out of the bed occur. In any application, possible differences in mechanical

properties of the solid (the nature of the parent material) must always be borne in mind.

Acknowledgements. The authors gratefully acknowledge the financial support for this

research awarded by the Grant Agency of the Academy of Science of the Czech Republic

through Grant No. IAA 400720701. Thanks are also due to the Research Fund for Coal and

Steel of the EC for the support through Grant No. RFCR-CT-2010-00009.

26

Symbols

a

fitted attrition rate parameter given by Eqs. (3) and (8)

m-1

A

cross – sectional area of bed

cm2, m2

b

fitted decay parameter given by Eqs. (3) and (9)

s-1

dp

diameter of spherical particle

µm, m

đp

mean particle size determined by sieving

µm, m

dw/d

rate of change of the relative mass of lime particles

s-1

Eexc

power input in excess of minimum fluidization

W

g

acceleration due to gravity

cm s-2, m s-2

Ka

effective attrition rate constant given by Eq. (2)

m-1

m

mass of lime particles in the bed at a given moment of time

g, kg

mo

initial mass of lime particles in the bed (i.e., at = 0)

g, kg

ms

mass of sand in the bed

g, kg

ra

rate of attrition defined by Eq. (1)

s-1

Remf

Reynolds number at the onset of fluidization (= Umf đp f / µf )

T

thermodynamic temperature

K

t

Celsius temperature

o

U

superficial gas velocity

m s-1, cm s-1

Umf

minimum fluidization velocity

m s-1, cm s-1

U - Umf excess gas velocity / flow

w

C

m s-1, cm s-1

relative mass of lime particles in the bed at a given moment of time (= m/mo)

Greek Letters

Δpb

pressure drop acros the bed

Pa, kg m-1 s-2

27

µf

fluid viscosity; µair = (4.261 x 10-7) T0.66

Pa s

f

fluid density; air = 352.8 / T (at ambient pressure)

kg m-3

elapsed time of fluidization/attrition

s

Other Symbols

e

base of natural system of logarithms; e = 2.7183

exp x

ex

ln

base e or natural logarithm

dx

differential of x

wt

weight

References

Abu El-Rub, Z., Bramer, E. A. & Brem, G. (2004). Review of catalysts for tar elimination in

biomass gasification processes. Ind. Eng. Chem. Res., 43, 6911-6919. DOI:

10.1021/ie0498403.

Arena, V., D´Amore, M. & Massimilla, L. (1983). Carbon attrition during the fluidized

combustion of a coal. AIChE J., 29, 40-49.

Ayazi Shamlou, P., Liu, Z. & Yates, J. G. (1990). Hydrodynamic influences on particle

breakage in fluidized beds. Chem. Eng. Sci., 45, 809-817.

Boynton, R. S. (1980). Chemistry and Technology of Lime and Limestone, 2nd ed., Wiley:

New York.

28

Chen, Z., Grace, J. R. & Jim Lim, C. (2008). Limestone particle attrition and size distribution

in

a

small

circulating

fluidized

bed.

Fuel,

87,

1360-1371.

DOI:

10.1016/j.fuel.2007.06.012.

Cook, J. L., Khang S. J., Lee, S. K. & Keener, T. C. (1996). Attrition and changes in particle

size distribution of lime sorbents in a circulating fluidized bed absorber. Powder Technol.,

89, 1-8. DOI: 10.1016/S0032-5910(96)03115-4.

Corella, J., Toledo, J. M. & Aznar, M. P. (2002). Improving the modeling of the kinetics of

the catalytic tar elimination in biomass gasification. Ind. Eng. Chem. Res., 41, 3351-3356.

DOI: 10.1021/ie0110336.

Forsythe, Jr. W. L. & Hertwig, W. R. (1949). Attrition characteristics of fluid cracking

catalysts: laboratory studies. Ind. Eng. Chem., 41, 1200-1206.

Gil, J., Caballero, M. A., Martin, J. A., Aznar, M. P. & Corella, J. (1999). Biomass

gasification with air in a fluidized bed: effect of the in-bed use of dolomite under different

operating conditions. Ind. Eng. Chem. Res., 38, 4226-4235. DOI: 10.1021/ie980802r.

Gupta, C. K. & Sathiyamoorthy, D. (1999). Fluid Bed Technology in Materials Processing,

CRC Press: Boca Raton, FL.

Hartman, M., & Coughlin, R. W. (1976). Reaction of sulfur dioxide with limestone and the

grain model. AIChE J., 22, 490-498. DOI: 10.1002/aic.690220312.

Hartman, M., Hejna, J. & Beran, Z. (1979). Application of the reaction kinetics and dispersion

model to gas-solid reactors for removal of sulfur dioxide from flue gas. Chem. Eng. Sci.,

34, 475-483. DOI: 10.1016/0009-2509(79)85092-7.

Hartman, M. & Svoboda, K. (1985). Physical properties of magnesite calcines and their

reactivity with sulfur dioxide. Ind. Eng. Chem. Process Des. Dev., 24, 613-621. DOI:

10.1021/i200030a016.

29

Hartman, M. & Svoboda, K. (1986). Predicting the effect of operating temperature on the

minimum fluidization velocity. Ind. Eng. Chem. Process Des. Dev., 25, 649-654. DOI:

10.1021/i200034a009.

Hartman, M., Svoboda, K., Trnka, O. & Veselý, V. (1988). Reaction of sulfur dioxide with

magnesia in a fluidized bed. Chem. Eng. Sci., 43, 2045-2050. DOI: 10.1016/00092509(88)87082-9.

Hartman, M., Svoboda, K. & Trnka, O. (1991). Unsteady-state retention of sulfur dioxide in a

fluidized bed with continual feeding of lime and limestone. Ind. Eng. Chem. Res., 30,

1855-1864. DOI: 10.1021/ie00056a027.

Hartman, M. & Martinovský, A. (1992). Thermal stability of the magnesian and calcareous

compounds for desulfurization processes. Chem. Eng. Comm., 111, 149-160. DOI:

10.1080/00986449208935985.

Hartman, M. & Trnka, O. (1993). Reactions between calcium oxide and flue gas containing

sulfur dioxide at lower temperatures. AIChE J., 39, 615-624. DOI: 10.1002/aic.690390410

Hartman, M. & Yates, J. G. (1993). Free-fall of solid particles through fluids. Collect. Czech.

Chem. Commun., 58, 961-982. DOI: 10.1135/cccc19930961.

Hartman, M. & Coughlin, R. W. (1993). On the incipient fluidized state of solid particles.

Collect. Czech. Chem. Commun., 58, 1213-1241. DOI: 10.1135/cccc19931213.

Hartman, M., Trnka, O. & Svoboda, K. (1994). Free settling of nonspherical particles. Ind.

Eng. Chem. Res., 33, 1979-1983. DOI: 10.1021/ie00032a012.

Hartman, M., Trnka, O. & Veselý, V. (1994a). Thermal dehydration of magnesium hydroxide

and

sintering

of

nascent

10.1002/aic.690400314.

magnesium

oxide.

AIChE

J.,

40,

536-542.

DOI:

30

Hartman, M., Trnka, O. & Svoboda, K. (2000). Fluidization characteristics of dolomite and

calcined dolomite particles. Chem. Eng. Sci., 55, 6269-6274. DOI: 10.1016/S00092509(00)00409-7.

Hartman, M., Svoboda, K., Trnka, O. & Čermák, J. (2002). Reaction between hydrogen

sulfide and limestone calcines. Ind. Eng. Chem. Res., 41, 2392-2398. DOI:

10.1021/ie010805v.

Hartman, M. & Trnka, O. (2002). Comments on „Proposal for regenerative high-temperature

process for coal gas cleanup with calcined limestone“. Ind. Eng. Chem. Res., 41, 62076208. DOI: 10.1021/ie020193u.

Hartman, M., Trnka, O. & Pohořelý, M. (2007). Minimum and terminal velocities in

fluidization of particulate ceramsite at ambient and elevated temperature. Ind. Eng. Chem.

Res., 46, 7260-7266. DOI: 10.1021/ie0615685.

Hartman, M., Trnka, O. & Svoboda, K. (2009). Use of presure fluctuations to determine

online the regime of gas-solids suspensions from incipient fluidization to transport. Ind.

Eng. Chem. Res., 48, 6830-6835. DOI: 10.1021/ie900055x.

Hartman, M., Trnka, O., Pohořelý, M. & Svoboda, K. (2010). High-temperature reaction in

the freeboard region above a bubbling fluidized bed. Ind. Eng. Chem. Res., 49, 2672-2680.

DOI: 10.1021/ie901760f .

Higman, Ch. & van der Burgt, M. (2008). Gasification, 2nd ed., Elsevier: Amsterdam.

Knoef, H. A. M. (Ed.) (2005). Handbook of Biomass Gasification, BTG biomass technology

group: Enschede, The Netherlands.

Kunii, D. & Levenspiel, O. (1991). Fluidization Engineering, 2nd ed.: ButterworthHeinemann: Boston.

31

Lee, S. K., Jiang, X., Keener, T. C. & Khang, J. (1993). Attrition of lime sorbents during

fluidization in a circulating fluidized bed absorber. Ind. Eng. Chem. Res., 32, 2758-2766.

DOI: 10.1021/ie00023a044.

Lin, L. W., Sears, J. T. & Wen, C. Y. (1980). Elutriation and attrition of char from a large

fluidized bed. Powder Technol., 27, 105-115. DOI: 10.1016/0032-5910(80)85045-5.

Oates, J. A. H. (1998). Lime and Limestone: Chemistry and Technology, Production and

Uses, Wiley-Vch: Weinheim.

Pohořelý, M., Svoboda, K. & Hartman, M. (2004). Feeding small quantities of particulate

solids. Powder Technol., 142, 1-6. DOI: 10.1016/j.powtec.2004.03.005.

Scala, F., Cammarota, A., Chirone, R. & Salatino, P. (1997). Comminution of limestone

during batch fluidized-bed calcination and sulfation. AIChE J., 43, 363-373. DOI:

10.1002/aic.690430210.

Scala, F., Montagnaro, F. & Salatino, P. (2007). Attrition of limestone by impact loading in

fluidized beds. Energy & Fuels, 21, 2566-2572. DOI: 10.1021/ef0700580.

Scala, F. & Salatino, P. (2010). Limestone fragmentation and attrition during fluidized bed

oxyfiring. Fuel, 89, 827-832. DOI: 10.1016/j.fuel.2009.03.024.

Sutton, D., Kelleher, B. & Ross, J. R. H. (2001). Review of literature on catalysts for biomass

gasification. Fuel Process Technol., 73, 155-173. DOI: 10.1016/S0378-3820(01)00208-9.

Yao, X., Zhang, H., Yang, H., Liu, Q., Wang, J. & Yue, G. (2010). An experimental study on

the primary fragmentation and attrition of limestones in a fluidized bed. Fuel Process.

Technol., 91, 1119-1124. DOI: 10.1016/j.fuproc.2010.03.025.

Yates, J. G. (1983). Fundamentals of Fluidized-Bed Chemical Processes, Butterworths:

London.

32

Zheng, J., Yates, J. G. & Rowe, P. N. (1982). A model for desulfurization with limestone in a

fluidized coal combustor. Chem. Eng. Sci., 37, 167-174.

2509(82)80151-6.

DOI: 10.1016/0009-