研究方法作業報告四

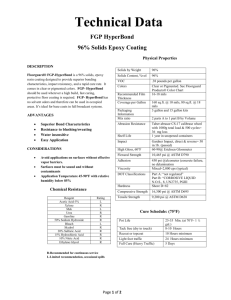

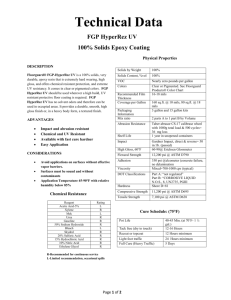

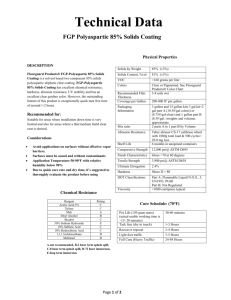

advertisement