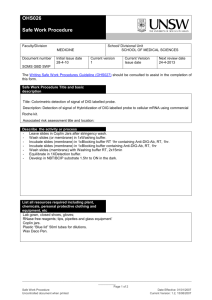

SWP M5 - Faculty of Medicine

advertisement

OHS026 Safe Work Procedure Faculty/Division School/ Divisional Unit Medicine POWCS/ORC Document number POWCS.ORC.SWPM5 Initial Issue date 18/03/2008 Current version 2 Current Version Issue date 18/03/2008 Next review date 01/12/2010 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Broths and buffers for molecular biology Description: Associated risk assessment title and location: POWCS.ORC.RA M5 Describe the activity or process This SWP describes the correct procedure for making up various broths and buffers that are used in molecular biology methodology. Due to the nature of the document, the reagents used will not be listed separately. Techniques employing the solutions described here will be described in other SWPs, and cross-referenced to this document. A number of the reagents listed are hazardous substances. The attached Risk Assessment and all relevant MSDSs must be accessed and read before any of these procedures are carried out. Many of these procedures require the use of the autoclave for sterilisation; SWP 16 and its associated Risk Assessment must be accessed and read, and training in the use of the autoclave undergone, before any of these procedures are carried out. Technical advice: (i) Buffers or broths should be autoclaved within 2 hr of being prepared, to prevent the possibility of bacterial contamination/growth within the solution (ii) Any reagent that requires melting before use (i.e. anything containing agar) should be dispensed into 500 mL bottles prior to autoclaving; otherwise it will not fit in the microwave (NB: - this constitutes a burn hazard) (iii) Any solution filling a bottle to greater than 70% capacity risks boiling over during autoclaving (iv) For best results, L-broth and LB agar should be made fresh. It is recommended that LB agar not be kept for longer than 1 month A. BUFFERS 1. EDTA stock solutions: - ethylene diamine tetraacetic acid, disodium salt (MW = 372.2) is used to prepare stock solutions for molecular biology techniques; it will not go completely into solution unless the pH is adjusted to 8.0 with NaOH (NB: - NaOH is corrosive) ______________________________________________________________________________________________________________________ Page 1 of 5 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process 2. Tris-EDTA buffer (TE buffer): - to make up 200 mL - Tris, pH 8.0, 10 mM (2 mL of 1 M stock) - EDTA 1 mM (800 µL of 0.25 M stock) - add ddH2O to 200 mL - sterilise by autoclaving (see SWP A16) and store at room temperature (NB: - Tris is an irritant) 3. Virion lysis buffer (for calculation of virus particles) - add 0.1% sodium dodecyl sulphate (SDS) to TE buffer (NB: - SDS is a hazardous substance) 4. Tris-acetate-EDTA buffer (TAE buffer): - to make up 1000 mL of 50x stock - Tris base (MW = 121.14) 242 g - dissolve in 500 mL ddH2O - add 57.1 mL glacial acetic acid - add 100 mL 0.5 M EDTA - add ddH2O to 1000 mL; the pH is not adjusted, but should be ~ 8.5 - the solution can be sterilised if desired (see SWP A16); this is recommended for procedures involving RNA - for running gels, dilute 40 mL 50x stock in 1960 mL ddH2O; this gives a final concentration of 40 mM Tris-acetate and 1 mM EDTA. (NB: - glacial acetic acid is flammable and a hazardous substance) Solution 1 (for preparation of DNA): - to make 200 mL - glucose 50 mM (20 mL of 0.5 M stock) - Tris, pH 8.0, 25 mM (5 mL of 1 M stock) - EDTA 10 mM (8 mL of 0.25 M stock) - add ddH2O to 200 mL - sterilise by autoclaving (see SWP A16) and store at 4oC (NB: - Tris is an irritant) 4. Solution 2 (for preparation of DNA): - to make 10 mL (NB: - this must be prepared fresh each time) - NaOH 0.2 M (2.0 mL of 1 M stock) - 1% SDS (1.0 mL of 10% stock) - ddH2O (7.0 mL) (NB: - NaOH and SDS are hazardous substances) 5. Solution 3 (for preparation of DNA): - to make 100 mL - potassium acetate 29.44 g - ddH2O 60 mL - glacial acetic acid 11.5 mL - add ddH2O to 100 mL - store at 4oC ______________________________________________________________________________________________________________________ Page 2 of 5 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 6. QIAGEN buffers (for preparation of DNA) (NB: - these are purchased either as part of a kit or as individual reagents: P1, cat. # 19051; P2, cat. # 19052; P3, cat. # 19053; QBT, cat. # 19054; QC, cat. # 19055; QF, cat. # 19056; QN is no longer sold separately) Buffer: Composition: Store at: Buffer P1 (resuspension buffer) 50 mM Tris-Cl, pH 8.0 10 mM EDTA 100 g/mL RNase A Room temperature, or at 4oC after the addition of RNase A Buffer P2 (lysis buffer) 200 mM NaOH 1% SDS (w/v) Room temperature Buffer P3 (neutralisation buffer) 3.0 M potassium acetate, pH 5.5 10-25% acetic acid Room temperature or 4oC Buffer QBT (equilibration buffer) 750 mM NaCl 50 mM MOPS, pH7.0 15% v/v isopropanol 0.15% v/v Triton X-100 Room temperature Buffer QC (wash buffer) 1.0 M NaCl 50 mM MOPS, pH 7.0 15% v/v isopropanol Room temperature Buffer QF (elution buffer) 1.25 M NaCl 50 mM Tris-Cl, pH 8.5 15% v/v isopropanol Room temperature Buffer QN (alternative elution buffer) 1.6 M NaCl 50 mM MOPS, pH 7.0 15% v/v isopropanol Room temperature (NB: - RNase A, buffer P2 and buffer P3 are irritants; buffers QBT, QC, QF and QN are irritants and flammable) B. BROTHS 1. Luria-Bertani Medium (L-broth or LB-broth or LB): - to make 1000 mL - NaCl 10.0 g - tryptone 10.0 g - yeast extract 5.0 g - adjust the pH to 7.0 - add ddH2O to 1000 mL - sterilise by autoclaving (see SWP A16) and store at room temperature 2. L-broth agar (LB agar): - to make 1000 mL Option A: - add 15 g Bacto-Agar (cat. # 0140-01) to 1000 mL LB - sterilise/melt by autoclaving (see SWP A16) and store at room temperature Option B: - add 32 g LB Agar (GE HealthCare/USB cat. # US75851) to 1000 mL ddH2O - sterilise/melt by autoclaving (see SWP A16) and store at room temperature 3. Terrific broth (T-broth or TB): - to make 1000 mL - Solution A: - KH2PO4 0.17 M 2.31 g - K2HPO4 0.72 M 12.54 g - dissolve in 90 mL ddH2O; add ddH2O to 100 mL - sterilise by autoclaving (see SWP A16) and allow to cool ______________________________________________________________________________________________________________________ Page 3 of 5 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 - tryptone 12.0 g - yeast extract 24.0 g - glycerol 4.0 mL - add to 900 mL ddH2O and stir or shake until dissolved - sterilise by autoclaving (see SWP A16) - allow to cool to 60oC or less and add 100 mL sterile Solution A - store at room temperature 4. S.O.C. broth (for transformation of bacteria / preparation of DNA): - to make 1000 mL (NB: - the terms “S.O.C. medium” and “S.O.C. broth” are often used interchangeably, but S.O.C. medium does not contain MgSO4. S.O.C. broth can be purchased commercially [Invitrogen, cat. # 15544-034] under the name “S.O.C. medium”.) - tryptone 20.0 g - yeast extract 5.0 g - NaCl 10 mM 2.0 mL of 5 M stock - KCl 2.5 mM 2.5 mL of 1 M stock - MgCl2 10 mM 10 mL of 1 M stock - MgSO4 10 mM 10 mL of 1 M stock - add to 900 mL ddH2O and shake or stir until dissolved - add ddH2O to 1000 mL and sterilise by autoclaving (see SWP A16) - allow to cool to 60oC or less - just before use, add 20 mL filter-sterilised 1 M glucose List all resources required including plant, chemicals, personal protective clothing and equipment, etc Latex Gloves, long-sleeve gown, Tris, SDS, NaOH, glacial acetic acid, RNase A and buffers P2 and P3, QBT, QC, QF and/or QN List potential hazards and risk controls including specific precautions required Hazardous only Hazardous and corrosive: Sodium Hydroxide, Glacial Acetic acid List emergency shutdown instructions List clean up and waste disposal requirements ______________________________________________________________________________________________________________________ Page 4 of 5 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List legislation, standards and codes of practice used in the development of the SWP Supervisory approval, training, and review Supervisor: Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: SWP review date: Responsibility for SWP review: ______________________________________________________________________________________________________________________ Page 5 of 5 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007