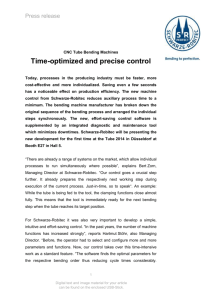

NC BUSBAR PROCESSING MACHINE

advertisement

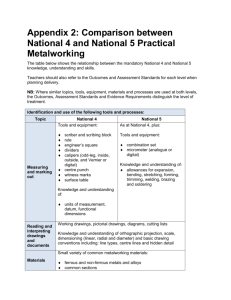

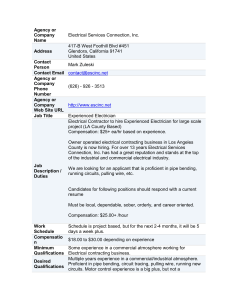

NC BUSBAR PROCESSING MACHINE This machine is special for processing aluminum and copper busbars used in electric power, high/low voltage electric apparatus and busway industries. It combines punching, cutting and bending functions together as well as some other functions such as embossing, twisting, flatting, pressing tie-in, etc. I Main features: Angle bending accuracy: +/- 1° Special punching mould, no pressing marks to the workpiece surface Special turret punch structure, with 4 punching heads, one time can punch 4 kind of holes without stopping machine to change tools Cutting device adopts patent double-column structure, smooth cut, no waste, no burr Double worktable for bending station, real separate working PLC control bending, bending angle can be pre-set and saved II Main technical data: For punching: Max. punching pressure: 300kN Hole diameter: 4.3-25mm Max. thickness: 12mm Max. width: 160mm Punching heads: 4 sets mounted on the machine (from 4.3~25mm) For cutting: Max. cutting thickness: 12mm Max. cutting width:160mm For bending: Max. bending pressure: 300KN Max. bending width:160mm Max. bending thickness: 12mm Equipped with two bending tools: R5 and R10 For vertical bending: Max. bending width: 120mm (10mm thick copper) Min. bending angle: 90° Dimension: 1700 x 1350 x 1500mm Weight: about1390kg Main driving motor power: 4kW x 3 III Main configuration 3.1 Main driving motors: from Taiwan 3.2 Oil pumps: from Taiwan 3.3 Electromagnetic valves and overflow valves: from Taiwan 3.4 Relays: Schneider 3.5 Contactors: Schneider 3.6 Other electric parts: from China 3.7 PLC: Panasonic from Japan 3.8 Touch screen: 7” big size from domestic IV Accessories Punching moulds: 8 sets (sizes can be selected) Cutting blade: one piece Horizontal bending moulds: two sets Vertical bending moulds: one set Embossing mould: one set Tool kit: one Foot switches: 3 pieces V Price Price basis: FOB Qingdao Payment: 30% down payment by T/T in advance, the balance by T/T against fax copy of B/L Lead-time: within 20 days after receiving down payment Unit price: USD 9,000 Note: Other optional tools: 1) For twisting: USD 690 per set 2) For flatting: USD 140 per set 3) For pressing tie-in: USD 160 per set (any sizes are available) 4) Extra punching tool: USD 260 per set VI Guarantee: within one year since the date of B/L Punching Tool & Sample Horizontal Bending Tool & Sample Vertical Bending Tool & Sample Embossing Tool Tie-in Pressing Tool