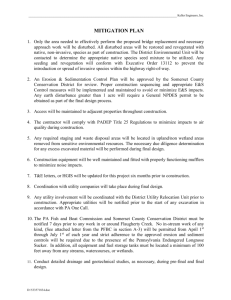

- Vacuum Dig

advertisement

Vacuum Dig Enterprises Inc Surface / Sub-Surface Utility And Structure Location Primary and Secondary Vacuum Locates Vacuum Dig Enterprises Inc. 1274 Mystic Way West Palm Beach FL 33414 Office: 561-798-3219 Cell: 561-603-5696 Email: erpowell@vacuumdig.com Our Website www.vacuumdig.com Vacuum Dig Enterprises Inc About The Company Vacuum Dig Enterprises Inc is a multifunctional Utility Location and subsurface structural location service. We offer a wide variety of work products designed to assist engineering and architectural firms produce accurate design drawings. Our firm can perform services ranging from simple surface marking of underground utilities up to, and including vacuum excavation and exposure of sub surface utilities and structures. Through our affiliate, the firm can also provide surveying and mapping services to further enhance the work product. Our mission is to provide timely customer service, producing an accurate and professional work product. Available Services Our services are typically referred to within the industry as sub-surface utility engineering (S.U.E.). There are circumstances in which conventional methods do not precisely locate the utilities. In these cases additional means may be utilized. These include ground penetrating radar (for non-metallics), and Vacuum Dig field of expertise; vacuum excavation. In order to give the client exact information as to where the utility-in question lies, we use the nation’s leading vacuum excavation technology for environmentally safe, non-destructive test holes. The S.U.E. Analyst will determine the exact location for test hole excavation by utilizing methods mentioned previously. Once the excavation location or conflict point is determined, the trained Vacuum Dig crew prepares the test hole for visual verification. Using a vacuum hose and pneumatic air lance in tandem, the soil is carefully disrupted and cleared to provide the safest method of utility exposure available. After the utility is located, the technician replaces the native soil, if possible, or, will use a special fill as determined by code or client. Depths of the utility are taken and a survey marker is posted in order to re-establish the test hole location at a future date, should the need occur. A typical utility line is exposed within 4” x 8” test holes. Test holes may be as big as 12” x 12” DATA MANAGEMENT AND WORK PRODUCT There are three steps to the data management of a S.U.E. project: 1. Preliminary Data Assignment and Assessment Once a job has been negotiated and accepted, the project manager analyzes the data as given by the client and researches the area of work. Necessary background information is provided by the client will be reviewed by our engineering staff and the S.U.E. analysts are briefed as to what to expect on-site. 2. Data Collection Using the information provided, the technicians assigned to the project will designate and locate the utilities as specified in the contract. Locations are performed utilizing the benchmarks and traverse points provided by the client. -OROur surveying and mapping affiliate will be contracted to provide survey quality location to existing landlines and /or the state plane coordinate system. A signed and sealed surveyor’s report may accompany the work product. Under this scenario, using state-of-theart computer systems, the survey information can be converted into computers plans in an AutoCAD format. The designation and location work performed can then be transported into a subsurface utility overlay of existing road design or other design product. 3. Work Product Test hole reports are made for each test hole with the computer generated sketch of the test hole location and all other pertinent information to form a concise, informative data sheet for the utility or structure. Alternately, should a computer generated work product not be required, a hand drawn sketch and data sheet may be provided. Collectively these steps constitute the standard practice, which is employed by Vacuum Dig Enterprises to provide our clients with the most accurate information in the safest manner. Proven to be extremely cost-effective and responsive to time constraints, Vacuum Dig Enterprises will work with your team to assure efficient and lowrisk completion of your projects. SUBSURFACE UTILITY ENGINEERING Vacuum Dig Enterprises Inc. provides “Subsurface Utility Engineering”, (SUE) which is a new technology that can reduce conflicts between highway construction and underground utilities. It provides accurate information on the horizontal and vertical location of the underground utility facilities during the early development of highway projects. Through use of this technology, engineers can identify conflicts points, design around the, and move projects faster. The three main components of subsurface utility engineering as defined by the Federal Highway Administration are Designation, Location and Data Management. Designation: The approximate horizontal location of subsurface facilities are detected using geophysical techniques such as electromagnetics and sonics. They are then marked with paint or other marking devices. This information will be recorded on plan sheets. This phase of the process allows broad-scope engineering decisions to be made early in the project. Location: Designation alone does not provide the high accuracy required for the detailed design of the highway project. The use of Vacuum Dig Enterprises vacuum excavation technology allows technicians to measure and record the precise depth and horizontal position of a utility line through a hole that may be no larger than 203 x 203 mm (8 x 8in), preserving both utility lines and surface integrity. Data Management: The key phase is data management involves incorporating information of utilities into the process of designing a highway project. The earlier the data is used the better. A project’s impact on underground utilities may be a critical factor in determining a cost-effective design. Quality Levels of Service as defined by The American Society of Civil Engineers are: QL “D” – This information results strictly from a Review of Utility Records. Such information is highly limited in terms of comprehensiveness and accuracy. QL “C” – This information is obtained by augmenting the QL “D” information. It involves surveying the locations of visible above ground utility objects and entering this data into a CAD system. QL “B” – This information is obtained through the use of “designating” technologies (i.e., geophysical prospecting technologies). Designating technologies are capable of providing good horizontal information as design activities advance, but are not capable of providing trustworthy vertical information. QL “A” – This involves obtaining accurate vertical data by digging a small hole using Vacuum Digs vacuum excavation techniques. This is the nondestructive, minimal intrusive capability to go into the ground, physically uncover a line, and measure it in three dimensions with a high degree of accuracy. QL “A” this provides accurate information at crucial highway/utility conflict points. QL “A”, information should be obtained and used every time an excavation crosses utility lines. VACUUM DIG ENTERPRISES INC – KEY PERSONNEL In addition Ernest R. Powell Jr. to the firm completes our management structure. Mr. Powell will as our Field Operations Manager and is to be the key contact point for our clients. His biography is a follows; ERNEST R POWELL JR Present Field Operations Manager, Vacuum Dig Enterprises Responsible for all phases of horizontal and vertical utility locating. 2003-2008 IT/Sales/Field Operations at Centex Homes. Top 3 Builder for the US. 1995-1999 Field Engineer Jet Mechanic for the US AirForce EDUCATION AND LICENSES: CISCO CERTIFICATION LAND ACQUISTION IN THE STATE FLORIDA BACHELOR OF SCIENCE IN COMPUTER INFORMATION SYSTEMS Colleges: Florida Atlantic University, USC, Georgia Military College