MBE 101 Allmänna krav

advertisement

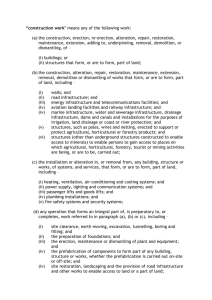

Sid. 1 (5) PROCEDURE AND REQUIREMENTS FOR INSTALLATION OF ELECTRICAL EQUIPMENT Heading Designation Dismantling MBE 901 Version 3 en Contents 1 1.1 1.2 2 3 3.1 3.2 4 4.1 4.2 4.3 4.4 4.5 Designation GENERAL...................................................................................2 Scope ...........................................................................................2 Prerequisites ................................................................................2 DEFINITIONS.............................................................................2 INSTALLATION REQUIREMENTS.........................................2 General requirements ...................................................................2 Requirements according to nuclear regulations ...........................2 INSTALLATION ........................................................................3 General ........................................................................................3 Dismantling in Cabinet/Embedding ............................................3 Dismantling of mechanical components......................................3 Dismantling of cables ..................................................................4 Dismantling of components .........................................................5 Version MBE 901 2016-02-17 (106741074) Date 3 en Replaces 2004-03-25 2 en MBE 901 1 GENERAL 1.1 Scope Version 3 en Sid. 2 (5) MBE 901 comprises dismantling in conjunction with electrical installation in sections which are in operation. 1.2 Prerequisites Administrative procedures and technical requirements shall clarify needs and permission for dismantling. Electrical disconnection shall be completed. 2 DEFINITIONS Dismantling Dismantling, taking apart. The opposite of installation. Can be included in the concept of "installation" in the wider definition applied by MBE. 3 INSTALLATION REQUIREMENTS 3.1 General requirements Dismantling is done in and near to plant components, which are in operation. For this reason, great care is needed to avoid incorrect work. The work must be prepared carefully and planned in a binder in the same way as for installation. The performance and safety of the plant must not be affected. Restoration after dismantling shall be done in accordance with the requirements in the appropriate MBE. Fire protection must not be compromised. Enclosure must not be compromised. Dismantled items can not be stored and left lying about, but must be transported out of the plant at once. 3.2 Requirements according to nuclear regulations Dismantling must not entail any increased risk for safety-classified equipment. The requirements for separation, component jeopardy and association still apply, unless otherwise specified in a work permit etc. 2016-02-17 (106741074) MBE 901 4 INSTALLATION 4.1 General Version 3 en Sid. 3 (5) It is important to plan the sequence of work in dismantling in order to minimise disturbance on the remaining operational components. This can mean that the time, which various protections need to be temporarily removed, must be as short as possible. Earth connections shall be removed as late as possible or not at all, to avoid problems with the occurrence of serial grounding or other faults. Shared electrical power supplies and other connections, ventilation and cooling of equipment and other items which could entail an adverse effect on the remaining material shall be reviewed very carefully with an open mind, so as to identify all aspects. 4.2 Dismantling in Cabinet/Embedding By dismantling procedures a base documentation shall be at hand, equivalent in extent to that of mounting procedures. Before commencing the dismantling a voltage checking control must be performed on all equipment, described in the base documentation, which is involved in the dismantling procedures. Dismantling must be performed with great precaution and in consideration to the surrounding equipment since there is a great risk of disturbances from other extinction voltage operating connections. If an increased risk potential or uncertainties about the work are identified it must be reported to the responsible design engineer for an amendment in the base documentation or the working methods. If any attachment is removed in order to facilitate the work when dismantling the connections between the aperture/opening and the cabinet/embedding great consideration must be taken to remounting the attachment in order to avoid any injury caused by crushing. Common voltage feed supply must not be left open. Relays, printed circuit cards etc. shall if dismantled be marked with a sign “reserved position” Wires of external reserved cables shall be end capsulated and placed in the same canal as other reserved wires. A cable being reserved should be marked with its cable number and an orange tag. The cable being dismantled is exposed from the embedding and inlets/ fire sealing are reset to proper class of embedding. 4.3 Dismantling of mechanical components The sections, which are to be left behind in the plant after dismantling, shall be reinstated in accordance with the demands in MBE 201 Protruding expanding fasteners etc shall always be removed. Repair of concrete and paint repairs after dismantling shall be notified to OKG/FKA building departments unless otherwise agreed. 2016-02-17 (106741074) MBE 901 4.4 Version 3 en Sid. 4 (5) Dismantling of cables Administrative procedures govern via work permits etc that cables are disconnected from voltage. Dismantling of connections between physical units can be done to different extents Terminals pulled out, isolation at screw terminals, i.e. the cable remains in place and are connected to the terminal Disconnected and laid out as a spare in the enclosure Removed and laid out as a spare outside the enclosure Removed from the cable route. Cables shall be laid out as spares inside enclosures in accordance with MBE 401. Cables shall be laid out as spares outside enclosures in accordance with instructions from the responsible designer. Cables or conductors must not be cut off inside encapsulations; they must be pulled out whole, including any cable glands. Opening of fire seals beneath cabinets is subject to administrative procedures. When cables are to be removed from cable routes, where other cables are located, two different methods can be used 1. A ring is threaded over the cable at the end where dismantling starts. The ring is marked with the cable number. As the cable is lifted off from the cable route, the ring is slid forwards, so that the identity of the cable is always ensured. When fire seals are opened and passed, the ring shall remain on one side when the seal is opened, so that the identity of the cable is always ensured. The cable should either be cut inside the ring or outside the duct/ladder. Please refer to MBE MI 9001. 2. If the cables are laid at random in the duct, the ring as described in item 1 can be difficult to use. The cables to be removed shall be progressively straightened out and laid outside the duct or on plastic pipes, which is laid crosswise above the duct. In this case, the cable must only be cut off in small pieces, so that the end of the cable is always visible. 3. The methods according to items 1 and 2 can always be combined. The lids on ducts and penetrations shall be restored at once when the cable has been removed from the duct. Packing pieces for modul seals must not be re-used. 2016-02-17 (106741074) MBE 901 4.5 Version 3 en Sid. 5 (5) Dismantling of components Dismantling documentation can also comprise removal of connected units in enclosures and other objects, such as sensors. After dismantling of units in the enclosures, touch guards, various shields between cable groups and other items, which form the isolation of the enclosure between different components and immunity to arcing, shall be restored in accordance with the manufacturer’s instructions. When items are dismantled, signs or markings for each section may be removed and new ones installed as necessary. 2016-02-17 (106741074)