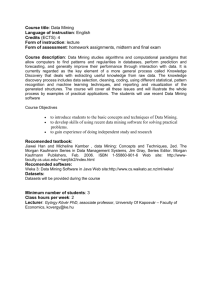

File

advertisement

Gemstone Extraction Techniques Reference: Yahoo Babel Fish Extraction of Rough Gemstones from the Ores: The process of extracting the gemstones from the ores varies from place to place and is dependent on the nature and quality of the gemstone. In general those from alluvial deposits are assorted by washing with sieves. Slurry containing the gemstone rough along with mud and other materials is washed with water on a sieve. A vibratory motion is applied to the sieve so as to separate the slurry quicker. The gem rough is then hand picked from the sieves. Depending on the size of the rough, different sieve sizes are employed. This method is commonly employed for most gemstones. Extraction of Rough Diamonds from the Ores: In the case of Diamond extraction from the mother rock, the process is more complicated. The entire process however utilizes the properties of diamonds to separate them. Following are the basic processes by which diamonds are recovered from the ore. 1. Crushing: Done to reduce the size of the rocks in the ore. 2. Heavy Media Separators: Make use of the property of specific gravity wherein a heavy stone will sink in a liquid of lower specific gravity. Either one or a series of Heavy Media Separators are used to separate the diamonds. A centrifugal force is applied to the liquid inside, for faster separation. 3. Grease Table or Belt: Uses the property that diamonds stick to grease. The ore is poured over this table and washed with water. A vibratory motion is given to the table. The diamonds with a few other minerals stick to the table while the rest is washed off. Heat is used to separate the diamonds from the grease. 4. X - Ray Separators: Uses the principle that diamonds fluoresce to X - rays. The ore is dropped in a fine stream through a channel and an X- ray beam is directed at it. As a diamond fluoresces, a detector activates an airjet and the diamond is directed into another channel. 5. Magnetic Separators: In areas where there are magnetic minerals present in the ore, a magnetic belt is used for separation. The material which is discarded, also known as tailings, after going through the processes in a treatment plant is sometimes re-checked and is considered in the evaluation of the efficiency of the plant. The diamonds which have been separated are now washed in acid and cleaned, ready for assortment. Diamonds which are coated will probably not react well to the above processes. Under the circumstances, the quality of the rough should be ascertained before the specific processes are employed. previous » Mining: The methods used in the mining of gem materials are many, from native mining to highly technical methods. Gemstone Mining 1. Open Cast Mining 1. Pit Mining 2. Terrace Mining 2. Underground Mining 1. Tunneling 2. Block Caving 3. Chambering 3. Water Bodies 1. River Diggings 1. Dry Diggings 2. Wet Diggings 2. Sea 1. Tidal 2. Undersea or Marine Mining Open Cast Mining: It includes the removal of overlying minerals or rocks to reach the gem bearing rocks. The gem - bearing rocks are then washed by jets of water under high pressure or by traditional methods to obtain the gem gravels. These gravels are then washed and assorted at the treatment plants. Opencast mining is done in many parts of the world e.g. Myanmar, Sri Lanka, U.S.A., Brazil etc. o Pit mining is the term used to describe a mining method where pits are dig up to about 12 meters. Open cast mining operations are generally initiated by pit mining. o Terrace mining is the term used to describe a mining method where the gem bearing rocks are exposed by digging horizontal terraces in step-like, generally circular formations. Blasting or digging is done and the debris is then washed to obtain the gem gravels. Emerald mining in Columbia (Chivor Mine) is the best example of terrace mining. Underground Mining: This includes mining from alluvial and pipe deposits. In the case of alluvial deposits where pit mining is done, deeper pits of over 10 metres are considered by some as a form of underground mining. o Tunneling technique is employed when there is a gem bearing rock either as an outcrop or as a seam running close to the surface. A tunnel is made from the surface to the gem - bearing rock and mining is done by blasting or by using pick axes to remove individual gem rough. This type of mining is seen at a few emerald mines in Columbia. o In Block caving, a series of parallel tunnels called scraper drifts are driven from the main shaft into the pipe, about 400 to 600 feet below the top of the mother rock. Starting at the top level, whole blocks of blue ground are mined out by blasting of the roof of the tunnels through conical draw points into the scraper drift. This is then transported to the main shaft and then to the surface. o In Chambering, initially a main vertical shaft is sunk into the rock surrounding the pipe. tunnels are driven into the pipe from the main shaft at established levels of 600, 1000 and 1600 feet. The ore is retrieved by blasting and transported to the main shaft and then to the surface. Levels are worked on, till a seam is exhausted. Block caving and chambering are commonly used in diamond mining where the deposit is a pipe deposit. In general, block caving techniques are almost completely mechanized; all operations are carried out in one level only. This gives better yields and higher levels of safety and efficiency, as against chambering techniques. River Diggings: Gemstones which have been deposited in river and lake beds can be mined by this method. o Dry Diggings: In this type of mining, a river has either changed its course naturally or is made to change. This is done artificially by blocking the river at two ends and creating a canal to divert the water. In whichever manner, the rock bed is allowed to dry and then the gravel is sieved to obtain the gem rough. o Wet Diggings: In such diggings the gravel is removed from the flowing river and then sieved to separate the gem rough. Sea: o Undersea or Marine Mining: This type of mining is used wherever there are marine deposits. These may be on the beach, as in the Namaqualand diamond deposits in West Africa, or they may be off - shore deposits. This type of mining may involve land reclamation or even deep sea dredging. Mention must be made of the organic gem materials and the manner in which they are retrieved. Amber and Jet are recovered by pit mining while amber is also fished out of the waters, as is seen in the Baltic Sea. Corals are collected by divers with specialized equipment to remove and cart them out. Pearls are recovered by divers who collect the pearl bearing mollusks from the sea bed.