Supplement I

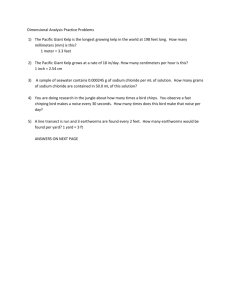

advertisement

Project Goals Improving shellfish habitat while securing local Bio-mass production. Using a renewable farm product for bio fuel , insuring sustainably and reliability Although first step in project is program specific this can lead to long term research and ability to produce and use bio-fuel on evergreen campus The next steps are multi-student and multi-departmental projects Bio fuels are the future of sustainable energy. With millions of cars on the road the demand for bio fuels will just increases as the price of gasoline goes up. People will look for a cheaper alternative. Currently several bio fuels are in research phase. I am going to focus my research on butanol production. Butanol has several advantages over other bio fuels including ethanol. It can be put directly into your gas tank without modifying the vehicle. Ethanol was chosen due to the lower cost of production and butanol was ignored due to the cost associated with anaerobic digestion. Tulane University has discovered aerobic bacteria called Tu-103. David Mullen of Tulane University t has agreed to provide me with a sample. This will allow me to test aerobic digestion of TU-103 on kelp. Aerobic bacterial digestion should cost less and incorporating an inexpensive farm product I can lower the production cost of butanol significantly. Kelp production has been done in Asia for the last half century. Kelp farms are a proven technology that can provide enough biomass to make butanol a possibility without impacting food production. This makes the whole system more sustainable. Bringing Butanol to the masses involves several key points first I need a place to grow kelp. Second I need logistical support to bring kelp to the digester. Third I will need to market butanol. As with any major project it starts with a small step. Kelp production alongside shellfish is a proven method of farming. I need to show our local shellfish farmers that bull kelp can benefit their shellfish farms. Bull kelp has the potential to reduce local ocean acidification. Ocean acidification is eating away at the clams and oyster our local farms really on for a living. If Kelp can be grown and protect shellfish farms from ocean acidification then our local farmers will grow all the biomass I will need to put into a major butanol production digester. I need to quantify how much water quality is change by a single kelp plant. I have chosen bull kelp as my experimental kelp due to it being our local verity. I will put nine plants in Isolation and log the PH change alongside alkalinity and daily water samples. Each plant needs its own bubblier and water cycler. Also I need to refrigerate the water to 10 degrees Celsius to allow for intimation of the ocean. Description Acrylic Tubing 10’’x3/4’x8’ water proofing 500 ft. tubing ½ inch Refrigeration Coupling and vales misc. Lumber misc. Water pumps Misc. 40% Qty 9 1 1 1 1 1 9 1 Cost $384.00 $34.98 $300.00 $250.00 $400.00 $500.00 $94.00 Budget Sub-total $3456.00 $34.98 $300.00 $250.00 $400.00 $500.00 $846.00 $2314.00 Total $8100.00