Example

advertisement

{finish spatial power of tractions}

Example 1

A Compressible Neo-Hookean Material undergoing

Homogeneous Stretch and Rotation

Motion

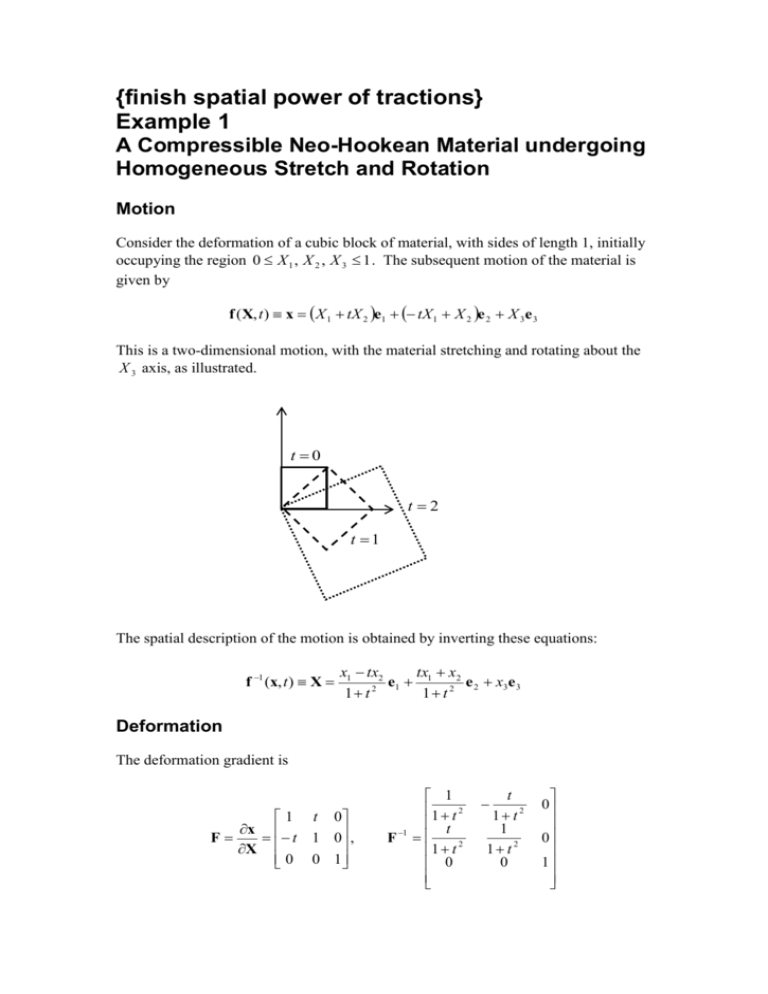

Consider the deformation of a cubic block of material, with sides of length 1, initially

occupying the region 0 X 1 , X 2 , X 3 1 . The subsequent motion of the material is

given by

f (X, t ) x X 1 tX 2 e1 tX 1 X 2 e 2 X 3e 3

This is a two-dimensional motion, with the material stretching and rotating about the

X 3 axis, as illustrated.

t 0

t2

t 1

The spatial description of the motion is obtained by inverting these equations:

f 1 (x, t ) X

x1 tx2

tx x

e1 1 2 2 e 2 x3e 3

2

1 t

1 t

Deformation

The deformation gradient is

1 t 0

x

F

t 1 0 ,

X

0 0 1

F 1

1

1 t 2

t

2

1 t

0

t

1 t2

1

1 t2

0

0

0

1

This deformation is homogeneous, meaning that the deformation is the same for all

points (F is independent of position). The Jacobian determinant is

J

dv

det F 1 t 2

dV

The right Cauchy-Green tensor is

1 t 2

0

T

C F F 0

1 t2

0

0

0

0

1

For example, the stretch for a line element (in the reference configuration) in the

direction dX e1 is given by 2 e1 C e1 C11 1 t 2 . In this simple case of a

homogeneous deformation, this stretch for line elements in the direction e1 is the

same for all points in the material.

The left Cauchy-Green tensor is b F F T and equals C is this example. It follows

that the stretch of a line element (in the current configuration) in the direction dx is

given by

1 t 2

0

1

dx

0

1 t2

2 dx

0

0

0

dx

0

dx

1

For example, in the direction dx e1 2e 2 at t 2 , the stretch is

5.

The deformation can be decomposed into stretch tensors through F R U or

F v R , where U and v are, respectively, the right (material) and left (spatial)

stretch tensors. Since C is diagonal,

1 t2

U C 0

0

and

0

1 t2

0

0

0

1

R FU

1

1

2

1 t

t

1 t2

0

0

0

1

t

1 t

1

2

1 t2

0

which is proper orthogonal, R R T I, det R 1. The deformation can thus be

decomposed into a pure stretch along the principal (material) axes, which here are just

the axes e1 , e 2 , e 3 , and then followed by a rotation about the X 3 axis. For example, at

t 1 , the rotation is 45 o clockwise.

The left stretch tensor is now obtained from v F R T and it turns out to be the same

as U (and b v 2 ). Thus the deformation can also be decomposed into, first, a rigidbody rotation, followed by a pure stretch to the subsequent configuration. For

example, considering the configuration at t 1 (see figure above), first rotate

clockwise by 45 o ; then the rotated line elements dx (1) (1 / 2 )e1 1 / 2 e 2 ,

dx

( 2)

2e1 map to the final positions v dx

(1)

e1 e 2 and v dx

( 2)

2e1 .

Nanson’s formula, nds JF T NdS , relates unit normals in the reference and current

configurations. Each of the six sides of the block has surface area dS 1 and

ds 1 t 2 . For example, the unit normal N e 2 is mapped to the unit normal

n te1 e 2 / 1 t 2 through

n1

n

2

n3

N e2

n

t

1 t2

1

1 t2

t

1 t 2 1 t 2

2

1 t

0

e1

1

1 t2

t

1 t2

1

1 t2

0

0

0

0 1

1 0

e2

Rates of Deformation

The velocity is (in the material description – the material coordinates are constant)

V ( X, t )

dx d

X 1 tX 2 e1 tX 1 X 2 e 2 X 3 e 3 X 2 e1 X 1e 2

dt dt

The velocity in the spatial description can be obtained by substituting into the above

expression the motion X f 1 (x, t ) , to get

v(x, t )

tx1 x2

x tx

e1 1 2 2 e 2

2

1 t

1 t

These two velocities are the same, they are the velocities of material particles in the

material, expressed in two different ways.

The acceleration is zero, A( X, t ) dV / dt 0 . The acceleration can also be obtained

directly from the spatial velocity using the material time derivative,

a(x, t )

dv(x, t ) v(x, t )

grad v v

dt

t

which turns out to be zero.

The spatial velocity gradient is now

t

1 t2

1

l grad v

2

1 t

0

1

1 t2

t

1 t2

0

0

0

0

This can be decomposed into its symmetric and skew-symmetric parts: the rate of

deformation

d

t

1 t 2

0

0

0

1

2

1 t

0

1

l lT

2

0

t

1 t2

0

0

0

0

and the spin

w

1

l lT

2

1

1 t2

0

0

0

0

0

The skew-symmetric spin can be written in the form of a vector, the angular velocity,

ω w23e1 w13e 2 w12e 3

1

e3

1 t 2

which clearly corresponds to a clockwise rotation of material particles about the e 3

axis.

Note also that

div v

v1 v2 v3

2t

x1 x2 x3 1 t 2

so that the rate of change of the volume ratio dv / dV is

J Jdiv v 2t

Stress

Suppose now that the Cauchy stress is

1 2 / 3 2

t

0

0

ln J 3 J

1

σ J 1

0

ln J J 2 / 3t 2

0

3

2 2 / 3 2

0

0

ln J J t

3

The Equations of Motion

The equations of motion in the spatial description are div σ b v and it can be

seen that the Cauchy stress is uniform throughout the material at any time instant,

div σ ij / x j o . There are also no accelerations and so there are no body

forces.

The PK1 stress is

P Jσ F T

1 2 / 3 2

t

ln J 3 J

1 t2

ln J 1 J 2 / 3 t 2

3

t

1 t2

0

1

3

t

1 t2

1

ln J J 2 / 3t 2

3

1 t2

ln J J 2 / 3t 2

0

0

0

2

ln J J 2 / 3t 2

3

The equations of motion in the material description are Div P B 0 A and these

three terms are also zero.

Balance of Mechanical Energy

Material Description

The PK2 stress is

S JF 1 σ F T

1 2 / 3 2

t

ln J 3 J

1 t2

0

0

0

1

3

1 t2

ln J J 2 / 3t 2

0

0

0

2

ln J J 2 / 3t 2

3

Also,

t 0 0

E F T d F 0 t 0

0 0 0

and then the stress power is

2t

S:E

1 t2

1 2 / 3 2

t

ln J 3 J

The same result can be obtained by using the alternative stress power expression,

P : F .

The stress power is independent of position within the material, and the volume in the

undeformed configuration V is unity so the total stress power is

2t

1

ln J J 2 / 3t 2

2

3

S : E dV S : E 1 t

V

Look now at the power of the power of the surface tractions: T VdS . The velocity

dS

is zero over the front and back faces (the sides with unit normals e 3 ), and is nonzero over the other four sides (with normals in the reference configuration e1 , e 2 ).

The PK1 traction is given by T P N and is shown in the figure for these four faces,

and given below (the PK1 stress is uniform throughout the material).

T( 2) P e 2 P12 e1 P22 e 2

T(3) P (e1 ) T(1)

T(1) P e1 P11e1 P21e 2

T( 4) P (e 2 ) T( 2)

1 2 / 3 2

t e1 te 2 ,

ln J 3 J

1

1

ln J J 2 / 3t 2 te1 e 2 ,

2

3

1 t

T(1)

T( 2 )

1

1 t2

Substituting in the velocity V X 2 e1 X 1e 2 now leads to

T(3) T(1)

T( 4 ) T( 2 )

T VdS T X

(1)

dS

e e 2 dS (1)

T e

2 1

dS(1)

( 2)

1

X 1e 2 dS ( 2 )

dS( 2 )

T X e dS

( 3)

2 1

( 3)

dS( 3 )

T X e dS

( 4)

1 2

( 4)

dS( 4 )

1 1

1 1

T(1) X 2 e1 e 2 dX 2 dX 3 T( 2 ) e1 X 1e 2 dX 1 dX 3

0 0

0 0

1 1

1 1

0 0

0 0

T(1) X 2 e1 dX 2 dX 3 T( 2 ) X 1e 2 dX 1 dX 3

1

1

1

1

T(1) e1 e 2 T( 2 ) e1 e 2 T(1) e1 T( 2 ) e 2

2

2

2

2

2t

1

ln J J 2 / 3t 2

2

3

1 t

which equals the stress power, and so the mechanical energy is balanced:

dV

T V dS B V dV S : E dV V dt

S

V

V

dV

V

Spatial Description

In the spatial description, the stress power is

σ : d J 1

2t

1 t2

1 2 / 3 2

ln

J

J t

3

The total stress power in the material, with dv JdV , is then

2t

1

ln J J 2 / 3t 2

2

3

σ : ddv σ : d dv Jσ : d 1 t

v

v

In the spatial description, the power of the surface forces is t v ds . Again, we only

s

need to look at four sides, since the velocity is zero over the front and back. The unit

normals to these four faces are shown in the figure.

n (3) n (1)

1

n ( 2)

1 t 2

te1 e 2

n ( 4 ) n ( 2 )

1

n (1)

1 t 2

e1 te 2

The tractions acting over these surfaces are then obtained from Cauchy’s law,

t σ n . Examining the first surface, the velocities of particles there are those for

particles with material coordinates X 1 1 , so, eliminating x1 ,

X1

tx x

x1 tx2 1 t 2 , v (1) 1 2 2 e1 e 2 t x2 e1 e 2

1 t X1 1

x1 tx2

1

1 t 2

The integration over

1

1

dX dx 1 is straightforward. The integration over

dX in the reference configuration corresponds to the

integration dl in the current configuration. With

3

0

0

3

1

2

0

dl

dx2

dx1

dl (dx1 ) 2 (dx 2 ) 2 1 t 2 dx 2 over this surface, we have

dl

1t

1 t 2 dx 2

t

The double integral in the reference confuguration

to the integral

f (x) J dx dx

2

3

J 23

f (X)dX

2

dX 3 can be converted

where J is the Jacobian for the change of variable:

X 2 / x2

X 2 / x3

X 3 / x2

X 3 / x3

1

1 t 2

The limits of integration are obtained

Thus the complete expression of the power of the tractions is

t v ds

s

1 1t

1

1

t v (1) dx 2 dx3

2 (1)

1 t 0 t

1 t2

1

1 t2

1 1 t

t

( 2)

v ( 2 ) dx1 dx3

0 t

1 1

t (3) v (3) dx2 dx3

0 0

1

1 t2

1 1

t

( 4)

0 0

v ( 4 ) dx1 dx3

The integral over the first surface is then

t (1) v (1) ds

s

1

1 t2

1 1 t

t

J 1

(1 t 2 ) 3 / 2

(1)

v (1) dx 2 dx3

0 t

J 1

(1 t 2 ) 3 / 2

1 1t

e

te 2 t x 2 e1 e 2 dx 2 dx3

1

0 t

1 1t

2t x dx dx

2

2

3

0 t

J 1

t 1 / 2

(1 t 2 ) 3 / 2

where ln J J 2 / 3t 2 / 3 .

1

1 t2

1 1 t

t

0 t

(1)

1

1 t2

1 1 t

J 1

v (1) dx1 dx3

(1 t 2 ) 3 / 2

1 1

t (3) v (3) dx2 dx3

0 0

te

1

e 2 e1 x1 t e 2 dx1 dx3

0 t

1 1 t

J 1

(1 t 2 ) 3 / 2

2t x dx dx

1

1

3

0 t

J 1

t 1 / 2

(1 t 2 ) 3 / 2

J 1

(1 t 2 ) 3 / 2

e

J 1

(1 t 2 ) 3 / 2

1 1

1 1

1

te 2 x 2 e1 dx 2 dx3

0 0

x dx dx

2

2

3

0 0

J 1

1 / 2

(1 t 2 ) 3 / 2

1

1 t2

1 1

t

0 0

( 4)

J 1

v ( 4 ) dx1 dx3

(1 t 2 ) 3 / 2

J 1

(1 t 2 ) 3 / 2

1 1

te

1

e 2 x1e 2 dx1 dx3

0 0

1 1

x dx dx

1

0 0

J 1

1 / 2

(1 t 2 ) 3 / 2

1

3

and the total is

t v ds J

s

1

2t

ln J J 2 / 3t 2 / 3

2 3/ 2

(1 t )

and so the mechanical energy is balanced in the spatial description:

dv

t v ds b v dv σ : ddv v dt dv

s

v

v

v

Strain Energy and Conservative Force System

The above Cauchy and PK2 stresses were actually derived from the strain energy

function

1

1

2

W ln J J 2 / 3 I b 3

2

2

This is the strain energy of a compressible Neo-Hookean material. It is a hyperelastic

model (since the stress is obtained from a strain energy function) of an isotropic

material (since the Cauchy stress is a function of the left Cauchy-Green strain b only).

Here, J det F . We write this in terms of the third invariant of b, III b det b :

III b J 2 . Differentiating W now gives J / III b III b / III b 1 / 2 J , so

W

W W

W 2

σ 2 J 1

III b I 2 J 1

I b b 2 J 1

b

III b

I b II b

II b

W J 2

W

2 J 1

J I 2 J 1

b

J

III

I

b

b

1

J 1 ln J I J 2 / 3 b trb I

3

The PK2 stress can also be obtained directly through

W W

W

W

S 2

I b I 2

C2

III b C 1

II b

III b

I b II b

1

ln JC 1 J 2 / 3 I trC C 1

3

leading to the PK2 stress given earlier.

1

1

2

Explicitly, from W ln J J 2 / 3 I b 3 , the time derivative of the strain

2

2

energy is

1

d

1

W J 1 J ln J J 2 / 3 trb J 2 / 3 trb

3

dt

2

Now J Jdiv v so

J 1 J div v

2t

1 t2

and

trb 3 2t 2

d

trb 4t

dt

so

2t

W

1 t2

1 2 / 3 2

t

ln J 3 J

It can be seen that this time derivative of the strain energy is precisely the stress

power, as expected for a hyperelastic material:

W 1 U

Jσ : d S : E

0

Here, U is a strain energy per unit mass, whereas W is the strain energy per unit

(reference) volume.