M.G. Sief, H.M. Arafa, and R.M. Hassan

advertisement

New Prediction Equations for Yarn Strength of Egyptian Cotton

Utilizing HVI Spectrum Data.

M.G. Sief, H.M. Arafa, and R.M. Hassan

Cotton Research Institute, Agricultural Research Center, Giza, Egypt.

Abstract

This investigation was conducted on ten Egyptian cotton varieties and

promising

crosses

namely,

Giza

80,

Giza

90,

(Giza

90×Aust.)

and

[G83×(G75X5844)]×G80 (Upper Egypt long staple cottons), as well as Giza 86 and

(10229×Giza 89) (Delta long staple cottons), Giza 88, Giza 92, Giza 93 (Giza77×Ps6)

and [G84×(G70×51B)]×P62 (extra long staple cottons), to develop prediction

equations for skein strength of 40’s and 60’s carded yarns by subjecting HVI testing

data (measurements of cotton quality properties and SCI) to multiple regression

analysis. The developed equations were applied to HVI spectrum data to test the

accuracy and reliability of the obtained predicted skein strength values. The predicted

values of skein strength matched very well the corresponding determined ones.

Regression and correlation between skein strength and SCI were studied.

Introduction

Classical low volume instruments (LVI) used for characterization of cotton

fiber as Fibrograph, Stelometer, Pressley tester, Micronaire…etc. were for practical

applications replaced by HVI (high volume instrument) testing systems which

provide rapid and accurate measurements of the basic cotton fiber properties. Using

HVI makes it possible to obtain a big amount of data, furthermore it is provided by

special software for automatic calculation of predicted yarn strength in the old

generations of HVI (900 system) and predicted SCI (spinning consistency index) in

HVI spectrum and new models. The predicted values of yarn strength and SCI were

calculated for each tested sample using the measured fiber quality data according to

the regression equation

y= a+ bix1+ b2x2+…………bnxn

Where y= yarn strength in HVI 900 systems and SCI in Spectrum and 1000

HVI systems.

x1, x2, …………xn are measurements of fiber quality properties.

Nemours research work has been carried out to study the relationship between yarn

quality and fiber properties as well as to develop prediction equations that provide

calculated values of yarn strength based on fiber quality measurements. Ethridge et

al. (1982), El Mogazhy and Broughton (1990), El Mogazhy et al (1992), Frydrych

(1992), Sief et al (1994) Cheng and Adams (1995), Moon et al (1998), Suh et al

(1998), Pan (2001), Ureyen and Kadoglu (2006) and Hequet and Abidi (2008)studied

this relationship using different statistical models and techniques and came to

different prediction equations, For instance, Ethridge et al. (1982) found a linear

empirical relationship between rotor yarn strength, fiber strength, micronaire, fiber

length uniformity ratio and grayness. They defined the CSP at the rotor yarn as:

CSP = - 6487.01 + 728.84 InS – 2913.89 M + 658.41 M2 – 50.10 M3 + 2258.54 InU –

0.00003(GXY)2

Where InS = the natural logarithm of fiber strength

M = the micronaire index raised to the power

InU = the natural logarithm of length uniformity ratio

( GXY)2 = the square product of grayness multiplied by yellowness

Hunter et al. (1982) proposed a range of regression equations for predicting the

strength of ring spun yarns from a range of fiber properties, some of these equations

are follows:

Ring yarn CSP = 43 UR + 125 BT – 103 BE – 65 Mc + 10.5 YC + 47.3 TF - 3601

Ring yarn tenacity ( cN/tex) = 0.31 UR + 0.80 BT – 1.1 BE – 0.73 Mc + 0.062 YC +

35 TF – 21.8

Where: UR = the uniformity ratio BT = bundle tenacity

Mc = micronaire value

BE = bundle elongation

YC = yarn count m/tex F = twist factor

TC = trash content measured by Shirley trash analyzer

NTP = the number of trash particles

SL 50% = 50% Span length

El- Moghazy (1988) developed the following regression equation for calculating the

count strength product (CSP) of yarns:

CSP = - 4184 + 1141.2 FL + 71.2 LU + 49.4 FE – 22.7 Rd + 2041/FF

Where: FL = UHM length in inches LU = length uniformity FS = fiber strength

FE = fiber elongation

Rd = reflectance

FF = micronaire value.

Ghosh et al. (2003) developed the following equation for spun yarn tenacity Q1 as:

Q1 = nh/ne. Fn. Qb/100. Con2 Q1

Where nh = the number of the fiber at the place of yarn break

ne = the average number of fiber in the yarn cross section

Fn = the fiber bundle tenacity

Qb = the percentage of broken fiber in the yarn failure zone

Q1 = the average helix of fiber at the time of yarn failure

Regarding Spinlab 900 HVI system the manufacturing company provided the system

with two equations for predicting skein breaking load and skein strength (CSP).

y1= 173.58+ 86.42 x2+ 1.95 x3+ 3.0 x4+ 8.72 x5+ 0.99 x6

y2= 1818.0- 24.0 x1+ 270.0 x2- 8.0 x3+ 45.0 x4- 112.0 x5- 2.21 x6- 1.10 x7

where y1 skein breaking load (SBr), y2 skein strength (count strength product)

for 22s carded yarns, x1 trash area %, x2 2.5% SL in., x3 LUR%, x4 fiber strength, x5

micronaire value, x6 Rd% and x7 +b.

In 1989 CRI found that the predicted values of yarn strength and breaking load

obtained from the mentioned two equations of HVI 900 system did not match well

the determined values of yarn strength and braking load for the 60’s carded yarns

spun from Egyptian cotton which was logic since the two equations were derived

from Upland cotton data and they were for 22s carded yarns. Therefore, a research

trial was conducted in Cotton Fiber Res. Section during 1990 and 1991 seasons to

develop two equations for predicting skein strength and breaking load for 60’s carded

yarns spun from the Egyptian cottons under the conditions of the 60 gm. technique

used in CRI (Sief et al. 1994). The obtained equations were:

y1 (breaking load) = 53.1+ 28.0 x2+ 0.84 x3+ 0.94 x4- 0.89 x5- 0.11 x6

y2 (CSP) = 1383.3- 326.9 x1+ 1766.1 x2- 27.4 x3+ 58.4 x4- 89.2 x5+ 13.2 x6- 17.8 x7

Where: y1 skein breaking load (SBr), y2 skein strength (count strength product CSP)

for 60s carded yarns, x1 trash area %, x2 2.5% SL in., x3 LUR%, x4 fiber strength, x5

micronaire value, x6 Rd% and x7 +b.

Applying the obtained equation of skein strength to HVI 900 fiber data of

Egyptian cotton automatically provided reliable predicted values of yarn strength for

about 10 years which was very useful in the quality evaluation of the big number of

samples delivered from the breeding program and other research trials and programs

of Cotton Res. Institute.

In 2002 fiber quality evaluation labs of CRI received the HVI Spectrum

system. The manufacturing company made a lot of modifications in this system to be

calibrated using HVI calibration cotton only, leading to big differences in fiber

strength values besides measuring UHML, ML and uniformity index % instead of

50%, 2.5 % span lengths and length uniformity ratio obtained from the old model

HVI 900. Moreover the manufacturing company provided the HVI Spectrum with a

prediction equation for calculating the spinning consistency index (SCI) instead of

skein strength. Unlikely, the Egyptian cotton breeders are accustomed to deal with

skein strength in the breeding program. Many attempts were done to modify

mathematically the HVI 900 skein strength prediction equation to be used with the

HVI Spectrum data, unfortunately the obtained skein strength predicted values was

not valid and accurate. Therefore, the main objective of this work is to develop new

equations for predicting yarn strength of Egyptian cottons using HVI Spectrum data

and Programming the HVI Spectrum system with this equations to obtain reliable

predicted values of yarn strength in the same table of HVI fiber data.

Materials and Methods

The present study was carried out in Cotton Technology Res. Department

Cotton Res. Institute, Agric. Res. Center at Giza on ten Egyptian cotton varieties and

promising

crosses

namely,

Giza

80,

Giza

90,

(Giza

90×Aust.)

and

[G83×(G75X5844)]×G80 (Upper Egypt long staple cottons), as well as Giza 86 and

(10229×Giza 89) (Delta long staple cottons) in addition to Giza 88, Giza 92, Giza 93

(Giza77×Ps6) and [G84×(G70×51B)]×P62 (extra long staple cottons). The chosen

cottons represent the long and extra long Egyptian cottons. 250 lint cotton samples

were obtained from the commercial crop of 2010 and 2011 seasons as will as from

field trials of cotton Research Institute. The raw cotton samples were of different

grades ranged from FG-1/4 to G-1/4 in most of these cottons. The cotton samples of

the selected cottons were tested using Uster HVI Spectrum system according to

ASTM standard test method (D 5867 – 05) to obtain the following fiber quality

measurements: the tensile strength (g/tex), fiber elongation %, micronaire value

(Mike), maturity ratio (MR), upper half mean length (UHML) in mm., length

uniformity index % (UI %), color reflectance percent (Rd %) and yellowness (+b).

40’s carded yarns at 4.0 T.M. were spun from the different samples of Upper Egypt

long staple cottons, while 60’s carded yarns at 3.6 T.M. were spun from Delta long

and extra long staple cottons. All the spun yarns were produced according to the 60

gram technique used in the experimental spinning mill in Spinning Res. Section,

Cotton Res. Institute, Giza. The spun yarns were tested for skein strength by Goodbrand Lea tester according to ASTM (D- 1598- 93R00). Moreover, the study

included and used the HVI and skein strength data of the cotton varieties and

promising crosses of Upper Egypt, Delta long staple and extra long staple Egyptian

cottons tested in trial B in 2010 and 2011 growing seasons. The obtained data was

computed using SAS* multiple regression analysis to develop prediction equations

for skein strength of Upper Egypt cottons at 40’s carded yarns, as well as to develop

prediction equations for skein strength of Delta long staple and extra long staple

Egyptian cottons at 60’s carded ring spun yarns. Data of SCI and actual skein

strength was subjected to linear regression and simple correlation analysis to study

the relationship between SCI and skein strength as well as to get a predicted value of

skein strength based on SCI data. Predicted values of skein strength were calculated

by applying the prediction equations to HVI spectrum data of 10 samples of each of

the mentioned cottons in 2011 season (another samples not used in the calculation of

the prediction equations). Differences between the determined skein strength and the

predicted ones were calculated for each cotton.

Results and discussion

Subjecting the obtained HVI Spectrum data and skein strength of the spun

yarns to regression analysis led to five prediction equations, for predicting skein

strength of 40’s carded ring yarns spun from Upper Egypt cottons, besides, another

five equations for predicting skein strength of 60’s carded ring yarns spun from Delta

long and extra long staple Egyptian cottons.

Equations for predicting skein strength of 40s yarns of Upper Egypt cottons:

Equation 1 includes length, length uniformity, strength, micronaire, Rd% and +b

Skein strength = -1277.937+ 45.410x Length + 4.402 x Uniformity index + 35.626 x

Strength - 39.355 x Micronaire - 0.919 x Rd +58.472 x +b

Equation 2 includes length, length uniformity strength and micronaire.

Skein strength = -961.717 + 46.954 x Length + 5.211 x uniformity index +

8.994x Strength - 20.442x Micronaire

Equation 3 includes length, length uniformity, strength, micronaire, and maturity ratio and

elongation%

Skein strength =-1683.455 + 50.970 x Length + 5.232 x uniformity index + 38.079 x

Strength - 22.646 x Micronaire + 178.272 x Maturity ratio + 59.850x Elongation

Equation 4 includes length, length uniformity, strength, micronaire, maturity ratio and Rd%.

Skein strength = -1094.35756 + 49.914 x Length + 5.2371 x uniformity index

+ 37.18052 x Strength - 44.83373 x Micronaire + 325.10457 x Maturity

Ratio – 1.3834 x Rd

Equation 5 includes SCI data

Skein strength = 734.528 + 9.445 x SCI

Equations for predicting skein strength of 60s yarns of Delta LS & ELS cottons

Equation 1: Skein strength = -2058.088+ 43.496x Length + 28.172 x Uniformity index +

36.222 x Strength – 129.105 x Micronaire – 4.906 x Rd +9.360x +b

Equation2: Skein strength = -2500.343 + 47.844 x Length + 28.365 x uniformity index +

37.044x Strength – 138.953x Micronaire

Equation 3: Skein strength = -2852.909 + 41.777 x Length + 21.562 x uniformity index +

25.292 x Strength – 308.535 x Micronaire + 2870.007 x Maturity

ratio + 43.654 x Elongation

Equation 4: Skein strength = -2736.083 + 41.741 x Length + 22.108x uniformity index

+ 25.622x Strength – 301.420 x Micronaire

+ 2744.514 x Maturity ratio – 5.791x Rd

Equation 5: includes SCI data

Skein strength = - 74.881 + 9.445 x SCI

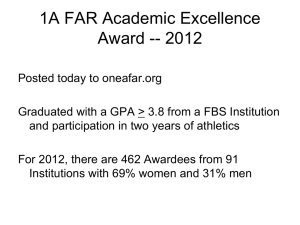

Prediction of yarn strength of Upper Egypt LS Cottons:

HVI Spectrum data, determined skein strength and corresponding predicted ones derived from the

five prediction equations for Upper Egypt cottons as well as the differences between determined

and predicted values of skein strength are shown in Table 1 and Fig. 1 (each cotton was represented

by ten random samples). Comparing the determined and predicted means of skein strength, the

results in Table 1 showed that the determined skein strength of 40s carded yarns spun from Giza 80

averaged 2263 while the predicted values of its skein strength averaged 2352, 2297, 2281, 2298 and

2339 derived from equations 1, 2, 3, 4 and 5 respectively. The determined skein strength of Giza 90

averaged 2193 while the predicted ones averaged 2193, 2191, 2204, 2197 and 2199 derived from

the four equations and SCI data respectively. The determined skein strength of Giza 90 x Australi

yarns averaged 2100, while the predicted ones obtained from the four equations and SCI data

averaged 2140, 2079, 2083, 2085 and 2064 respectively. The determined skein strength of

[G83×(G75X5844)]×G80 yarns averaged 2261 while the predicted ones obtained from the four

equations and SCI data averaged 2217, 2239, 2247, 2233 and 2227 respectively. These results

indicated that the differences between means of the determined skein strength of Upper Egypt

cottons and the corresponding predicted ones ranged from 0 to 40 units which were very low

compared to the testing error in measuring skein strength (100 – 150 units). However the

differences between the individual values of determined skein strength and the corresponding

predicted ones are bigger than noticed between average values, which is logic since the individual

values are characterized by bigger variation than averages. The differences between individual

values ranged from 1 to 118 units in the prediction using equation 1, ranged from 2 to 82 units in

the values obtained from applying equation 2, ranged from 3 to 95 units when applying equation 3

and from 0 to 92 units when applying equation 4, while ranged from 2 to 131 units when based on

SCI data. It is clear from these results that all the prediction equations provide reasonable and

reliable predicted skein strength values, however equations 2, 3 and 4 showed smaller differences

between individual values of determined skein strength and the corresponding ones (< 100 units)

compared to equation 1 and the prediction via SCI data. Furthermore, it is more practical to use

equation 2 since it depends only on the main four fiber properties: length, length uniformity,

strength and mike, while the addition of Rd% and +b in equation 1, maturity ratio and elongation in

equation 2, maturity ratio and Rd% in equation 4 did not improve the accuracy of the prediction

compared to equation 2.

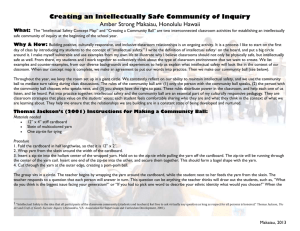

Prediction of yarn strength of Delta LS & ELS Cottons:

HVI Spectrum data, determined skein strength and corresponding predicted ones obtained from the

five prediction equation for Delta LS and ELS cottons as well as the differences between

determined and predicted values of skein strength are shown in table 2 and Fig. 2 (each cotton was

represented by ten random samples. The results in Table 2 showed that the determined skein

strength of 60s carded yarns spun from Giza 86 averaged 2486 while the means of predicted values

of its skein strength were 2540, 2549, 2491, 2503 and 2577 derived from equations 1, 2, 3, 4 and

SCI data respectively. The determined skein strength of 10229 x Giza 86 averaged 2495 while the

predicted ones averaged 2535, 2539, 2498, 2519 and 2576 derived from the four equations and SCI

data respectively. The determined skein strength of Giza 88 yarns averaged 2987 while the

predicted ones obtained from the four equations and SCI data averaged 3023, 2981, 22956, 3005

and 2931 respectively. The determined skein strength of Giza 92 yarns averaged 2978 while the

predicted ones obtained from the four equations and SCI data averaged 2844, 2901, 2957, 2926 and

2976 respectively. The determined skein strength of Giza 77 x Ps6 yarns averaged 3100 while the

predicted ones obtained from the four equations and SCI data averaged 3097, 3054, 3085, 3105 and

2986 respectively The determined skein strength of [G84×(G70×51B)]×P62 yarns averaged 2926

while the predicted ones obtained from the four equations and SCI data averaged 2843, 2859, 2872,

2853 and 2859 respectively These results indicated that the differences between means of the

determined skein strength of Delta LS & ELS cottons and means of the corresponding predicted

ones ranged from 2 in Giza 92 to 114 units in Giza 77 x Ps6 which is lower than the testing error in

measuring skein strength. However the differences between the individual values of determined

skein strength and the corresponding predicted ones are bigger than noticed between average

values. These differences ranged from 0 to 116 units for the prediction using equation 1, ranged

from 1 to 108 units for the values obtained from applying equation 2, ranged from 1 to 110 units

when applying equation 3 and from 0 to 114 units when applying equation 4, while showed bigger

range when using SCI data, being from 5 to 140. It is clear from these results that all the prediction

equations provide reliable predicted skein strength values except the prediction based on SCI data

which showed higher fluctuation than the other equations, however equations 2, 3 and 4 showed

smaller differences between individual values of determined skein strength and the corresponding

ones (< 100 units) compared to equation 1 and the prediction via SCI data. Furthermore, as noticed

in case of Upper Egypt cottons, it is more practical to use equation 2 since it depends only on the

main four fiber properties: length, length uniformity, strength and mike, while the addition of Rd%

and +b in equation 1, maturity and elongation in equation 2, maturity and Rd% in equation 4 did not

improve the accuracy of skein strength prediction compared to equation 2.

Based on the obtained data it is decided to use the equation that include length, uniformity, strength,

and mike (equation 2) in programming HVI spectrum system in Cotton Res. Institute to get reliable

predicted values of skein strength in the same table of HVI fiber quality data.

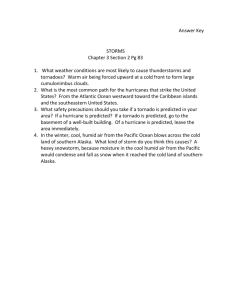

The relationship between SCI and yarn strength:

SCI is a calculation for predicting the overall quality and spinability of cotton to be used on bale

management and quality evaluation programs. It depends on fiber data and derived from regression

equation. It is developed by HVI manufacturers to substitute the predicted values of CSP and

breaking load of the tested cotton samples. Therefore it is worthy to study the relationship between

yarn strength and the corresponding SCI values. The results in Table 1, Table 2, Figure 1, Figure 2

and Fig. 3 indicated that the correlation between skein strength and SCI was highly significant

whether calculated from Upper Egypt cottons data or from the Delta LS & ELS fiber cottons data.

The recorded values of simple correlation coefficients were 0.86 for Upper Egypt cottons and 0.95

for Delta LS and ELS cottons. These results indicate that SCI is a good Criterion for expressing the

spinning value of cotton. However the prediction of yarn strength via SCI data showed more

fluctuation in the predicted values compared to the prediction via fiber data.

References

ASTM D1578-93R00. (2005). Standard Test Method for Breaking Strength of Yarn in Skein Form.

Annual Book of ASTM Standards. Vol. 7. 02 Section 7.

ASTM D5867-05. (2005). Standard Test Method for measurement of physical properties of cotton

fibers by High Volume Instruments. Annual Book of ASTM Standards. Vol. 7. 02 Section 7.

Cheng L., and D. L. Adams. Yarn strength prediction using neural networks. I. Fiber properties and

yarn strength relationship. Textile Research Journal, vol. 65, no. 9, pp. 495–500, 1995.

El-Mogazhy, Y., Broughton, R. M. (1992). Regression observation of HVI fiber properties, yarn

quality, and processing performance of medium staple cotton. Part I: HVI fiber parameter, Text.

Res. J., 62 (4), 218-226.

El-Mogazhy, Y., Broughton, R., and Lynch, W. K.(1990). A statistical approach for determining the

technological value of cotton using HVI fiber properties, Text. Res. J., 60 (9), 495-500.

Ethridge, M. D., J. D. Towery, and J. F. Hembree. (1982). Estimating func nal relationships

between fiber properties and the strength of open-end spun yarns. Text. Res. J., vol. 52, no. 1, pp.

35–45.

Frydrych, I., (1992). A new approach for predicting strength properties of yarns. Tex.Res. J., 62,

340-348.

Hequet, E.F. and Abidi, N. (2008). Relationships between fiber and yarn tensile properties

properties. Proceedings of 2008 Beltwide Cotton Conferences, Nashville, Tennessee ,PP. 14681471.

Moon W. Suh, Hyun-Jin Koo and Michael D. Watson. (1998). Estimation of HVI Bundle Modulus

and Toughness as Determinants to Tensile Properties of Spun Yarns. Proceedings of 1998 Beltwide

Cotton Conferences, PP 1530-1537.

Pan, N. (2001). Relationship between fiber and yarn strength, Tex. Res. J., 61, 960-964.

Price, C. Senter, H. J. Foulk, G. Gamble, and W. Meredith. (2009). Relationship of fiber properties

to vortex yarn quality viapartial least squares. Journal of Engineered Fibers and Fabrics, vol. 4, no.

4, pp. 37–46.

Sief, M. G., S. H. M. El-Hariry, and M. B. El- Kadi (1994). Predicted yarn strength of Egyptian

cotton using HVI testing. The 19th Int. Conf.for Stat. & Computer Science, Cairo, Egypt, April

1994:213-227.

Suh M.W., K. Hyun-Jui, and C. Xiaoling. (1998). Prediction of yarn tensile properties based on

HVI testing of 36 U.S. Upland cottons,. in Proceedings of the Beltwide Cotton Conferences,

pp.786–790, San Diego, Calif, USA, January.

Ureyen M. E. and H. Kadoglu. (2006). Regressional estimation of ring cotton yarn properties from

HVI fiber properties. Text. Res. J., vol. 76, no. 5, pp. 360–366.

الملخص العربى

معادالت جديدة للتنبؤ بمتانة الغزل في القطن المصري باستخدام قياسات

HVI Spectrum

تتميز الطرز الحديثة من أجهزة HVIبالسرعة العالية والدقة المطوبة في قياس صفات جودة القطن

عالوة علي حساب معامل للقيمة الغزلية للقطن SCIمن خالل معادالت تنبوء تعتمد علي صفات جودة التيلة

المقاسة مما يمثل فائدة كبيرة لكل المعنيين بصفات جودة القطن .ولما كان مربي القطن في مصر يعتمد علي

متانة الشلة في تقييم صفات جودة التراكيب الوراثية واألصناف التجارية في برامج التربية والمحافظة علي

النقاوة الوراثية ألصناف القطن المصري لذا لزم إجراء هذه الدراسة للوصول إلي أفضل المعادالت للتنبوء

بمتانة الغزل ألقطان الوجه القبلي وألقطان الوجه البحري الطويلة وفائقة الطول من قياسات صفات جودة التيلة

المقدرة بجهاز HVI spectrumوبرمجته بها للحصول علي قيمة تقديرية لمتانة الشلة للعينات المختبرة

إلستخدامها حين اليكفي وزن العينة للغزل واختبارات الخيوط.

إشتملت الدراسة علي عشرة من أصناف القطن المصري والهجن المبشرة هي جيرة , 80حيزة 90

جيزة / 90أسترالي ,ج // 83ج /// 5844 / 75ج 80من أقطان الوجه القبلي ,جيزة / 10229, 86ج 86

من األقطان الطويلة بالوجه البحري وجيزة , 88جيزة 92وجيزة , 93ج //84ج / 70ج51ب ///س 62من

ااألقطان فائقة الطول حيث تم تقدير صفات جودة التيلة بجهاز HVI spectrumلعدد 250عينة من رتب

مختلفة موسم 2011 , 2010وغزل أقطان الوجه القبلي علي عد 40مسرح وبرم 4وأقطان الوجه البحري

علي عد 60مسرح وبرم 3,6كما هو متبع في برامج التربية والمحافظة بمعهد بحوث القطن بالجيزة .تم تقدير

متانة الشلة للخيوط المغزولة واستخدمت قياسات التيلة وقيم SCIومتانة الشلة في حساب خمسة معادالت أنحدار

متعدد للتنبوء بمتانة الشلة من قياسات صفات جودة التيلة المقدرة بجهاز HVIلألقطان المختبرة.

تم إختبار مدي دقة معادالت التنبوء المتحصل عليها بتطبيقها علي قياسات HVIلألقطان المذكورة موسم 2011

وحساب الفروق بين متانة الشلة المقاسة والمتنبأ بها لكل صنف وهجين مبشر وقد بينت الدراسة دقة المعادالت

التي تم التوصل إليها وكان أفضلها المعادلة التي إشتملت فقط علي قياسات طول التيلة وإنتظام الطول ومتانة

التيلة وقراءة الميكرونير حيث كانت الفروق بين متانة الشلة المقاسة بجهاز جودبراند والمحسوبة من هذه

المعادلة أقل من 100وحدة .

بينت الدراسة أن العالقة بين متانة الشلة ومعامل الغزل SCIموجبة وعالية المعنوية إال أن قيم متانة

الشلة المحسوبة من بيانات SCIاتصفت بالتباين العالي وارتفاع الفروق بينها وبين متانة الشلة المقاسة إلى 140

وحدة في بعض الحاالت

تم برمجة جهاز HVI spectrumبالمعادلة التي تشتمل علي الطول وانتظامه والمتانة والميكرونير وهي كما

يلي :

متانة الشلة لخيوط 40مسرح ألقطان الوجه القبلي = x 46.954 + 961.717-الطول بالمم x 5.211 +

انتظام الطول x 8.994+متانة التيلة x 20.442 -قراءة الميكرونير

متانة الشلة لخيوط 60مسرح ألقطان الوجه البحري وفائق الطول = x 47.844 + 2500.343-الطول بالمم

x 28.365انتظام الطول x 37.044 +متانة التيلة x 138.953 -قراءة الميكرونير

Table 1: HVI fiber data, SCI, determined and predicted skein strength of 40’s carded yarns for Upper Egypt LS commercial cotton

varieties and promising crosses.

Genotype

G80

Mean

Max

Min

G90

Mean

Max

Min

UHM UI

Str. Elon.

mm

% g/tex

%

3.7

0.89

31.5 85.0 37.1

8.0

3.9

0.91

31.2 84.2 39.0

8.0

3.5

0.88

30.2 85.5 36.3

7.6

3.5

0.88

31.4 85.7 36.0

8.1

3.5

0.87

31.1 85.0 37.0

8.0

3.3

0.85

30.8 85.4 35.7

7.4

3.5

0.87

30.8 85.8 36.1

7.5

3.5

0.86

31.0 85.3 37.9

8.0

3.6

0.89

31.3 85.2 35.3

7.5

3.5

0.86

31.1 83.9 36.4

7.5

3.6

0.88

31.0 85.1 36.7

7.8

3.9

0.91

31.5 85.8 39.0

8.1

3.3

0.85

30.2 83.9 35.3

7.4

4.1

0.94

30.5 85.3 37.7

8.2

3.8

0.90

30.0 83.3 34.0

8.3

3.7

0.90

31.0 83.1 35.5

8.4

4.1

0.93

30.0 83.0 35.0

7.9

4.2

0.95

30.4 84.0 36.0

7.9

4.3

0.94

30.3 85.0 35.4

7.9

4.3

0.94

30.0 85.6 35.5

8.3

4.0

0.90

29.4 84.0 34.7

8.3

4.2

0.92

30.2 85.0 35.7

8.2

3.8

0.90

30.1 85.3 34.0

8.2

4.1

0.92

30.2 84.4 35.4

8.2

4.3

0.95

31.0 85.6 37.7

8.4

3.7

0.90

29.4 83.0 34.0

7.9

P1: Predicted skein strength using equation 1

P2: Predicted skein strength using equation 2

P5: Predicted skein strength using SCI data

Mike

Mat.

Rd

dtr.P1

P2

.+b SCI Detr.

%

P1

66.3 12.2 170 2260 2355 -95 2331

66.6 12.9 170 2370 2438 -68 2383

66.1 12.8 169 2295 2313 -18 2246

66.9 12.5 172 2225 2339 -114 2291

67.9 12.7 172 2315 2369 -54 2313

66.9 12.5 171 2190 2308 -118 2254

67.0 12.9 172 2225 2339 -114 2268

67.5 12.5 175 2270 2387 -117 2345

65.1 12.7 165 2225 2317 -92 2255

65.5 12.8 163 2255 2351 -96 2284

66.6 12.7 170 2259 2352

89

2297

67.9 12.9 175 2370 2438 118 2383

65.1 12.2 163 2185 2308

18

2246

65.5 11.8 167 2245 2294 -49 2301

63.9 12.1 146 2080 2162 -82 2129

66.1 11.9 155 2205 2250 -45 2235

62.7 11.7 145 2185 2162

23

2160

64.9 11.8 154 2210 2220 -10 2221

65.8 11.8 156 2230 2194

36

2196

65.5 11.2 159 2250 2151

99

2189

66.1 11.9 151 2125 2141 -16 2128

65.8 11.7 158 2250 2198

52

2205

66.7 11.9 159 2150 2161 -11 2144

65.3 11.8 155 2193 2193

42

2191

66.7 12.1 167 2250 2294

99

2301

62.7 11.2 145 2080 2141

10

2128

P3: Predicted skein strength using equation 3

P4: Predicted skein strength using equation 4

dtr.P2

-71

-13

49

-66

2

-64

-43

-75

-30

-29

44

75

2

-56

-49

-30

25

-11

34

61

-3

45

6

32

61

3

P3

2333

2385

2218

2299

2310

2212

2235

2339

2228

2250

2281

2385

2212

2319

2147

2263

2158

2223

2197

2212

2143

2220

2157

2204

2319

2143

dtr.P3

-73

-15

77

-74

5

-22

-10

-69

-3

5

39

77

5

-74

-67

-58

27

-13

33

38

-18

30

-7

34

74

3

P4

2334

2383

2248

2297

2311

2253

2268

2338

2265

2283

2298

2383

2248

2308

2137

2243

2171

2232

2201

2193

2125

2205

2149

2197

2308

2125

dtr.P4

-74

-13

47

-72

4

-63

-43

-68

-40

-28

45

74

4

-63

-57

-38

14

-22

29

57

0

45

1

33

63

0

P5

Via SCI

2340

2340

2331

2359

2359

2350

2359

2387

2293

2274

2339

2387

2274

2312

2114

2199

2104

2189

2208

2236

2161

2227

2236

2199

2312

2104

dtr. P5

-80

30

-36

-134

-44

-130

-134

-117

-108

-19

86

140

19

-67

-34

6

81

21

22

14

-36

23

-86

39

86

6

Table 1: continue.

G90XAUS

Genotype

{G83(G75×8544)}G80

Mean

Max

Min

Mean

Max

Min

UHM UI

Str. Elon.

mm

% g/tex

%

0.93

4.5

30.3 85.1 32.5

7.6

0.93

4.5

29.9 82.5 33.9

8.5

0.93

4.5

29.3 83.0 34.9

7.6

0.94

4.6

29.1 83.6 33.9

8.1

0.95

4.6

28.2 83.5 32.1

7.8

0.93

4.5

28.9 84.0 33.3

8.0

0.94

4.5

29.1 84.3 33.5

8.2

0.95

4.6

30.1 85.8 33.8

8.3

0.96

4.5

29.3 83.8 35.0

7.6

0.95

4.6

30.1 85.8 33.9

8.3

0.94

4.5

29.4 84.1 33.7

8.0

1.0

4.6

30.3 85.8 35.0

8.5

0.9

4.5

28.2 82.5 32.1

7.6

0.94

4.5

29.2 84.5 38.5

8.3

0.93

4.4

31.9 86.7 38.7

7.8

0.92

4.3

29.6 83.6 37.3

8.2

0.94

4.2

30.3 84.3 38.2

8.1

0.92

4.2

29.4 84.4 34.6

8.3

0.93

4.4

29.4 84.9 35.4

8.2

0.92

4.4

29.4 84.5 36.0

8.0

0.93

4.4

29.4 83.6 38.2

8.3

0.92

4.3

30.5 84.3 37.5

8.3

0.93

4.4

29.5 83.0 36.9

7.8

0.93

4.4

29.9 84.4 37.1

8.1

0.94

4.5

31.9 86.7 38.7

8.3

0.92

4.2

29.2 83.0 34.6

7.8

P1: Predicted skein strength using equation 1

P2: Predicted skein strength using equation 2

P5: Predicted skein strength using SCI data

Mike

Mat.

Rd

dtr.P1

P2

.+b SCI Detr.

%

P1

61.8 12.9 144 2100 2151 -51 2080

63.3 12.9 136 2250 2170 -20 2102

60.1 12.4 138 2105 2154 -49 2115

58.5 12.9 136 2140 2139

1

2068

62.8 12.9 131 2000 2029 -29 1955

62.1 13.1 139 2050 2122 -72 2039

59.8 13.1 140 2080 2142 -62 2058

65.9 13.1 153 2085 2195 -110 2123

58.8 13.2 142 2200 2100 100 2123

58.7 12.9 149 2090 2194 -104 2127

61.2 12.9 141 2110 2140

60

2079

65.9 13.2 153 2250 2195 110 2127

58.5 12.4 131 2000 2029

1

1955

66.5 11.5 159 2265 2226

39

2259

66.8 11.6 186 2385 2375

10

2407

67.3 11.5 155 2300 2204

96

2230

67.4 11.6 163 2330 2281

49

2304

67.7 11.6 152 2145 2112

33

2122

66.3 11.6 154 2205 2136

69

2152

67.1 11.5 154 2255 2149 106 2173

67.0 11.7 156 2210 2235 -25 2254

66.0 11.5 160 2270 2257

13

2284

66.8 11.8 150 2240 2197

43

2205

66.9 11.6 159 2261 2217

46

2239

67.7 11.8 186 2385 2375 106 2407

66.0 11.5 150 2145 2112

10

2122

P3: Predicted skein strength using equation 3

P4: Predicted skein strength using equation 4

dtr.P2

20

48

-10

72

45

11

22

-38

77

-37

38

77

10

6

-22

70

26

23

53

82

-44

-14

35

38

82

6

P3

2063

2136

2092

2076

1945

2040

2073

2149

2105

2152

2083

2152

1945

2275

2403

2240

2314

2140

2164

2171

2270

2304

2193

2247

2403

2140

dtr.P3

37

14

13

64

55

10

7

-64

95

-62

42

95

7

-10

-18

60

16

5

41

84

-60

-34

47

38

84

5

P4

2087

2104

2118

2075

1960

2041

2066

2126

2137

2139

2085

2139

1960

2249

2404

2221

2304

2119

2147

2163

2244

2279

2197

2233

2404

2119

Act.P4

13

46

-13

65

40

9

14

-41

63

-49

35

65

9

16

-19

79

26

26

58

92

-34

-9

43

40

92

9

P5

Via SCI

2095

2019

2038

2019

1972

2047

2057

2180

2076

2142

2064

2180

1972

2236

2406

2199

2274

2170

2189

2189

2208

2246

2151

2227

2406

2151

dtr. P5

5

131

67

121

28

3

23

-95

124

-52

65

131

3

29

-21

101

56

-25

16

66

2

24

89

43

101

2

Table 2: HVI fiber data, SCI, determined and predicted skein strength of 60’s carded yarns for Delta LS and ELS Egyptian commercial cotton

varieties and promising crosses.

UHM UI

Str.

mm

% g/tex

4.7

0.96 33.4 86.6 44.3

4.8

0.96 34.0 86.9 44.3

4.8

0.98 33.7 86.2 44.4

4.6

0.95 34.1 86.2 45.7

4.8

0.96 33.6 86.4 44.6

Giza 86

4.5

0.95 33.4 85.6 45.4

4.5

0.98 34.2 86.0 43.0

4.6

0.95 33.7 85.8 45.1

4.6

0.98 33.5 86.8 43.3

4.7

0.96 33.5 86.6 42.2

Mean

4.7

0.96 33.7 86.3 44.2

Max

4.8

0.98 34.2 86.9 45.7

Min

4.5

0.95 33.4 85.6 42.2

4.3

0.94 33.5 87.6 40.0

4.2

0.95 33.8 87.6 43.5

4.3

0.94 34.4 87.2 42.0

4.3

0.94 34.7 87.9 41.7

4.3

0.92 33.5 87.8 40.1

10229XG86

4.3

0.95 34.3 87.0 41.7

4.3

0.94 34.3 87.4 40.1

4.3

0.93 34.1 87.8 40.0

4.3

0.94 33.4 88.5 40.0

4.4

0.94 34.5 87.7 41.7

Mean

4.3

0.94 34.1 87.7 41.1

Max

4.4

0.95 34.7 88.5 43.5

Min

4.2

0.92 33.4

87

40

P1: Predicted skein strength using equation 1

P2: Predicted skein strength using equation 2

P5: Predicted skein strength using SCI data

Genotype

Mike

Mat

Elon. Rd

dtr.P1

.+b SCI Deter.

%

%

P1

7.6

75.7 8.2 197 2430 2538 -108

7.8

77.4 8.8 200 2450 2557 -107

7.8

77.9 8.5 197 2470 2522 -52

7.8

78.4 8.0 203 2550 2605 -55

7.7

78.7 8.5 199 2530 2527

3

7.5

77.3 8.3 199 2590 2568

22

7.9

78.3 8.6 196 2460 2525 -65

7.4

78.2 8.6 199 2555 2562

-7

7.3

75.0 8.4 196 2470 2530 -60

7.1

76.1 8.3 192 2355 2465 -110

7.6

77.3 8.4 198 2486 2540

59

7.9

78.7 8.8 203 2590 2605 110

7.1

75.0 8.0 192 2355 2465

3

7.8

79.6 8.8 196 2515 2453

62

7.8

77.7 8.8 201 2530 2615 -85

7.2

78.0 8.2 201 2595 2555

40

7.4

75.6 8.4 202 2570 2591 -21

7.6

75.6 8.6 195 2480 2480

0

7.6

75.1 8.6 197 2460 2552 -92

7.6

74.8 8.6 194 2450 2507 -57

7.1

70.8 8.1 192 2410 2521 -111

7.7

74.5 8.7 197 2420 2498 -78

7.7

74.3 8.7 199 2515 2573 -58

7.6

75.6 8.6 198 2495 2535

60

7.8

79.6 8.8 202 2595 2615 111

7.1

70.8 8.1 192 2410 2453

0

P3: Predicted skein strength using equation 3

P4: Predicted skein strength using equation 4

P2

2532

2555

2535

2630

2543

2582

2543

2577

2529

2459

2549

2630

2459

2471

2629

2577

2600

2481

2556

2508

2506

2492

2571

2539

2629

2471

dtr.P2

-102

-105

-65

-80

-13

8

-83

-22

-59

-104

64

105

8

44

-99

18

-30

-1

-96

-58

-96

-72

-56

57

99

1

P3

2465

2455

2488

2513

2440

2509

2557

2492

2551

2440

2491

2557

2440

2438

2598

2547

2557

2397

2540

2479

2473

2458

2499

2498

2598

2397

dtr.P3

-35

-5

-18

37

90

81

-97

63

-81

-85

59

97

5

77

-68

48

13

83

-80

-29

-63

-38

16

52

83

13

P4

2487

2479

2506

2531

2451

2517

2574

2491

2559

2435

2503

2574

2435

2447

2617

2536

2570

2422

2564

2506

2500

2492

2535

2519

2617

2422

dtr.P4

-57

-29

-36

19

79

73

-114

64

-89

-80

64

114

19

68

-87

59

0

58

-104

-56

-90

-72

-20

61

104

0

P5

via SCI

2568

2588

2568

2648

2595

2595

2554

2595

2554

2491

2577

2648

2491

2554

2662

2622

2635

2541

2568

2528

2501

2558

2595

2576

2762

2501

dtr. P5

-138

-138

-98

-98

-65

-5

-94

-40

-84

-136

91

138

5

-39

-132

-27

-65

-61

-108

-78

-91

-138

-80

82

138

27

Table 2: continue.

UHM UI

Str.

mm

% g/tex

4.0

0.96 36.8 87.0 48.1

3.9

0.95 36.0 88.9 46.0

3.9

0.95 37.4 88.0 48.1

4.0

0.95 37.5 87.0 47.6

3.9

0.94 36.4 88.9 49.4

Giza 88

3.9

0.95 37.4 88.2 47.9

3.9

0.94 36.4 88.0 46.0

4.0

0.96 37.7 87.0 49.6

3.9

0.95 37.4 88.6 46.2

4.0

0.96 36.3 88.6 48.5

Mean

3.9

0.95 36.9 88.0 47.6

Max

4.0

0.96 37.7 88.9 49.6

Min

3.9

0.94 36.0 87.0 46.0

3.9

0.97 34.3 88.2 48.7

3.7

0.96 34.1 87.2 47.8

3.7

0.95 34.3 88.7 47.1

3.8

0.96 34.0 88.8 48.1

3.6

0.95 33.9 88.1 46.7

Giza 92

3.7

0.95 33.8 87.6 48.6

3.6

0.94 34.4 87.9 48.0

3.6

0.94 35.1 88.1 49.0

3.7

0.96 34.4 88.8 47.9

3.8

0.96 33.4 88.7 48.5

Mean

3.7

0.95 34.2 88.2 48.0

Max

3.9

0.97 35.1 88.8 49.0

Min

3.6

0.94 33.4 87.2 46.7

P1: Predicted skein strength using equation 1

P2: Predicted skein strength using equation 2

P5: Predicted skein strength using SCI data

Genotype

Mike

Mat

Elon

%

7.3

7.1

7.4

7.5

7.3

7.0

7.2

7.6

7.0

7.0

7.2

7.6

7.0

7.3

6.9

6.9

6.7

6.6

6.6

6.4

7.2

6.6

6.0

6.7

7.3

6.0

Rd

Act.P1

.+b SCI Deter.

%

P1

65.7 11.9 218 2935 3008 -73

66.5 11.9 221 2930 2960 -30

66.4 11.9 225 3070 3072

-2

64.4 11.6 219 3025 2988

37

67.8 11.1 232 2985 3087 -102

68.1 11.2 227 2995 3056 -61

69.2 11.2 219 2995 2932

63

68.4 11.8 226 2990 3088 -98

68.5 11.7 224 2955 3008 -53

67.3 11.4 227 2990 3034 -44

67.2 11.6 223 2987 3023

56

69.2 11.9 232 3070 3088 102

64.4 11.1 214 2930 2932

2

78.0 8.9 229 3005 2900 105

74.5 8.8 220 2900 2852

48

77.0 8.8 227 2975 2866 109

77.9 8.8 230 2980 2874 106

78.5 9.2 225 2900 2826

74

76.7 8.6 225 2995 2887 108

78.3 8.8 228 2975 2887

88

77.7 8.8 233 3065 2962 103

73.6 8.8 228 2990 2919

71

76.4 8.9 229 2990 2868 122

76.9 8.8 227 2978 2884

93

4

78.5 9.2 233 3065 2962 108

73.6 8.6 220 2900 2826

48

P3: Predicted skein strength using equation 3

P4: Predicted skein strength using equation 4

P2

2954

2906

3025

2932

3051

3023

2899

3053

2972

2990

2981

3053

2899

2905

2861

2887

2899

2850

2888

2917

2993

2925

2890

2901

2993

2850

dtr.P2

-19

24

45

93

-66

-28

96

-63

-17

0

45

96

0

100

39

88

81

50

107

58

72

65

100

76

108

39

P3

2942

2908

2986

2915

2973

3005

2892

3003

2970

2980

2956

3005

2892

2938

2938

2932

2955

2938

2940

2968

2988

3002

2972

2957

3002

2932

dtr.P3

-7

22

84

110

12

-10

103

-13

-15

10

39

110

7

67

-38

43

25

-38

55

7

77

-12

18

38

77

7

P4

3004

2957

3050

2975

3026

3040

2911

3065

3003

3020

3005

3065

2911

2928

2928

2910

2917

2891

2905

2914

2977

2984

2909

2926

2984

2891

Act.P4

-69

-27

20

50

-41

-45

84

-75

-48

-30

49

84

20

77

-28

65

63

9

90

61

88

6

81

57

90

6

P5

via SCI

2850

2890

2943

2896

3037

2970

2863

2957

2930

2970

2931

3037

2796

2997

2876

2970

3011

2943

2943

2984

3051

2984

2997

2976

3051

2876

dtr. P5

85

40

127

129

-52

25

132

33

25

20

67

129

20

8

24

5

-31

-43

52

-9

14

6

-7

20

52

5

Table 2: continue.

UHM

UI

Str.

mm

%

g/tex

3.3

0.92

37.2

88.8 46.4

3.2

0.89

36.2

87.7 46.6

3.1

0.89

37.1

87.4 45.7

3.3

0.93

36.5

88.8 46.8

3.2

0.89

36.8

87.1 46.2

3.2

0.92

38.0

88.8 45.3

3.2

0.90

38.1

88.8 45.5

3.1

0.92

37.0

88.3 49.2

3.1

0.91

36.9

88.0 46.7

3.1

0.91

36.5

87.5 47.2

Mean

3.2

0.91

37.0

88.1 46.6

Max

3.3

0.93

38.1

88.8 49.2

Min

3.1

0.89

36.2

87.1 45.3

3.9

0.93

35.8

87.5 47.6

3.9

0.96

36.5

86.5 46.7

4.0

0.94

36.5

88.8 45.3

4.1

0.95

35.8

87.2 46.2

4.0

0.96

36.5

87.1 46.4

4.0

0.94

35.5

87.7 45.9

4.1

0.95

35.9

87.2 47.5

4.1

0.94

36.2

86.8 44.5

4.0

0.94

36.1

88.4 44.8

4.1

0.94

35.8

88.7 46.0

Mean

4.0

0.95

36.1

87.6 46.1

Max

4.1 0.96

36.5 88.8 47.6

Min

3.9 0.93

35.5 86.5 44.5

P1: Predicted skein strength using equation 1

P2: Predicted skein strength using equation 2

P5: Predicted skein strength using SCI data

{G84×(G70×G51B)}×P62

G77XPs6

Genotype

Mike

Mat.

Elon Rd

dtr.P1

.+b SCI Deter.

%

%

P1

6.8

65.9 11.3 229 3100 3099

1

6.4

64.7 11.6 228 3100 3053

47

6.3

64.0 11.7 225 3100 3069

31

6.6

66.7 11.7 229 3060 3083 -23

6.3

65.5 11.1 220 3070 3039

31

6.0

65.7 11.7 228 3100 3111 -11

6.2

66.9 11.5 230 3100 3115 -15

6.3

64.4 11.6 235 3150 3213 -63

6.7

66.0 11.5 227 3100 3101

-1

6.4

65.7 11.6 226 3120 3090

30

6.4

65.6 11.5 227 3100 3097

25

6.8

66.9 11.7 235 3150 3213

63

6.0

64.0 11.1 220 3060 3039

1

6.2

76.4 8.8 224 2980 2892

88

6.4

76.4 8.8 218 2950 2862

88

6.5

74.5 8.7 223 2965 2872

93

6.8

75.3 8.8 216 2925 2813 112

6.0

76.4 9.0 219 2910 2857

53

6.0

75.1 8.8 218 2915 2817

98

6.2

74.3 9.3 219 2990 2874 116

6.7

73.6 8.4 209 2815 2762

53

6.3

76.2 8.8 220 2850 2817

33

6.2

73.0 9.0 221 2960 2861

99

6.3

75.1 8.8 219 2926 2843

83

6.8 76.4 9.3 224

2990 2892 116

6

73 8.4 209

2815 2762

33

P3: Predicted skein strength using equation 3

P4: Predicted skein strength using equation 4

P2

3059

3001

3016

3040

2998

3070

3082

3166

3060

3046

3054

3166

2998

2916

2888

2887

2828

2880

2830

2890

2772

2838

2863

2859

2916

2772

dtr.P2

41

99

84

20

72

30

18

-16

40

74

49

99

16

64

62

78

97

30

85

100

43

12

97

67

100

12

P3

3080

2994

3028

3099

2991

3156

3098

3218

3096

3096

3085

3218

2984

2897

2958

2879

2821

2952

2853

2888

2763

2851

2859

2872

2958

2763

dtrP3

20

106

72

-39

79

-56

2

-68

4

24

47

106

2

83

-8

86

104

-42

62

102

52

-1

101

64

104

1

P4

3117

3011

3053

3121

3008

3154

3101

3239

3127

3114

3105

3239

3008

2877

2913

2854

2815

2889

2820

2878

2752

2806

2849

2853

2913

2752

dtr.P4

-17

89

47

-61

62

-54

-1

-89

-27

6

45

89

1

103

37

111

110

21

95

112

63

44

111

83

112

21

P5

via SCI

2997

2977

2960

2997

2966

2984

3011

3078

2970

2987

2986

3078

2960

2930

2850

2917

2823

2863

2850

2863

2729

2876

2890

2859

2930

2729

dtr. P5

103

123

140

63

134

116

89

72

130

133

119

140

63

50

100

48

102

47

65

127

86

-26

70

72

127

26

skein strength

Actual

P1

P2

P3

P4

P5

2500

2400

2300

2200

2100

2000

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

G 80

G 90

G 90×Aus.

{G 83(G 75×8544)}G 80

Fig.1 Determined and predicted skein strength for 40’s carded yarns spun from Upper Egypt

cottons.

Skein strength

Actual

P1

P2

P3

P4

P5

3200

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

G 86

10229XG 86

G 88

G 92

G 77XPs6

{G 84×(G 70×G 51B)}×P62

Fig.2 Determined and predicted skein strength for 60’s carded yarns spun from Delta LS & ELS

Egyptian cottons

y= 1340.6+5.5319x r = 0.86

y = 1040.8-17.969x r = 0.95

3300

Determined skein strength

Determined skein strength

2400

2350

2300

2250

2200

2150

2100

2050

2000

3100

3000

2900

2800

2700

2600

2500

2400

2300

1950

1900

100

3200

110

120 130

140

150

SCI

160 170

180

190

2200

190 195 200 205 210 215 220 225 230 235 240

SCI

Upper Egypt cottons data

Delta LS & ELS cottons data

Fig.3 Regression equations and correlation coefficients for SCI and determined skein strength of

Upper Egypt and Delta LS & ELS cottons.