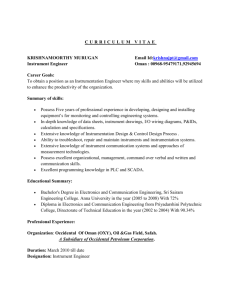

Curriculum Vitae

Curriculum Vitae

B.GAVASKAR

B.E

,

6/71,R.C.School street,

Kavalkinaru ,

Tirunelveli Dist ,

Tamilnadu, 627105 .

Phone : 0091-9043114313, 0091-9942526055 .

E-mail : bgavaskar@yahoo.co.in

Qualification:

Bachelor’s Degree

University

:

:

B.E Degree in ELECTRONICS & COMMUNICATION

Manonmanium Suntharanar University, Tirunelveli.

Experience :( 9 years)

1) From Sep 2008 to till date in OFFSHORE Azurite (FDPSO) vessel

Designation : INSTRUMENT & CONTROL SUPERVISOR

Client

Company

:

:

MURPHY OIL COMPANY.

PROSAFE, Singapore & Congo.

2) From Mar 2008 to Aug 2008,

Designation

Client

Company

3) From April 2007 to Mar 2008,

Designation

Client

:

:

:

INSTRUMENT & CONTROL SYSTEM ENGINEER

YEMEN LNG COMPANY, Yemen.

TECHNIP, UAE.

:

:

:

SYSTEM ENGINEER

Qatar Gas, Qatar (Ras Laffan Site)

Doha Petroleum Construction Co LTD, Qatar. Company

4) From March 2006 to Feb 2007,

Designation

Client

:

:

:

INSTRUMENT ENGINEER

Petroleum Development Oman (PDO)

Al-Turki Enterprises L.L.C., Oman. Company

5) From 2004 Aug to Feb 2006,

Designation

Client

Company

:

:

:

INSTRUMENT MAINTENANCE ENGINEER

Oil India Limited , India.

OFS Industries PVT LTD, Rajasthan.

6) From 2002 July to 2004 July in OFFSHORE field,

Designation : INSTRUMENT SUPERVISOR

Client

Company

:

:

Oil and Natural Gas Corporation (ONGC)

S.S.Construction (Oil & Gas Field), Mumbai.

.

1) From Sep 2008 to till date in FDPSO Azurite, Singapore & Congo

Present Job/Responsibility : -

Working as an Instrument & Control Supervisor in Offshore for AZURITE Floating Drilling

Production Storage & Offloading ( FDPSO) vessel with 28/28 rotation and responsible for all the Instrument &

Control system operations of the vessel.

Special Knowledge & Skills:

Having good experience in Maintenance and troubleshooting of all Top side modules instruments and

PM, CM and SCPM according to the Maximo server report.

Having good knowledge and experience in Metering system instruments and the control system .

Having good experience in Proving skid system ( Omni flow computer system ).

Working on Maximo software for Work Order creation, Purchase Order creation, Inventory Report and

service report etc..

Having good experience & knowledge in Instrument & Control systems of the vessel ICSS system such

as Siemens PLC, Triconex PLC, and Delta V DCS etc.

Having good experience in Minerva 2000 addressable Fire & Gas panel configuration and commissioning of the system.

Having knowledge in all types of Smoke detectors, Heat detectors and Gas detectors.

Working experience in Alborg boilers (90 tons of steam per hour) and having good knowledge in

Burner Management System (BMS) , Oil and Gas Fuel system and troubleshooting of boilers.

Working experience on SHINKO Steam turbines control system, Woodward 505 turbine control panel.

Having good experience in Sea water filtration and injection module system.

Having good experience in calibration & commissioning of analyzer instruments such as Oil in Water

Analyzers (Teledyne, Sigrist), Oxygen Analyzers (Rosemount) and water in oil analyzer (BS&W) .

Having good experience in Cargo Control system with the Hydraulic operated valves such as &

DOMCOS & Nakakita cargo control valves.

Having good knowledge in Emerson SAB Radar system .

Having good knowledge and experience in all types of field related instruments such as all kind of transmitters, Control valves , analyzers, detectors, all kind of switches etc….

Auto calibration & Tuning of HART protocol positioner such as Fisher 6010, 6020 etc….

Having good knowledge in Fire water pump & Foam fire fighting system.

Having knowledge in Spread mooring chain jack system .

Having good experience in working with SIEMENS PLC’s such as Siemens Quad log PLC, Simatic

S7-400 system and familiar the hardware system of the PLC.

Trained for Siemens PLC for operation by Company.

Familiar with the automation software , 4-mation and able to read the logic of the system.

Having good experience in ICONIX graphics software to change & create the graphics.

Having good experience and knowledge in LAN, WAN networking of the control system.

Familiar in taking server back-up and having good knowledge in creation of alarm events & Trends.

Knowledge in interface between the ICSS with the third party system such as vendor systems.

Having good knowledge of serial MODBUS communication, Ethernet communication and also the

protocols such as RS-232, RS-485 hardware protocols etc.

Having good experience working in VSAT communication system of the vessel.

Having good knowledge in PABX system, PAGA, Radar systems, GPS, Gyro system and CCTV .

Having good knowledge in networking system so that able to troubleshoot network related problems.

Additional Knowledge in Electrical systems:

Having experience on working in 6.6 KV High voltage operations Switch board with SIMOPRIME

Siemens High voltage control panel.

Having the good experience on normalizing the plant equipments in case of power Blackouts.

Having good experience in power Blackout sequences.

Having experience on Synchronization of the steam turbines with Essential generators, Emergency generator.

Having the operation knowledge of Process switchboard, Essential switch board and Emergency switchboard.

Having good knowledge about the motor control panels.

Having the knowledge of Ballasting pump control panels.

Knowledge about Electrical lighting systems, Navigational lights, Galley equipments etc.

Knowledge about electrostatic colaser transformer in the process modules.

2) From March 2008 to Aug 2008 in Yemen YLNG project (Balhaf)

Job/Responsibility : -

Worked as an Instrument / Control System Engineer in TECHNIP and responsible for the instrument control system activities for Yemen LNG project.

Special Knowledge & Skills:

Having good knowledge and experience in LNG projects such as Qatar Gas II LNG project, Yemen

LNG project.

Working with CSU team in YLNG project and having the good knowledge about the Integrated Control

& Safety System ( ICSS ) including PCS, PSS, SSS, FGS and MMS .

Writing Pre-Commissioning and Commissioning procedures for all Fire & Gas Systems, Control

systems such as Triconex ESD system, Fire & Gas system and High Integrity Pressure Production

System (HIPPS).

Writing the Functional Test procedures for all types of Control Valves, Motor Operated Valves (MOV)

and all the instruments.

Having the good knowledge about ICAPS system.

Populating all types of instruments in ICAPS system by referring the P&ID diagrams, Loop diagrams.

Having good knowledge in P&ID diagrams, Cause & Effect diagrams and Loop folder.

Reviewing Vender Documents and making Loop folder for the vender packages.

Having the good knowledge of all kind of field instruments.

ESD,F&G and HIPPS Systems(Triconex 10.3)

Working experience with Instrument Protective System (IPS) , Fire & Gas Detection System (FGS) with

Triconex PLC (Ver 10.3) & High Pressure Integrity Protection System (HIPPS) with Trident (Ver 1.3)

Having the knowledge of Functional Block diagrams, Logic Diagrams, reading of Cause & Effect

Diagrams etc.

Having experience on Checking the Functionality of the Triconex system according with the Cause &

Effect diagram.

Having good knowledge on configuration of Triconex system I/O cards, Communication cards etc……

Knowledge of Triconex System Hard ware, marshalling cabinets, installation and troubleshooting.

Having experience of Triconex system SAT activities such as checking Triconex system panel,

Marshaling cabinets etc…

Involved in Power Up, Hot SAT, Pre commissioning and commissioning activities of Triconex

Systems, Documents updating so on….

Redundancy check and functional check up of ESD & FGS systems controllers, I/O cards and diagnostics checks, SOE (Sequence of Events) checks etc…..

Updating package drawings and making As-builds.

3) From April 2007 to March 2008 in Qatar Gas II project (Ras Laffan Site)

Job/Responsibility : -

Worked as System Engineer in DOPET with EMERSON PROCESS MANAGEMENT (Main

Instrument & Control Contractor (MICC)) in Qatar Gas II project .

Special Knowledge & Skills:

i) DELTA V

Process Management System

Having experience in Delta V (Ver. 9.3) Distributed Control System with Foundation Field Bus (FF)

(Product of EMERSON PROCESS MANAGEMENT SYSTEM) in Qatar Gas II project.

Having experience of Foundation Field Bus System (FF) such as Field Bus Instruments Installation,

Calibration, Commissioning, Decommissioning and Configuration of the system etc…..

Having Good experience in commissioning the Field Bus devices such a Field Bus Transmitters, Digital

Valve Controllers (DVC) etc…..

Having experience of Field Bus system Field Bus Transmitter checking, noise checking, capacitance & resistance checking of Field Bus Signal Communication etc…e

Commissioning the Field Bus devices with the Delta V control system and doing the Lop check and

Functional check of the Field Bus devices.

Having the good knowledge on MODBUS Serial Communication, Ethernet Communication and

RS232, RS485 communication.

Communicating third party control system with Delta V control system.

Having the knowledge of Delta V system networks such as Plant Information Network(PIN),Process

Control Network(PCN),Operator Station Network(OSN),Operator Network(OS),Asset Management system Network etc…….

Experience in communicating third party Systems(using MODBUS protocol communication) such as

IPS, FGS, HIPPS, MMS, RDAS etc…. with Delta V systems.

Experience in Configuration of Delta V Redundant controllers, Field Bus cards (H1 cards), Analog I/O cards, Digital I/O cards and Serial cards.

Commissioning the HART and Field Bus Digital Valve Controllers (DVC, FISHER ) with Delta V control system and doing Partial Stroke Test for the ESD and BDV valves.

Having good experience & knowledge in DeltaV control system and familiar with Delta V explorer,

Operator configure, Control studio, Diagnostics etc………

Involved in all DeltaV DCS system Unpowered Checkup’s, Cold SAT, Hot SAT (Site Acceptance

Test), Document updating and punch clearance activities.

Involved in system Power Up, Hot SAT, Pre commissioning and commissioning activities of DeltaV

System cabinets, Marshalling cabinets, PDB panel and FO (Fiber Optic) cabinets.

ii) Asset Management System(AMS)

Experience in installation and configuration of AMS system software, installation of Multiplexers

(peperl + Futches, MTL) for HART transmitters etc…….

Configuration of Multiplexers to communicate with AMS system and connecting HART Transmitters with the system.

Connecting Delta V FF devices with AMS and configuration of Field Bus instruments, Digital Valve

Controllers (DVC) etc…..

Partial Stroke Checking of ESD valves and BDV using Valve Link software.

Connecting package systems with AMS systems and configuration of Multiplexers, Transmitter detection, calibration and loop checking using AMS system.

4) From March 2006 to Feb 2007 in PDO-Oman

Job/Responsibility : -

Working as Instrumentation Engineer in Al-Turki Enterprises, Muscat in PDO at BAHJA/NIMR sites,

South Oman.

Special Knowledge & Skills:

Working as a Maintenance Engineer in NRPS (NIMR Production Station) at NIMR site & Zulia

Production Station at BHAJA site.

Routine maintenance & calibration of all the instruments in NRPS & ZPS.

Involved in daily preventive, breakdown maintenance of plants systems and instruments.

Having hands on experience in start up, routine, breakdown, preventive maintenance and shut down activities in Oil & Gas field.

Hands on experience on all types of process field instruments (pressure, flow, level and temperature elements, transmitters, valves, MOV’s, controllers and communicators) including smart valve

positioners .

Completed the Project of water injection/water supply wells at Al-Burj with latest technology atomization with Auma actuators operated choke valve, Honeywell’s PID controller, Electro magnetic

flow meter ROSEMOUNT & (Endress+Hauser), with ESP skid (make: Schlumberger, where 3 wells are w/s & 5 wells are w/I).

Installation & Commissioning of all instruments & V Monitor RTU with 2.4 GHz radio & Gate way

(repeater) networking with communication to control room. (As per DEP, SP, ERD&PDO Standard)

Completed project of well hook up for high production well gas/oil self high pressure Well (250 bar to

400 bar),Installation & Commissioning of all instruments, control panels (IPS (Invensys)), Hydraulic panel (FRAMES), high pressure instrumentation impulse line for control choke valve, SSSV, SSV , IPF valve, SCADA communication etc…. at Oman –Al-Noor.

Achievements:-

Won the “ SUKRAN AWARD” for the project of “ NIMR C early water Injection Projectphase I” from client Petroleum Development of Oman.

5) From 2004 Aug to Feb 2006- Oil India Limited ONSHORE Gas Plant:

Job/Responsibility : -

Worked as Maintenance Engineer of the Instrumentation, SCADA & Communication system of Oil

India plant.

Special Knowledge & Skills:

Responsible for Instrument crew for all the maintenance activities.

Involving daily in SCADA field Equipments ( SERCK Controls, Uk ), Remote Telemetry Unit (RTU)

such as Ferranti, ECIL, NELCO etc…

Hands-on experience on HART and Field Bus protocol Communicator(Fisher Rosemount-375), BT-

200 (Yokogawa Blue Star)

Calibration and commissioning of control valves (Fisher Xomox, MIL) and MOV’s (Rotork, Auma),

I/P converters (Fisher) etc…

Replacement of cards & defective parts, Calibration of Instruments, Loop checking & routine

maintenance of all type of Instruments.

Maintenance, calibration, installation & commissioning of SCADA System, high-pressure tubing, & field instrument with Remote Telemetry Units (RTU) & Radio Communication System etc...

Maintenance of 3 phase separator, MP separator, LP separator instruments such as level transmitters, pressure Transmitters, Temperature Transmitters, Flow Transmitters, Automatic control valves,

Pneumatic Transmitters, Pneumatic controllers, control switches etc…

6) From 2002 July to 2004 July - Oil and Natural Gas Corporation (ONGC), OFFSHORE field

Job/Responsibility : -

Worked as a Instrument Supervisor in Mumbai satellite field offshore platforms NEELM and HEERA platforms.

Special Knowledge & Skills:

Responsible for Instrument crew and supervising all maintenance activities.

Attended the Process Gas Compressor (PGC) shutdown in NEELAM platform.

Calibration, installation, loop-checking, commissioning and troubleshooting of pressure, flow, level, temperature transmitters.

Loop checking and trouble shooting of all type of process control instruments

Calibration of Instruments such as Automatic control valves, all type of Transmitters, Optical and

Ionized smoke detectors, UV/IR Flame detectors, UV/IR Gas detectors, H2S detectors, Heat detectors.

Special Courses done: i) Pressure Measurement for

Instrumentation & Process control ii) Level & Flow measurement for

Instrumentation & Process control iii)Temperature Measurement for

Instrumentation & Process control

COURSES ATTENDED:

1.

STCW 95 safety course

:

:

:

Government Of India

Ministry of Labour & Employment

Government Of India

Ministry of Labour & Employment

Government of India

Ministry of Labour & Employment

2.

H2S awareness & Escaping (Emergency Response Procedure)

3.

Gas Testing Course

4.

Job Hazard Analysis (JHA) Course

5.

Permit To Work (PTW) signatory Course( Permit Applicant)

Attended the PDO Permit Applicant Assessment and having a card of the same.

PERSONAL DETAILS

Name

Date of Birth

Nationality

:

:

:

:

B.Gavaskar

19/07/1981

Indian

Single Marital status

PASSPORT DETAILS

Passport No

Date of Issue

Date of Expiry

Place of Issue

B.Gavaskar

:

:

:

:

H8989271

18/02/2010

17/02/2020

Madurai